Abstract

Storage insects are aerobic organisms requiring oxygen for their survival. Therefore, they respond to altered atmospheric gas compositions containing low O2 or high CO2. The lower the grain moisture content (m.c.) and the corresponding intergranular humidity, the higher the mortality—due to the desiccation effect on insects caused by low O2 or elevated CO2 concentrations. To achieve insect control, the temperature of the grain should be above 21 °C. Hermetic storage is based on the principle of generation of an oxygen-depleted, carbon dioxide-enriched interstitial atmosphere caused by the respiration of the living organisms in the ecological system of a sealed storage. A sufficiently low oxygen and elevated CO2 atmosphere is created through a natural metabolic process based on insect respiration and, in cases where the commodity has sufficiently high moisture, the respiration of the microorganisms within a sealed storage system. An O2 ingress rate of 0.05 %/day is sufficient to arrest the theoretical weight loss at a level of 0.018 % over 1-year storage period. At this ingress rate, the possibility of a residual surviving insect population is eliminated. This low O2 ingress level could serve as a guideline for the sealing specifications of structures appropriate to the hermetic storage method. The applications for which hermetic technology has been most widely accepted are (a) for long-term storage of cereal grains, primarily rice, corn, barley, and wheat; (b) for long-term storage of a variety of seeds to preserve germination potential and vigor, and (c) for quality preservation of high-value commodities, such as dried fruits.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

In developed countries, the consumers’ preferences for quality food, uncontaminated by insecticidal residues and not contaminated by molds and insects, are particularly important. In developing countries, poor handling and storage methods under warm and humid climatic conditions promote rapid deterioration of the stored foodstuffs. Post-harvest losses of food grain in developing countries have been conservatively estimated during the 1980s at 10–15 % by the FAO’s Special Action Program for the Prevention of Food Losses. For example, losses of corn due only to insects in farmers’ stores in Nigeria, Swaziland, and Kenya, were in the order of 6–10 %.

Increased public concern over the adverse effects of pesticide residues in food and the environment has led to the partial substitution of use of contact pesticides (typically organophosphates and pyrethroids) and fumigants by alternative control methods. It is worth noting that of the 14 fumigants listed some 27 years ago by Bond (1984), only those that remain today in regular worldwide use are phosphine and methyl bromide, which are used only in developing countries. Methyl bromide kills insects relatively quickly, but because of its contribution to stratospheric ozone depletion (UNEP 2002), it was phased out in developed countries by 2005, and its phase out in developing countries (UNEP 2006) is scheduled by 2015. In contrast, phosphine remains popular, particularly in developing countries, because it is easier to apply than methyl bromide. However, many insects have developed resistance to phosphine over the last decade.

Storage of food commodities for extended periods is possible without insect infestation and at low water activity, which prevent microbial growth. However, qualitative losses that consist of changes in physical appearance, in nutritional degradation due to oxidation and increase in free fatty acids, in the presence of insects or their fragments, or in contamination by mold or the presence of mycotoxins still occur. Some of these are difficult to detect visually. If the moisture content is maintained sufficiently low, then insects remain the main concern for the quality preservation of durable agricultural commodities.

Modified atmosphere (MA) offers an alternative that is safe and environmentally benign, to the use of conventional residue producing chemical fumigants for controlling insect pests attacking stored grain, oilseeds, processed commodities, and packaged foods. MA has been researched extensively for more than 30 years (Adler et al. 2000; Calderon and Barkai-Golan 1990; Jay 1984b; Navarro 2006), and processes such as airtight or hermetic storage have been used successfully to maintain grain quality in South America (Argentina), the Middle East, India, and North Africa. These atmospheres also prevent fungal growth and maintain product quality. An important development stimulating further work on MA, took place in the US in 1980 and 1981. The Environmental Protection Agency (EPA) approved an exemption from tolerance for CO2, N2, and products from an “inert” gas generator when used to control insects in raw (Federal Register 1980) and processed (Federal Register 1981) agricultural products. The development of this technology has come about mostly over public concern for the adverse effects of pesticide residues in food and the environment. Although this method has become well established for control of storage pests, its commercial use is still limited to a few countries. Investigations that are more recent have attempted to integrate MA application into the twenty-first century version of raw product and manufactured food storage and transportation (Navarro 2006).

Objectives and uses of MA storage

MA storage aims to attain a composition of atmospheric gases rich in CO2 and low in O2, or a combination of these two gases at normal or altered atmospheric pressure within the treatment enclosure, for the exposure time necessary to control the storage pests and preserve the quality of the commodity. Terms used in reference to MA storage for the control of storage insect pests or for the preservation of food have appeared in the literature as CA, as sealed storage, or atmospheres used at high or low pressures to define the same method of treatment but using different means. Therefore, an attempt is made here to propose definitions that will add clarity to the available storage insect control methods when used at normal atmospheric pressure or under altered atmospheric pressure.

Modified atmosphere (MA) is proposed to serve as the general term, including all cases in which the composition of atmospheric gases or their partial pressures in the treatment enclosure has been modified to create in it conditions favorable for the control of storage insects and preserve the quality of the commodity. In the MA treatment, the atmospheric composition within the treated enclosure may change during the treatment period. This term will comprise all the following designations.

MAs under normal atmospheric pressure

Controlled atmosphere (CA)

CA is a modified gas composition, usually produced artificially, and maintained unchanged by additionally generating the desired gases (CO2 or N2) or by further purging the storage with these gases, supplied from pressurized cylinders or otherwise. This supplementary introduction of gases is carried out when their concentration in the sealed container falls to below the desired level. The CA method is intended to rectify changes caused by possible small leakages of gases (that cause the increase of O2 or decrease of CO2 content in the enclosure) which are almost impossible to avoid. Thus, the term CA, although commonly employed as the one describing the entire subject, has actually its own limited and specific meaning.

Biogeneration of MA or Hermetic storage

Hermetic storage is a type of MA that can be applied for the protection of grain; it is also called “sealed storage” or “air-tight storage” or “sacrificial sealed storage” or “biogenerated MA”. This method takes advantage of sufficiently sealed structures that enable insects and other aerobic organisms in the commodity or the commodity itself to generate the MA by reducing the O2 and increasing the CO2 concentrations through respiratory metabolism to prevent insect development.

Assisted hermetic storage

Assisted hermetic storage is another type of hermetic storage that uses Exothermic Gas Generators, Catalytic Oxygen Converters or Respiration Gases of plant material. In this type of hermetic storage, the atmosphere has been modified by the supply of an atmosphere generated externally from the storage container, so that a gas composition of low oxygen (<1 %) and high carbon dioxide atmosphere can be achieved artificially, by using exothermic or catalytic gas generators. The exothermic Gas Generators burn fossil fuels to generate the low O2 atmosphere. The catalytic oxygen converters burn propane or butane by catalytic conversion processes without flame. Oxygen can also be removed from the air by respiration using various plant materials or wastes placed in a generator externally.

MAs under altered atmospheric pressure

Vacuum treatment

In a low pressure environment, there is a close correlation between the partial pressure of the remaining O2 and the rate of kill. Until recently, this treatment could only be carried out in specially constructed rigid and expensive vacuum chambers. A practical solution has been proposed that uses flexible liners. To achieve the low pressures in the flexible liners, sufficiently low pressures (25–50 mmHg absolute pressure) can be obtained (using a commercial vacuum pump) and maintained for indefinite periods.

High pressure carbon dioxide treatment

CO2 treatments can be significantly shortened to exposure times that may be measured in hours using increased pressure (10–37 bars) applied in specially designed metal chambers that withstand the high pressures. Because of the high initial capital investment, these high pressure chamber treatments may be practical only for high-value products such as spices, nuts, medicinal herbs, and other special commodities.

Effects of MA on stored-product insects and mites

Low oxygen and anoxia

In addition to nitrogen that is commonly used to produce a low oxygen atmosphere, rare gases like helium and argon were also tested (Ali Niazee 1972; Lindgren and Vincent 1970) to demonstrate that caused anoxia with effects similar to that of nitrogen. Nitrogen is only active in producing a progressive hypoxia or anoxia when used alone at a high purity level. Generally the lower the oxygen level the higher is the mortality.

Although suppressed storage insect development was observed at about 5 % (Bailey 1955, 1956, 1957), the exposure time required to kill the insects was very long. Experiments with Tribolium castaneum (Herbst) in nitrogen showed significant differences in mortality of adults between 0.1 and 1.0 % O2 (Navarro 1978). Similar experiments with Tribolium confusum J. du Val in nitrogen (Jay and Pearman 1971; Shejbal et al. 1973; Tunc and Navarro 1983) showed a critical oxygen level at 0.9 % and that >1.4 % O2 was found to be ineffective.

Insects can tolerate low levels of oxygen for prolonged periods. Using N2 to replace O2 must result in O2 being below 2 %, preferably 1 % for rapid death (Adler et al. 2000; Banks and Annis 1990; Fleurat-Lessard 1990; Navarro 1978). This effect is reversed below 1 % O2 in N2 where adult rice weevils, Sitophilus oryzae (L.) (Navarro 1978) showed tolerance, increasing the lethal exposure time by apparently closing their spiracles. In particular, S. oryzae adults are killed more quickly at 1.0 % O2 rather than at 0.1 or 2 % O2 under the same conditions (Fig. 1). T. castaneum in N2 showed significant differences in adult mortality between 0.1 and 1.0 % O2 (Navarro 1978). Adults are generally most susceptible to treatment, and S. oryzae or Rhyzopertha dominica (F.) was found to be more tolerant than Tribolium spp. The lowest level of tolerance to lack of O2 was attained around the 1 % concentration level. Therefore, Annis (1987) concluded that O2 levels of 1 % are needed to kill insects in 20 days (Table 1) (Navarro and Donahaye 1990).

Relationship between oxygen concentration and the time required for 95 % mortality (a), and the effect on daily percent loss in weight (b) of three stored-product insects at 54 % r.h. and 26 °C (Redrawn, from Navarro 1978)

Adults of the grain mite, Acarus siro L. were exposed to various O2 atmospheres in nitrogen. The exposure time to obtain complete mortality at 2 % O2 was 48 and 72 h at temperatures of 26 and 15 °C, respectively (Navarro et al. 1985b). Conyers and Bell (2003) carried out laboratory investigations into the effects of MA on the eggs of mite pests of grain and cheese. Four species of astigmatid mite were tested; Acarus farris (Oudemans), A. siro, Lepidoglyphus destructor (Schrank) and Tyrophagus longior (Gervais). Three low oxygen (O2) MA mixtures were used, based on carbon dioxide (CO2), nitrogen (N2), or simulated burner gas (0.5 or 2 % O2, 10 % CO2, and balance N2) plus 60 % CO2 in air (8 % O2). The mites were exposed at 15 °C and 80 % r.h. The exposure periods required to prevent egg hatch for each species in every mixture were given. T. longior was the most tolerant species, followed by A. siro and A. farris, with L. destructor the most susceptible. Burner gas was the most effective mixture overall with 0.5 % O2 but with an increase in the O2 level to 2 % for all the mixtures, CO2 became the more effective control agent. With 60 % CO2 in air some loss of efficacy was observed against the three most tolerant species and even more so for L. destructor. Sublethal exposures to MAs for at least 4 days in L. destructor, 6 days in A. farris and A. siro, and 8 days for T. longior caused a delay in egg hatch.

Sánchez-Molinero et al. (2010) after 264 days of processing, subjected dried ham to infestation with mobile forms of Tyrophagus putrescentiae (Schrank), mites commonly found in dry-cured ham companies. The use of reduced oxygen atmospheres to 0.5 % O2 for 25 days eliminated and prevented the growth of mobile forms of T. putrescentiae in previously contaminated hams.

High carbon dioxide and hypercarbia

Elevated CO2 levels cause spiracles to open resulting in insect death from water loss. Above 10 % CO2 spiracles remain permanently open. Toxic effects are entirely through the tracheae, not the hemolymph; CO2 has direct toxic effects on the nervous system. In some cases, CO2 can acidify the hemolymph leading to membrane failure in some tissues (Nicolas and Sillans 1989).

Elevated, but sub-lethal CO2 levels, for prolonged periods can have deleterious effects on insect development, growth, and reproduction (Nicolas and Sillans 1989; White et al. 1995). Atmospheres containing about 60 % carbon dioxide rapidly kill stored-product insects. Although at 26 °C, about 4 days of exposure would be sufficient to kill all stages (including eggs) of most stored-product insects, at lower temperatures longer exposures are required (Table 1). When the concentration level in CO2 is reduced to about 35 %, after 10 days of exposure, less than 1 % of T. confusum larvae survived the treatment (Ronai and Jay 1982). This concentration seems to be the target level above which carbon dioxide poisoning occurs (Jay and Pearman 1973). Laboratory tests on the major stored-product insects have shown that adults can be killed with pure CO2 within 10–48 h, whereas exposure times of more than 14 days are required to kill them when the atmosphere contains less than 40 % CO2 even at temperature levels above 20 °C (Kashi 1981). The symptoms of carbon dioxide poisoning in insects initially include a narcotic effect leading to a knockdown, i.e., immobilization of the insects under carbon dioxide-enriched atmospheres (Edwards and Batten 1973).

There are more laboratory data for S. oryzae than any other stored-product pest and, excluding Trogoderma spp. it appears to be the most tolerant of high CO2 atmospheres. The minimum concentration required to control all developmental stages of S. oryzae is slightly less than 40 % (Table 1). Eggs are significantly affected by 20 % CO2, while at >20 %, adult insects are the most susceptible stage (Banks and Annis 1990; Navarro and Jay 1987).

Diapausing Trogoderma granarium Everts larvae are the most tolerant to high CO2 atmospheres of any species and stage so far reported (Annis 1987). They are tolerant of CO2 concentrations of 60 % or less in air at 25 °C, and less than 95 % mortality has been obtained after 25 days, the longest exposure so far tested. It appears that diapausing Trogoderma variabile (Ballion) larvae may have a similar response (Banks and Annis 1990). Other Trogoderma species are also very tolerant (Jay 1984b).

Riudavets et al. (2009) aimed to establish the efficacy of using MA packaging (MAP) with a high CO2 content to control pests in final food products during their storage, distribution, and marketing. In their study, Riudavets et al. included a spectrum of species and all of their developmental stages that could be present in a wide range of food products. Two CO2 MAPs, 50 and 90 %, were applied to identify the pest species and developmental stages that were most tolerant to the treatments. They tested four external-feeding Coleoptera (Lasioderma serricorne (F.), Cryptolestes ferrugineus (Stephens), Oryzaephilus surinamensis (L.), and T. confusum), two internal feeding Coleoptera (S. oryzae and R. dominica), two Lepidoptera (Plodia interpunctella (Hübner) and Ephestia kuehniella Zeller), a psocid (Liposcelis bostrychophila Badonnel), and a mite (T. putrescentiae). The beetles S. oryzae, R. dominica, C. ferrugineus, and L. serricorne were among the most tolerant species as pupae or eggs. The mite T. putrescentiae was also highly tolerant. Moths were easier to kill than the other species tested. They concluded that the use of MAPs with CO2 levels equal to or higher than 50 % is an effective alternative for controlling stored-product pests affecting processed food.

De Carli et al. (2010) also studied the effect of MAP on the mortality of Sitophilus spp. in organic maize grain. Maize grains were packed with five different atmospheres consisting of 20 % O2, or 20, 40, 60, 80 % CO2 with remaining N2. The packages were stored for 30 days at 26 °C. At 5, 15, and 30 days of storage no significant differences were observed in the percentages of dead insects when CO2 was used. The results of progeny indicated that from the fifth day the number of emerging insects was low at 20, 60, and 80 % CO2. Complete inhibition of the insects was achieved with 30 days of exposure in CO2 atmospheres.

Combinations of low oxygen and high carbon dioxide

Atmospheres with 60 % CO2 and 8 % O2 are very effective at killing internal seed-feeding insects, while low O2 atmospheres are more rapid in killing external-feeding insects (Banks and Annis 1990). High CO2 levels even with 20 % O2 rapidly kill insects because of CO2 toxicity. CO2 levels must be at 40 % for 17 days, 60 % for 11 days, 80 % for 8.5 days at temperatures above 20 °C or 70 % declining to 35 % in 15 days at 20 °C (Annis 1987). Higher temperatures accelerate CO2 toxicity as insect metabolism is elevated. Even low levels of CO2 (7.5–19.2 %) for prolonged periods sharply increase immature and adult mortality (White et al. 1995).

Researchers have been interested in increasing the efficacy of MA on insects by attempting to combine very low oxygen in combination with very high carbon dioxide concentrations. However, increasing the carbon dioxide concentration in the normal atmosphere reduces proportionally the partial pressure of the oxygen available to insects. Gas burners or fossil fuel burners also have the capability to generate a combination low in oxygen and high in carbon dioxide. For example, a typical propane burner would produce an atmosphere of 0.5 % oxygen, 13.5 % carbon dioxide, 1 % nitrogen, and 1 % argon. Therefore, unless a mixture of nitrogen and carbon dioxide or a gas burner atmosphere is used, the simplest way to achieve a low oxygen and high carbon dioxide atmosphere is by using carbon dioxide in air (Storey 1975).

In the case of hypoxia (2–5 % O2), when a small proportion of CO2 (5–40 % CO2) is added to the initial mixture of N2/O2, the mortality rate increases considerably (Fig. 2) (Calderon and Navarro 1979). When CO2 is added to low O2 atmospheres, there is a synergistic effect, which is obvious from the significant interaction between the concentrations of these two gases (Calderon and Navarro 1980).

Calculated exposure times and carbon dioxide levels to produce 95 % mortality for Tribolium castaneum adults at four oxygen concentrations and two temperatures at 57 % r.h. (Redrawn, from Calderon and Navarro 1979)

Krishnamurthy et al. (1986) tested the response of adults of Sitophilus granarius (L.), T. castaneum, O. surinamensis, C. ferrugineus, and R. dominica exposed to simulated combusted atmospheres containing low O2 (0.5–2.6 %) and increased CO2 (10–30 %) with the balance N2 at 20 °C and 70 % r.h. The mixtures containing 1–1.6 % O2 killed all the insects within 7 days if they also contained greater than or equal 10 % CO2. At 2.0–2.6 % O2, C. ferrugineus was more tolerant of CO2 than the other insects tested, whereas at 0.5 % O2, S. granarius was the most tolerant sp., needing 8–10 days for complete kill.

Conyers and Bell (2007) carried out laboratory tests on five species of stored-product beetles, C. ferrugineus, O. surinamensis, S. granarius, S. oryzae, and T. castaneum to MAs based on simulated burner gas, four different O2 levels, 3, 4, 5, and 6 %, with CO2 levels of 9.5, 8.5, 7.5, and 6.5 %, respectively, at 20 and 25 °C, and 75 and 85 % r.h. After exposure to the MAs for 28 days, an assessment was made of the mortality of adults, the number of adults from progeny produced under the MAs and, for the simulated burner gas, the number of adults from progeny produced in a 28 days period after exposure to the MA. The O2 content preventing population growth varied with species and temperature. For simulated burner gas or N2, it was about 4 % for O. surinamensis, S. granarius, and S. oryzae, and about 3 % for C. ferrugineus and T. castaneum at 25 °C. At 20 °C, it was about 3 % for all species tested. When CO2 was increased to 10 or 20 %, reducing O2 to 5 % was sufficient to eliminate emergence of S. granarius at 20 °C, but a few individuals emerged at 25 °C. For C. ferrugineus, there was a 95 % reduction with 5 % O2 plus 20 % CO2 at 20 °C, but not at 25 °C.

Mitcham et al. (2006) in a review article on the mode of action of insecticidal CAs concluded that arthropods cope with reduced oxygen and elevated carbon dioxide atmospheres with a reduction in metabolic rate, also called metabolic arrest. Despite the similarities in response, arthropod mortality is generally greater in response to high carbon dioxide as apposed to low oxygen atmospheres. There appears to be a greater decrease in ATP and energy charge in arthropods exposed to high carbon dioxide as compared with low oxygen atmospheres, and this may be due to greater membrane permeability under carbon dioxide leading to an inefficient production of ATP. Reduced oxygen and elevated carbon dioxide atmospheres can have an additive effect in some cases, depending on the concentrations used.

Effects of low pressures

It has been shown that mortality of insects under low pressures is caused mainly by the low partial pressure of oxygen resulting in hypoxia (Navarro and Calderon 1979). The partial pressure of oxygen has a decisive effect on insect mortality, while no significant function could be attributed to the low pressure itself. At 50 mmHg, the partial pressure of oxygen is equivalent to 1.4 % O2, this being similar to the target oxygen concentration under a MA obtained by nitrogen flushing. Finkelman et al. (2003b) conducted the experiments in a calculated atmospheric partial pressure equivalent to an oxygen concentration of 1.3–1.8 %. This oxygen level is close to critical levels needed for insect disinfestations using low oxygen levels achieved by displacement with nitrogen (Donahaye 1992). Finkelman et al. (2004) showed that less than three days under 50 mmHg at 30 °C would control all stages of Ephestia cautella (Walker), P. interpunctella, and T. castaneum, the times needed to obtain 99 % mortality being 45, 49, and 22 h, respectively. The eggs of all three species were the most tolerant to low pressure.

Additionally, according to Finkelman et al. (2006) when T. granarium, L. serricorne, and O. surinamensis were subjected to 50 mmHg at 30 °C, the egg was again the most tolerant stage in all three species, the times needed to obtain 99 % mortality being 46, 91, and 32 h, respectively (Table 2). Adults of T. granarium and L. serricorne, and pupae of O. surinamensis were the most susceptible.

Mbata and Phillips (2001) tested eggs, larvae, and pupae of T. castaneum, P. interpunctella, and R. dominica exposed to 32.5 mmHg in glass chambers at 25, 33, 37, and 40 °C for times ranging from 30 min to 144 h. Pupae of T. castaneum and R. dominica were more tolerant to low pressure than larvae. In all life stages, mortality increased with increasing exposure time to low pressure and also with increasing temperature. Immature stages of R. dominica were more tolerant to low pressure than immature stages of the other two species. The LT99 for R. dominica eggs was 176 h at 25 °C, and that for P. interpunctella eggs was 28 h at the same temperature. An increase in temperature to 33 °C resulted in a LT99 of 86 h for R. dominica and 6 h for P. interpunctella.

Mbata et al. (2004) determined that the sensitivity of eggs to vacuum varied with their age. Eggs of P. interpunctella were most sensitive to low pressure when they were 3 or 48 h old, whereas those of R. dominica were most sensitive at 12 and 120 h of age. In subsequent experiments, eggs of Cadra cautella (Walker), P. interpunctella, R. dominica, and T. castaneum were exposed to pressures of 50, 75, 100, 200, and 300 mmHg in glass chambers at 5, 15, 22.5, 30, and 37.5 °C for times ranging from 12 to 168 h. In all four species, the mortality of eggs increased with increasing exposure time and temperature. Low temperatures and high pressures were the least effective conditions for killing eggs, compared with high temperatures combined with low pressures in all species investigated.

Mbata et al. (2005) studied the mortality of life stages of the cowpea weevil, Callosobruchus maculatus (F.), exposed to different low pressures and temperatures for various exposure periods. The adults were the most susceptible life stage to low pressure; 99 % mortality was achieved within 0.8 h at 32.5 mmHg, 30 °C. The pupae were the most tolerant life stage to low pressure, requiring exposure periods between 29 and 153 h at 20–35 °C to achieve 99 % mortality. Mortality increased with exposure time and also with increasing temperature in all life stages. Early-stage eggs (3 h old) and late-stage eggs (48 h old) experienced higher mortality (values for LT99 of 42 and 47 h, respectively) compared with intermediate aged eggs (24 h old; LT99 of 75 h) under the same conditions of low pressure and temperature.

Effects of high carbon dioxide pressure

Extremely short exposure times of a few hours are needed to control all stages of storage insects with carbon dioxide at pressures between 10 and 37 bar. Generally, increasing the pressure reduces the lethal exposure time.

Exposure of L. serricorne, O. surinamensis, T. castaneum, T. confusum, T. granarium, Corcyra cephalonica (Stainton), Ephestia elutella (Hübner), E. cautella, P. interpunctella, and Sitotroga cerealella (Olivier) to carbon dioxide at 37 bar for 20 min, 30 bar for 1 h, and 20 bar for 3 h at 20 °C, resulted in 100 % mortality of all insects. However, survivors of T. confusum were found after treatment with 10 bars for 20 h. Only Cryptolestes turcicus (Grouvelle) survived all tested pressures and exposure times. Consequently, Adler et al. (2000) concluded that extrapolation of laboratory results with carbon dioxide and high pressures to field situations are risky. The rate of decompression of pressurized storages may also have an impact on insect mortality (Ulrichs 1994; Ulrichs et al. 1997a, b).

Riudavets et al. (2010) investigated the efficacy of CO2 at high pressure against different stages of O. surinamensis, C. ferrugineus, L. serricorne, S. oryzae, R. dominica, Acanthoscelides obtectus (Say), E. kuehniella, L. bostrychophila, and T. putrescentiae for different times at two high pressures, 15 and 20 bar. Tests were carried out at temperatures between 20 and 25 °C. A high level of control was achieved for most species and development stages when they were treated with CO2 at 20 bar for 60 min. However, the efficacy at 15 bar was much lower. The eggs of L. bostrychophila and L. serricorne showed the highest tolerance of all species/stages and survived the most extreme conditions tested which were CO2 at 20 bar for 60 min. The beetle O. surinamensis, the moth E. kuehniella, and the mite T. putrescentiae were easier to kill than the other species tested.

Effect of air relative humidity and MA

Laboratory studies have shown that lowering the relative humidity (r.h.) increases the effectiveness of MAs. Jay et al. (1971), working with adults of T. confusum, T. castaneum, and O. surinamensis, found that decreasing the r.h. in atmospheres containing 99 % N2 (balance O2) from 68 % r.h. to 9 % r.h. gave an increase in mortality of from 3 to 98.5 % in 24-h exposure of the red flour beetle. The two other insects showed a similar response to reduced r.h. These three species also exhibited a similar response to mixtures of CO2 in air at lowered relative humidities.

Desiccation plays a large role in the mortality of stored-product insects when exposed to some MAs. Jay and Cuff (1981) showed that when larvae, pupa, and adults of the red flour beetle were exposed to varying concentrations of CO2 or O2, weight loss was much higher in some of the atmospheres than in others or in air. Navarro and Calderon (1974) showed a linear relationship of the combined effect of CO2 and r.h. in producing a lethal environment for E. cautella pupae (Fig. 3). Navarro and Calderon (1980) demonstrated also the strong dependence of low concentrations of CO2 and O2 on causing mortality in E. cautella pupae (Fig. 4). Other laboratory studies have shown that the susceptibility of different species or strains of the same species vary considerably when insects are exposed to the same concentrations of MAs (Jay and Pearman 1971).

Combined effect of carbon dioxide and relative humidity on the time needed to produce 95 % mortality values for Ephestia cautella pupae after four days of exposure. (Redrawn, from Navarro and Calderon 1974)

Effect of 4.3 % carbon dioxide and 3.2 % oxygen on adult emergence from Ephestia cautella pupae exposed to different relative humidities at 26 °C (Navarro and Calderon 1980)

The tested r.h. in their study by Chiappini et al. (2009) was sufficiently low (<18 %) to result in complete mortality after 120 h at 3 % O2 and 29 °C. However, Calderon and Navarro (1979) demonstrated that, after 120 h exposure to 2 % O2 and 30 °C at 57 % r.h., mortality of T. castaneum adults was only 50 %.

Effect of temperature and MA

At temperatures from 20 to 30 °C, most species and developmental stages show >95 % mortality in <10 days at both 0 and 1.0 % O2 (Annis 1987). T. granarium larvae (12 days at 0 % O2), S. oryzae pupae (20 days at 0 % O2; >14 days at 1 % O2), and S. granarius adults (16 days at 1 % O2) are the only exceptions so far found (Annis 1987).

The effect of temperature on the length of time necessary to obtain good control with MAs is as important as with conventional fumigants. Jay (1971) states that to obtain good control; “the temperature of the grain should be above 21 °C during the application of CO2”. Navarro and Calderon (1980) compared the effect of temperature on exposure time required to produce mortality of adults of three storage insects to MAs. Chiappini et al. (2009) aimed to evaluate the time necessary to obtain total mortality of insects treated in CAs with O2 percentages higher than those normally used in practice. They estimated the possible positive influence of a temperature increase to compensate for the effects of the reduced anoxia by exposing T. confusum adults to various range of O2 percentages (1–10 %) and temperatures (23–40 °C). Their results showed that total mortality could be achieved within a week, even in quite moderate conditions of temperature (29–37 °C) and lowered O2 percentage (5–8 %). They demonstrated that the total mortality achieved in the various exposure periods was due to the effect of the two parameters (temperature and O2 percentage) together.

Donahaye et al. (1994) reported on responses of larval, pupal, and adult stages of the Nitidulid beetles Carpophilus hemipterus (L.) and Urophorus humeralis (F.) exposed to simulated burner gas concentrations at three temperatures of 26, 30, and 35 °C. Comparison of exposure times showed that the effect of temperature on treatment efficacy was most pronounced at the 1 % O2 level where for the three stages of both species tested, values of LT50 at 26 °C were about half those at 35 °C. However, at 3 % O2 and 35 °C, LT50 levels were only marginally reduced (Donahaye et al. 1994).

Soderstrom et al. (1992) examined the influence of temperature over the range of 38–42 °C on the influence of hypoxia and hypercarbia on T. castaneum adults for 60-h exposures. Although the different experimental conditions make comparison difficult, their results clearly indicate that increased temperatures could be used to reduce treatment duration. Donahaye et al. (1996) exposed egg, larvae, pupae, and adults of T. castaneum to three low oxygen concentrations at 26, 30, and 35 °C. At all levels of O2 (1, 2, and 3 %) in typical respiration atmospheres in hermetic conditions (similar to burner gas atmospheres) the LT99 values at 35 °C were significantly lower than at 26 °C. Work on all four development stages of E. cautella showed the strong influence of temperature on mortality values when the insects were exposed to CO2 concentrations varying from 60 to 90 % in air (Navarro et al. 2002, 2003b) (Table 3).

Downes et al. (2008) studied the effect of changing environmental conditions on the metabolic heat rate (MHR) of S. oryzae and T. castaneum with the attempt to demonstrate that heat treatments for disinfestation performed in a hypoxic or hypercarbic CA may be effective at lower temperatures than required in air. The MHR of adult S. oryzae was changed little over a wide range of oxygen concentrations, the value in air was close to that in pure oxygen and was only reduced by about 20 and 50 % at oxygen concentrations of 5 and 2 %, respectively. Heat treatment at 45 °C was more effective when the CA was 5 % O2 + 60 % CO2 + N2, or 60 % CO2 + N2, than in air, but larval T. confusum still survived in the former CA, indicating there were differences in the response between species and/or stage.

Mitcham (2007) reviewed the response of insects to high temperature during exposure to CAs. The author noted that, in general, the higher the temperature, the faster mortality is achieved under a given atmosphere.

Development of insect tolerance to CAs

Bond and Buckland (1979) were the first to show that stored-product insects have the genetic potential to develop tolerance to CAs, when they obtained a three-fold increase in tolerance to CO2 by S. granarius after selecting for seven generations. Navarro et al. (1985a) obtained a similar level of resistance for S. oryzae exposed to hypercarbia by selection over ten generations. T. castaneum populations were exposed to high levels of CO2 (65 % CO2, 20 % O2, and 15 % N2) (Donahaye 1990a) or low levels of O2 (0.5 % O2 and 99.5 % N2) (Donahaye 1990b), and 95 % r.h. for 40 generations. Selection pressure in both cases was between 50 and 70 % mortality each generation. At 40 generations, the insects exposed to high CO2 levels had an LT50 9.2 times greater than non-selected insects. Insects exposed to low O2 had an LT50 5.2 times greater than non-selected insects. While these insects were able to adapt to extreme atmospheric composition to a moderate extent, the conditions used would not occur naturally.

Generation and application of MA

Under normal atmospheric pressure

Gas supply from pressurized cylinders

CA is a modified gas composition, usually produced artificially, and maintained unchanged by adding of the desired gases (CO2 or nitrogen [N2]), supplied from pressurized cylinders or otherwise. This supplementary introduction of gases is carried out when their concentration in the sealed container drops to below the desired level.

The objective of CA treatment is to attain a composition of atmospheric gases rich in CO2 and low in O2, or a combination of these two gases within the storage enclosure or treatment chamber. These set concentrations are maintained for the time necessary to control the storage pests. A widely used source for production of such atmospheric gas compositions is tanker-delivered liquefied CO2 or N2, when the target CA gas composition is <1 % O2 or high CO2 concentration. For large-scale application of N2 or CO2, vaporizers are essential. These vaporizers consist of a suitably designed receptacle with a heating medium (electricity, steam, diesel fuel, or propane), a super-heated coil with hot-water-jacket, and forced or natural draught (Banks 1984; Navarro and Donahaye 1990).

Exothermic gas generators

For on-site generation of MAs by combustion of hydrocarbon fuel to produce a low O2 atmosphere containing some CO2, commercial installations—termed exothermic gas generators or gas burners—are available (Storey 1973). Such equipment was originally designed for MA storage of fresh fruits. Their MA composition had been designed to allow the presence of approximately 2–3 % O2 (though now it is lower), and to remove CO2 through scrubbers. Several adaptations are required for their use in the grain industry: tuning equipment to obtain an O2 level of <1 %; utilizing to full advantage the CO2 generated; and removing excessive humidity from the atmosphere generated (Navarro et al. 1979). Combustion of propane and butane yields approximately 13 and 15 % CO2, respectively. The CA generated is more toxic than a N2 atmosphere deficient in O2 because of the presence of CO2 in the MA, causing hypercarbia, which together with hypoxia, are synergistic in their effect on insect mortality.

On-site N2 Generators

Commercial equipment, termed also “pressure-swing adsorption” systems, using the process of O2 adsorption from compressed air passed through a molecular sieve bed, is available. For continuous operation, a set of two adsorbers is provided, which operate sequentially for O2 adsorption and regeneration. Nitrogen at a purity of 99.9 % can be obtained through regulation of inlet air-flow. This method of N2 generation is a relatively new approach in MA generation technology. Equipment is now being manufactured that is rated to supply an outlet flow rate of 120 m3/h at an outlet purity of 98 % N2. However, in view of the high capital cost investment involved, it would seem wise to undertake a long-term cost-benefit analysis to explore the justification of usage of these installations.

Ozone

Ozone can be generated and used to kill insects although it reacts with caulking in bins and may bleach grain. Ozone also lowers levels of microflora on seed. It is suggested for use in railcars at low temperatures and low humidity (McClurkin and Maier 2010). It is also effective in killing insects at 1,800 ppm for 120 min and can be applied in specially modified augers (McDonough et al. 2010). Lu et al. (2009) investigated the effect of ozone on the respiration of S. oryzae, R. dominica, and T. castaneum adult in an air-tight system at 23–25 °C and 50 % r.h. The experiments showed that the effects of ozone on respiration had two distinct phases. Phase 1 involved a lower respiration rate of the adult stored-product Coleoptera under ozone atmosphere and reflected the need for insects to reduce ozone toxicity. During phase 2, respiration of S. oryzae, R. dominica, and T. castaneum adults treated with ozone increased as the ozone degraded to oxygen.

Biogeneration of MAs

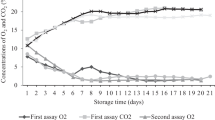

A form of biogeneration of MA is hermetic storage. Hermetic storage is based on the principle of generation of an oxygen-depleted, carbon dioxide-enriched interstitial atmosphere caused by the respiration of the living organisms in the ecological system of a sealed storage. A sufficiently low oxygen and elevated CO2 atmosphere is created through a natural metabolic process based on insect respiration and, in cases where the commodity has sufficiently high moisture, the respiration of the microorganisms within a sealed storage system. A high level of gastightness is required for a structure to be suitable for hermetic storage of dry grain.

Hermetic storage in flexible plastic storage systems, under sub-tropical climatic conditions continues to offer an excellent solution, provided there is a certain degree of tolerance to the presence of live insects at critical places in the storage structure, particularly at the grain surface, where moisture condensation is likely to occur. At the end of long-term hermetic storage, when unloaded grain is destined for immediate consumption, the risk of spreading insect infestation was found to be negligible. Insect control success due to the hermetic storage treatments is comparable to conventional fumigants (over 99.9 % kill), and losses due to insect activity and fungal damage are minimal (0.12 % loss in weight per year) (Navarro et al. 1984; Varnava 2002).

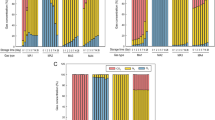

An O2 ingress rate of 0.05 %/day is sufficient to arrest the theoretical weight loss at a level of 0.018 % over one year storage period. At this ingress rate, the possibility of a residual surviving insect population is eliminated (Fig. 5). For higher O2 ingress rates, the weight loss continues to rise in proportion to the O2 ingress rate (Fig. 6). This low O2 ingress level, is difficult to obtain in rigid structures, but is achievable in practice using flexible liners. It could serve as a guideline for the sealing specifications of structures appropriate to the hermetic storage method.

Calculated oxygen concentrations in a 10 m3 grain mass containing a fixed level of initial infestation of 2 insects/kg, having an oxygen intake of 157 μl per insect per day, using a sealed liner at different oxygen ingress rates (Redrawn, from Navarro et al. 1994)

Calculated oxygen concentrations in a 10 m3 grain mass containing different infestation levels of insects and having an oxygen intake of 157 μl per insect per day, using a sealed liner with an oxygen ingress rate of 0.24 % per day (Redrawn, from Navarro et al. 1994)

Under altered atmospheric pressure

High pressure carbon dioxide treatment

Carbon dioxide remains slower acting and more expensive than phosphine or methyl bromide. To address this problem, the stored-product pests' laboratories at Bordeaux and Berlin have investigated the use of high pressure and carbon dioxide (Fleurat-Lessard 1990; Reichmuth and Wohlgemuth 1994). After extensive testing in the laboratory, a high-pressure fumigation chamber was designed and built in collaboration with MG SIAC (France). The chamber can hold the equivalent of the contents of one transport trailer. The unit is designed to recover at least 85 % of the carbon dioxide used. The pressure rises to 19 atmospheres in 90 min, it is held there for 60 min, and takes about 30 min to release the pressure. With loading, fumigation, and unloading, a full cycle takes approximately 4 h.

Prozell et al. (1997) described a high pressure chamber (CARVEX) connected to a tank of liquid CO2 placed on a balance. This unit is commercially available and utilized in Germany.

Low pressure (vacuum treatment)

Finkelman et al. (2003a) reported on the introduction of flexible transportable sealed chambers made of welded PVC liners that has opened new opportunities to implement low pressures (vacuum treatment) as a competitive and affordable treatment to control storage insect pests. Under vacuum, these chambers shrink over the periphery of the commodity and hold it fast. The system is sealed by an air-tight zipper and is able to retain vacuum.

Finkelman et al. (2003a) showed that it is not a practical approach to attempt to hold a pressure below 45 mmHg; because of the energy required for prolonged operation of the pump. Conversely, pressures above 55 mmHg prolong the time to achieve kill.

Durable commodities (corn, corn chips, garden peas, chick peas, wheat, wheat flour, rice, sun flowers seeds, and semolina) packed in different ways were exposed to 5 days vacuum treatment. In all tested commodities, the treated product was well preserved and in cases where initial infestation was detected, complete mortality of insects was observed. The advantage of this treatment is that no toxic chemicals are employed. In comparison with phosphine, exposure times to provide the kill are similar, and the exposure time of 5 days falls within a range suitable for quarantine treatments where no rapid treatment is essential. In contrast to fumigations where schedules are provided by defining dosages to be applied for a predetermined time, at a set temperature range, low pressure treatment schedules must be presented as exposure times at both, a temperature range and a r.h. that is in equilibrium with the commodity moisture content. The application of vacuum in cocoons made of flexible liners as a treatment of durable commodities that can withstand the low pressures is now being implemented by commercial companies.

Types of structures in which CA and MA have been used

Controlled atmospheres have been used in a wide array of grain storage structures. The most important consideration is that they must be air-tight for long-term storage or relatively air-tight for CO2 or N2 fumigation. Acceptable air-tightness for CO2 fumigation is determined by negative pressure testing and should at most hold a negative pressure from 500 to 250 Pa in 10 min (Annis and Graver 1990). Attempts have been made to predict gas tightness relative to leakage areas (Mann et al. 1999; Lukasiewicz et al. 1999). Provisional guidelines based on best estimates from comparative of variable pressure tests are presented in Table 4 (Navarro 1999). The suggested times given in Table 4 were doubled for empty storages as an approximation to the intergranular airspace.

Rigid structures

Existing silos were modified to provide a high degree of hermetic seal for the application of MA using CO2 (Navarro et al. 1991). Others were purposely constructed for the application of MA using CO2 from pressurized cylinders. The gastight metal silos were used for organic grain for which conventional fumigation was not acceptable. These silos were equipped with specially designed pressure relief valves and gas expansion chambers to permit high velocity gas purge (Navarro et al. 1991).

Bolted steel bins

Bolted steel bins are not airtight but they can be sealed for partially successful fumigation with CO2. Alagusundaram et al. (1995) placed dry ice in insulated coolers under a CO2 impervious plastic sheet above wheat 2.5 m deep in a 5.6 m diameter bin. CO2 levels were 30 % at 0.55 m above the floor where 90 % of rusty grain beetles, C. ferrugineus were killed; CO2 levels of 15 % at 2.0 m above the floor resulted in 30 % mortality.

A bolted, galvanized-iron silo (21.5 tonnes) was sealed using a polyvinyl resin formulation sprayed onto joints from the inside. The silo was loaded with wheat, into which cages of insect-infested wheat were introduced, and conditions monitored with thermocouples and gas sampling lines. Oxygen levels were reduced to <1 % by purging with N2, and similar levels were then maintained by a slow N2 bleed for 35 days, after which the silo was emptied. All adult insects were dead but, as expected, some immature survived. This was because the maintenance period was too short to ensure complete kill at the observed grain temperatures of <15 °C (Williams et al. 1980).

Sealed steel bins

Airtight, galvanized-steel bins have been manufactured in Australia for the last 30 years and are commercially available (Moylan Silos 2011). Welded-steel hopper bins can be modified for CO2 fumigation for a few hundred dollars. Carbon dioxide from dry ice must be re-circulated through the grain and a pressure relief valve installed to the bin. The top and bottom hatches must be gasket sealed. After 10 days at 20 °C, 75 % of applied the CO2 was retained while 99 % of the caged C. ferrugineus were killed (Mann et al. 1999).

Concrete grain elevators

Carbon dioxide fumigation of grain has been successful in concrete elevators holding 209 tonnes of wheat. The bottom hopper was sealed and the grain purged with CO2 for 4 h (1 tonne of CO2), and additional gas is added as needed. All caged test insects were killed (White and Jayas 2003).

A large installation for the application of CO2-based CA was installed to treat more than 200,000 tonnes of rice annually in flat bins each of 5,000 tonnes capacity in Mianyang, China (Fig. 7).

Railcars

Hopper railcars have been treated in-transit with phosphine gas for flour and wheat in Australia and North America (Eco2Fume 2003). Carbon dioxide fumigation requires a much greater level of air-tightness than synthetic fumigation. Efforts have been made to seal a railcar containing 90 tonnes of wheat. Even after sealing top hatches with CO2-impermeable plastic and caulking the bottom hoppers, 118 kg of dry ice produced only 21 % CO2 at 1 day, a level too low for insect control (Mann et al. 1997). If the railcar had been moving gas loss would have been rapid (Banks et al. 1986).

Flexible structures

There is a growing use of hermetic storage in flexible structures throughout the world. Although some structures are not airtight and are easily punctured (Darby and Caddick 2007), with the introduction of new materials very satisfactory results with high levels of gastightness can be achieved (Jonfia-Essien et al. 2010; Rickman and Aquino 2007). They rapidly produce hermetic storage (Jonfia-Essien et al. 2010; Navarro et al. 2007).

The manufacture of PVC liners and other gastight laminates that conform to required specifications of resistance to adverse climatic conditions, gas-permeability, and physical properties, enabled the development of storage systems based on the hermetic principle. These are:

-

Bunker storage for conservation of large bulks of 10,000 to 15,000 tonnes capacity (Navarro et al. 1984; 1993) (Fig. 8).

-

Flexible silos supported by a weld mesh frame of 50–1,000 tonnes capacity for storage of grain in bulk or in bags (Calderon et al. 1989; Navarro et al. 1990, 1998b).

-

Liners for enclosing stacks of 10–50 tonnes capacity Volcani cubes termed also GrainPro Cocoons™, and designed for storage at the farmer-cooperative and small trader level (Fig. 9) (Donahaye et al. 1991a). These structures are in current use for capacities of up to 1,000 tonnes termed MegaCocoon™ for bagged storage of cereals (Fig. 10).

-

The problem of applying present-day technology to provide hermetic storage for subsistence farmers lies in the need to provide an easily sealable low-cost container of 50–100 kg capacity. The most recent attempt to address this problem has been through the construction of a small granary for use by small scale farmers, suitable to store up to 1,000 kg, termed GrainSafe™ (Navarro et al. 1998c) (Fig. 11). This granary was equipped with an upper collapsible sleeve for loading and a lower collapsible sleeve for unloading. The hermetic flexible bag was inserted into a rigid sheath surrounding the vertical sides of the hermetic bag (Fig. 11).

-

A highly efficient method of using air-tight bags for masses of 25–1,000 kg of product are commercially available. This development is based on hermetic storage bags called SuperGrainbags™, designed to hold 50 kg of paddy or corn. These gastight liners are now available with capacities of 1,000 kg. SuperGrainbags™ serve as gastight liners for outer bags made of either polypropylene or jute (Fig. 12).

-

Recently, a hermetic liner for 20′ and 40′ shipping containers called TranSafeliner™ has become available (Fig. 13) (GrainPro 2008). Moisture movement occurs when convection currents are encouraged by gradients of temperature generated particularly when a container is exposed to solar heat. High temperature causes moisture movement from the commodity to the free air space at the top of the container. As the temperature is reduced during the cooler times of the day, the moisture in the air condenses on the metal roof and drips from the top and walls of the container causing damage to the commodity. With the use of TranSafeliner™, the moisture exchange between the commodity and the free air space is prevented. The liner enables the separation of the commodity’s atmosphere from the container atmosphere. Further even in a high humidity atmosphere the moisture content of the commodity does not change despite major temperature changes in transport, since moist air cannot enter the TranSafeliner™.

Fig. 13 TranSafeliner™ being installed in a standard shipping container (GrainPro 2008)

-

Silo Bags of 200 tonnes capacity for on-farm grain storage are used directly in the field and, with the available handling equipment, is quite simple to load and unload. This technique was originally used for grain silage; it involves storing dry grain in sealed plastic bags. This sealed storage method adopted in South America is used for temporary storage of dry grain and oilseeds (Bartosik 2010) (Fig. 14).

Experience gained using flexible liners

Our accumulated experience of hermetic storage using several types of flexible liners for above-ground storage, in-the-open, under tropical and subtropical conditions (Calderon et al. 1989; Navarro and Donahaye. 1993; Navarro et al. 1968; 1984; 1993; 1998b) is summarized in the following observations:

Structural durability

The use of PVC-based sheeting without mesh reinforcement produces a material of suitable strength and elasticity for storing grain. This material was formulated to have a high resistance to solar UV irradiation. Rodents find it difficult to gain a tooth-hold on the smooth surface. This has been corroborated by laboratory studies using wild-caught roof rats and house mice. Liners have been used continuously for over 10 years, and though they have lost some plasticity, permeability to gases decreases as the plasticizers evaporate. This characteristic renders the liners more effective with time in retaining gas concentrations.

Moisture migration

Diurnal temperature fluctuations, accentuated by solar radiation on liners, followed by rapid cooling at night, cause successive moistening and drying cycles at the upper grain surface. This may result in gradual moisture accumulation, particularly during the transient seasons between summer and winter when temperature fluctuations are greatest. The result is that initially dry grain may rise to above critical moisture levels enabling limited microfloral spoilage to occur. For bunkers of 12,000–15,000 tonnes capacity, the condensation phenomenon has been eliminated by leveling the peaked apex (with a ridge of less than 2 m) to a slightly convex, wide apex of bunker cross section (with a ridge of more than 6 m) which is sufficient to permit rain-water run-off (Navarro et al. 1994; Silberstein et al. 1998). For dry grain kept in “cocoons” in subtropical climates, moisture migration is not a pronounced phenomenon. However, for storage in the tropics, moisture migration is more pronounced because the initial grain moisture is closer to its critical level. Moisture migration has been solved by placing a reflective cover over the cocoons (Figs. 9, 10).

Specific applications of MA

Cereal grain preservation using MA

The initial research carried out during recent decades concentrated first on the possible application of the MA technology to cereal grains (Adler et al. 2000; Banks and Annis 1990; Jay 1984a; Navarro et al. 1990). Additional studies relating to the preservation of cereal grain are well documented in the book of Calderon and Barkai-Golan (1990) and the chapter of Adler et al. (2000).

Tree nuts and dried fruits preservation using MA

The possibility of applying MAs to control insects in dried fruits and tree nuts has been reviewed by Soderstrom and Brandl (1990). The major volume of MA treatments relates to the finished, packaged product. Bulk storages require extensive sealing before MA can be applied, and the industry considers the process too slow and costly in comparison to other control methods. The influence of low O2 or high CO2 atmospheres as alternatives to fumigation of dried fruits has also been investigated by Soderstrom and Brandl (1984); Soderstrom et al. (1986); and Tarr et al. (1994).

Ferizli and Emekci (2000) applied CO2 for treating dried figs in a gastight flexible storage unit loaded with 2.5 tonnes of dried figs in perforated plastic boxes. Results showed that oxygen concentrations in the containers decreased to 0.8 % and carbon dioxide concentrations increased to 96 %. For the next 5 days, both O2 and CO2 concentrations remained stable. These conditions resulted in complete mortality of both insects and mites.

Prozell et al. (1997) exposed cocoa beans, hazel nuts, and tobacco to a quick disinfestation process of exposure to carbon dioxide under pressure of 20–40 bars for a few hours. Experiments with caged insects (developmental stages and adults) of 12 species were carried out on one-tonne of bagged products in a 3 m3 chamber. At about 10 °C and at 20 bar of CO2, the lethal treatment period was slightly longer (3 h) than that at 20 °C. At 20 °C and 30 and 37 bars, complete control was achieved within 1 h and within 20 min, respectively (Fig. 15).

Current applications of hermetic storage

Hermetic storage of rice

As a result of extensive studies at IRRI (Rickman and Aquino 2007) and later by PhilRice (Sabio et al. 2006), over the last 10 years, the benefits of storing both rice and rice seeds in hermetic storage are now well understood and in widespread use, particularly in Asia. The Cocoon™ shown in Fig. 9 has been used in many countries of Africa and by the National Food Authority of the Philippines, to store rice paddy safely for up to 1 year (Montemayor 2004). Hermetic storage applications for rice and/or rice seed is currently found in such countries as: Cambodia, East Timor, Indonesia, India, Pakistan, Sri Lanka, and Vietnam.

Multi-tonne storage containers called Cocoons are currently in use in sizes from 5 to 1,000 tonnes capacity (Fig. 10). IRRI itself has also adopted the use of the portable hermetic storage liners called SuperGrainbags™, now available with capacities of 10 to 1,000 kg. SuperGrainbags serve as liners for either polypropylene or jute outer bags (Fig. 12). Recently, a hermetic liner for 20′ and 40′ shipping containers called TranSafeliner™ became available (Fig. 13) (GrainPro 2008).

Hermetic storage of corn

Cocoons are widely used in Rwanda, Ghana, and the Philippines for storing both shelled and unshelled corns, typically in capacities ranging from 50 to 150 tonnes. Similar results were obtained for corn when stored in 60 kg capacity SuperGrainbags. The large flexible hermetic storage units are generally used at the village level, but also as strategic reserves to prevent famine at the district level (Montemayor 2004; Navarro 2006; Navarro et al. 1995). In 2007, 100,000 SuperGrainbags were delivered to Ghana for a variety of uses, including household use.

Hermetic storage of wheat and barley

Hermetic storage of wheat in “Bunkers” with capacities ranging from 10,000 to 15,000 tonnes was first introduced in the early 1990s, as shown in Fig. 8. Hermetic storage of wheat, stored at or below its critical moisture content of 12.5 %, provides storage without significant degradation of quality, including maintenance of baking qualities, for up to 2 years (Navarro et al. 1984, 1993). In Cyprus, such bunkers allowed quality preservation of barley for 3 years, with total losses of 0.66–0.98 %, and with germination remaining above 88 % (Varnava and Muskos 1997).

Hermetic storage of pulses (beans)

Beans in storage are subject to invasive pests, such as C. maculatus and Callosobruchus chinensis (L.), which are controlled through hermetic storage. In Rwanda and Ghana, storage of beans in Cocoons of 20–150 tonnes capacity has permitted groups of farmers to hold their crops off the market, while waiting for more favorable market prices (MINAGRI 2006).

Hermetic storage of coffee

Field data from Costa Rica shows that preventing the penetration of external humidity alone has proved sufficient to protect coffee bean quality for up to 9 months (Aronson et al. 2005). Coffee is now stored commercially in portable SuperGrainbags, or in larger Cocoons for storage to preserve quality, and for long transit-time shipments in shipping containers without refrigeration, using SuperGrainbags, or TranSafeliners™. Hermetic coffee storage of green coffee beans is now practiced in Costa Rica, East Timor, Ethiopia, Jamaica, Hawaii, Peru, and the continental United States. A recent U.S. scientific study of coffee and its processing effects concludes that under standard warehouse conditions, long-term hermetic storage, compared to jute, may preserve coffee much better, leading to moisture content in the desired range and ultimately to better cup scores.

Insect control and preservation of organic cereals, pulses, nuts, and flours using vacuum

Ten durable commodities; corn, corn chips, garden peas, chick peas, wheat, wheat flour, rice, sun flowers seeds, and semolina, were exposed to 5 days vacuum treatment (Finkelman et al. 2003a). Corn, garden peas, chickpeas, and sun flower seeds were stored in 1 tonne capacity big-bags. Wheat, rice, and semolina were stored in 50-kg bags, and corn chips and wheat flour were stored in 25-kg bags loaded on wooden pallets. In all the tested commodities, the treated product was well preserved and in cases where initial infestation was detected, complete mortality of insects was observed. The advantage of this treatment is that no toxic chemicals are employed. In comparison with phosphine, exposure times to provide the kill are comparable, and the exposure time of 5 days falls within a range suitable for quarantine treatments where no rapid treatment is essential. Where the commodity can be placed in flexible liners, and packed in a manner that can withstand the low pressure, vacuum treatment can provide an appropriate solution. The transportable system was made of flexible PVC, which has been in use commercially for hermetic storage of grain and other commodities to control insect disinfestation by naturally obtained MAs (Navarro et al. 1999). For the disinfestation of durable commodities, these flexible storage containers can be considered for the application of vacuum as an alternative to treatments with methyl bromide and other toxic fumigants.

Disinfestation of dates

As a potential alternative to methyl bromide fumigation, the influence of different CAs in causing emigration of Carpophilus spp. larvae from dates was compared with that of methyl bromide by Navarro et al. (1989) and Donahaye et al. (1991b). A concentration of 35 % CO2 was found to cause a similar emigration to methyl bromide. This method was used for several years in the largest packing house in Israel.

Laboratory experiments were carried out to investigate the influence of different MAs (20 % CO2 in air or 2.8 % O2 in N2), low pressures alone or methyl bromide alone in causing nitidulid beetles to emigrate from infested dates (Navarro et al. 1998a). At 4-h exposure and at 26 °C, the treatments that had a marked influence in causing insects to abandon the infested dates were a low pressure of 100 mmHg and 2.8 % O2 in N2, both of which caused over 80 % of the initial insect populations to emigrate from the fruit. In addition to causing emigration of nitidulid beetles from dates, CO2 atmospheres were studied for long-term preservation of the dates. Under laboratory conditions (Navarro et al. 1998a) and in field tests at ambient temperatures Navarro et al. (1992) showed that MAs significantly delayed browning and sugar formation in dates and extended shelf life as compared to storage at −18 °C.

Quality preservation of stored cocoa beans using biogenerated atmospheres

Intermediate moisture contents (at equilibrium air relative humidities of 65–75 %) of stored commodities are inevitable in tropical climates because of the difficulties in maintaining safe moisture contents for long-term storage. Under hermetic conditions, stored commodities with intermediate moisture contents generate MAs due to the respiration of the microflora and the commodity itself. Data are shown for insect control and for quality preservation of stored cocoa beans by employing a novel approach through the use of biogenerated MAs as a methyl bromide alternative. The respiration rates of fermented cocoa beans at equilibrium relative humidities of 73 % at 26 °C in hermetically sealed containers depleted the oxygen concentration to <1 % and increased the carbon dioxide concentration to 23 % within 6 days. Laboratory studies in Israel were implemented under field conditions in a cocoa bean storage facility. A hermetically sealed flexible structure containing 6.7 tonnes of cocoa beans at an initial moisture content of 7.3 % (70 % equilibrium r.h.) was monitored for oxygen concentration and quality parameters of the beans (Navarro et al. 2007) (Fig. 9). The measurements showed a decrease in oxygen concentration to 0.3 % after 5.5 days. No insects survived the oxygen-depleted biogenerated atmosphere. These encouraging results reveal the possibility of utilizing biogenerated atmospheres in integrated pest management (IPM) for quality preservation (by preventing the development of FFA, molds, and mycotoxins), and insect control of cocoa pests (Jonfia-Essien et al. 2008a, b).

Preservation of high moisture corn using biogenerated atmospheres

Under humid and warm conditions, harvested grains are susceptible to molding and rapid deterioration. Therefore, they should be dried to safe moisture levels that inhibit the activity of microorganisms. Drying to these moisture levels is not economical for farmers in developing countries. Laboratory studies were carried out on the effect of various moisture contents on the quality of corn grains in self-regulated MAs during hermetic storage (Weinberg et al. 2008). Laboratory results experiments indicated that corn at the tested moisture levels can be stored satisfactorily under sealed conditions in which self-regulated atmospheres provide protection against microflora damage. Further large-scale trials were carried out to evaluate the economic feasibility of storing high moisture corn. Shelled corn of 26 % moisture content was stored in a Cocoon™ under hermetic conditions for 96 days to demonstrate the effectiveness of maintaining its quality before subsequent drying or processing into feeds or ethanol. The initial oxygen concentration dropped within 1 day and remained at an average of 0.54 % throughout the storage period. No significant change in starch content was observed throughout the storage period. Corn in the control bags deteriorated after 3 days and temperature increased to 55 °C. The high moisture corn in the Cocoon™ initially had 59 ppb of aflatoxin which increased to 90 ppb after 1 week of storage and remained at that level for 96 days (Arnold and Navarro 2008). Feeding trials indicated that the corn from hermetic storage was palatable to cows and swine. Results of the study indicate that wet corn can be safely stored for extended periods without significant increase in aflatoxin, and without significant changes in starch.

Packaging of food

Lang (1993) discussed the use of atmospheric gases in the packaging of meat and fish, milk products, bakery products, fruit, vegetables, and nuts. The effects of storage temperature (8 and 36 °C) and packaging atmosphere (air and N2) on the quality of almonds were studied by Garcia-Pascual et al. (2003). The quality of unshelled almonds remained high after 9 months, even under storage at ambient temperature. No significant differences were observed for any of the measured parameters in nuts stored in air or N2. Guidelines for using MAs in packaged food, with special emphasis on microbiological and nutritional aspects, have been published by the Council of Europe (Anonymous 1999).

Fresh storage of fruits and vegetables

Fresh fruits and vegetables may be shipped or stored in CAs. This topic is covered in depth in the book of Calderon and Barkai-Golan (1990) and in a special chapter in the book of Ben-Yehoshua et al. (2005).

Narcissus bulbs treatments

The large narcissus fly Merodon eques F. attacks narcissus bulbs and also bulbs of other geophytes. This species has not been recorded in the USA; it is therefore included within quarantine requirements that demand total mortality before export to the USA (Donahaye et al. 1997). Fumigation with methyl bromide has been used to eliminate narcissus fly infestation in flower bulbs due to its rapid killing time (4 h). However, MB is also known to cause damage to the bulbs. Therefore, our initial trials were aimed at finding alternative treatments to MB so as to prevent phytotoxicity. These trials were carried out in flexible plastic chambers that replaced the previously used rigid fumigation chambers (rooms).

In experimental procedures, Navarro et al. (1997) found that there was an extremely rapid depletion of O2 within the sealed gastight enclosure where the bulbs were stored due to the respiration of the newly harvested narcissus bulbs. This procedure also revealed the significant anoxia achieved within less than 20 h (less than 0.1 % O2 and about 15 % CO2) during treatment at 28 to 30 °C and the possibility of using it alone as a control measure (Rindner et al. 2003). This use of bio-generated MA utilizing the bulb respiration alone was adopted by farmers as an alternative to methyl bromide; offering a practical solution in specially designed flexible treatment chambers (Navarro et al. 2003a).

References

Adler C, Corinth HG, Reichmuth C (2000) Modified atmospheres. In: Subramanyam Bh, Hagstrum DW (eds) Alternatives to pesticides in stored-product IPM. Kluwer Academic Publishers, Boston, pp 105–146

Alagusundaram K, Jayas DS, White NDG, Muir WE, Sinha RN (1995) Controlling Cryptolestes ferrugineus (Stephens) adults in wheat stored in bolted-metal bins using elevated carbon dioxide. Can Agr Eng 37:217–223

Ali Niazee MT (1972) Susceptibility of the confused and red flour beetles to anoxia produced by helium and nitrogen in various temperatures. J Econ Entomol 65:60–64

Annis PC (1987) Towards rational controlled atmosphere dosage schedules—a review of the current knowledge. In: Donahaye EJ, Navarro S (eds) Proceedings of 4th international working conference on stored products protection. Maor-Wallach Press, Jerusalem, pp 128–148

Annis PC, Graver J van S (1990) Suggested recommendations for the fumigation of grain in the ASEAN regions. Part 2. Carbon dioxide fumigation of bag stacks sealed in plastic enclosures: an operations manual. Australian Centre for International Agricultural Research, Canberra, p 58

Anonymous (1999) Guidelines for packaging in modified atmospheres with special emphasis on microbiological and nutritional aspects. Council of Europe Publishing, p 26

Arnold RE, Navarro S (2008) Hermetic storage of high moisture corn under tropical conditions. In: Daolin G, Navarro S, Jian Y, Cheng T, Zuxun J, Yue L, Haipeng W (eds) Proceedings of the 8th international conference on controlled atmosphere and fumigation in stored products. Sichuan Publishing Group, Chengdu, pp 259–263

Aronson S, Raudales R, Trubey R, Villers P (2005) Breakthrough in storing high quality coffee. Tea Coffee Trade J 177:11

Bailey SW (1955) Air-tight storage of grain: Its effect on insect pests. I. Calandra granaria L. (Coleoptera, Curculionidae). Aust J Agr Res 6:33–51

Bailey SW (1956) Airtight storage of grain—its effects on insect pests. II. Calandra oryzae (small strain). Aust J Agr Res 7:7–19

Bailey SW (1957) Airtight storage of grain—its effects on insect pests. III. Calandra oryzae. Aust J Agr Res 8:595–603

Banks HJ (1984) Current methods and potential systems for production of controlled atmospheres for grain storage. In: Ripp BE, Banks HJ, Calverley DJ, Jay EG, Navarro S (eds) Proceedings of international symposium on practical aspects of controlled atmosphere and fumigation in grain storages. Elsevier, Amsterdam, pp 523–542

Banks HJ, Annis PC (1990) Comparative advantages of high CO2 and low O2 types of controlled atmospheres for grain storage. In: Calderon M, Barkai-Golan R (eds) Food preservation by modified atmospheres. CRC Press, Boca Raton, pp 93–122

Banks HJ, Sharp AK, Irving AR (1986) Influence of transport on gas loss from freight containers under fumigation. Part 1: experimental investigation. Pestic Sci 17:207–220

Bartosik R (2010) Challenges and characteristics of the South American grain and oilseed postharvest system. In: Carvalho MO, Fields PG, Adler CS et al (eds) Proceedings of 10th international working conference on stored-product protection. Estoril, Portugal Julius-Kühn-Archiv, 425. Bundesforschungsinstitut für Kulturpflanzen, Berlin, pp 57–62

Ben-Yehoshua S (2005) Environmentally friendly technologies for agricultural produce quality. CRC Press Taylor & Francis Group, Boca Raton

Bond EJ (1984) Manual of fumigation for insect control. FAO Plant Prod Prot Paper No. 54

Bond EJ, Buckland CT (1979) Development of resistance of carbon dioxide in the granary weevil. J Econ Entomol 72:770–771

Calderon M, Barkai-Golan R (1990) Food preservation by modified atmospheres. CRC Press Boca Raton, Florida

Calderon M, Navarro S (1979) Increased toxicity of low oxygen atmospheres supplemented with carbon dioxide on Tribolium castaneum adults. Entomol Exp Appl 25:39–44

Calderon M, Navarro S (1980) Synergistic effect of CO2 and O2 mixture on stored grain insects. In: Shejbal J (ed) Controlled atmosphere storage of grains. Elsevier, Amsterdam, pp 79–84

Calderon M, Donahaye E, Navarro S, Davis R (1989) Wheat storage in a semi-desert region. Trop Sci 29:91–110

Chiappini E, Molinari P, Cravedi P (2009) Mortality of Tribolium confusum J. du Val (Coleoptera: Tenebrionidae) in controlled atmospheres at different oxygen percentages. J Stored Prod Res 45:10–13

Conyers ST, Bell CH (2003) The effect of modified atmospheres on the survival of the eggs of four storage mite species. Exp Appl Acarol 31:115–130

Conyers ST, Bell CH (2007) A novel use of modified atmospheres: storage insect population control. J Stored Prod Res 43:367–374

Darby JA, Caddick LP (2007) Review of grain harvest bag technology under Australian conditions. CSIRO entomology, technical report, vol 105, pp 111

De Carli M, Bresolin B, Noreña CPZ, Lorini I, Brandelli A (2010) Efficacy of modified atmosphere packaging to control Sitophilus spp. in organic maize grain. Braz Arch Biol Technol 53:1469–1476

Donahaye E (1990a) Laboratory selection of resistance by the red flour beetle Tribolium castaneum (Herbst) to an atmosphere of low oxygen concentration. Phytoparasitica 18:189–202

Donahaye E (1990b) Laboratory selection of resistance by the red flour beetle Tribolium castaneum (Herbst) to a carbon dioxide enriched atmosphere. Phytoparasitica 18:299–308

Donahaye E (1992) Physiological differences between strains of Tribolium castaneum selected for resistance to hypoxia and hypercarbia, and the unselected strain. Physiol Entomol 17:219–229

Donahaye E, Navarro S, Ziv A, Blauschild Y, Weerasinghe D (1991a) Storage of paddy in hermetically sealed plastic liners in Sri Lanka. Trop Sci 31:109–121

Donahaye E, Navarro S, Rindner M, Dias R (1991b) The influence of different treatments causing emigration of nitidulid beetles. Phytoparasitica 19:273–282

Donahaye E, Navarro S, Rindner M (1994) The influence of temperature on the sensitivity of two nitidulid beetles to low oxygen concentrations. In: Highley HE, Wright EJ, Banks HJ, Champ BR (eds) Proceedings of 6th international working conference on stored-product protection. (Canberra.) CAB International, Wallingford, pp 88–90

Donahaye EJ, Navarro S, Rindner M, Azrieli A (1996) The combined influence of temperature and modified atmospheres on Tribolium castaneum (Herbst) (Coleoptera: Tenebrionidae). J Stored Prod Res 32:225–232

Donahaye EJ, Navarro S, Dias R, Rindner M, Azrieli A (1997) Sensitivity of narcissus flies (genera: Eumerus and Merodon) to Methyl Bromide. In: Donahaye EJ, Navarro S, Varnava A (eds.) Proceedings of international conference on controlled atmospheric fumigation in stored product. PrintCo Ltd., Nicosia, Cyprus, pp 25–29

Downes CJ, van Epenhuijsen CW, Lill RE, Downes JE, Carpenter A, Brash D (2008) Calorimetric evaluation of responses of Sitophilus oryzae and Tribolium confusum to elevated temperatures and controlled atmospheres. J Stored Prod Res 44:295–303

Eco2Fume (2003) Eco2Fume fumigant gas hopper car fumigation trial. www.cytec.com/specialty…/PhosphineGas/Hoppercartrialreport.pdf. Accessed 09 Feb 2011

Edwards L J, Batten RW (1973) Oxygen consumption in carbon dioxide anesthetized houseflies, Musca domestica Linn. (Diptera: Muscidae). Comp Biochem Phys A 44:1163

Federal Register (1980) Tolerances and exemptions from tolerances for pesticides chemicals in or on raw agricultural commodities; carbon dioxide, nitrogen, and combustion product gas 45(223):75663–75664

Federal Register (1981) Carbon dioxide, nitrogen, and combustion product gas; tolerances for pesticides in food administered by the Environmental Protection Agency 46(122):32865–32866

Ferizli AG, Emekci M (2000) Carbon dioxide fumigation as a methyl bromide alternative for the dried fig industry. In: Obenauf GL, Obenauf R (eds) Annual international research conference on methyl bromide alternatives and emission reduction. Orlando, Florida, p 81