Abstract

Per- and polyfluoroalkyl substances (PFASs) are lipophilic pollutants of increasing health concern due to their environmental persistence, bioaccumulation, and toxicity. Remediation techniques have been set up for PFAS removal, such as electron beam, which exhibits excellent performance due to its cost-effective ability of producing large amounts of both reducing and oxidizing species. However, the degradation efficiency and mechanisms of the shorter-chain PFASs by eBeam irradiation are poorly known. Herein, perfluoroheptanoic acid was exposed to different eBeam doses of 0–75 kGy. We tested the effect of pH (6.0 and 13.0), nitrate ions, and fulvic acids in water. Results show that highly alkaline conditions favored the removal of perfluoroheptanoic acid at 100.0 μg/L with complete elimination at eBeam doses of 50 kGy and 75 kGy. Nitrate, fulvic acid, and CaCO3 alkalinity did not inhibit perfluoroheptanoic acid degradation. Defluorination and decarboxylation are proposed to be the major degradation pathways based on the identification of two degradation products. Overall, our findings show that eBeam irradiation is a promising remediation technique to break down the shorter-chain PFASs.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Per- and polyfluoroalkyl substances (PFASs) are of serious concern to human health and ecological systems (Chu et al. 2020; Pelch et al. 2019). Among PFASs, it is generally accepted that perfluorocarboxylic acids (PFCAs) are persistent, bioaccumulative, ubiquitously present in the environment, and recalcitrant to removal by drinking water and municipal wastewater treatment processes (Wang et al. 2017; Zhang et al. 2019a, b). These compounds have been measured in drinking water at numerous sites in the United States and in other parts of the world at concentrations ranging up to several tens of ng/L (Ateia et al. 2019). Researchers have confirmed that PFCAs have multiple toxic effects on humans such as immunotoxicity, hepatotoxicity, developmental toxicity, and carcinogenicity (Piekarski et al. 2020). In monitoring PFCAs, most of the attention has been payed on perfluorooctanoic acid (PFOA) (Lindim et al. 2016; Ong et al. 2020). Research on the other analogs such as perfluoroheptanoic acid (PFHpA) is largely missing. PFHpA is likely to be present in water and is one of the intermediates of the degradation of PFOA (Trojanowicz et al. 2019). Investigations on PFHpA may also shed light on understanding its degradation mechanisms under man-made remediation processes. We have, therefore, focused on studying the degradation of PFHpA in water.

A number of methods have been investigated to remove PFASs, including adsorption, reverse osmosis, and nanofiltration (Mahinroosta and Senevirathna 2020; Zhang et al. 2019a, b). Thermal techniques have the ability to degrade PFASs (Ahrens et al. 2019; Wu et al. 2019; Zhang et al. 2016). Advanced oxidation processes (AOPs) like UV, ozonation, and Fenton oxidation have been sought to eliminate PFASs. The AOPs use highly reactive oxidizing species such as hydroxyl radicals (·OH) and sulfate radicals (SO4·−) to degrade PFASs (Hori et al. 2005, 2007, 2008; Liu et al. 2017, 2019, 2020; Qu et al. 2016; Yang et al. 2020; Zhang et al. 2016). Other technologies such as ionizing radiation (photons and electrons) to degrade PFCAs are emerging and have shown the ability to eliminate different PFASs including PFOA (Kim et al. 2018; Ma et al. 2017; Trojanowicz et al. 2019; Wang et al. 2016). The decomposition of studied PFASs is highly dependent on experimental conditions such as pH and oxygen levels (i.e., absence or presence of oxygen in water). Very few in-depth studies have been performed to know the degradation mechanisms of PFHpA (Trojanowicz et al. 2019). Therefore, we focused on the degradation mechanisms of PFHpA in laboratory grade distilled water when exposed to high energy (10 million electron volts) electron beam (eBeam) irradiation doses between 0 and 75 kGy. Previous studies in our laboratory and elsewhere have identified some key parameters that could influence PFAS degradation (Wang et al. 2016; Trojanowicz et al. 2019, 2020).

The current paper has the following objectives: (i) to investigate the effect of solution pH on the degradation of PFHpA by eBeam irradiation at different eBeam doses (0–75 kGy) to establish the optimum conditions for its removal; (ii) to examine the influence of typical water constituents, e.g., alkalinity, nitrate ion, and fulvic acid, to understand the possible inhibitors of eBeam-mediated degradation of PFHpA in water; and (iii) to elucidate the major degradation pathways by which PFHpA degrades when exposed to eBeam doses in aqueous samples.

Experimental methods

Chemicals and supplies

Perfluoroheptanoic acid (PFHpA) (50.0 μg/mL in methanol) was obtained from Wellington Laboratories (ON, Canada). Methanol and water of HPLC grades were purchased from Macron Fine Chemicals and Sigma-Aldrich, respectively. Sodium hydroxide (98.4% purity), ammonium acetate, and ammonium hydroxide were individually obtained from J.T. Baker, BDH, and Ward’s Science (ON, Canada). The Oasis WAX vacuum cartridges (30 μm particle size, 1 cc) used for solid-phase extraction (SPE) were obtained from Waters.

eBeam irradiation and dose measurements

The samples were exposed to varying eBeam irradiation doses (i.e., 5, 10, 25, 50, and 75 kGy) at the eBeam facility of the National Center for Electron Beam Research (NCEBR) at Texas A&M University using a 10 MeV, 15 kW linear accelerator. The delivered dose was calibrated based on the alanine dosimetry using the BrukerScan EPR spectrometer (Wang et al. 2016). During eBeam irradiation, a large number of aqueous electrons (e−aq), hydrogen radicals (H·), and ·OH are expected to be produced when interacting with water according to Eq. 1 (Miller 2005):

Values in brackets represent the “G values” (number of species produced by 0.1 MeV of energy absorbed), and H·, e−aq, and ·OH are highly reactive species, while H3O+ is the hydrated proton.

Sample preparation

Stock solutions were used in preparing the experimental samples. In preparing the samples for eBeam irradiation, the initial concentration of PFHpA was set at 100.0 μg/L, which was obtained after diluting the stock solution in water. The effect of solution pH was studied at pH 13.0 and 6.0, which were prepared using 0.1 M NaOH and without pH adjustment, respectively. Fifty milliliters (50 mL) of the experimental sample were placed in HDPE bottles and purged with nitrogen in an oxygen-free glove box to remove the dissolved and headspace oxygen. Additionally, to investigate the effect of typical water components, different concentrations of alkalinity (i.e., 25, 50, 50, and 75 mg/L CaCO3) added as bicarbonate, nitrate ions, i.e., 5, 10, 15, and 20 mg/L, and natural organic matter, e.g., fulvic acid at 25, 50, 75, and 100 μg/L, were added as the experimental variables. The samples were amended with these constituents prior to nitrogen purging. Afterward, the samples were sealed with parafilm and exposed to different eBeam doses.

eBeam dosing

The samples were exposed to high energy (10 MeV) eBeam doses by placing the samples on an automated sample conveyance system. This system was calibrated to ensure that the samples received the specific target eBeam dose as the samples traversed under the eBeam linear accelerator’s scan horn from produced the high energy electrons. The samples were stored at 4 °C before and after eBeam treatment.

Sample processing

After irradiation, the samples were passed through the Oasis WAX vacuum cartridges (30 μm particle size, 1 cc), which were first pre-conditioned with 1.0 mL 0.1% ammonium hydroxide in methanol (3 times), followed by 1.0 mL 100% methanol (3 times). Each sample was vortexed for 5–10 s to ensure uniformity at a speed of 10 using MINI VORTEXER before loading 1 mL with a vacuum running. Ammonium acetate (1.0 mL of 25 mM) was added using a regular vacuum setting (10′’-20′’ Hg Vacuum). The cartridges were dried at a low vacuum for 3–5 min and then eluted by 0.1% ammonium hydroxide in methanol (1.0 mL) under a low vacuum. The eluted solution was transferred into 1.5 mL microfuge tubes, covered with parafilm, and stored at 4 °C prior to performing liquid chromatography-mass spectrometry/mass spectrometry (LC–MS/MS) analysis.

Analytical methods

PFHpA analysis

The analysis of PFHpA was performed by Integrated Metabolomics Analysis Core (IMAC) at Texas A&M University. Specifically, PFHpA in the samples was detected and quantified on a triple quadrupole mass spectrometer (Altis, Thermo Scientific, Waltham, MA) coupled to a binary pump HPLC (Vanquish, Thermo Scientific). The MS parameters were optimized for PFHpA under direct infusion at 5 µL/min to identify the SRM transitions (precursor/product fragment ion pair) with the highest intensity. The optimized parameters included polarity (negative), precursor (m/z 363.1), product (m/z 318.9), collision energy (10.23 V), and RF Lens (36 V). Samples were maintained at 4 °C on an autosampler before injection. The injection volume was 10 µL. Chromatographic separation was achieved on a Hypersil Gold column (5 µm, 50 × 3 mm, Thermo Scientific) maintained at 30 °C using a 9.5-min solvent gradient method. Solvent A was water (0.1% formic acid) and solvent B was acetonitrile (0.1% formic acid). The flow rate was 0.6 mL/min. Sample acquisition and analysis were performed with TraceFinder 3.3 (Thermo Scientific). A variety of quality control samples were run alongside the experimental samples. Experiments were carried out in triplicates, and standard errors were less than 10%.

Product identification

The transformation products of PFHpA were measured by untargeted liquid chromatography high resolution accurate mass spectrometry (LC-HRAM-MS) analysis. It was performed on a Q Exactive Plus orbitrap mass spectrometer (Thermo Scientific, Waltham, MA) coupled to a binary pump HPLC (UltiMate 3000, Thermo Scientific). Full MS spectra were obtained at 70,000 resolution (200 m/z) with a scan range of 50–750 m/z. Full MS followed by ddMS2 scans were obtained at 35,000 resolution (MS1) and 17,500 resolution (MS2) with a 1.5 m/z isolation window and a stepped NCE (20, 40, 60). Samples were maintained at 4 °C before injection. The injection volume was 10 µL. Chromatographic separation was achieved on a Hypersil Gold column (5 µm, 50 × 3 mm, Thermo Scientific) maintained at 30 °C using a 9.5-min solvent gradient method. Solvent A was water (0.1% formic acid), and solvent B was acetonitrile (0.1% formic acid). The flow rate was 0.6 mL min−1. Sample acquisition was performed using Xcalibur (Thermo Scientific). Data analysis was performed with Compound Discoverer 3.1 (Thermo Scientific).

Results and discussion

Degradation efficiency of PFHpA by eBeam irradiation

Effect of solution pH

In this study, the removal performance of PFHpA (100.0 μg/L) by different eBeam doses (0–75 kGy) was explored at two different initial pH values (6.0 and 13.0). As shown in Fig. 1a, increasing elimination of PFHpA was observed with the increase in eBeam dose. Complete removal of PFHpA was achieved at 50 kGy and 75 kGy at pH 13.0. In comparison, there was only partial PFHpA degradation (< 10%) at pH 6.0 even at 75 kGy of eBeam dose. Previous studies from our laboratory (Wang et al. 2016) and other laboratories (Trojanowicz et al. 2019, 2020; Ma et al. 2017) have reported similar results, in which PFOA and perfluorooctanoic sulfonate degradation was favored by highly alkaline conditions. It is well known that aqueous electrons (e−aq) predominate under alkaline conditions compared to the ·OH that predominates under acidic conditions (Trojanowicz et al. 2019, 2020; Ma et al. 2017). It is noteworthy to mention that the removal of PFHpA at both pH conditions appears to follow the pseudo-first-order reaction kinetics (Fig. 1b).

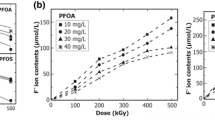

Effect of alkalinity, nitrate ion, or natural organic matter

To investigate the effect of common water components, the PFHpA solutions were individually amended with bicarbonate, nitrate ions, and natural organic matter (used as fulvic acid) at varying concentrations, and then irradiated with 50 kGy eBeam at pH 13.0. As presented in Fig. 2, complete removal of PFHpA was found even in the presence of these additives at the test concentrations, indicating no inhibitory effect from these three water components. Differently, our recent study suggested the significantly enhanced effects of alkalinity and nitrate ions for defluorination performance of PFOA via eBeam irradiation (Wang et al. 2016). It is known that the reactive species such as e−aq and ·OH could interact with bicarbonate and nitrate ions to form carbonate radicals (CO3·−) and nitrate radicals (NO3·−), respectively. The results from Fig. 2a and b suggested that these two secondary radicals may also play a positive role in oxidizing PFHpA in water.

In previous studies, we had shown that natural organic matter in the form of fulvic acid was capable of attenuating the reduction of PFOA (Wang et al. 2016). However, in this study, despite fulvic acid concentration was ranged from 25 to 100 µg/L, there was still complete degradation of PFHpA at 50 kGy (Fig. 2c).

Transformation products and pathways

The transformation products of PFHpA by eBeam irradiation were analyzed using untargeted high resolution LC–MS analysis. As listed in Table 1, two reaction products of PFHpA were identified as P-282 and P-294 with their individual molecular formulas of C6HF11 and C7H4F10O. It is noteworthy that a good agreement between the experimental and calculated molecular weights was observed, as indicated by the small errors (< 5 ppm). Based on these identified byproducts (i.e., P-282 and P-294), the reaction pathways of PFHpA by eBeam irradiation were tentatively proposed and are shown in Fig. 3. Defluorination and decarboxylation appear to be the two major reaction patterns. Previous studies with PFOA also appear to show that both defluorination and decarboxylation reactions occur during eBeam irradiation (Trojanowicz et al. 2019). More in-depth investigations can be performed in future to measure the inorganic fluoride ions released from PFHpA and the mineralization efficiency after eBeam irradiation.

Conclusion

In this study, the breakdown of PFHpA under varying eBeam doses in laboratory grade distilled water was evaluated. It is observed that highly alkaline condition (i.e., pH 13.0) favored the decomposition of PFHpA with complete breakdown observed at 50 and 75 kGy. This was in contrast to less than 10% breakdown at pH 6.0 even at 75 kGy eBeam dose. The presence of bicarbonate, nitrate ions, and natural organic matter did not appear to have any inhibitory effect in degrading PFHpA under the experimental conditions. Two transformation products of PFHpA by eBeam irradiation at 50 kGy were identified using untargeted LC–MS analysis, indicating defluorination and decarboxylation as two dominant reaction pathways that occur at this dose. Overall, this study demonstrates the efficacy of high energy eBeam irradiation for the complete breakdown of a 7-carbon PFAS.

References

Ahrens L, Benskin JP, Cousins IT, Crimi M, Higgins CP (2019) Themed issues on per- and polyfluoroalkyl substances. Environ Sci Water Res Technol 5:1808–1813. https://doi.org/10.1039/c9ew90049g

Ateia M, Alsbaiee A, Karanfil T, Dichtel W (2019) Efficient PFAS removal by amine-functionalized sorbents: critical review of the current literature. Environ Sci Techno Lett 6:688–695. https://doi.org/10.1021/acs.estlett.9b00659

Chu C, Zhou Y, Li Q, Bloom MS, Lin S, Yu Y, Chen D, Yu H, Hu L, Yang B, Zeng X, Dong G (2020) Are perfluorooctane sulfonate alternatives safer? New insights from a birth cohort study. Environ Int 135:105365. https://doi.org/10.1016/j.envint.2019.105365

Hori H, Yamamoto A, Hayakawa E, Taniyasu S, Yamashita N, Kutsuna S, Kiatagawa H, Arakawa R (2005) Efficient decomposition of environmentally persistent perfluorocarboxylic acids by use of persulfate as a photochemical oxidant. Environ Sci Technol 39:2383–2388. https://doi.org/10.1021/es0484754

Hori H, Yamamoto A, Koike K, Kutsuna S, Osaka I, Arakawa R (2007) Persulfate-induced photochemical decomposition of a fluorotelomer unsaturated carboxylic acid in water. Water Res 41:2962–2968. https://doi.org/10.1016/j.watres.2007.02.033

Hori H, Nagaoka Y, Murayama M, Kutsuna S (2008) Efficient decomposition of perfluorocarboxylic acids and alternative fluorochemical surfactants in hot water. Environ Sci Technol 42:7438–7443. https://doi.org/10.1021/es800832p

Kim T, Yu S, Choi Y, Jeong T, Kim SD (2018) Profiling the decomposition products of perfluorooctane sulfonate (PFOS) irradiated using an electron beam. Sci Total Environ 631–632:1295–1303. https://doi.org/10.1016/j.scitotenv.2018.03.055

Lindim C, van Gils J, Cousins IT (2016) Europe-wide estuarine export and surface water concentrations of PFOS and PFOA. Water Res 103:124–132. https://doi.org/10.1016/j.watres.2016.07.024

Liu J, Qu R, Wang Z, Mendoza-Sanchez I, Sharma VK (2017) Thermal- and photo-induced degradation of perfluorinated carboxylic acids: Kinetics and mechanism. Water Res 126:12–18. https://doi.org/10.1016/j.watres.2017.09.003

Liu G, Zhou H, Teng J, You S (2019) Electrochemical degradation of perfluorooctanoic acid by macro-porous titanium suboxide anode in the presence of sulfate. Chem Eng J 371:7–14. https://doi.org/10.1016/j.cej.2019.03.249

Liu Y, Ptacek CJ, Baldwin RJ, Cooper JM, Blowes DW (2020) Application of zero-valent iron coupled with biochar for removal of perfluoroalkyl carboxylic and sulfonic acids from water under ambient environmental conditions. Sci Total Environ 719:137372. https://doi.org/10.1016/j.scitotenv.2020.137372

Ma S, Wu M, Tang L, Sun R, Zang C, Xiang J, Yang X, Li X, Xu G (2017) EB degradation of perfluorooctanoic acid and perfluorooctane sulfonate in aqueous solution. Nucl Sci Tech 28:137. https://doi.org/10.1007/s41365-017-0278-8

Mahinroosta R, Senevirathna L (2020) A review of the emerging treatment technologies for PFAS contaminated soils. J Environ Manage 255:109896. https://doi.org/10.1016/j.jenvman.2019.109896

Miller RB (2005) Electronic irradiation of foods: an into the technology. Springer, New York

Ong TTX, Blanch EW, Jones OAH (2020) Surface enhanced Raman spectroscopy in environmental analysis, monitoring and assessment. Sci Total Environ 720:137601. https://doi.org/10.1016/j.scitotenv.2020.137601

Pelch KE, Reade A, Wolffe TAM, Kwiatkowski CF (2019) PFAS health effects database: protocol for a systematic evidence map. Environ Int 130:104851. https://doi.org/10.1016/j.envint.2019.05.045

Piekarski DJ, Diaz KR, McNerney MW (2020) Perfluoroalkyl chemicals in neurological health and disease: human concerns and animal models. Neurotoxicology 77:155–168. https://doi.org/10.1016/j.neuro.2020.01.001

Qu R, Liu J, Li C, Wang L, Wang Z, Wu J (2016) Experimental and theoretical insights into the photochemical decomposition of environmentally persistent perfluorocarboxylic acids. Water Res 104:34–43. https://doi.org/10.1016/j.watres.2016.07.071

Trojanowicz M, Bartosiewicz I, Bojanowska-Czajka A, Kulisa K, Szreder T, Bobrowski K, Nichipor H, Garcia-Reyes JF, Nałęcz-Jawecki G, Męczyńska-Wielgosz S, Kisała J (2019) Application of ionizing radiation in decomposition of perfluorooctanoate (PFOA) in waters. Chem Eng J 357:698–714. https://doi.org/10.1016/j.cej.2018.09.065

Trojanowicz M, Bartosiewicz I, Bojanowska-Czajka A, Szreder T, Bobrowski K, Nałęcz-Jawecki G, Męczyńska-Wielgosz S, Nichipor H (2020) Application of ionizing radiation in decomposition of perfluorooctane sulfonate (PFOS) in aqueous solutions. Chem Eng J 379:122303. https://doi.org/10.1016/j.cej.2019.122303

Wang L, Batchelor B, Pillai SD, Botlaguduru VSV (2016) Electron beam treatment for potable water reuse: removal of bromate and perfluorooctanoic acid. Chem Eng J 302:58–68. https://doi.org/10.1016/j.cej.2016.05.034

Wang Z, DeWitt JC, Higgins CP, Cousins IT (2017) A never-ending story of per- and perfluoroalkyl substances (PFASs)? Enviorn Sci Technol 51:2508–2518. https://doi.org/10.1021/acs.est.6b04806

Wu B, Hao S, Choi Y, Higgins CP, Deeb R, Strathmann TJ (2019) Rapid destruction and defluorination of perfluorooctanesulfonate by alkaline hydrothermal reaction. Environ Sci Techno Lett 6:630–636. https://doi.org/10.1021/acs.estlett.9b00506

Yang L, He L, Xue J, Ma Y, Xie Z, Wu L, Huang M, Zhang Z (2020) Persulfate-based degradation of perfluorooctanoic acid (PFOA) and perfluorooctane sulfonate (PFOS) in aqueous solution: review on influences, mechanisms and prospective. J Hazard Mater 393:122405. https://doi.org/10.1016/j.jhazmat.2020.122405

Zhang T, Pan G, Zhou Q (2016) Temperature effect on photolysis decomposing of perfluorooctanoic acid. J Environ Sci 42:126–133. https://doi.org/10.1016/j.jes.2015.05.008

Zhang DQ, Zhang WL, Liang YN (2019a) Adsorption of perfluoroalkyl and polyfluoroalkyl substances (PFASs) from aqueous solution—a review. Sci Total Environ 694:133606. https://doi.org/10.1016/j.scitotenv.2019.133606

Zhang X, Lohmann R, Sunderland EM (2019b) Poly- and perfluoroalkyl substances in seawater and plankton from the Northwestern Atlantic margin. Environ Sci Technol 53:12348–12356. https://doi.org/10.1021/acs.est.9b03230

Acknowledgements

This research is funded (Grant RD839650) by the US Environmental Protection Agency (EPA) as part of the Science to Achieve Results (STAR) program, EPA-G2018-STAR-B1. This research was also carried out as part of the activities of the IAEA Collaborating Center for Electron Beam Technology at Texas A&M University. Funds from USDA-NIFA administered through the Texas A&M AgriLife Research Hatch grant H-8708 was also expended on this project.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Feng, M., Gao, R., Staack, D. et al. Degradation of perfluoroheptanoic acid in water by electron beam irradiation. Environ Chem Lett 19, 2689–2694 (2021). https://doi.org/10.1007/s10311-021-01195-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10311-021-01195-x