Abstract

A monolithic solid-phase microextraction (SPME) fiber was fabricated based on a molecularly imprinted polymer which could be coupled with gas chromatography for extraction, pre-concentration and determination of methamphetamine (MAMP). Methacrylic acid, ethylene glycol dimethacrylate and MAMP play the roles of functional monomer, cross-linker and template, respectively. The effective factors influencing the polymerization and extraction procedures were investigated and will be detailed here. The fabricated fiber was firm, inexpensive, stable, selective and durable which gives it vital importance in SPME. Selectivity of the fabricated fiber in relation to the template in solution containing MAMP, related and unrelated compounds was also investigated. Under the optimum conditions, the calibration plot was linear in the range of 50–3,500 ng mL−1 (r 2 = 0.997). The high extraction efficiency was obtained for MAMP giving a detection limit of 14 ng mL−1. The fabricated fiber was successfully applied to SPME of MAMP from human saliva samples followed by gas chromatography-flame ionization detector analysis.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Methamphetamine (MAMP) is a central nervous system stimulant that produces euphoria, hallucinations, increased alertness and wakefulness [1]. The drug’s strong reinforcing and addictive potentials result in drug abuse and also tolerance to the drug’s psychotropic effects leading to the use of toxic doses. Due to the widespread abuse of MAMP, drug testing for MAMP and its metabolites is routinely performed in clinical and forensic laboratories. Generally, liquid–liquid extraction (LLE) and solid phase extraction (SPE) [2–6] are applied for sample preparation. However, most of these pretreatment methods involve multi-steps, which are time consuming, and using large amounts of organic solvents in the conditioning and elution steps, which may in turn, result in the loss of analytes.

Solid-phase microextraction (SPME) is a powerful, simple, fast and solvent-free extraction method which provides solution to many problems of sampling and sample injection into analytical instruments. Recently, various solid-phase microextraction methods such as direct SPME [7, 8], headspace SPME [9–12] and in-tube SPME [13] have been developed and applied to determine MAMP. The main disadvantage of these methods is the poor selectivity which results in great drawbacks in the analysis of the real samples. Moreover, commercially available fibers suffer from lower selectivity, low stability, low strength and high cost. To improve these characteristics, a considerable amount of research has been focused on the preparation of various fibers [14–21].

Molecularly imprinted polymers (MIPs) are artificial materials with highly specific recognition ability for analyte molecules in which specific recognition sites are formed in a polymeric matrix by synthesis in the presence of analyte as an imprinting molecule (template). MIPs are cross-linked synthetic polymers obtained through copolymerization of a monomer with a cross-linker in the presence of a template molecule. The polymer, with its template being washed away, contains recognition sites that are complementary in size, shape and chemical functionality to the template molecule. The MIP is able to rebind selectively with the template and its analogous structures.

The combination of molecular imprinting and SPME methods would provide a powerful analytical tool which includes simplicity, flexibility, and the selectivity characteristics of both methods [22]. This was the main goal in fabricating monolithic fibers on the basis of MIPs which have successfully been used for the selective extraction and subsequent gas chromatography (GC) or gas chromatography-mass spectrometry (GC-MS) analysis of diacetylmorphine [23], codeine [24] and atrazine [25].

The objective of this work was the fabrication of a monolithic SPME fiber based on MAMP-MIP and its application for the extraction and pre-concentration of MAMP from human saliva for its subsequent gas chromatography-flame ionization detector (GC-FID) analysis.

Experimental

Chemicals

Methacrylic acid (MAA), ethylene glycol dimethacrylate (EGDMA), 2,2′-azobis-isobutyronitrile (AIBN) and acetonitrile were purchased from Merck (Darmstadt, Germany). MAMP hydrochloride, amphetamine (AMP) sulphate, 3,4-methylenedioxymethamphetamine (MDMA, Ecstasy) and codeine phosphate were provided by the Local Criminal Investigation Labs. (Tehran, Iran). Ibuprofen and chlorpheniramine maleate were provided by the Dana Pharmacy Company (Tabriz, Iran). Triazine herbicides were purchased from Sigma-Aldrich.

Instrumentation

Monitoring the analytes was performed using a gas chromatograph (Shimadzu 2014, Kyoto, Japan) equipped with a flame ionization detector (FID) and a hydrogen generator (model OPGU 1500 S, Shimadzu). A Forte capillary column of 30 m × 0.25 mm i.d. coated with a 0.25 μm film thickness (BPX5, SGE Analytical Science, Forte, Australia) was used.

The column temperature was programmed from 90 °C (3 min) rising at 30 °C min−1 to 210 °C (4 min), rising at 50 °C min−1 to 250 °C (5 min). The linear velocity of the carrier gas and total flow were 36 cm s−1 and 51.4 mL min−1, respectively. Analyte desorption from the fiber was performed at 260 °C (3 min).

Ultrasonic and water baths were purchased from Grant (Cambridge, UK) and used for MIP fiber preparation. A Carbolite furnace from Bemaford (Sheffield, UK) was used for thermal conditioning of the fabricated fibers. The 4.5-mL sample vials sealed with a silicone-rubber septum cap were from Supelco (Bellefonte, PA, USA) and used as the extraction vessels. Sample agitation during the SPME procedure was performed by a magnetic stirrer from Gerhardt (Konigswinter, Germany).

Preparation of Poly (MAA–EGDMA) Monolithic SPME Fiber

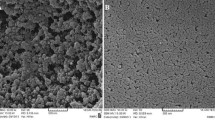

A 2.1-mmol sample of the template molecule (MAMP) was dissolved in 30 mL porogen solvent (acetonitrile). Then, 30 mmol functional monomer (MAA) and 120 mmol cross-linker (EGDMA) were added to the solution and the resulting mixture was ultrasonically stirred for 5 min. Then 280 mg of initiator (AIBN) was added. The mixture was degassed with a stream of helium gas for 10 min. Monolithic fibers were fabricated as described in previous papers [23–25]. For this purpose, the laboratory-made capillary glass tubes with 4 cm length and 0.3 mm internal diameter (as molds) were inserted into the test tubes containing pre-polymer solution. Capillary glass tubes were filled immediately by this solution. Test tubes were immediately sealed with a rubber cap and the mixture was then cured in a water bath for 12 h at 60 °C. The non-imprinted polymer (NIP) was also fabricated according to the above procedure in the absence of MAMP during polymerization.

Fiber Conditioning

The fabricated MIPs or NIPs monolithic fibers were immersed in a mixture containing methanol, acetic acid and double-distilled water 4:1:1 (v/v/v) several times until MAMP template, porogen solvent and other impurities were removed as far as possible. The fibers were then modified by heating at 220 °C in the presence of water vapor in a Carbolite furnace for 15 min. All the modified fibers were conditioned at 280 °C for 20 min in a GC injection port under a helium flow.

SPME and GC Procedures

A 4-mL sample of a model aqueous solution, containing 5% (w/v) NaCl with pH 7 adjusted by phosphate buffer (50 mM), was poured into a vial which was then sealed with a silicone-rubber septum cap containing a Teflon stirring bar. The vial septum was punctured with the fiber sheath of the proposed fiber that had been mounted on the home-made SPME device. The extraction of analyte was carried out by direct immersion of 25 mm of MIP or NIP fiber into the sample for 40 min. Samples were agitated during extraction by a magnetic stirrer at a rate of 600 rpm. After extraction, the fiber was inserted into the inject port of GC for 3 min and the analytes were thermally desorbed at 260 °C and analyzed by GC.

Real Sample Analysis

A 4-mL human saliva sample obtained from a volunteer with no history of drug abuse was spiked with 1 μg mL−1 of MAMP. After addition of 5% (w/v) NaCl, the extraction and analysis of the analyte were performed as described in the previous section.

SPME Procedure Using a Commercial Poly-dimethylsiloxane Fiber

This procedure was carried out under the optimum conditions as described in the literature [7]. A 4-mL aqueous sample solution containing 30% (w/v) NaCl with pH 12.4, adjusted by 5 M KOH, was introduced into a vial which was then sealed with a silicone-rubber septum cap containing a Teflon stirring bar. The vial septum was punctured with the fiber sheath of 100 μm poly-dimethylsiloxane (PDMS) fiber. SPME was accomplished by direct immersion of the fiber in the sample for 30 min. Samples were agitated during SPME by a magnetic stirrer. Then, the fiber was retracted and removed from the vial. The analyte was thermally desorbed from the fiber for 1 min at 250 °C and analyzed by GC.

Results and Discussion

Optimization of Polymerization Conditions

Previous works [23–25] have revealed that using MAA, EGDMA, AIBN and acetonitrile as functional monomer, cross-linker, initiator and porogen, respectively, lead to monolithic SPME fibers on the basis of MIP with high affinity and selectivity toward template molecules. However, polymerization time and temperature as well as ratio of template to MIP components may vary for various template molecules. The effect of these parameters was therefore investigated by performing polymerization in different conditions.

Optimization of Polymerization Time and Temperature

For this purpose, the curing of MIP was carried out at different temperatures from 50 to 65 °C with 5 °C intervals and various times (6–15 h) in a water bath. The fabricated fibers were conditioned as described above and used for the extraction of target molecules from the model solution. The variations of the extraction ability of the resultant fibers, by means of chromatographic peak area versus polymerization time in different temperatures are illustrated in Fig. 1. According to the results, the extraction ability of the fibers at all the temperatures studied reached a plateau in 12 h. In addition, the extraction ability increased with polymerization temperature and reached its maximum at 60 °C. Therefore, 12 h and 60 °C were selected as the optimum polymerization time and temperature, respectively.

The effect of time and temperature of polymerization reaction on the extraction ability of the fabricated fibers: A 50 °C, B 55 °C, C 60 °C and D 65 °C. Pre-polymer solution consist of 2.1 mmol of template was used. SPME was performed with 4 mL of aqueous standard solution containing 1 μg mL−1 of MAMP at room temperature for 20 min by fabricated MIP-MAMP fibers. Extracted amounts were determined by GC-FID. The bars indicate the maximum and minimum of three extractions and determinations

Optimization of Template to MIP Components Ratio at Various Temperatures

For this purpose, various types of fiber were fabricated in the presence of different amounts of MAMP (1.5–2.3 mmol) during 12 h of polymerization and various polymerization temperatures. The fabricated fibers were used for the extraction of MAMP from 4 mL of an aqueous model solution under similar conditions. Figure 2 shows the variation of extraction efficiency of MAMP versus template amount at various polymerization temperatures. The result revealed that 2.1 mmol was the optimum amount of template which was independent of the polymerization temperature. Considering these results and the results obtained in previous works for diacetylmorphine, codeine, atrazine and their homologues [23–25] it can be concluded that the ratio of the template to MIP components (functional monomer and cross-linker) is almost independent of the type of the template molecules for the present MIP components and this may lead to the fabrication of monolithic MIP fibers for the other molecules accordingly. The fiber synthesized in this way was flexible enough for easy manipulation and mounting on the laboratory-made SPME syringe.

The effect of template amount and temperature of polymerization reaction on the efficiency of fabricated fibers with 12 h duration of polymerization: A 50 °C, B 55 °C, C 60 °C and D 65 °C. Other experimental conditions were as given as for Fig. 1. The bars indicate the maximum and minimum of three extractions and determinations

Optimization of Extraction and Desorption Conditions

Optimization of Extraction Time

SPME is an equilibrium-based technique. The higher sensitivity and reproducibility in SPME can be achieved if the distribution or equilibrium of analytes between fiber and sample solution is attained. For this purpose, extraction time profiles were investigated using MIP and NIP fibers. Figure 3 shows the variations of extraction efficiency of MAMP by the fibers versus extraction time. The results proved that the extraction efficiency of MAMP by NIP was very low compared to that by MIP. After 40 min, the extraction efficiency of MIP reached a maximum and remained constant. Further experiments were therefore carried out with 40 min as the optimum extraction time.

Investigation of Desorption Time

In SPME, optimization of desorption time is a very important parameter to prevent memory effect and to achieve a high analytical signal. To do this, after extraction of MAMP, the fibers were inserted into the injection port of GC and remained for various times (0.5–5 min). The desorption percentage of MAMP versus desorption time is illustrated in Fig. 4. The results showed that after 3 min, desorption of the analyte was complete and no memory effect observed.

Effect of pH

The pH of aqueous sample solution is an important factor in the extraction of an acidic or alkaline analytes by the MIP fibers. The effect of the sample pH on the extraction efficiency of the MAMP by MIP and NIP fibers was studied at various pH values ranging from 2 to 11. Figure 5 shows the effect of the sample pH on the extraction efficiency. The results showed that the extraction efficiency of MAMP using an NIP fiber was very low at all the studied pH values. However, extraction efficiency using MIP fiber increased with pH, reaching a maximum at pH 7 and decreasing thereafter. In addition to the attraction based on the size and shape compatibility of analyte molecules and MIP cavities, other interactions such as hydrogen bonding and ionic interactions also participated in adsorption of MAMP on the MIP fiber. At the lower pH values, the extraction was poor, because MAMP and MAA were in their protonated forms. Therefore, carboxylic groups of MAA could probably be interacted only with hydronium ions rather than with the hydrogen atom of the amino group of MAMP which led to low extraction efficiency. By increasing sample pH, MAMP was still in the protonated form (pK a = 9.2), while MAA lost H+ ion (pK a = 4.66) and was converted to its anionic form. Therefore, a relatively strong interaction based on ionic interactions could be formed between cationic MAMP and anionic carboxylate groups of MIP. As a result, the extraction efficiency within that pH range was high and reached a maximum at pH 7. At the higher pH values MAMP and MAA were in their molecular and anionic forms, respectively. Therefore, only hydrogen bonding could be established between them which caused lower extraction efficiency. Therefore, in the following studies, pH 7 was selected as the optimum pH.

Effect of Stirring Speed

Extraction efficiency depends on equilibrium being achieved between the concentration of analyte in the sample solution and that on the fiber. Therefore, the speed of stirring of the sample solution can be an important factor. The efficiency of the extraction from 4 mL of the model solution containing 1 μg mL−1 MAMP was evaluated with different stirring speeds changing from 200 to 700 rpm. The results (Fig. 6) showed that the efficiency of extraction for a constant extraction time increased with stirring speed. The extraction profiles reached a maximum at 600 rpm and then decreased at higher rates. So, in the subsequent experiments the sample solutions were consequently stirred at 600 rpm.

Effect of Ionic Strength

The SPME procedure was performed on solutions containing different amounts of NaCl. The extraction efficiencies relating to the extracted amount of MAMP against NaCl concentration are presented in Fig. 7. The extraction efficiency decreased when the amount of NaCl was increased and reached a plateau at 5% (w/v). From the theoretical point of view, increasing of ionic strength could be showed two opposing effects on the extraction efficiency: (1) increasing salting-out effect, which normally favors the extraction procedure, (2) increasing ionic competition between Na+ and HMAMP+ to establish ionic interaction with carboxylate ion of MIP matrix. The second effect was an unfavorable factor and could be decreased the extraction efficiency. Experimental results in this research proved that the second case was the dominant effect. Considering the presence of salt in the real samples, calibration graph and other analytical characteristic of the proposed method should be established in the presence of 5% NaCl.

Effect of salt concentration on the efficiency of extraction, stirring speed was 600 rpm and other experimental conditions were as given as for Fig. 6. The bars indicate the maximum and minimum of three extractions and determinations

Effect of Extraction Temperature

Temperature is another effective parameter on the extraction performance of MIP. The extraction procedure by MIP and NIP fibers was carried out in the stirred solutions at different temperatures ranging from 20 to 70 °C with 10 °C intervals followed by thermal desorption and GC analysis of the analyte. The results are presented in Fig. 8. As the results revealed, the extraction efficiency increased with temperature and reached a plateau at 50 °C. From the theoretical point of view, analyte-MIP binding constant depends on the complex formation energy which increases with temperature [26]. Therefore, a better extraction performance was expected at the higher temperatures. Furthermore, the cavities can expand and molecule motion aggravates at high temperatures [27]. So, by increasing the temperature, many cavities could be used and MAMP molecules fall off in the bonding sites aggregately. Therefore, further extractions were performed at 50 °C.

Effect of extraction temperature on the efficiency of extraction of MAMP by MIP (A) and NIP (B) fibers. Solutions containing 5% (w/v) NaCl and the other experimental conditions were as given as for Fig. 7. The bars indicate the maximum and minimum of three extractions and determinations

Chemical Stability

Chemical stability of the SPME fiber is another important factor to be considered because it is indispensable in carrying out the SPME from acidic or basic aqueous samples and organic solvents. Three MIP-MAMP fibers were fabricated. First, each fiber was used for three repetitive extractions and desorptions of MAMP from model solutions. Then, one of these fibers was immersed in methanol, the other in an aqueous solution of 1 M HCl and the third in an aqueous solution of 1 M NaOH, for 24 h at 20 °C. Afterwards, the fibers were washed with double-distilled water and then were used again for three repetitive extractions and desorptions of MAMP from model solutions. The results were compared with the results obtained before dipping the fibers into solvent or solution as mentioned above (Table 1). According to the results, a considerable variation in the extraction behavior of the fabricated fibers was not observed. Therefore, it could be concluded that the fabricated fibers were chemically stable.

Fiber Durability

One fiber was used for 100 extraction/desorption cycles over one month. All the experiments were based on a sample of MAMP (1 μg mL−1) freshly prepared for each experiment. The results are presented in Table 2. It was observed that the extraction efficiencies of analyte (chromatographic peak areas) on this fiber were similar with a total RSD of 7.7%. This means that the fabricated fiber was stable and could be used for a number of tests and was durable for longer time spans.

Selectivity Study

The behavior of the proposed fiber was investigated by the extraction of MAMP (1 μg mL−1) from a model solution containing the same concentration of compounds structurally similar with MAMP such as amphetamine, 3,4-methylenedioxymethamphetamine and unrelated compounds such as codeine, ibuprofen, chlorpheniramine maleate and some triazine herbicides (simiazine, atrazine and ametryn). The results are presented as a chromatogram in Fig. 9. The chromatogram showed that the fabricated MIP fiber could extract MAMP and its analogues compounds, while other structurally unrelated compounds showed almost no extraction. Relative peak areas (MIP) of the studied compounds relative to MAMP are presented in Table 3. The high selectivity of the fabricated MIP fiber to MAMP was clearly induced during the imprinting process. In order to investigate the imprinting behavior of the prepared fiber, the absolute recoveries (using calibration graphs by direct injection) were measured for MAMP and other analogue compounds. Absolute recovery amounts of the compounds are shown in Table 3. The results revealed that the fabricated MIP fiber had different imprinting behaviors towards MAMP and the related compounds, and its ability toward the template molecule was higher than the analogues compounds.

Selectivity study of the fabricated fiber, chromatogram corresponding to the extraction of 1 μg mL−1 of MAMP by the fabricated MIP fiber in the optimum condition from a solution containing related and unrelated compounds (1 μg mL−1): A amphetamine, B methamphetamine, C chlorpheniramine, D ibuprofen, E simiazine, F atrazine, G ametryn, H codeine, I ecstasy

Analytical Approach

Under the optimized conditions, a calibration graph was obtained using the proposed fiber followed by GC-FID determination. The calibration graph was linear for concentrations ranging from 50 to 3,500 ng mL−1. The squared correlation coefficient (r 2) was found to be greater than 0.99. The detection limit was calculated by progressively reducing the amount of extracted and desorbed MAMP until the response had a peak height three times larger than the average noise around the peak. The detection limit was 14 ng mL−1. The value was indicative of a good performance of the fabricated fiber. The relative standard deviation (RSD) was 5.5% for 1 μg mL−1 of MAMP (6 replicated experiments in 1 day). With respect to the results, quantitative analysis of the studied compound was also implemented.

Study of Applicability of the Fabricated Fiber to Real Sample Analysis

The applicability of the fabricated fiber to extraction of MAMP from human saliva sample was studied and compared with the polydimethylsiloxane (PDMS) fiber which is the most favorable commercial fiber for SPME of MAMP [7]. The extraction of MAMP was implemented by the fabricated and PDMS fibers in the optimum condition of each fiber followed by GC-FID analysis. The chromatograms of extracted compounds are presented in Fig. 10. Figure 10a shows the chromatogram using the fabricated MAMP-MIP fiber from non-spiked and non-historical saliva sample. The results proved that there was no chromatographic peak in the MAMP position. This also indicated the absence of any organic compounds in human saliva which could be overlapped with MAMP chromatographic peak. Figure 10b illustrates the chromatogram resulted after the extraction from the sample spiked with MAMP (1 μg mL−1) using the fabricated fiber. GC quantitative analysis showed that in the optimum conditions, absolute recovery of MAMP from saliva was 6.8% despite 7.8% from aqueous model solutions which had been investigated previously in the section of selectivity study. This means that 87% of the added MAMP to saliva (relative to aqueous model solutions) could be analyzed. Figure 10c represents the chromatogram obtained by using commercial PDMS fiber for extracting MAMP from the spiked human saliva sample. Comparing the chromatograms in Fig. 10b and c proved that the extraction efficiency of MAMP with the fabricated fiber was three times more than the extraction efficiency of MAMP with commercial PDMS fiber and it also revealed the excellent selectivity of the MAMP-MIP fiber toward the template molecule.

Comparison of the Proposed Method with Other Methods

Table 4 summarizes the analytical characteristics of some analytical methods along with those of the proposed MIP-SPME coupled with GC-FID for the extraction and determination of MAMP in different biological samples. Most of the analytical characteristics of the proposed method were good and comparable with other corresponding methods except for the SuplMIP-SPE/LC-MS-MS method which is sophisticated and very expensive [6].

Conclusion

In this study a monolith, stable and flexible SPME fiber was fabricated based on MIP. The fabricated fiber was used for the extraction and pre-concentration of MAMP from a model aqueous solution. Easy fabrication, high stability, durability, selectivity, better repeatability and very low cost are the main advantages of the fabricated MIP fiber in comparison with the commercial fibers such as PDMS fiber. The efficiency of the fabricated fiber to extract MAMP from the real samples was investigated by the implementation of SPME in spiked saliva. High extraction efficiency was achieved resulting in a low detection limit. This type of monolithic MIP fiber showed good compatibility in dealing with biological samples such as saliva.

References

Bar AM, Panenka WJ, MacEwan W, Thornton AE, Lang DJ, Honer WG, Lecomte T (2006) J Psychiatry Neurosci 31:301–313

Kraemer T, Maurer HH (1998) J Chromatogr B 713:163–187

Pichini S, Pacifici R, Pellegrini M, Marchei E, Lozano J, Nurillo J, Vall O, Garcia-Algar O (2004) Anal Chem 76:2124–2132

Hendrickson HP, Milesi-Halle A, Laurenzana EM, Owens SM (2004) J Chromatogr B 806:81–87

Moeller MR, Steinmeyer S, Kraemer T (1998) J Chromatogr B 713:91–109

González-Marino I, Quintana JB, Rodríguez I, Rodil R, González-Penas J, Cela R (2009) J Chromatogr A 1216:8435–8441

Myung SW, Min HK, Kim S, Kim M, Cho JB, Kim TJ (1998) J Chromatogr B 716:359–365

Ugland HG, Krogh M, Rasmussen KE (1997) J Chromatogr B 701:29–38

Raikos N, Christopoulou K, Theodoridis G, Tsoukali H, Psaroulis D (2003) J Chromatogr B 789:59–63

Yashiki M, Kojima T, Miyazaki T, Nagasawa N, Iwasaki Y, Hara K (1995) Forensic Sci Int 76:169–177

Lord HL, Pawliszyn J (1997) Anal Chem 69:3899–3906

Chia KJ, Huang SD (2005) Anal Chim Acta 539:49–54

Fan Y, Feng Y, Zhang J, Da S, Zhang M (2005) J Chromatogr A 1074:9–16

Cormack PAG, Elorza AZ (2004) J Chromatogr B 804:173–182

Andrade R, Reyes FGR, Rath S (2005) Food Chem 91:173–179

Zhou F, Li X, Zeng Z (2005) Anal Chim Acta 538:63–70

Djozan Dj, Pournaghi-Azar MH, Bahar S (2004) Chromatographia 59:595–599

Djozan Dj, Assadi Y (2001) Anal Chem 73:4054–4058

Gierak A, Seredych M, Bartnicki A (2006) Talanta 69:1079–1087

Jiang R, Zhu F, Luan T, Tong Y, Liu H, Ouyang G, Pawliszyn J (2009) J Chromatogr A 1216:4641–4647

Mohammadi A, Yamini Y, Alizadeh N (2005) J Chromatogr A 1063:1–8

Mullet WM, Martin P, Pawliszyn J (2001) Anal Chem 73:2383–2389

Djozan Dj, Baheri T (2007) J Chromatogr A 1166:16–23

Djozan Dj, Baheri T, Pournaghi Azar MH, Mahkam M (2007) Mater Manuf Process 22:758–763

Djozan Dj, Ebrahimi B (2008) Anal Chim Acta 616:152–159

Sellergren B (2003) Techniques and instrumentation in analytical chemistry, vol 23. Elsevier, Amsterdam

Qi J, Li X, Li Y, Zhu J, Qiang L (2008) Chem Eng China 2:109–115

Cháfer-Pericás C, Campíns-Falcó P, Herráez-Hernández R (2004) Anal Biochem 333:328–335

Huang Z, Zhang S (2003) J Chromatogr B 792:241–247

Kudo K, Ishida T, Hara K, Kashimura S, Tsuji A, Ikeda N (2007) J Chromatogr B 855:115–120

Acknowledgments

The authors would like to thank the Research Office at the University of Tabriz for financial support.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Djozan, D., Farajzadeh, M.A., Sorouraddin, S.M. et al. Synthesis and Application of High Selective Monolithic Fibers Based on Molecularly Imprinted Polymer for SPME of Trace Methamphetamine. Chromatographia 73, 975–983 (2011). https://doi.org/10.1007/s10337-011-1984-8

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10337-011-1984-8