Abstract

Recycling scrap printed circuit boards for recovery of valuable metal resources is a major environmental issue. Most available disposal technologies are not environmentally safe. Here, printed circuit board particles were subjected to solvothermal treatment using poly(ethylene glycol)/sodium hydroxide. Results show that residual ratio of bromine varied with temperature, treating time and sodium hydroxide addition. The optimal temperature, treating time and sodium hydroxide addition were 180 °C, 10 h and 0.4 g, with the lowest residual bromine ratio of 1.7%. After treatment, the separation of residue was done by gravity separation and the purity of copper in the recovered metallic components was 97.8%. The recyclability of scrap printed circuit boards before crushing was also compared, the residue of which yielded a complete separation of copper foils and glass fibers. The purity of copper in the foil was achieved at 96.6%. We conclude that this novel process represents an applicable way to recycle high value resources from scrap printed circuit boards.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

With the rapid upgrade and replacement of electrical and electronic equipment in the past few years, the quantities of scrap printed circuit boards are continuing to grow substantially (Wath et al. 2015). The printed circuit boards are commonly a mixture of 30% metals mainly including copper, tin, lead and 70% of nonmetal materials. These nonmetal materials were usually consisted of thermoset resins as a binder and glass fibers as the reinforcing materials (Xiang et al. 2010; Zhan and Xu 2011). It also should be noted that brominated flame retardants such as tetrabromobisphenol A cured by a number of hardeners are frequently incorporated in thermoset resins (Wang et al. 2016). This constitutes brominated epoxy resins and can be used to increase the fire resistance of printed circuit boards (Wath et al. 2015).

The disposal of scrap printed circuit boards is rather difficult since brominated epoxy resins cannot be melted or reformed in point of their highly cross-linked network structure in the polymer skeleton (Wath et al. 2015; Yang et al. 2012). Moreover, brominated epoxy resins in scrap printed circuit boards are usually reinforced by glass fibers (Xing and Zhang 2013). Land burial, pyrolysis and incineration are not environmental benign (Guo et al. 2009; Zhang and Xu 2016; Wang and Xu 2014; Yang et al. 2013; Estrada-Ruiz et al. 2016), and glass fibers significantly reduce the combustion efficiency. Supercritical fluids were highly effective for disposal of scrap printed circuit boards, but their high pressure meant high energy consumption and equipment investment. In respect of valuable resources it contains, the recycling of scrap printed circuit boards has become the focus of research in recent years. However, serious pollution will be generated due to negative environmental effects of brominated epoxy resins (Diaz et al. 2016). Therefore, the elimination of brominated epoxy resins followed by the separation of scrap printed circuit boards provides a novel and practicable approach.

In terms of brominated epoxy resins elimination, chemical recycling has been extensively studied as one of the most promising treatment technologies. It can dissolve or disrupt epoxy resins by using reactive inorganic and organic solvents (Dang et al. 2005; Zhu et al. 2012). Zhu et al. (2012) utilized ionic liquid of 1-ethyl-3-methylimidazolium tetrafluoroborate to dissolve brominated epoxy resins. Dang et al. (2005) implied that nitric acid was feasible for efficient solvolysis of epoxy resin cured by amine, but the low leaching rate limited the application. Poly(ethylene glycol)/sodium hydroxide has been employed in chemical recycling of epoxy resin cured by methyl tetrahydrophthalic anhydride (Yang et al. 2012). Moreover, poly(ethylene glycol)/sodium hydroxide is also an catalytic system in dehydrohalogenation (Kimura and Regen 1982). Therefore, the removal of brominated epoxy resins and simultaneous metals recovery from scrap printed circuit boards were conducted by using this system. Thus far, there is no report regarding application of poly(ethylene glycol)/sodium hydroxide for the recyclability of scrap printed circuit boards.

In this study, the application of poly(ethylene glycol)/sodium hydroxide in solvothermal procedure for the recyclability of scrap printed circuit boards was investigated. The aim of this study was to develop an applicable approach for separation of scrap printed circuit boards.

Experimental section

Materials

Scrap printed circuit boards used in this work were provided by XIAMEN OASIS Sources Corporation Limited. They were mainly composed of metals, glass fibers and brominated epoxy resins as flame retardant. After the electronic components such as capacitors and relays were disassembled manually, the scrap printed circuit boards were cut into fragments using scissors (printed circuit boards A) and ground to powder (printed circuit boards B). Dichloromethane was products of pesticide analysis grade from J&K Chemical Limited, USA. Certified standard stock solution of bromine ion from National Research Center for Certified Reference Materials, China, was used for the analysis of bromine content. Analytical-grade reagents including poly(ethylene glycol)200, ethanol, sodium hydroxide and anhydrous sodium sulfate were supplied by Sinopharm Chemical Reagent Company of Beijing.

Experimental procedures

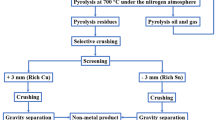

Figure 1 shows flowchart of scrap printed circuit boards separation and recovery of valuable resources by solvothermal technique. Quantitatively weighed sodium hydroxide was first dissolved in poly(ethylene glycol) (20 mL) and mixed with scrap printed circuit boards in the reactor. After a desired treating time, the solid and liquid mixture was separated by centrifugation (10,000 g, 10 min). The solid residue of printed circuit boards A was delaminated to obtain copper foils and glass fibers. The solid residue of printed circuit boards B was subjected to gravity separation, which was achieved by mixing with deionized water in the tube. After the mixture was shaken well, glass fibers were mainly suspended in the supernatant and the metallic components were sunk on the bottom of the tube. The solid residue of printed circuit boards B was separated into metallic components and glass fibers by decanting the supernatant. The temperature at 90, 120, 150 and 180 °C, treating time at 2, 5, 10 and 35 h, and sodium hydroxide amount at 0, 0.1, 0.4 and 1.0 g with other conditions unchanged were examined to optimize the residue yields and residual bromine ratios. All the experiments were repeated three times, and the results are the mean values with standard errors.

Proposed solvothermal process of printed circuit boards separation using poly(ethylene glycol)/sodium hydroxide. Note that copper foils and glass fibers were obtained from the solid residue of printed circuit boards A, whereas the solid residue of printed circuit boards B was separated into particles of metallic components and glass fibers

In order to determine the bromine content, raw printed circuit boards and solid residue after treatment were subjected to oxygen bomb combustion–ion chromatography (Dionex ICS-2000, USA) analysis as described in a previous study (Zhang and Zhang 2012). Gas chromatography–mass spectrometric analysis was performed using a gas chromatograph with a mass spectrometry detector and a HP-5 capillary column (Agilent 7890A/5975C, USA). High-purity He was used as carrier gas at a constant flow rate of 1 mL/min. The oven temperature was initially set at 50 °C and then ramped to 150 °C at 20 °C/min, 180 °C at 10 °C/min, 280 °C at 3 °C/min and held for 2 min at 280 °C. Scrap printed circuit boards B before and after treatment were characterized by in situ Fourier transform infrared spectrometer (Bruker Tensor 27), Philips PW 1700 X-ray diffractometer and scanning electronic microscopy (Hitachi S-3000 N). The separated copper foils and metallic components were digested by nitric acid–perchloric acid–hydrofluoric acid and subjected to analysis of inductively coupled plasma optical emission spectrometer (OPTIMA 2000).

Results and discussion

Effects of parameters on residue yield and residual bromine ratio

After the treatment, copper foils and glass fibers were obtained from the solid residue of printed circuit boards A, whereas the solid residue of printed circuit boards B was separated into particles of metallic components and glass fibers (Fig. 1). This was mainly attributed to decomposition of organic polymers such as brominated epoxy resins during the treatment process. Therefore, the yield of residue could be used to evaluate removal of brominated epoxy resins in scrap printed circuit boards (Li and Xu 2015). The calculated formula of residue yield is listed by Eq. 1 as follows:

where R is the yield of residue; M is the weight of scrap printed circuit boards before treatment; m is the residue weight after treatment.

The residual ratio of bromine was calculated according to the bromine content of scrap printed circuit boards before and after treatment. As shown in Fig. 2, the residue yield and residual ratio of bromine decreased with the increase in temperature. Meanwhile, they decreased rapidly initially and then varied in a certain range as the increase in treating time and sodium hydroxide addition (Figs. 2, 3a). Under this condition, treatment temperature of 180 °C, a period of 10 h and sodium hydroxide addition of 0.4 g were optimum to obtain lowest residual bromine ratio of 1.7%. This indicated that the removal efficiency of brominated epoxy resins was up to 98.3%.

Effects of treating temperature and time on residue yield and residual bromine ratio: a temperature (time 10 h; sodium hydroxide addition 0.4 g), b time (temperature 180 °C; sodium hydroxide addition 0.4 g). Note that the treatment temperature of 180 °C and a period of 10 h were optimum to obtain lowest residual bromine ratio

Compared with printed circuit boards A and B, it demonstrates that the fragments and particles of printed circuit boards show similar trends in the residue yields and residual bromine ratios under the same condition. Moreover, the residue yields and residual bromine ratios of printed circuit boards B were always lower than that of printed circuit boards A due to relatively complete removal of brominated epoxy resins. This is mainly because the swelling ratio between printed circuit boards and poly(ethylene glycol)/sodium hydroxide system was significantly influenced by surface area. The increase in surface area accelerated the diffusion of poly(ethylene glycol)/sodium hydroxide into printed circuit boards, enhanced the mass transfer of poly(ethylene glycol)/sodium hydroxide penetrating printed circuit boards and thus improved the removal efficiency of brominated epoxy resins.

Recovery of metals and glass fibers

Figure 4a shows Fourier transform infrared spectrometer spectra of printed circuit boards B before and after solvothermal treatment. It can be seen that the strong peak at 1730 cm−1 assigned to ester almost vanishes and the intensity of the –OH band increases after solvothermal treatment. The Fourier transform infrared spectrometer spectra of printed circuit boards B before and after solvothermal treatment confirmed that brominated epoxy resins were removed after treatment.

Fourier transform infrared spectrometer (a) and X-ray diffractometer (b) analyses of printed circuit boards before and after solvothermal treatment. Conditions: temperature 180 °C; time 10 h; sodium hydroxide addition 0.4 g. Note that brominated epoxy resins were removed and inorganic metallic components as well as glass fibers were greatly maintained after treatment

The X-ray diffractometer patterns of printed circuit boards B before and after solvothermal treatment are described in Fig. 4b. The main characteristic peaks of printed circuit boards before the treatment correspond to copper, tin and lead. Similar X-ray diffractometer patterns of printed circuit boards were obtained except that the peaks of tin were absent and the intensity of copper and lead diffraction peaks slightly reduced after the treatment. This result indicated that inorganic metallic components were greatly maintained.

The morphologies of printed circuit boards B before and after solvothermal treatment showed that the surface morphology of printed circuit boards changed from dark gray to light gray after solvothermal treatment. This was attributed to the absence of brominated epoxy resins in printed circuit boards. The glass fibers were easily aggregated together after the treatment; thus, the particles were larger than that of before treatment. Since solid residue was mainly composed of metallic components and glass fibers, the solid residue could be separated by gravity separation using water as separation medium. The metal balance and copper recovery efficiency were calculated as follows:

where m 1 is the weight of metals after gravity separation; M is the weight of printed circuit boards before treatment; ω is the metal contents in original printed circuit boards; φ 1 is the copper purity in the separated metals after gravity separation; φ is the copper content in original printed circuit boards.

The analysis of inductively coupled plasma optical emission spectrometer indicated that copper content accounted for 21.1% of the total printed circuit boards before the treatment (wt%) and the purity of copper in the separated metallic components was 97.8%. The metal balance was 97.1% after solvothermal treatment and the copper recovery efficiency achieved at 96.5% following the gravity separation. After the solid residue of printed circuit boards A was delaminated, the purity and the recovery efficiency of copper foil were achieved at 96.6 and 98.1%, respectively.

Recovery mechanism of printed circuit boards

The gas chromatography–mass chromatograms of organic component in liquid phase illustrated that the major compounds were bisphenol A besides poly(ethylene glycol). Tetrabromobisphenol A was formed with inadequate sodium hydroxide addition amount of 0.1 g at 10 h, while it was not observed under conditions such as more sodium hydroxide addition amount or longer treating time. This reveals that tetrabromobisphenol A was formed from brominated epoxy resins decomposition and could be debrominated to produce bisphenol A after solvothermal treatment. The ion chromatography analysis of inorganic component in liquid phase reveals that bromide was generated after treatment. This was mainly because brominated epoxy resins were dissolved and decomposed to produce bisphenol A and hydrogen bromine. Hydrogen bromine could react with OH− dissociated from sodium hydroxide leading to the formation of sodium bromide. According to a previous study (Xiu and Zhang 2010), the final concentration of bromide ion could be adjusted in order to be suitable for the recovery of bromine. After a simple distillation process in laboratory scale, bromine was recovered as hydrogen bromine solution, which can be widely used in industry.

On the basis of the obtained products, recovery mechanism of printed circuit boards was investigated. In poly(ethylene glycol)/sodium hydroxide system, brominated epoxy resins in printed circuit boards could be rapidly dissolved and decomposed. As the ether bond of the brominated benzene ring was relatively weak and easily broken down, tetrabromobisphenol A was initially formed (Kimura and Regen 1982). Corresponding to the increase in inorganic bromine in the liquid phase, tetrabromobisphenol A could be finally transformed into bisphenol A. This is consistent with previous reports (Liu et al. 2009; Luo et al. 2010; Yin et al. 2011), which suggested that the brominated epoxy resins were mainly decomposed into bisphenol A monomer at low-temperature treatment and decomposed into phenol and other low molecule bromine-free compounds at high temperature.

The result demonstrates that poly(ethylene glycol)/sodium hydroxide system shows high degradation ability for brominated epoxy resins. According to Fig. 3b, it has been reported that poly(ethylene glycol) tends to coordinate with sodium ions and forms sodium poly(ethylene glycol) alkoxide with a crown-like structure at the terminal of polymer chain via self-complexation. Thus, it can phase-transfer itself into the organic phase and result in high efficiency of catalyzing dehydrohalogenation as a potent nucleophile (Yang et al. 2012).

The same gas chromatography–mass chromatogram of poly(ethylene glycol) before and after treatment demonstrated thermal stability of poly(ethylene glycol) in solvothermal process. Moreover, poly(ethylene glycol) is a nontoxic catalyst with relatively low cost, excellent safety and good dispersibility. These characteristics have led to its use in a wide range of applications and further demonstrate the superiority of this process.

Conclusions

Solvothermal procedure using sodium hydroxide in poly(ethylene glycol) was an efficient and practical approach for brominated epoxy resins removal and recovery of printed circuit boards. Temperature, treating time and sodium hydroxide addition were the main factors controlling residue yield and residual bromine ratio. The optimum temperature, time and sodium hydroxide addition were 180 °C, 10 h and 0.4 g, respectively, while the lowest residual bromine ratio achieved at 1.7%. Bisphenol A and bromide ion were formed via the tetrabromobisphenol A passway due to the catalytic dehydrohalogenation of poly(ethylene glycol)/sodium hydroxide system. The obtained metallic components contained 97.8% of copper, and the purity of copper in the foil was achieved at 96.6% after the separation, which could be directly reused in industry.

References

Dang W, Kubouchi M, Sembokuya H, Tsuda K (2005) Chemical recycling of glass fiber reinforced epoxy resin cured with amine using nitric acid. Polymer 46:1905–1912. https://doi.org/10.1016/j.polymer.2004.12.035

Diaz LA, Lister TE, Parkman JA, Clark GG (2016) Comprehensive process for the recovery of value and critical materials from electronic waste. J Clean Prod 125:236–244. https://doi.org/10.1016/j.jclepro.2016.03.061

Estrada-Ruiz RH, Flores-Campos R, Gámez-Altamirano HA, Velarde-Sánchez EJ (2016) Separation of the metallic and non-metallic fraction from printed circuit boards employing green technology. J Hazard Mater 311:91–99. https://doi.org/10.1016/j.jhazmat.2016.02.061

Guo J, Tang Y, Xu Z (2009) Wood plastic composite produced by nonmetals from pulverized waste printed circuit boards. Environ Sci Technol 44:463–468. https://doi.org/10.1021/es902889b

Kimura Y, Regen SL (1982) Poly (ethylene glycols) are extraordinary catalysts in liquid-liquid two-phase dehydrohalogenation. J Org Chem 47:2493–2494. https://doi.org/10.1021/jo00133a056

Li K, Xu Z (2015) Application of supercritical water to decompose brominated epoxy resin and environmental friendly recovery of metals from waste memory module. Environ Sci Technol 49:1761–1767. https://doi.org/10.1021/es504644b

Liu GB, Zhao HY, Thiemann T (2009) Zn dust mediated reductive debromination of tetrabromobisphenol A (TBBPA). J Hazard Mater 169:1150–1153. https://doi.org/10.1016/j.jhazmat.2009.03.114

Luo S, Yang S, Wang X, Sun C (2010) Reductive degradation of tetrabromobisphenol A over iron–silver bimetallic nanoparticles under ultrasound radiation. Chemosphere 79:672–678. https://doi.org/10.1016/j.chemosphere.2010.02.011

Wang R, Xu Z (2014) Recycling of non-metallic fractions from waste electrical and electronic equipment (WEEE): a review. Waste Manag 34:1455–1469. https://doi.org/10.1016/j.wasman.2014.03.004

Wang J, Guo J, Xu Z (2016) An environmentally friendly technology of disassembling electronic components from waste printed circuit boards. Waste Manag 53:218–224. https://doi.org/10.1016/j.wasman.2016.03.036

Wath SB, Katariya MN, Singh SK, Kanade GS, Vaidya AN (2015) Separation of WPCBs by dissolution of brominated epoxy resins using DMSO and NMP: a comparative study. Chem Eng J 280:391–398. https://doi.org/10.1016/j.cej.2015.06.007

Xiang Y, Wu P, Zhu N, Zhang T, Liu W, Wu J, Li P (2010) Bioleaching of copper from waste printed circuit boards by bacterial consortium enriched from acid mine drainage. J Hazard Mater 184:812–818. https://doi.org/10.1016/j.jhazmat.2010.08.113

Xing M, Zhang FS (2013) Degradation of brominated epoxy resin and metal recovery from waste printed circuit boards through batch sub/supercritical water treatments. Chem Eng J 219:131–136. https://doi.org/10.1016/j.cej.2012.12.066

Xiu FR, Zhang FS (2010) Materials recovery from waste printed circuit boards by supercritical methanol. J Hazard Mater 178:628–634. https://doi.org/10.1016/j.jhazmat.2010.01.131

Yang P, Zhou Q, Yuan XX, Van Kasteren JMN, Wang YZ (2012) Highly efficient solvolysis of epoxy resin using poly (ethylene glycol)/NaOH systems. Polym Degrad Stab 97:1101–1106. https://doi.org/10.1016/j.polymdegradstab.2012.04.007

Yang X, Sun L, Xiang J, Hu S, Su S (2013) Pyrolysis and dehalogenation of plastics from waste electrical and electronic equipment (WEEE): a review. Waste Manag 33:462–473. https://doi.org/10.1016/j.wasman.2012.07.025

Yin J, Li G, He W, Huang J, Xu M (2011) Hydrothermal decomposition of brominated epoxy resin in waste printed circuit boards. J Anal Appl Pyrolysis 92:131–136. https://doi.org/10.1016/j.jaap.2011.05.005

Zhan L, Xu Z (2011) Separating and recovering Pb from copper-rich particles of crushed waste printed circuit boards by evaporation and condensation. Environ Sci Technol 45:5359–5365. https://doi.org/10.1021/es200243f

Zhang L, Xu Z (2016) A review of current progress of recycling technologies for metals from waste electrical and electronic equipment. J Clean Prod 127:19–36. https://doi.org/10.1016/j.jclepro.2016.04.004

Zhang CC, Zhang FS (2012) Removal of brominated flame retardant from electrical and electronic waste plastic by solvothermal technique. J Hazard Mater 221–222:193–198. https://doi.org/10.1016/j.jhazmat.2012.04.033

Zhu P, Chen Y, Wang LY, Qian GY, Zhou M, Zhou J (2012) A new technology for separation and recovery of materials from waste printed circuit boards by dissolving bromine epoxy resins using ionic liquid. J Hazard Mater 239–240:270–278. https://doi.org/10.1016/j.jhazmat.2012.08.071

Acknowledgements

This work was supported by financial supports from the National Natural Science Foundation of China (21507151), the Open Fund of Shanghai Cooperative Center for WEEE Recycling (B50ZS120003), the National Water Pollution Control and Management Program (2012ZX07202-005) and the Science Promotion Program of Research Center for Eco-Environmental Sciences, CAS (YSW2013B05).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhang, CC., Zhang, FS. High copper recovery from scrap printed circuit boards using poly(ethylene glycol)/sodium hydroxide treatment. Environ Chem Lett 16, 311–317 (2018). https://doi.org/10.1007/s10311-017-0676-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10311-017-0676-5