Abstract

The topic of decomposition and reduction of greenhouse gases is becoming an important issue in tackling the global warming effect since several years ago. Several technologies, including plasma-utilized process, were proposed to improve the treatment ability for the destruction of green house gases usually emitted by industrial activities. In this review paper, the application of plasma to reduce the emission of greenhouse gases was briefly summarized.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The emission from various industrial areas into ambient environment causes problems to the environment (Shah and Singh 1988). Those emissions usually contain greenhouse gases, such as carbon dioxide (CO2), methane (CH4), and chlorinated volatile organic compounds (CVOCs), e.g., methylene chloride (CH2Cl2), chloroform (CHCl3), and carbon tetrachloride (CCl4). Among all greenhouse gases, however, CO2 together with CH4 contributes the most of man-made greenhouse effects. Numerous amounts of CO2 were released into the environment, estimated to be around 2 × 1015 g per annum, and industrial sector has been suspected as the main contributor (Kiani et al. 2004; Yabe 2004). Chlorinated VOC emissions, caused by degradation of chlorine-containing chemicals, could be the source of chloric acid (HCl) and suspected to contribute in the acid rain problem (Sanhueza 2001). Some studies reported that these compounds, in stratosphere, could produce highly active chlorine radicals due to solar radiation reactions and could possibly to react and reduce the ozone molecules (US EPA 2002). However, the most significant problem related to the emission of chlorinated VOCs are remained on its high toxicity and carcinogenicity (International Agency for Research on Cancers 1987).

Concerning this situation, Kyoto protocol obligates industrialized countries to cut their greenhouse gas emissions by an average 5.2% between 2008 and 2012. This will deliver a strong message to us for finding effective methods for eliminating these industrial wastes (Frosch 1995). In this discussion, we would like to address the issue of the use of plasma technology as an alternative way to reduce or decompose gaseous emissions. The topic will not stress too much on the physical-theoretical or mathematical terms but on the application of plasma for environmental purposes.

Plasma in general

The discovery of plasma and its application have been known for more than a century (Roch 1995). Electric-created plasma-assisted chemical process has been intensively studied in the way of finding some potential applications for new chemical synthesis or other purposes. Moreover, worldwide application and industrial large-scale process using plasma are getting famous, e.g., ozone production and surface treatment (Kogelschatz 2003; Fridman et al. 1999). One of the main advantages of the plasma method is that the plasma is able to produce very high density discharge species compared to other methods, e.g., electrochemical (Raizer 1997) and combustion.

In general, based on the flame temperature, plasma can be divided into two major parts, thermal and cold (non-thermal) plasma (Roch 1995). Thermal plasma, sometimes called very high temperature plasma (T > 10,000 K), is widely used to decompose (strong bond) toxic chemicals and solid particle synthesis. This type of plasma has very high-energy species, able to destroy stable or strong chemical-bond of the compounds. Some of them, e.g., thermal-arc, torch or supersonic plasma, can handle high input flow rates with very short reaction time. The second type of plasma is called non-thermal or non-equilibrium plasma. Although it is not as strong as thermal plasma, cold (non-thermal) plasma is much favorable for the application in gaseous chemical synthesis type reactions, such as methane conversion for synthesis gas production. Non-thermal plasma refers to the temperature of the bulk gas which is usually as low as room temperature. The examples are quite many and some of them are already being applied in industrial scale (Roch 1995), such as corona, dielectric barrier discharge, microwave plasma, and radio frequency plasma for ozone production and solid surface treatment.

Instead of their physical characteristics, the consideration to choose the plasma used for its application also depends on other aspects. Table 1 shows the general comparison between thermal and cold plasma in some non-physical factors. This table clearly shows some advantages and some limitations of each division. Thermal plasma consumes high energy and the installation and/or the operating cost is expensive. On the other hand, the cold plasma has a main problem related to the low conversion of the reactants, especially for toxic gas decomposition when the concentration levels are higher than hundred of ppm. Compared to thermal plasma, the maintenance and operation cost are relatively easy and cheap. Moreover, regardless of the type of plasma that we use, optimization is necessary in order to obtain better performance with lower cost to meet the market requirements. Currently, the remaining key point for plasmachemical methods to be acceptable as a chemical-advanced process is how to optimize the condition to produce profitable reactions.

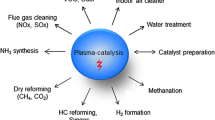

Plasma for chemical synthesis offers a wide spectrum of possible application. In particular, depending on the physical characteristics of the plasma produced by different ionization systems, three types of processes can be classified: (1) destruction of toxic/harmful materials; (2) modification of existing materials, e.g., surface treatment for catalyst; (3) creation of new materials (Bonizzoni and Vassallo 2002). For the first point, many researches have been conducted by decomposing many industrial emissions, such as H2S (Dalaine et al. 1998), N2O (Krawczyk and Mlotek 2001), CHCl3 and CCl4 (Krawczyk and Ulejczyk 2003, 2004). High percentage of destruction efficiency have been claimed using plasma. However, in this discussion, we would like to focus the discussion on the decomposition of three industrial gaseous: chlorinated volatile organic compounds, methane (CH4) and carbon dioxide (CO2).

Decomposition of chlorinated volatile organic carbons

The most widely adopted or common technique for the treatment of chlorinated volatile organic carbon emission was thermal combustion or incineration (Lou and Chang 1997). This method was mostly used due to its easiness and simplicity by reacting directly to the reactants with air under high-temperature condition, ca. 800–1,100 °C. It was reported that when the combustion does not occur perfectly (incomplete combustion), the reactions tend to produce a large amount of complex chlorinated products (Taylor and Dellinger 1988) which could be more toxic than the reactant itself. To avoid side stream reactions, some possibilities to control the reactions by introducing metal and/or metal oxide catalyst have also been investigated. Using this method, the decomposition rate could be faster and the product selectivity was very good, but the catalyst became easily deactivated by impurities and by the presence of solid products (Alberici and Jardim 1997). This method also, requires elevated temperatures to achieve the appropriate catalyst temperature and reaction rate. Another limitation to apply this method for industrial plants is the input flow rates were very small.

Currently, many studies were carried out on the application of combined process or new alternative methods such as plasma-assisted technology, which could overcome the above mentioned problems. Plasma-assisted technology for environmental purposes, such as radio frequency plasma (Lee et al. 1996), surface discharge reactors (Oda et al. 2002), dielectric barrier discharge reactors (Tonkyn et al. 1996), pulsed discharge reactors (Yamamoto et al. 1992), capillary-tube type discharge reactors (Kohno et al. 1998), and gliding arc (Krawczyk and Ulejczyk 2003, 2004) have been studied and developed. Lee et al. (1996) tried to decompose 1,1-dichloroetylene (DCE) using RF plasma. It showed that below 10% DCE (diluted in oxygen) at gas flow rate of 15 cm3, the DCE was totally removed. The products were dominated by CO and CO2 were the concentration reached 50% at high oxygen feeds. This method, however, has a major drawback that at higher O2 injections, instead of raising the CO2 concentration, the concentration of COCl2 (phosgene) was also increasing (Lee et al. 1996). This phenomenon could happen due to the reaction between chloride molecules with oxygen (Lee et al. 1996; Indarto et al. 2005a; 2006a)

Using dielectric barrier discharge, Oda et al. (2002) tried to remove trichloroetylene (TCE) and mentioned that the presence of some packed materials could save energy and reduce the power supplied to the reactor. Toykyn et al. (1996) observed that the reduction mechanism was likely a synergistic effect that involves changes in the plasma density, scavenging of low energy secondary electrons, and possible surface passivation. This point, which could be the advantage of plasma-assisted process, could be the important factor on the decomposition process and the energy density supplied from electrical generator should be measured in order to control the strength of the energy for the reaction. This idea was supported by Yamamoto et al. (1992), who performed the decomposition of various VOCs, including DCE and trichlorotrifluoroethane (known as CFC-113). They concluded that the plasma process strongly depended on the energy strength of the electron. The experiment itself was able to remove the reactants up to ca. 67% and the presence of noble gases could help increasing the decomposition rate by halogen-collision mechanism with atom carbon of the VOC molecules. Kohno et al. (1998) also conducted experiments to remove some VOCs using capillary column plasma. The authors claimed that they were able to remove the VOCs as high as 90% under a short residence time (3.8 ms) with a destruction energy efficiency of up to 95 g of compound/kWh. Following this promising result, the authors proposed to use this system for the semiconductor clean-room environment. Currently, a series of experiment to decompose VOCs has been conducted by Indarto et al. (Indarto et al. 2005a, 2006a, b, c, d, 2007a, b). Using gliding arc plasma and another type of non-thermal plasma which produced arcs from two or more electrode blades. Compared to the other non-thermal plasmas, gliding arc plasma produced higher flame temperatures, stronger powers, and was able to handle higher input flow rates (Fridman et al. 1999). This type of plasma is currently becoming famous and it has better possibility to be utilized for industrial chemical applications.

Kinetic model of chlorinated methane compound decomposition in dry air (mostly, VOCs were presented together with atmospheric air) under plasma conditions has been investigated also (Indarto et al. 2005a; 2006a; 2007b; Penetrante et al. 1995; Koch et al. 1995; Nichipor et al. 2000). The theoretical model suggested that the main product could be Cl2, COCl2, CO, CO2, ClNO3 and ClO3. Decomposition of chlorinated methane compound itself consists of two kinds of reaction mechanism (Penetrante et al. 1995). The mechanism took place when chlorinated carbon compounds collide with dissociated species, such as ground state atomic oxygen O(3P) and excited atomic oxygen O(1D),

The second mechanism occurred through the secondary electrons. The secondary electrons could dissociate CVOCs, e.g., CCl4, to produce CCl3 and negative ion Cl−.

The presence of chlorine atom could act as an auto-catalyzing agent for further decomposition reaction when this species collides with chlorinated molecules. Moreover, radical ClO and CCl3 were detected as the most important intermediate species in the formation of products and the O and Cl atoms has mostly responsible on the radical reactions both during initiation and termination reaction. CO, Cl2 and CO2 could be formed by dissociative process of COCl2 (phosgene) by electron according to (Lee et al. 1996; Nichipor et al. 2000):

and CO could react continuously into CO2:

More detailed mechanism for specific VOC molecules, e.g., chloroform (CHCl3), carbon tetrachloride (Indarto et al. 2005a, 2006b, 2007b; Penetrante et al. 1995; Koch et al. 1995; Nichipor et al. 2000), and dichloro methane (Indarto et al. 2006d), can be found in the references.

Methane conversion

Instead of being an energy source, methane could be the potential source of green house gases. The man-made activities, e.g., gas flaring in mining sites, petrochemical industry, and natural decomposition of organic compounds have converted methane into the second largest global warming-caused emissions. Conversion of methane into usable energy and/or higher-price compounds, such as hydrogen, synthesis gas, acetylene, and other higher hydrocarbons or black carbon is still posing a challenge (Lunsford 2000). Together with carbon dioxide (CO2), many studies have been done intensively for several decades, especially for direct methane conversion. The main problem that we are facing so far so is the inertness of the molecule to any kinds of reaction.

Many research groups used thermal-catalytic method to activate the methane molecule and reported some interesting results. The activation of methane on the surface of catalyst is the key point of the process. However, the results were still not satisfying when further problems appeared. Carbon solid deposition on surface, produced by fragmentation of C–H bond, reduced the catalyst performance. Moreover, the catalyst required a specific temperature operation range which is usually ca. 100–200 °C higher than room temperature. Small flow of injected raw gas is another barrier to apply this process in industrial scale.

Nowadays, plasma-assisted processes, both thermal and non-thermal plasmas, have been studied for methane conversion. Generally, many researches were focused on the utilization of high concentration methane for industrial purposes in order to reduce the methane released to the atmosphere. This technology was targeted to be in-situ process, built in the same location where the source of methane was found, such as gas mining facilities, or petrochemical plants. One of the interesting point of using plasma technology is that the different plasmas and operation conditions, used in the process, could produce different products distribution. This characteristic made it suitable for chemical synthesis selection. Methane utilization using glow discharge (Diamy et al. 2001; Legrand et al. 1997, 1999), dielectric barrier discharge (Kado et al. 2004; Zhang et al. 2003; Hwang et al. 2003, Kim et al. 2003a; 2003b, Jeong et al. 2001, Larkin et al. 2001), corona (Legrand et al. 1997, Liu et al. 1997), spark (Legrand et al. 1997), arc plasma-jet (Coltrin and Dandy 1993), radio frequency plasma (Savinov et al. 2004, Lee et al. 2001) and thermal plasma (Fabry et al. 2001, Kim 2004) have been investigated already. Other parameters of plasma methane reaction, such as plasma power generator (Yao et al. 2001, Song et al. 2004a), catalyst process-assisted (Kim et al. 2004, Song et al. 2004b), water vapor injection (Hijikata et al. 1999) were also investigated experimentally.

The conversion of CH4 will produce higher hydrocarbons (HCs), especially when non-thermal plasmas are used. Higher energy plasma or thermal plasma will convert CH4 mainly into carbon (C) and hydrogen (H2) (Indarto et al. 2006e)

Higher HCs could be formed by coupling reactions of methyl radical (Indarto et al. 2008) or carbon with radical species (Diamy et al. 2001).

The same coupling reactions also occurred in temperature-based reactions (Choudhary et al. 2003). In some particular cases, the reaction between carbon and radical shows important role, especially in the case when the concentration of acetylene is the highest among other products (Diamy et al. 2001). Legrand et al. (1997, 1999) the investigation have investigated methane conversion using dielectric barrier discharge. Using IR spectroscopy to analyze the excitation of N2, they proposed that the reactions were not initiated by electron, but by the existence of excited nitrogen compounds. This result is interesting, but arguable since in the absence of N2, the conversion of methane can be obtained in a higher rate by increasing the supplied power. Raising the supplied power could increase the population of electron inside the reactor. Based on the (movement) speed comparison, electron is much faster than other species such as ion, radical, or excited molecule (Roch 1995) which means electron could play a dominant role in the reactions. Moreover, apart from these two different arguments, the formation of metastable N2 as well as noble gases, e.g., Ar, Ne, and He, could help the decomposition rate of the reactants.

In the case of non-thermal plasmas, numerous research papers have been published which show very diverse results. Diamy et al. (2001; Legrand et al. 1997, 1999) found that the acetylene formed the majority of the products when corona-like discharge was used. Other groups (Kim et al. 2003a, 2003b; Jeong et al. 2001; Indarto et al. 2008) found ethane (C2H6) as the major products although the distribution could be different with some process manipulations or optimization. By kinetic calculation, Indarto et al. (2005b) showed that the concentration of ·CH3 radical (·CH3) and hydrogen atom (H) was increased sharply just after the initiation of plasma reaction, then ·CH3 was consumed and reacted to form higher mass molecules. An interesting result from Kim et al. (2003a, 2003b), and majority of papers (Indarto et al. 2006f, 2008), is that the coupling reactions occurred and would be followed by dehydrogenation reactions.

The coupling reactions would compete with H radical attack to ·CH3 to form hydrogen molecule (H2) and lone-pair CH2. Near the electrode part, the reaction would be dominated by methane fragmentation similar to reaction 11. Later on, atom carbon, with lone pair electron, could react with planar ·CH3 to form acetylene by C + ·CH3 → C2H2 + H. This reaction together with the final result of reaction 14 could be the reason why the concentration of acetylene in the products in some plasma experiments was the highest. This could only occurr when the electrode surface has enough power to fully decompose methane into carbon. Again, as there is still no evidence of the real detailed analysis of this mechanism, the idea is still arguable.

From the transition region between non-thermal and thermal plasma, e.g., gliding arc (Indarto et al. 2006e), the reaction was dominated by total fragmentation of CH4 into carbon and hydrogen (H2), similar to the thermal cracking (Indarto et al. 2006f). As CH4 can be converted into various products, the important factors in the consideration of the choosing the best method is the energy efficiency and instrumentation. Some power supplies, due to the different wave power, have different energy efficiencies.

Decomposition of CO2

Emission of carbon dioxide (CO2) into the atmosphere has been known as the major reason for the global warming effect. CO2 initiated and participated in ozone-depleting reactions (US Environmental Protection Agency 2002; Shah and Singh 1988). The increasing amounts of CO2 released into the environment by transportation, daily household, agricultural, and industrial activities, are estimated to be around 2 × 1015 g per annum, have increased the demand for finding effective methods to reduce its concentration. That is also the reason why the conversion of CO2 into more valuable gases is becoming a challenge now (Yamaji 1997).

The main problem to reduce the concentration of CO2 from industrial gas waste is the bond energy of CO2 which is chemically strongly–bounded. The thermodynamic calculation of CO2 decomposition resulted that the homolytic-cracking of C–O bond starts at 1500 °C. The proposed way to avoid the above mentioned problem is by introducing ionic system which allows ionic dissociation mechanism that has lower decomposition energy that is hemolytic-cracking. Plasma which is populated by ionic species could be a good solution.

In recent years, some studies have been carried out on the application of new technologies to reduce the emission of CO2. Plasma-assisted method, such as RF plasma (Savinov et al. 1999), corona (Wen and Jiang 2001; Maezono and Chang 1990), dielectric barrier discharge (Li et al. 2004), glow discharge (Wang et al. 1999; Buser and Sullovan 1970), and thermal plasma (Kobayashi et al. 2002), have also been developed. Currently, Indarto et al. (2006g, 2007c; Indarto 2007) tried to convert CO2 into CO and O2. Wen and Jiang (2001) showed that CO2 could be destroyed using corona discharge which known as the lowest electrons density of non-thermal plasmas. At 24 ml/min, the conversion of CO2 was below 10% and significantly increased up to 16% when the reactor was packed with Al2O3. The yield of CO was between 15 and 23%. Very low conversion of CO2 was due to the lack of electron and energy to enhance the conversion of CO2 (Maezono and Chang 1990). From this point, some process modification should be done to improve the conversion rate of CO2. The presence of Al2O3, for example, could help to increase the conversion of CO2 by adsorbing CO2 on the surface of solid material which this phenomenon was exactly similar to the thermal-adsorption process. Instead of CO and O2 as the main products, ozone (O3) was also found in few concentrations. Another experiment by Maezono & Chang (1990) on CO2 diluted in dry air using another type of corona discharge, so-called corona torch, showed that the conversion rate could be increased significantly by addition of noble gases, such as argon (Wen and Jiang 2001), helium (Wang et al. 1999). Light and lower excitation energy of noble gases will enable plasma to produce numerous amounts of active species which are useful to break the C–O bond. N2, ca. 80% of atmospheric air fraction, actually acted the same as Ar and He; however, the presence of oxygen will result side products, such as NO2, NO, or N2O (Indarto et al. 2006g, 2007c). Bi-functional behavior of O2 was detected as oxygen can abstract O from CO2 in the beginning of the reaction

and later on it can oxidize C and CO back to CO2

Li et al. (2004) investigated the effect of dielectric materials of dielectric barrier discharge on the conversion of CO2 to CO and O2. They mentioned that choosing the correct dielectric material was very important to increase the conversion of CO2. A comprehensive experimental to study the plasma parameters for CO2 conversion by using dielectric barrier discharge was done by Wang et al. (1999). The conversion of CO2 will increase by increment of frequency, residence time, supplied voltages, and the amounts of noble gases. In the absence of the catalyst, the process was far from efficient. Not all additive gases work well to enhance the better conversion of CO2. Buser and Sullovan (1970) found that H2 reduced the dissociation of CO2 in the dielectric barrier discharge.

By thoroughly investigating on the different rates of two isotopic carbon (12C16O2 and 13C16O2) diluted in nitrogen (N2), Savinov et al. (2002) concluded that the decomposition of CO2 was due to the vv-transfer of energy (transfer of vibrational energy between molecules) within the asymmetric mode of CO2 vibration.

As the energy difference caused by first excitation of N2 due to plasma was almost similar to asymmetric vibrational mode of CO2, the C–O breaking occurred naturally. In the absence of nitrogen, Indarto et al. (2006g; 2007c) successfully decomposed CO2 into O2 and CO in relatively high conversion rate. Later on by simulating the kinetic model, they mentioned the importance of fast electron in collision with CO2 (Indarto et al. 2007d).

Once the population of radical oxygen (1O), ionic oxygen (O2 +), and excited oxygen increased, these species could significantly fasten the decomposition rate of CO2 by recombination reaction

Furthermore, by variation of the O2 to N2 ratios of the input, they showed that the effect of N2 to the CO2 conversion is less than that by electron. Moreover, the behavior of N2 itself is almost similar to noble gases. The application of thermal plasma is initiated by Kobayashi et al. (2002). High thermal efficiency was achieved above 80% by using high-energy torch. In very strong supplied power, the decomposition of CO2 could break the two C–O bonds and produce solid carbon and oxygen.

Some researchers took advantage of this process to produce nano-sized carbon or black carbon. However, the energy efficiency of thermal plasma was usually very low compared to non-thermal plasma (Indarto et al. 2007c).

Conclusion

The application of plasma to decompose toxic compounds has just been studied for a few years. This area is attracting more and more researchers’ attention and is flourishing. However, there are still a lot of problems needed to be solved. The low conversion of reactant and the utilization cost which are usually very expensive have to be overcome. Most of the experiments on plasma conversion of gaseous emissions are still based on trial and error method in which the detailed mechanism on the global reaction has not been significantly addressed. Only a few mechanisms were assumed in the experiments, but they are still needed to be improved. However, it is shown that the plasma application is a visible method to be used for reducing the green house emissions and such combination, e.g., with appropriate catalyst, may be a good choice to increase the performance.

References

US Environmental Protection Agency (2002) Greenhouse gases and global warming potential values, Washington, DC, EPA 430-R–02–003.

Alberici RM, Jardim WF (1997) Photocatalytic destruction of VOCs in the gas-phase using titanium dioxide. Appl Catal B: Environ 14:55–68

Bonizzoni G, Vassallo E (2002) Plasma physics and technology; industrial applications. Vacuum 64:327–336

Buser RG, Sullovan JJ (1970) Initial process in CO2 glow discharges. J Appl Phys 41(2):472–479

Choudhary TV, Aksoylu E, Goodman DW (2003) Nonoxidative activation of methane. Catal Rev 45:151–203

Coltrin ME, Dandy DS (1993) Analysis of diamond growth in subatmospheric dc plasma-gun reactors. J Appl Phys 74(9):5803–5820

Dalaine V, Cormier JM, Lefaucheux PA (1998) A gliding discharge applied to H2S destruction. J Appl Phys 83(5):2435–2441

Diamy A-M, Hrach R, Hrachova V, Legrand J-C (2001) Influence of C atom concentration for acetylene production in CH4/N2 afterglow. Vacuum 61:403–407

Fabry F, Flamant G, Fulcheri L (2001) Carbon black processing by thermal plasma analysis of the particle formation mechanism. Chem Eng Sci 56:2123–2132

Fridman A, Nester S, Kennedy LA, Saveliev A, Yardimci OM (1999) Gliding arc gas discharge. Prog Energy Combust Sci 25:211

Frosch RA (1995) The industrial ecology of the 21st century. Sci Am 283:180–183

Hijikata K, Ogawa K, Miyakawa N (1999) Methanol conversion from methane and water vapor by electric discharge (effect of electric discharge process on methane conversion). Heat Trans Asia Res 28(5):404–417

Hwang B-B, Yeo Y-K, Na B-K (2003) Conversion of CH4 and CO2 to syngas and higher hydrocarbons using dielectric barrier discharge. Korean J Chem Eng 20(4):631–634

Indarto A (2007) Kinetic of CO2 reduction by gliding arc plasma. Asia J Water Environ Pollut 4(1):191–194

Indarto A, Choi JW, Lee H, Song HK (2005a) Gliding arc processing for decomposition of chloroform. Toxicol Environ Chem 87(1–4):509–519

Indarto A, Choi JW, Lee H, Song HK (2005b) Kinetic modeling of plasma methane conversion using gliding arc plasma. J Nat Gas Chem 14:13–21

Indarto A, Choi JW, Lee H, Song HK (2006a) Decomposition of CCl4 and CHCl3 on gliding arc plasma. J Environ Sci 14(1):81–88

Indarto A, Choi JW, Lee H, Song HK (2006b) Treatment of CCl4 and CHCl3 emission in a gliding-arc plasma. Plasma Device Oper 14(1):1–14

Indarto A, Choi JW, Lee H, Song HK (2006c) Discharge characteristics of a gliding-arc plasma in chlorinated methanes diluted in atmospheric air. Plasma Device Oper 14(1):15–26

Indarto A, Choi JW, Lee H, Song HK (2006d) Treatment of dichloromethane using gliding arc plasma. Intl J Green Energy 3(3):309–321

Indarto A, Choi JW, Lee H, Song HK (2006e) Methane conversion using dielectric barrier discharge: comparison with thermal process and catalyst effects. J Natur Gas Chem 15(2):87–92

Indarto A, Choi JW, Lee H, Song HK (2006f) Conversion of CO2 by gliding arc plasma. Environ Eng Sci 23(6):1047–1057

Indarto A, Choi JW, Lee H, Song HK (2006g) Effect of additive gases on methane conversion using gliding arc discharge. Energy 31:2650–2659

Indarto A, Yang DR, Azhari CH, Mohtar WH, Choi JW, Lee H, Song HK (2007a) Advanced VOCs decomposition method by gliding arc plasma. Chem Eng J 131(1–3):337–341

Indarto A, Yang DR, Choi JW, Lee H, Song HK (2007b) CCl4 decomposition by gliding arc plasma: role of C2 compounds on products distribution. Chem Eng Comm 19(8):1111–1125

Indarto A, Yang DR, Choi JW, Lee H, Song HK (2007c) Gliding arc plasma processing of CO2 conversion. J Hazard Mat 146(1–2):309–315

Indarto A, Coowanitwong N, Choi JW, Lee H, Song HK (2008) Kinetic modeling of plasma methane conversion in a dielectric barrier discharge. Fuel Process Technol 89(2):214–219

International Agency for Research on Cancers (1987) Monographs on the evaluation of carcinogenic risk to humans, Supplements 7

Jeong H-K, Kim S-C, Han C, Lee H, Song HK, Na B-K (2001) Conversion of methane to higher hydrocarbons in pulsed DC barrier discharge at atmospheric pressure. Korean J Chem Eng 18(2):196–201

Kado S, Sekine Y, Nozaki T, Okazaki K (2004) Diagnosis of atmospheric pressure low temperature plasma and application to high efficient methane conversion. Catal. Today 89:47–55

Kiani B, Hamamoto Y, Akisawa A, Kashiwagi T (2004) CO2 mitigating effects by waste heat utilization from industry sector to metropolitan areas. Energy 29:2061–2075

Kim S-S, Lee H, Choi J-W, Na B-K, Song HK (2003a) Kinetics of the methane decomposition in a dielectric-barrier discharge. J Ind Eng Chem 9(6):787–791

Kim S-S, Lee H, Na B-K, Song HK (2003b) Reaction pathways of the methane decomposition in a dielectric-barrier discharge. Korean J Chem Eng 20(5):869–872

Kim KS, Nam JS, Choi SI, Hong SH (2004a) Thermal plasma decomposition of methane for production of hydrogen and carbon black Proc 5th Int Symp Pulsed Power and Plasma Appl pp. 379–385

Kim S-S, Lee H, Na B-K, Song HK (2004b) Plasma-assisted reduction of supported metal catalyst using atmospheric dielectric-barrier discharge. Catal Today 89:193–200

Kobayashi A, Osaki K, Yamabe C (2002) Treatment of CO2 gas by high-energy type plasma. Vacuum 65:475–479

Koch M, Cohn DR, Patrick RM, Schuetze MP, Bromberg L, Reilly D, Hadidi K, Thomas P, Falkos P (1995) Electron beam atmospheric pressure cold plasma decomposition of carbon tetrachloride and trichloroethylene. Environ Sci Technol 29:2946–2952

Kogelschatz U (2003) Dielectric-barrier discharges Principle and applications. Plasma Chem Plasma Process 23(1):1–46

Kohno H, Berezin AA, Chang JS, Tamura M, Yamamoto T, Shibuya A, Honda S (1998) Destruction of volatile organic compounds used in a semiconductorindustry by a capillary tube discharge reactor. IEEE Trans Ind Appl 34(5):953–966

Krawczyk K, Mlotek M (2001) Combined plasma-catalytic processing of nitrous oxide. Appl Catal B: Environ 30:233–245

Krawczyk K, Ulejczyk B (2003) Decomposition of chloromethanes in gliding discharges. Plasma Chem Plasma Process 23(2):262–281

Krawczyk K, Ulejczyk B (2004) Influence of water vapor on CCl4 and CHCl3 conversion in gliding discharge. Plasma Chem Plasma Process 24(2):155–167

Larkin DW, Lobban LL, Mallinson RG (2001) Production of organic oxygenates in the partial oxidation of methane in a silent electric discharge reactor. Ind Eng Chem Res 40:1594–1601

Lee WJ, Chen CY, Lin WC, Wang YT, Chin CJ (1996) Phosgene formation from the decomposition of 1, 1–C2H2Cl2 contained gas in an RF plasma reactor. J Hazard Mat 48:51–67

Lee H, Savinov SY, Song HK, Na B-K (2001) Estimation of the methane conversion in a capacitively coupled radio-frequency discharge. J Chem Eng Jpn 34(11):1356–1365

Legrand JC, Diamy AM, Hrach R, Hrachova V (1997) Kinetic of reaction in CH4/N2 afterglow plasma. Vacuum 48:671–675

Legrand JC, Diamy AM, Hrach R, Hrachova V (1999) Mechanism of methane decomposition in nitrogen afterglow plasma. Vacuum 52:27–32

Li R, Yamaguchi Y, Yin S, Tang Q, Sato T (2004) Influence of dielectric barrier materials to the behavior of dielectric discharge plasma for CO2 decomposition. Solid State Ionics 172:235–238

Liu C, Marafee A, Mallinson R, Lobban L (1997) Methane conversion to higher hydrocarbons in a corona discharge over metal oxide catalysts with OH groups. Appl Catal A: Gen 164:21–33

Lou JC, Chang YS (1997) Thermal oxidation of chloroform. Combust Flame 109:188–197

Lunsford JH (2000) Catalytic conversion of methane to more useful chemicals and fuels: a challenge for 21st century. Catal. Today 63:165–174

Maezono I, Chang J-S (1990) Reduction of CO2 from combustion gases by DC corona torches. IEEE Trans Ind Appl 26(4):651–655

Nichipor H, Dashouk E, Chmielewski AG, Zimek Z, Bulka S (2000) A theoretical study on decomposition of carbon tetrachloride, trichloroethylene and ethyl bromide in dry air under the influence of an electron beam. Rad Phys Chem 57:519–525

Oda T, Takahahshi T, Yamaji K (2002) Nonthermal plasma processing for dilute VOCs decomposition. IEEE Trans Ind Appl 38(3):873–878

Penetrante BM, Hsiao MC, Bardsley JN, Merritt BT, Vogtlin GE, Wallman PH, Kuthi A, Burkhart CP, Bayless JR (1995) Electron beam and pulsed corona processing of carbon-tetrachloride in atmospheric pressure gas streams. Phys Lett A 209:69–77

Raizer P (1997) Gas discharge physics. Springer, Berlin

Roch JR (1995) Industrial Plasma Engineering: Volume 1 Principles, Univ Tennessee

Sanhueza E (2001) Hydrochloric acid from chlorocarbons: a significant source of background rain acidity. Tellus 53B:122–132

Savinov SY, Lee H, Song HK, Na B-K (1999) Decomposition of methane and carbon dioxide in a radio-frequency discharge. Ind Eng Chem Res 38:2540–2547

Savinov SY, Lee H, Song HK, Na B-K (2002) The decomposition of CO2 in glow discharge. Korean J Chem Eng 19(4):564–566

Savinov SY, Lee H, Song HK, Na B-K (2004) A kinetic study on the conversion of methane to higher hydrocarbons in a radio-frequency discharge. Korean J Chem Eng 21(3):1–10

Shah JJ, Singh HB (1988) Distribution of volatile organic chemicals in outdoor and indoor air. Environ Sci Technol 22:1381–1388

Song H-K, Lee H, Choi J-W, Na B-K (2004a) Effect of electrical pulse forms on the CO2 reforming of methane using atmospheric dielectric barrier discharge. Plasma Chem Plasma Process 24(1):57–71

Song HK, Choi J-W, Yue SH, Lee H, Na B-K (2004b) Synthesis gas production via dielectric barrier discharge over Ni/γ-Al2O3 catalyst. Catal Today 89:27–33

Taylor PH, Dellinger B (1988) Thermal degradation characteristics of chloromethane mixtures. Environ Sci Technol 22:438–447

Tonkyn RG, Barlow SE, Orlando TM (1996) Destruction of carbon tetrachloride in a dielectric barrier/packed-bed corona reactor. J Appl Phys 80(9):4877–4886

Wang J-Y, Xia G-G, Huang A, Suib SL, Hayashi Y, Matsumoto H (1999) CO2 decomposition using glow discharge plasmas. J Catal 185:152–159

Wen Y, Jiang X (2001) Decomposition of CO2 using pulsed corona discharges combined with catalyst. Plasma Chem Plasma Process 21(4):665–678

Yabe N (2004) An analysis of CO2 emissions of Japanese industries during the period between 1985 and 1995. Energy Policy 32:595–610

Yamaji K (1997) A study of the role of end-of-pipe technologies in reducing CO2 emissions. Waste Manag 17(5/6):295–302

Yamamoto T, Ramanathan K, Lawless PA, Enser DS, Newsome JR (1992) Control of volatile organic compounds by an ac energized ferroelectric pellet reactor and a pulsed corona reactor. IEEE Trans Ind Appl 28(3):528–534

Yao S, Nakayama A, Suzuki E (2001) Acetylene and hydrogen from pulsed plasma conversion of methane. Catal Today 71:219–223

Zhang Y-p, Li Y, Wang Y, Liu C-j, Eliasson B (2003) Plasma methane conversion in the presence of carbon dioxide using dielectric-barrier discharges. Catal Today 83:101–109

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Indarto, A., Choi, JW., Lee, H. et al. Decomposition of greenhouse gases by plasma. Environ Chem Lett 6, 215–222 (2008). https://doi.org/10.1007/s10311-008-0160-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10311-008-0160-3