Abstract

Recently, α-l-arabinofuranosidases (EC3.2.1.55) have received increased attention primarily due to their role in the degradation of lignocelluloses as well as their positive effect on the activity of other enzymes acting on lignocelluloses. As a result, these enzymes are used in many biotechnological applications including wine industry, clarification of fruit juices, digestion enhancement of animal feedstuffs and as a natural improver for bread. Moreover, these enzymes could be used to improve existing technologies and to develop new technologies. The production, mechanisms of action, classification, synergistic role, biochemical properties, substrate specificities, molecular biology and biotechnological applications of these enzymes have been reviewed in this article.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Lignocelluloses of plant cell walls are composed of cellulose, hemicellulose, pectin and lignin. Hemicelluloses are one of the most abundant renewable polymers on the earth. Moreover, cellulose, hemicelluloses, lignin and pectins are the key components in the degradation of lignocelluloses. Many enzymes are involved in the degradation of these polymeric substrates [129]. l-arabinosyl residues are widely distributed in these polymers as side chains. The presence of these side chains restricts the enzymatic hydrolysis of hemicelluloses and pectins [93, 99, 101]. Further, it also represents a formidable technological barrier that retards the development of various industrial processes [99]. The use of a single accessory enzyme for partial or specific modification of lignocelluloses might offer new interesting options for the utilization of these low-cost raw materials [72, 110].

The α-l-arabinofuranosidases (α-l-AFases) are accessory enzymes that cleave α-l-arabinofuranosidic linkages and act synergistically with other hemicellulases and pectic enzymes for the complete hydrolysis of hemicelluloses and pectins [77, 113]. These enzymes warrant substantial research efforts because they represent potential rate-limiting enzymes in the degradation of lignocelluloses from agricultural residues [99]. The action of α-l-AFase alone or in combination with other lignocellulose-degrading enzymes represents a promising biotechnological tool as alternatives to some of the existing chemical technologies such as chlorination in pulp and paper industry [44, 46, 74], synthesis of oligosaccharides [94, 95] and pretreatment of lignocelluloses for bioethanol production [100, 101]. Considering the potential and future prospects of α-l-AFases, this paper reviews the various aspects of these enzymes with emphasis on their potential for biotechnology.

Hemicelluloses and pectins

Hemicelluloses and pectins are the matrix polysaccharides of the plant cell wall. They account for 25–35% of lignocellulose biomass [99]. The hemicellulose xylans contain a β-1,4-linked d-xylose backbone [30]. In many plants, xylan backbone is substituted by different side chains with l-arabinose, d-galactose, acetyl, feruloyl, p-coumaroyl and glucuronic residues [1, 30]. Xylans from grasses, cereals, softwood and hardwood differ in their composition. This is due to the differences in the frequency and composition of the side chain substituents of xylans [30, 99, 100]. Similarly, arabinoxylans are found in the cell walls of the cereal plants and grasses belonging to the family Gramineae [1, 70]. They contain xylan backbone that is partially substituted at intervals with α-l-arabinofuranose residues [1]. Moreover, wheat arabinoxylan also contains other substituents as shown in Fig. 1 [1, 30].

The main structural features considered present within water-soluble wheat arabinoxylans. The diagram also indicates the variety of enzymes that are active against arabinoxylans. Modified from Ref. [1]

Pectins are a family of complex heteropolysaccharides that contain two well-defined regions called as smooth and hairy (Fig. 2) [17, 30]. The three pectic polysaccharides homogalacturonan, rhamnogalacturonan-I and substituted galacturonan have been isolated from plant cell walls [28, 30]. The dominant feature of the pectins is the presence of a linear backbone of galacturonic acid containing varying proportion of methyl ester groups. Pectin polymer backbone is interspersed at intervals with rhamnose residues carrying the neutral sugars side chains containing arabinose and galactose that form arabinans, arabinogalactans or galactans (Fig. 2) [17, 49]. Pectins are abundant in the soft tissues of citrus fruits [49, 131], sugar beet pulp and apple [20, 28].

Schematic drawing of pectin (rhamnogalcturonan I) showing the smooth and hairy regions. Modified from Ref. [30]

The α-l-AFases

The α-l-AFases (α-l-arabinofuranoside arabinofuranohydrolases, EC 3.2.1.55) are the enzymes involved in the hydrolysis of l-arabinose linkages. These enzymes have been purified from several bacteria, fungi and plants [51, 73, 93]. They form a part of the array of glycoside hydrolases required for the complete degradation of arabinose-containing polysaccharides [99, 115]. The action of these enzymes accelerates the hydrolysis of the glycosidic bonds by more than 1017 fold, making them one of the most efficient catalysts known [98, 107]. Such enzymatic hydrolysis releases soluble substrates, which are utilized by both prokaryotic and eukaryotic microorganisms [77]. The α-l-AFases specifically catalyze the hydrolysis of terminal nonreducing-α-l-1,2-, α-l-1,3- and α-l-1,5-arabinofuranosyl residues from different oligosaccharides and polysaccharides [99, 101, 112]. Whereas the nature of a glycone sugar can influence the catalytic activity of other arabinose-releasing enzymes, the α-l-AFases do not distinguish between the saccharide link to the arabinofuranosyl moiety and thus exhibit wide substrate specificity [93, 97]. Effective hydrolysis of α-l-arabinofuranosyl residues from various pectic, homo-hemicellulosic polysaccharides (branched arabinans, debranched arabinans), heteropolysaccharides (arabinogalactans, arabinoxylans, arabinoxyloglucans, glucuronoarabinoxylans, etc.) and different glycoconjugates is carried out by the α-l-AFases [8, 112]. Moreover, most microbial α-l-AFases are secreted into the culture media; thus, they are likely to attack polysaccharides [84].

The synergistic role of α-l-AFases

The importance of α-l-AFases has come from the fact that arabinose side chains on hemicelluloses and pectins participate in cross-linking within the plant cell wall structure. The presence of these side chains also affects the form and functional properties of hemicelluloses and pectins [29]. They reduce the interaction between polymers chains due to their inherently more flexible water-hungry furanose conformations. Moreover, the l-arabinofuranoside substitutions on xylan strongly inhibit the action of xylan-degrading enzymes (Fig. 1), thus preventing the complete degradation of the polymer to its basic xylose units [99, 107]. Similarly, l-arabinofuranoside substitutions in pectin (Fig. 2) prevent the complete degradation of this polymer to its basic units. The α-l-AFases act synergistically with other hemicellulases and pectinases for the complete degradation of hemicelluloses and pectins, respectively [4, 29, 67, 102]. Moreover, in some cases, α-l-AFases possessing β-xylosidase activity or xylanases with α-l-arabinofuranosidase activity also have been described [73, 74, 83, 121]. Furthermore, some α-l-AFases with both exo- and endo-activity on arabinan, one of the major constituents of pectins, has been reported [11, 87].

The role of α-l-AFases in the degradation of arabinose-containing polymers is well known. They have a cooperative role facilitating the action of other lignocellulose-degrading enzymes [118, 120]. This has been confirmed for α-l-AFase from Thermomonospora fusca that worked in truly synergistic relationship with endoxylanase from the same bacterium releasing 0.6 and 0.3 mg of reducing sugars from oat spelt xylan and ball-milled wheat straw, respectively [4]. α-l-AFase played an important role to increase the release of reducing sugars from these lignocelluloses. However, other authors report the synergistic action of these enzymes with other pectinases and hemicellulases on lignocelluloses. For instance, the two enzymes α-l-AFases (kabfA and kabjB) from Aspergillus kawachii acted synergistically with xylanase in the degradation of arabinoxylan, releasing higher amounts of ferulic acid in the presence of feruloyl esterase [68]. Furthermore, Hashimoto and Nakata [51] showed that hemicellulose from soy sauce materials was decomposed synergistically by xylanase, β-xylosidase and α-l-AFase produced by Aspergillus oryzae HL15 during moromiFootnote 1 fermentation. They also suggested that α-l-AFase of A. oryzae HL15 was very closely involved in releasing not only arabinose but also xylose into moromi mash. The same effect has been shown when these enzymes act synergistically on arabinoxylan. Moreover, an exo-arabinanase, Abnx from Penicillium chrysogenum, released very little arabinobiose from arabinan, as the action of Abnx was inhibited by the arabinofuranose unit linked as a side chain [102]. When Abnx acted in combination with either α-l-AFases (AFQ1 or AFS1), from the same fungus, the arabinose contents in the reaction mixtures were higher than the sum of those by the two enzymes acting separately [102]. Furthermore, Morales et al. [88] reported that the two α-l-Afases, i.e., AF64 and AF53 from Bacillus polymyxa, facilitate the action of the endoxylanase on oat spelt xylan and wheat bran arabinoxylan. An increase in the production of smaller xylooligosaccharides has occurred because of the cooperative action of α-l-AFases used in these experiments. α-l-AFases also act synergistically with endo-arabinanase and cinnamoyl esterase (CinnAE) from Aspergillus niger. When sugar-beet pulp (SBP) was incubated with the mixture of the former enzymes, the esterase was able to release 14 times more of the alkali-extractable ferulic acid present in the whole pulp as free acid than CinnAE alone [70].

Classification of arabinose-releasing enzymes

Kaji [60] classified α-l-AFases based on their sources and substrate specificity. Beldman et al. [8] classified arabinose-releasing enzymes depending on the mode of action and their substrate specificity. However, both classifications were not effective as they were too broad to define the substrate specificities of these enzymes. Moreover, newly isolated enzymes have shown different modes of action than those enzymes classified before. Because of this, further subclasses and a new class need to be added to the existing system of classification proposed by Beldman et al. [8]. In view of this, three subclasses of the existing arabinoxylan-α-l-arabinofuranohydrolases class could be introduced [38, 122, 123] and designated Subclass (1) AXHB-md 2, 3, Subclass (2) AXHB-m 2,3 and Subclass (3) AXHd3.

Subclass (1) AXHB-md 2,3 includes enzymes that release arabinose from both singly and doubly substituted xylose, and able to hydrolyze p-nitrophenyl α-l-arabinofuranoside at a rate similar to that for oligosaccharide substrates. This subclass was exemplified by the enzyme arabinoxylan arabinofuranohydrolase isolated from germinated barley [38].

Subclass (2) AXHB-m 2,3 includes enzymes that hydrolyze arabinose residues from C2 or C3 linked to a single-substituted xylose residue and do not hydrolyze p-nitrophenyl α-l-arabinofuranoside. The enzyme isolated from Bifidobacterium adolescentis [122] represents this subclass.

Subclass (3) AXHd3 includes enzymes that are able to release only C3-linked arabinose residues from double-substituted xylose residues but do not hydrolyze p-nitrophenyl α-l-arabinofuranoside. This subclass was represented by the enzyme isolated from B. adolescentis [123].

Recently, new types of α-l-AFases have been isolated with properties that have not been reported earlier. Such enzymes could not be assigned to any of the arabinose-releasing enzyme classes. These enzymes have the ability to act on both interior α-1,5 backbone and α-1,3–side chains of arabinan and debranched arabinans; in addition, they are able to act on p-nitrophenyl α-l-arabinofuranoside. In view of this, these enzymes should be assigned into a new class represented by α-l-AFase isolated from the thermophilic bacterium PRI-1686 [11] and Tm-AFase from the hyperthermophilic bacterium Thermotoga maritima MSB8 [87].

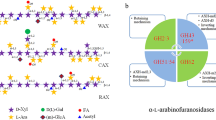

The most recent classification scheme based on amino acid sequences, primary structure similarities and hydrophobic cluster analysis has classified α-l-AFases into five glycosyl hydrolases families (GHs), i.e., GH3, GH43, GH51, GH54, and GH62 [23, 52]. This classification is useful to study evolutionary relationship, mechanistic information and structural features of these enzymes [25].

Mechanisms of action of α-l-AFases

Like other glycoside hydrolases, α-l-AFases mediate glycosidic bond cleavage via acid/base-assisted catalysis employing two major mechanisms, giving rise to either an overall retention or an inversion of the anomeric configuration [26, 136]. In both mechanisms, as shown in Fig. 3, the hydrolysis usually requires two carboxylic acids, which are conserved within each glycoside hydrolases family [98] and proceed through an exocarbonium ion-like transition state [92, 98, 107].

General mechanisms for a retaining and b inverting glycosidases. Adapted from Ref. [98]

Retaining α-l-AFases are members of GH3, GH51 and GH54 families that cleave the glycosidic bond using a two-step double-displacement mechanism, as shown in Fig. 3a. This was also confirmed by the crystal structure studies and snapshots along the reaction pathway of GH51 described by Hövel et al. [56]. In the first step of the reaction (glycosylation), the acid–base residue acts as a general acid, protonating the glycosidic oxygen and stabilizing the leaving group. The nucleophilic residue attacks the anomeric carbon of the scissile bond, forming a covalent glycosyl-enzyme intermediate with the opposite anomeric configuration of the substrate. In the second step (deglycosylation), the acid–base residue, acting this time as a general base, activates a water molecule that attacks the anomeric center of the glycosyl-enzyme intermediate from the same direction of the original bond, liberating the free sugar with an overall retention of the anomeric configuration [36, 56].

Inverting α-l-AFases that represent GH43 family use a single displacement mechanism, in which one carboxylate acts as a general base catalyst, deprotonating the nucleophilic water molecule that attacks the bond, while the other carboxylic acid acts as a general acid catalyst by protonating the leaving aglycone (Fig. 3b) [107, 136].

Production of α-l-AFases

The α-l-AFases production is influenced by the carbon source and composition of the growth medium. Various carbon sources including monomeric sugars and complex polysaccharides have been used to assess their effect on the production, induction and substrate specificity of α-l-AFases (Table 1). For example, pentoses d-arabinose, l-arabinose, d-xylose and hexoses d-galactose, d-glucose, d-mannose, l-sorbose have been commonly used. Other sugars cellobiose, lactose, lactulose, maltose, mellibose, sucrose, trisaccharide, raffinose, d-arabitol, l-arabitol, d-mannitol, d-sorbitol and xylitol also have been used. Sugar beet pulp (starch-free), wheat bran (starch-free), wheat straw, oatmeal, rice straw and corn cob are some of the lignocelluloses that have been used for the production of α-l-AFases. Polysaccharides such as oat spelt xylan, birchwood xylan, beechwood xylan, wheat arabinoxylan, arabinogalactan, larch wood arabinogalactan, sugar beet arabinan, galactan CMC, guar gum, gum Arabic and locust bean gum have also been used. Pectins, schizophyllan, starch, xanthan, carboxymethyl cellulose, potato β-1,4-galactan, carob galactomannan, Me-β-xyloside and lactobionic acid are some other carbon sources utilized for α-l-AFases production.

Generally, arabinose-containing substrates are essential for the efficient production of α-l-AFases [9, 68]. Monomeric compounds l-arabitol and l-arabinose induce the genes involved in the production of these enzymes in some microorganisms [27]. Conversely, other monosaccharides such as glucose and galactose may inhibit the production of α-l-AFases [9, 68]. Arabinogalactans and oatmeal were found to be the best inducers for α-l-AFase isolated from Bacillus pumilus PS213 [32]. α-l-AFase was produced by Rhodothermus marinus when the culture was grown on birchwood xylan [46]. l-Arabitol was the inducer for the production of α-l-AFases enzymes araA and araB by the A. niger mutants [26]; ABF1 by the Penicillium purpurogenum [15, 27] and kabfA and kabjB by the A. kawachii [68]. α-l-AFase production by Pseudomona cellulosa was repressed when glucose was used in the production medium [9].

The experiments carried out by Gomes et al. [46] indicated that carbon and nitrogen sources influence the production of α-l-AFase by R. marinus. In these experiments, different concentrations of xylan (2–6 g/l) and yeast extract (4–12 g/l) were used to increase the enzyme production. The highest enzyme activity (108 nkat/ml) was obtained with medium containing 3 and 9 g/l of Birchwood xylan and yeast extracts, respectively. The lowest enzyme activity (86 nkat/ml) was obtained with medium containing 5 and 7 g/l of Birchwood xylan and yeast extracts, respectively [46]. A. niger showed highest α-l-AFase activity (243 U/ml) when grown on a solid-state medium with C: N ratio of 15:9. The carbon and nitrogen sources used were dried skins of grape pomace and casein peptone, respectively [57]. T. fusca BD25 showed highest α-l-AFase activity (0.136 U/mg protein) when grown in a medium containing 0.6% (w/v) oat spelt xylan and 0.6% (w/v) yeast extract corresponding to C:N ratio of 4:1 [117–119].

Production of α-l-AFase by Aspergillus nidulans was high when ammonium sulfate or ammonium chloride was used as nitrogen source [37]. A. kuwachii IF04308 produced highest amounts of α-l-AFase when grown on a medium supplemented with a mixture of bactotryptone, yeast extract and NaNO3 as a nitrogen source [68]. Similarly, when a mixture of urea, ammonium sulfate and neopeptone was used as a source of nitrogen, the production of α-l-AFase by P. purpurogenum was enhanced [27].

Both temperature and pH of the growth medium are known to influence growth and enzyme production by microorganisms. The thermophilic bacterium R. marinus produced 5.32 U/mg of α-l-AFase when grown in a shake flask for 96 h at 61°C and pH 8. Similarly, the fungus P. chrysogenum 31B produced higher amounts of two α-l-AFases when grown under static conditions for 12 days at pH 5.0 and 30°C [102, 103].

Batch cultivation system in shake flasks has been used for α-l-AFases production by bacteria [32, 46] and fungi [51, 68, 102]. Yields of α-l-AFase were relatively better (88.7 nkat/mg protein) when R. marinus was grown in shake flasks as compared to that obtained when grown in a bioreactor (54.5 nkat/mg protein) [46]. Solid-state fermentation (SSF) has been used successfully for α-l-AFases production from different fungi [40, 96, 57]. SSF system resembles the natural habitat of microbes and, therefore, may prove efficient in producing certain enzymes and metabolites. However, not much is known about α-l-AFases production by bacteria using SSF.

Biochemical properties of α-l-AFases

The available information on the biochemical properties of α-l-AFases is mostly derived from the studies carried out on the enzymes isolated from bacteria, fungi and plants. Microbial α-l-AFases vary in their molecular masses, which can be as high as 495 kDa for α-l-AFase from Streptomyces purpurascens IFO 3389 [66] (Table 1).

The effect of temperature and pH on the α-l-AFase depends on the source from which the enzyme is isolated (Table 1). The highest temperature stability has been obtained for α-l-AFase from T. maritima MSB8. This cloned enzyme has an optimal temperature of 90°C at pH 7. Moreover, at this temperature (90°C) and pH (7), the enzyme was stable for 24 h. It also retains 50% of its activity at 100°C over a period of 20 min [87]. The other example is α-l-AFase from R. marinus, which is stable at 85°C for 8.3 h in a pH range of 5.0–9.0 [46, 76].

The activities of α-l-AFases are affected by metal ions, ionic and nonionic detergents, and chelating and reducing agents depending on the enzyme and concentration of the agent used [54, 76]. For instance, the activities of α-l-AFase (abfB) from Bifidobacterium longum B667 [76] and α-l-AFase (AbfD3) from Thermobacillus xylanilyticus D3 were not affected by EDTA, DTT, but were affected by Cu2+ ions [31, 76]. Metal ions such as Ag+, Hg2+, Zn2+, Cd+2, Co+2 and Ni had an inhibitory effect on some of these enzymes [76, 102, 116].

Molecular biology of α-l-AFases

Some α-l-AFases have been studied up to molecular level. The genes coding for these enzymes have been identified, cloned and expressed in different bacterial and fungal systems. In addition, the protein products of these genes have been sequenced and the evolutionary relationship among some of the sequenced proteins has been reported using the phylogenetic tree analysis [32]. For example, some of the cloned genes, i.e., STX-IV from Streptomyces thermoviolaceus OPC-520 chromosome [116], AkabfA and AkabfB from A. kawachii and AwabfA and AwabfB from Aspergillus awamori [68], xarB from the thermophilic anaerobe Thermoanaerobacter ethanolicus JW200 [74], α-l-AFase gene from B. longum B667 [76], Bifidobacterium breve K-110 [108] and from the Clostridium cellulovorans genomic library [69] have been characterized. Similarly, genes such as Abf51A from the genomic library of Psuedomonas cellulosa [9], abf1 from P. purpurogenum [15], abfA from T. maritima TM0281 [87] and abfB from Fusarium oxysporum f. sp. dianthi (Fod) [18] also have been well characterized.

Amino acid sequencing as well as crystal structure studies indicate the presence of substrate-binding domain (SBD) in some of the reported enzymes. The SBD may take part in the efficiency of the enzyme function [71]. However, the possible role of α-l-AFases in the release of arabinofuranosyl residues is not yet clear [65]. Some α-l-AFases with SBD have been reported, i.e., α-l-AFases from Pseudomonas fluorescens and Streptomyces lividans have a cellulose-binding domain (CBD) [63] and a xylan-binding domain (XBD) [125], respectively. Other α-l-AFases such as those produced by Streptomyces chartreusis GS901 possess additional functional domains at both the N-terminal and the C-terminal regions. However, these domains did not show any similarities to the known SBD observed in many other types of glycanases. It might represent a novel kind of SBD [84]. A. kawachii IFO4308 α-l-AFase (AkAbfB) was found to have an arabinose-binding domain (ABD) that showed a number of distinct characteristics that are different from those of carbohydrate-binding module (CBM) [86]. Recently, Bolam et al. [13] showed that the X4 modules from a Cellvibrio japonicus α-l-AFase (Abf62A) binds to polysaccharides. This protein comprises a new family of CBMs, designated as Abf62A-CBM35. There are more than 13 α-l-AFases that have been grouped in family 42 of CBM [23].

So far, only three α-l-AFases have been studied for their three-dimensional structure. There appears considerable diversity in the three-dimensional structure of these enzymes. These enzymes are α-l-AFase B (AkabfB) (EC 3.2.1.55) from A. kawachii IFO 4308 located within GH 54 family [86], α-l-AFase (AbfA) (EC 3.2.1.55) from Geobacillus stearothermophillus T-6 located within GH 51 family [56, 107] and the bifunctional xylanase D/ α-l-arabinofuranosidase (XynD)/(Xyn43A) (EC 3.2.1.8 and EC 3.2.1.55, respectively), of Paenibacillus polymyxa located within GH 43 family [56].

Biotechnological applications of α-l-AFases

The importance of lignocellulose-degrading enzymes is well defined because of their role in many industrial and biotechnological processes. This resulted in re-establishment of a new era for the efficient utilization of the cheap agricultural waste materials. α-l-AFases, with their synergistic action with other lignocellulose-degrading enzymes, are the promising tools in various agro-industrial processes [3, 99]. These include production of important medicinal compounds, improvement of the wine flavors, bread quality, pulp treatment, juice clarification, quality of animal feedstock, production of bioethanol and the synthesis of oligosaccharides.

Production of arabinose as antiglycemic agent

Recently, there is a growing interest for l-arabinose as a possible food additive because of its sweet taste, and its low uptake due to its poor absorption by the human body [84]. Moreover, it has been proved that l-arabinose selectively inhibits intestinal sucrase in a competitive manner and thus reduces the glycemic response after sucrose ingestion in animals [106]. Studies carried out on mice suggest that l-arabinose dose-dependently suppressed the increase of blood glucose level after the ingestion of sucrose [108]. Furthermore, l-arabinose delays and reduces the digestion, absorption and the net energy derived from sucrose when both are ingested simultaneously. Based on these findings, l-arabinose can be used as a physiologically functional sugar that inhibits sucrose digestion. In this way, l-arabinose is useful in preventing postprandial hyperglycemia in diabetic patients [104 Footnote 2]. Therefore, effective l-arabinose production is a vital perquisite for its use in this respect as well as for its importance in food industry. To achieve this goal, it is necessary to use arabinose-releasing enzymes α-l-AFases, and defined polysaccharides and oligosaccharides from different agricultural raw materials [84, 93, 115].

Production of antimetastatic and anticarcinogenic compounds

Ginsenosides Rb2 and Rc are the main components of ginseng (the root of Panax ginseng C.A. Meyer, Araliaceae). These roots are frequently used as a traditional medicine in China, Korea, Japan and other Asian countries. Ginsenosides Rb2 and Rc are l-arabinofuranoside- and l-arabinopyranoside-bound glycosides, respectively, in ginsenoside Rd [108]. These ginsenosides are transformed to compound K, via ginsenoside Rd, by intestinal bacteria in human intestine by the action of α-l-AFase [7] (Fig. 4). The pharmacological actions of these ginsenosides have been explained based on the biotransformation of ginsenosides by glycosidases of human intestinal bacteria [2, 6, 7, 50, 128]. The latter bacteria utilize α-l-AFase to transform the protopanaxadiol ginsenosides to compound K that exhibits antimetastatic and/or anticarcinogenic effects. Moreover, compound K can be produced effectively by different arabinosidases including α-l-AFases and α-l-arabinopyranosidase [61].

Proposed metabolic conversions for the ginsenoside Rb2 by α-l-arabinofuranosidase from B. breve K-110. Modified from Ref. [108]

α-l-AFases and wine industry

One of the most important characteristics of wine quality is its aromatic fragrance. It is now well established that certain monoterpenes contribute significantly to the flavor of wine [80]. Terpenols are strongly aromatic molecules that represent an important part of aromas [42]. They are not volatile and are directly accessible to the olfactory mucosa [12, 127, 132]. A major portion of these monoterpenols in grapes musts, wines, other alcoholic beverages (brandy, bitters, etc.) and fruit juices (apple, apricot, peach, papaya, passion fruit etc.) [12, 105] are linked to disaccharide moieties, in which the major terminal non-reducing sugar is α-l-arabinofuranose which can be released by the action of α-l-AFases [12]. It is now clear that the glycosidically bound volatiles can be released by sequential enzymatic hydrolysis in two stages. In the first step, and depending on the precursor, the glycosidic linkage is cleaved by α-l-AFases, followed by the action of the other glycosidase, which then liberates the monoterpenols (Fig. 5) [42, 43, 78, 113, 114, 133]. Thus, α-l-AFases treatment followed by the addition of other glycosidases can be used for the enhancement of wine flavor by the release of free terpenols. Moreover, Yannai and Sato [134] have reported that α-l-AFase from Pichia capsulata X91 is active at ethanol concentrations found in wine and able to release considerable amount of monoterpenols, especially linalool, citronellol and geraniol, thereby increasing the aromatic flavors of different wines. Furthermore, the immobilized α-l-AFase, β-d-glucopyranosidase and α-l-rhamnopyranosidase from A. niger increased the aroma of a model wine solution to more than 600 mg/l of total free terpenols [113, 114].

Mechanism of action of the glycosidase α-l-arabinofuranosidase and β-d-glucopyranosidase (βG) on diglycosidic precursors. ROH is a volatile aglycone such as monoterpenols and other alcohols. Modified from Ref. [113]

Today, a lot of interest has been generated in the involvement of α-l-AFases in enhancing the aroma. This is mainly achieved by using the recombinant yeast strain (YCA1) [Saccharomyces cerevisiae strain T73 (CECT1894) transformed with YCAbfB from A. niger N400 (CPS 120.49)] that was capable of efficiently secreting α-l-AFase directly in vinification process or by directly adding the purified enzyme obtained from it [110]. Preliminary experiments carried out with this recombinant yeast strain (YCA1) have shown increased levels of some volatile compounds involved in wine aroma [110]. Furthermore, during wine aging, a number of the fragrant precursors (such as linalol, nerol and geraniol) turn into less-fragrant compounds (α-terpineol, diols, and triols, oxides, etc.) so that after 6–7 months of aging for an aromatic wine (Muscato wines), the final result is often a reduction in the more fragrant-free terpenes. The addition of glycosidases to the wine increases its aroma without this disadvantage [12]. For instance, α-l-arabinofuranosidase (EC 3.2.1.55) and β-d-glucopyranosidase (βG, EC 3.2.1.21) are currently produced on an industrial scale from A. niger [3], and are used in the aromatization of musts, wines and other alcoholic beverages [12, 105].

α-l-AFases, acetic acid production and quality of the bread

Staling is probably the main problem that occurs during bread storage. This results in a decreased bread shelf life and causes serious economic losses to the bread industry [45]. Pentosans are important functional ingredients in bread and their positive role in bread texture and staling is well known [16, 58, 64]. Pentosans added to the dough may be moderately hydrolysed by wheat flour enzymes and especially by exogenous enzymes such as xylan-degrading system including α-l-AFases [39, 59]. These enzymes produce free pentoses (mainly arabinose and xylose) thereby increasing the availability of soluble carbohydrates in the dough [44, 45, 59, 79]. This positively interferes with the metabolism of sourdough lactic acid bacterium Lactobacillus hilgardii [44]. This bacterium increases the acidification rates and the production of acetic acid. For example, Gobbetti et al. [45] showed that by using pentosans, α-l-AFase from A. niger and Lactobacillus plantarum 20B, soluble carbohydrate availability, acidification rate and production of acetic acid increased during sourdough fermentation. (α-l-AFase mainly hydrolyse the exterior arabinofuranosyl linkages of pentosans in the dough thereby making pentoses available for fermentation by L. plantarum [45]. Recently, α-l-AFases along with pentosanse and other enzymes have been considered as natural improvers that greatly enhance the overall quality of bread [59, 79]. The enzyme treatment delayed the bread staling and increased the shelf life of the bread thereby giving economic benefits to the bread industry [45, 59, 79].

α-l-AFases in pulp and paper industry

Several commercial xylanase preparations are available for the treatment of pulp [124]. Application of α-l-AFase would further enhance the delignification of pulp as the enzyme acts to release the arabinose side chain that retards the action of other bleaching enzymes [10, 48]. The removal of lignin from semi-bleached kraft pulp was improved when the pulp was treated with α-l-AFase from B. stearothermophilus L1 together with xylanase [10]. The enzyme acted synergistically with a thermophilic xylanase in the delignification process, releasing 19.2% of lignin. Delignification obtained using the combined enzyme treatment exceeded the sum of the amounts obtained using the enzymes individually [10]. According to Margolles-Clark et al. [77], Trichoderma reesei α-l-AFase ( could also liberate >60% of the arabinose from arabinoglucuronoxylan isolated from pine kraft pulp. The treatment of softwood kraft pulp with the crude α-l-AFase-rich xylanase and mannanase from R. marinus increased the bleachability of the pulp when used in a X–Q–d–Q–P bleaching sequence, where X was enzyme treatment, Q was chelation, D was chlorine dioxide treatment with NaClO2 in acidic solution and P was the peroxide bleaching [46]. The highest increase in brightness (1.8% ISO) was achieved when the mixture of α-l-AFase-rich xylanase and mannanase was used for the pulp treatment. The observed increase in the brightness (1.9–2.1%) was similar to the value obtained using commercial enzyme preparation [46]. The high thermal and pH stability, broad pH optima and lack of cellulose activity of the α-l-AFase, xylanases [48, 75] and mannanase produced by R. marinus are most useful for biobleaching of pulp and paper [24, 46].

α-l-AFases and animal feedstock

The digestion of feedstuffs by ruminal microorganisms results in the production of acids and microbial cells, which provide the host animal with its main sources of energy and protein [35]. Although hemicelluloses (mainly xylans) represent 30–40% of the total forage carbohydrate, their contribution to dietary energy available to the animal is often decreased because of low overall (40–60%) digestion [21, 34, 130]. The increase in digestibility of feedstuffs is well correlated with the decrease in the degree of substitution of the hemicellulose polymers with arabinosyl residues [47, 89]. l-arabinose residues prevent the total hydrolysis of xylans. Therefore, any mechanism able to remove the arabinosyl side chains from hemicellulose should increase its digestibility [21, 22, 33, 34, 53]. The utilization of cell wall polysaccharides by poultry and pigs was improved by the addition of cellulases, pectinases and xylanases [19]. Moreover, the addition of α-l-AFases removes arabinose side groups that restrict the action of glycanases and could further promote the hydrolysis of solubilized cell wall polysaccharides [47, 54, 67]. It has been shown that the use of commercial enzymes preparation containing α-l-AFases enhanced the activity of xylanase because the latter prefers unsubstituted regions of xylan as a substrate, thereby reducing the viscosity of the feedstuffs used [81]. Cotta [22] reported that α-l-AFase isolated from Ruminococcus albus 8 removed arabinosyl residues from alfalfa cell wall (ACW), pectic and hemicellulosic polysaccharides, thereby making these substrates more susceptible to attack by other glycanases. For a given species, such as R. albus, digestion can vary from a low of 5 to a high of 88% for corn [53]. α-l-AFases helps endo-xylanases in the hydrolysis of arabinoxylan, thereby improving the feed digestibility [14, 96]. The addition of mixture of xylanases and α-l-AFases as a strategy to increase digestion is currently being used in some countries [96]. This approach has been considered in the European Community (AIR contract number AIR1 CT92) [96]. Genetic manipulation of anaerobic bacteria and ruminal organisms is yet another strategy to increase the production of xylan-degrading enzymes, which can be used to improve the digestion of plant materials [62, 90, 121]. This has to involve cloning of α-l-AFase genes into the manipulated ruminal bacteria to increase the efficiency of xylan-degrading enzymes. This approach has been proved good when the cloned α-l-AFase from Prevotella ruminicola was used [41].

α-l-AFases in fruits juice industry

α-l-AFases are receiving attention for their applications in fruit juice clarification [97]. The preparations of pectinolytic enzymes utilized so far contain significant amounts of α-l-AFases [91, 130, 132]. These enzymes specifically remove the 1,3-side chains present on the main 1,5-linked arabinan chains. This results in a precipitate (haze) consisting of 1,5 arabinans. The α-1,5 arabinanase acts on 1,5 arabinans that help to increase the solubility of the precipitate [20, 28, 126]. As industrial enzymes often do not require extensive purification, the juice industry can use α-l-AFases and arabinanase-containing plant extracts [55, 109]. For example, in apple and pear juice production, haze formation is a problem due to the presence of solubilized arabinans [20]. The precipitates can most probably be avoided by adding sufficient amounts of α-l-AFase and endo-arabinanase [85, 126, 131]. Birgisson et al. [11] reported an α-l-AFase from the thermophilic bacterium PRI-1686 belonging to the recently described phylum of Thermomicrobia. This enzyme has the ability to degrade the interior α-1,5 backbone as and α-1,3-side chains of arabinan. Moreover, Miyazaki [87] described a thermophilic α-l-AFase from the hyperthermophilic bacterium T. maritima MSB8 that had the ability to degrade arabinan and debranched arabinan. Such properties are useful to avoid haze formation in fruits juice industry.

Production of fermentable sugars for bioethanol industry

Enzyme-catalyzed conversion of sugarcane, sugar beet, corn or wheat to ethanol by distillers yeast S. cerevisiae is the current process for the industrial production of bioethanol [111]. These substrates contain non-fermentable hemicelluloses. These hemicelluloses remain unutilized and accumulate as by-product residues (˜70 % by weight of the total residue) during the process of ethanol production [1, 5, 111]. The utilization of these residual hemicelluloses is essential for the efficient conversion of these compounds to ethanol, value-added products and industrial chemicals [99, 100, 135]. Nevertheless, these substrates require a suitable pretreatment before they can be used for the production of ethanol [100]. For instance, acid hydrolysis can be used for the hydrolysis of arabinoxylans in hemicelluloses to monosaccharides. However, enzymatic hydrolysis is preferred due to reduced formation of byproducts that may inhibit the subsequent microbial fermentation [99]. The complexity and heterogeneity of the arabinoxylans in hemicelluloses demand enzyme systems that convert these substrates into fermentable sugars [40, 72, 100, 111]. Such an enzyme system needs to include de-polymerizing and the side-group cleaving enzymes to degrade hemicelluloses into pentoses monosaccharides [100]. Moreover, such a system will also need a microorganism not only capable of utilizing pentoses, but also able to withstand high concentrations of ethanol produced during the process [72, 100, 101, 135]. Therefore, tailored enzymes are required to hydrolyse lignocellulosic substrates to fermentable sugars [100, 111]. The synergistic action of α-l-AFases with lignocellulose-degrading enzymes makes them potential agents for saccharifying various pretreated agricultural and forestry residues to monomeric sugars for the production of fuel and chemicals [99]. Designed hemicellulosic enzymes consisting of Celluclast 1.5 l from T. reesei and Ultraflo L from Humicola insolens exhibited a strong synergistic interaction in catalyzing the release of xylose and arabinose from wheat arabinoxylans, which otherwise will be accumulated as by-products during the production of ethanol. This was mainly due to the cooperative action of α-l-AFases, endo-1,4-xylanases and xylosidase present in the two enzyme preparations. Moreover, this study suggested that such synergistic interaction might be useful for the production of efficient enzyme cocktails to improve the utilization of wheat hemicellulose by-products produced during the production of ethanol [111]. Furthermore, Saha and Bothast [101] suggested that the high activity of the α-l-AFase from Aureobasidium pullulans on both arabinan and debranched arabinan, its ability to release l-arabinose from arabinoxylans, and its high thermostability make this enzyme a promising candidate for the production of fermentable sugars from hemicellulosic biomass for ethanol production [101].

Synthesis of pentose-containing compounds

Increasingly, enzymes are being adopted for the synthesis of oligosaccharides and glycoconjugates via enzymatic or mixed chemo-enzymatic routes. The glycoside hydrolases (EC 3.2.1) and glycosyltransferases (EC 3.2.4) are promising enzymes as they play an important role in the synthesis strategies by performing glycosylation in one stereoselective step. Glycoside hydrolases (mainly exo-acting hydrolases) often display more relaxed regioselectivity, and unlike glycosyltransferases, an extensive palette of glycoside hydrolases, displaying a wide range of sugar specificities, are available [36]. Some α-l-AFases are robust and thermostable and do not require the use of costly sugar donors. For example, thermostable α-l-AFase (AbfD3) from T. xylanilyticus [31] has the ability to catalyze transglycosylation in the presence of p-nitrophenyl α-l-arabinofuranoside (pNPAraf) and various alcohols. Moreover, Rémond et al. [95] reported the synthesis of several pentose-containing oligosaccharides using this enzyme. The enzyme AbfD3 possessed the ability to synthesize oligosaccharides in kinetically controlled transglycosylation reactions. The products of these reactions could be useful analytic tools as reference compounds for the analysis of hemicellulase action, and for raising antibodies to well-defined motifs for immunochemical-based analysis of plant cell walls [94, 95]. Moreover, α-l-AFases that display transglycosylation ability constitute potentially interesting tools for chemoenzymatic synthesis of arabinose-containing compounds that are difficult to access via organic synthetic methods [95].

Future prospects

Achieving efficient breakdown of the plant cell wall polysaccharide hemicelluloses and pectins represents an important and lucrative goal for biotechnologists. For that, further research has to be carried out to explore many aspects of α-l-arabinofuranosidases, in much detail. Further, studies on the synergistic effects of the robust enzyme on the action of other hemicellulases and pectinases that already exist as commercial enzymes may lead to improvement of many existing industrial products. Understanding how these enzymes interact and act on lignocelluloses and the relationship between their structure and function at molecular level are other aspects that need to be studied. Moreover, isolation and characterization of robust α-l-AFases and genes encoded for these enzymes will likely have significant implications in the design of industrial processes that can be accomplished within a wide range of conditions and in commercial production of biomass-degrading enzymes. Manipulation and genetics engineering of bacteria for obtaining complete and a more efficient lignocellulose-degrading enzymes system including α-l-AFases genes will be a novel path into complete saccharification system, which is required for many technologies including ethanol production. Furthermore, chemical treatments in some industries such as paper and pulp bleaching and ethanol production which cause environmental problems could be reduced or replaced by using an efficient hemicellulose-degrading enzymes system.

Notes

Moromi is a fermenting mixture or mash of rice, water, koji (malted soybeans) and A. oryzae, which is produced during the traditional fermentation of soy sauce and in the production of sake, the traditional alcoholic beverage in Japan.

as cited by [108].

References

Adams EL, Kroon PA, Williamson G, Gilbert HJ, Morrisa VJ (2004) Inactivated enzymes as probes of the structure of arabinoxylans as observed by atomic force microscopy. Carbohydr Res 339:579–590

AkaoT, Kida H, Kanaoka M, Hattori M, Kobashi K (1998) Intestinal bacterial hydrolysis is required for the appearance of compound K in rat plasma after oral administration of ginsenoside Rb1 from panax ginseng. J Pharm Pharmacol 50:1155–1160

Aryon AP, Wilson B, Strauss CR, Williams PJ (1987) The properties of glycosidases of Vitis vinifera and a comparison of their β-glucosidase activity with that of exogenous enzymes. An assessment of possible applications in enology. Am J Enol Viticult 38:182–188

Bachmann SL, McCarthy AJ (1991) Purification and cooperative activity of enzymes constituting the xylan-degrading system of Thermomonospora fusca. Appl Microbiol Biotechnol 57:2121–2130

Bacic A, Stone BA (1980) A (1→3)- and (1→4)-linked β-d-glucan in the endosperm cell-walls of wheat. Carbohydr Res 82:372–377

Bae E-A, Choo M-K, Park S-Y, Shin H-Y, Kim D-H (2002) Metabolism of ginsenoside Rc by human intestinal bacteria and its related antiallergic activity. Biol Pharm Bull 25:743–747

Bae E-A, Park S-Y, Kim D-H (2000) Constitutive β-glucosidase hydrolyzing ginsenoside Rb1 and Rb2 from human intestinal bacteria. Biol Pharm Bull 23:1481–1485

Beldman G, Schols HA, Pitson SM, Searl-van Leeuwen MJF, Voragen AGJ (1997) Arabinans and arabinan degrading enzymes. Adv Macromol Carbohydr Res 1:1–64

Beylot M-H, Mckie VA, Voragen AGJ, Doeswijk-Voragen CHL, Gilbert HJ (2001) The Pseudomonas cellulosa glycoside hydrolase family 51 arabinofuranosidase exhibits wide substrate specificity. Biochem J 358:607–614

Bezalel L, Shoham Y, Rosenberg E (1993) Characterization and delignification activity of a thermostable α-l-arabinofuranosidase from Bacillus stearothermophilus. Appl Microbiol Biotechnol 40:57–62

Birgisson H, Fridjonsson O, Bahrani-Mougeot FK, Hreggvidsson GO, Kristjansson JK, Mattiasson BA (2004) New thermostable α-l-arabinofuranosidase from a novel thermophilic bacterium. Biotechnol Lett 26:1347–1351

Biskup SE, Intert F, Holthnujzen JH, Stengele M, Schultz G (1993) Glycosically bound volatiles-A review 1986–1991. Flav Fragr J 8:61–80

Bolam DN, Xie H, Pell G, Hogg D, Galbraith G, Henrissat B,Gilbert HJ (2004) X4 Modules represent a new family of carbohydrate-binding modules that display novel properties. J Biol Chem 279:22953–22963

Campbell GL, Bedford MR (1992) Enzyme applications for monogastric feeds: a review. Can J Anim Sci 72:449–466

Carvallo M, de Ioannes P, Navarro C, Chavez R, Peirano A, Bull P, Eyzaguirre J (2003) Characterization of an α-l-arabinofuranosidase gene (abf1) from Penicillium purpurogenum and its expression. Mycol Res 107:388–394

Casier JPJ, De Paepe G, Brummer JM (1973) Effect of water-soluble wheat and rye pentosans on the baking properties derived from wheat flours and other raw materials. Getreide Mehl und Brot 27:36–43

Catoire L, Goldenberg R, Pierron M, Morvan C, Hervé du Penhoat C (1998) An efficient procedure for studying pectin structure which combines limited depolymerization and C13 NMR. Eur Biophys J 27:127–136

Chacòn-Martènez CA, Anzola JM, Rojasa A, Hernández F, Junca H, Ocampo W, Del Portillo P (2004) Identification and characterization of the α-l-arabinofuranosidase B of Fusarium oxysporum f. sp. Dianthi (Fod). Phys Mol Plant Pathol 64:201–208

Chesson A (1987) Supplementary enzymes to improve the utilization of pig and poultary diets. In: Haresigin W, Cole DJA (eds) Recent advances in animal nutrition, Butterworths, London, pp 71–89

Churms SC, Merrifield EH, Stephen AM, Walvyn DR, Polson A, Merwe van den KJ, Spies HSC, Costa N (1983) An L-arabinan from apple-juice concentrates. Carbohydr Res 113:339–344

Coen JA, Dehority BA (1970) Degradation and utilization of hemicellulose from intact forages by pure cultures of rumen bacteria. Appl Microbiol 20:362–368

Cotta MA (1993) Utilization of Xylooligosaccharides by Selected Ruminal Bacteria. Appl Environ Microbiol 59:3557–3563

Coutinho PM, Henrissat B (1999) Carbohydrate-active enzymes server at http://www.afmb.cnrs-mrs.fr/_/cazy/CAZY/index.html

Dahlberg L, Holst O, Kristjansson JK (1993) Thermostable xylanolytic enzymes from Rhodothermus marinus grown on xylan. Appl Microbiol Biotechnol 40:63–68

Davies G, Henrissat B (1995) Structures and mechanisms of glycosyl hydrolases. Structure 3:853–859

de Grootet LMJ, van de Vondervoort PJI, de Vries RP, vanKuyk PA, Ruijter IJG, Visser J (2003) Isolation and characterization of two specific regulatory Aspergillus niger mutants shows antagonistic regulation of arabinan and xylan metabolism. Microbiology 149:1183–1191

De Ioannes P, Peirano A, Steiner J, Eyzaguirre J (2000) An α-l-arabinofuranosidase from Penicillium purpurogenum: production, purification and properties. J Biotechnol 7:253–258

De Vries JA, Rombouts FM, Voragen AGJ, Pilnik W (1982) Enzymic degradation of apple pectins. Carbohydr Polym 2:25–33

De Vries RP, Kester HCM, Poulsen CH, Benen JAE, Visser J (2000) Synergy between enzymes from Aspergillus involved in the degradation of plant cell wall polysaccharides. Carbohydr Res 327:401–410

De Vries RP, Visser J (2001) Aspergillus enzymes involved in degradation of plant cell wall polysaccharides. Microbiol Mol Biol Rev 65:497–522

Debeche T, Cummings N, Connerton I, Debeire P, O’Donohue MJ (2000) Genetic and biochemical characterization of a highly thermostable α-l-arabinofuranosidase from Thermobacillus xylanilyticus. Appl Environ Microbiol 6:1734–1736

Degrassi G, Vindigni A, Venturi VA (2003) Thermostable α-arabinofuranosidase from xylanolytic Bacillus pumilus: purification and characterization. J Biotechnol 101:69–79

Dehority BA (1965) Degradation and utilization of isolated hemicellulose by pure cultures of cellulolytic rumen bacteria. J Bacteriol 89:1515–1520

Dehority BA (1967) Rate of isolated hemicellulose degradation and utilization by pure cultures of rumen bacteria. Appl Microbiol 15:987–993

Dehority BA, Scott HW (1967) Extent of cellulose and hemicellulose digestion in various forages by pure cultures of rumen bacteria. J Dairy Sci 50:1136–1141

Ferchichi M, Rèmond C, Simo R, O’Donohue MJ (2003) Investigation of the functional relevance of the catalytically important Glu28 in family 51 arabinosidases. FEBS Lett 553:381–386

Fernández-Espinar MT, Pena JL, Pinaga F, Valles S (1994) Alpha ararbinofuranosidase production by Aspergillus nidulans. FEMS Microbiol Lett 115:107–112

Ferré H, Broberg A, Duus JØ, Thomsen KK (2000) A novel type of arabinoxylan arabinofuranohydrolase isolated from germinated barley. Analysis of substrate preference and specificity by nano-probe NMR. Eur J Biochem 267:6633–6641

Fessas D, Schiraldi A (1998) Texture and staling of wheat bread crumb: effects of water extractable proteins and pentosans. Thermochim Acta 323:17–26

Filho EFE, Puls J, Coughlan MP (1996) Purification and characterization of two arabinofuranosidases from solid-state cultures of the fungus Penicillium capsulatum. Appl Environ Microbiol 62:168–173

Gasparic A, Romana M-L, Martin J, Wallace RJ, Nekrep FV, Flint HJ (1995) Isolation of genes encoding β-d-xylanase, β-d-xylosidase and α-l-arabinofuranosidase activities from the rumen bacterium Prevotella ruminicola B14. FEMS Microbiol Lett 125:135–142

Giinata Z, Bitteur S, Brillouet JM, Bayanove C, Cordonnier R (1988) Sequential enzymic hydrolysis of potentially aromatic glycosides from grape. Carbohydr Res 184:139–149

Giinata Z, Dugelay I, Sapis JC, Baumes R, Baya-nove C (1990) Action des glycosidases exogknes au tours de la vinification: liberation de I’arome a partir de prcurseurs glycosidiques. J Int Sci Vigne Vin 24:133–144

Gobbetti M, De Angelis M, Arnaut P, Tossut P, Corsetti A, Lavermicocca P (1999) Added pentosans in breadmaking: fermentations of derived pentoses by sourdough lactic acid bacteria. Food Microbiol 16:409–418

Gobbetti M, Lavermicocca P, Minervini F, De Angelis M, Corsetti A (2000) Arabinose fermentation by Lactobacillus plantarum in sourdough with added pentosans and α-l-arabinofuranosidase: a tool to increase the production of acetic acid. J Appl Microbiol 88:317–324

Gomes J, Gomes I, Terler K, Gubala N, Ditzelmüller G, Steinera W (2000) Optimisation of culture medium and conditions for α-l-rabinofuranosidase production by the extreme thermophilic eubacterium Rhodothermus marinus. Enzyme Microb Technol 27:414–422

Greve LC, Labavitch JM, Hungate RE (1984) α-l-Arabinofuranosidase from Ruminococcus albus 8: purification and possible roles in hydrolysis of alfalfa cell wall. Appl Environ Microbiol 47:1135–1140

Gübitz GM, Haltrich D, Latal B, Steiner W (1997) Mode of depolymerisation of hemicellulose by various mannanases and xylanases in relation to their ability to bleach softwood pulp. Appl Microbiol Biotechnol 47:658–621

Habibi Y, Heyraud A, Mahrouz M, Vignon MR (2004) Structural features of pectic polysaccharides from the skin of Opuntia ficus-indica prickly pear fruits. Carbohydr Res 339:1119–1127

Hasegawa H, Sung JH, Benno Y (1997) Role of human intestinal Prevotella oris in hydrolyzing ginseng saponins. Planta Med 63:436–440

Hashimoto T, Nakata Y (2003) Synergistic degradation of arabinoxylan with α-l-arabinofuranosidase, xylanase and β-xylosidase from soy sauce koji mold, Aspergillus oryzae, in high salt condition. J Biosci Bioeng 95:164–169

Henrissat B, Davies GJ (2000) Glycoside hydrolases and glycosyltransferases families, modules and implications for genomics. Plant Physiol 124:1515–1519

Hespell RB, Cotta MA (1995) Degradation and utilization by Butyrivibrio fibrisolvens H17c of xylans with different chemical and physical properties. Appl Environ Microbiol 61:3042–3050

Hespell RB, O`Bryan P (1992) Purification and characterization of an α-L-arabinofuranosidase from Butyrivibrio fibrisolvens GS113. Appl Environ Microbiol 58:1082–1088

Hood EE, Jilka JM (1999) Plant-based production of xenogenic proteins. Curr Open Biotechnol 10:382–386

Hövel K, Shallom D, Niefind K, Belakhov V, Shoham G, Baasov T, Shoham Y, Schomburg D (2003) Crystal structure and snapshots along the reaction pathway of a family 51 α-l-arabinofuranosidase. EMBO J 22:4922–4932

Huerta-Ochoa S, Nicolàs-Santiago MS, Acosta-Hernàndez WD, Prado-Barragàn LA, Gutiérrez-López GF, Garcia-Almendàrez BE, Regaldo-González C (2003) Production and partial purification of glycosidases obtained by solid-state fermentation of grape Pomace using Aspergillus niger 10. In: Nathan VE, Gutierrez-Lopez GF, Barbosa G (eds) Food science and food biotechnology. CRS Press, Florida, pp 119–137

Jankiewicz M, Michniewicz J (1987) The effect of soluble pentosans isolated from rye grain on staling of bread. Food Chem 25:241–246

Jiménez T, Martinez-Anaya MA (eds) (1999) Enzymes, a key to improve bread and dough quality: degradation by products and relationship with quality. In: Abstracts of the 17th ICC Conference of the Cereal Across the Continents, Instituto de Agroquimica Tecnologia de Alimentos, Valencia, p 168

Kaji A (1984) L-arabinosidases. Adv Carbohydr Chem Biochem 42:382–394

Kaji A, Tagawa K (1970) Purification, crystallisation, and amino acid composition of α-l-arabinofuranosidase from Aspergillus niger. Biochim Biophys Acta 207:456–464

Kaneko S, Arimoto M, Ohba M, Kobayashi H, Ishii T, Kusakabe I (1998) Purification and substrate specificities of two α-L-arabinofuranosidases from Aspergillus awamori IFO 4033. Appl Environ Microbiol 64:4021–4027

Kellet LE, Poole DM, Ferreira LMA, Durrant AJ, Hazlewood GP, Gilbert HJ (1990) Xylanase B and an arabinofuranosidase from Pseudomonas fluorescens subsp. cellulosa contain identical cellulose-binding domains and are encoded by adjacent genes. Biochem J 272:369–376

Kim SK, D’Appolonia BL (1977) Bread staling studies. III. Effect of pentosans on dough, bread, and bread staling rate. Cereal Chem 54:225–229

Kimura I, Yoshioka N, Kimura Y, Tajima S (2000) Cloning, sequencing and expression of an α-L-arabinofuranosidase from Aspergillus sojae. J Biosci Bioeng 89:262–266s

Komae K, Kaji A, Sato M (1982) An α-l-arabinofuranosidase from Streptomyces purpuascens IFO 3389. Agric Bio Chem 46:1899–1905

Kormelink FMJ, Voragen AGJ (1993) Degradation of different [(glucurono)arabino] xylans by combination of purified xylan degrading enzymes. Appl Microbiol Biotechnol 38:688–695

Koseki T, Okuda M, Sudah S, Kizaki Y, Iwano K, Aramaki I, Matsuzawa H (2003) Role of two α-l-arabinofuranosidases in arabinoxylan degradation and characteristics of the encoding genes from shochu koji molds, Aspergillus kawachii and Aspergillus awamori. J Biosce Bioeng 96:232–241

Kosugi A, Murashima K, Doi RH (2002) Characterization of two noncellulosomal subunits, ArfA and BgaA, from Clostridium cellulovorans that cooperate with the cellulosome in plant cell wall degradation. J Bacteriol 184:6859–6865

Kroon PA, Williamson G (1996) Release of ferulic acid from sugar-beet pulp by using arabinanase, arabinofuranosidase and an esterase from Aspergillus niger. Biotechnol Appl Biochem 23:263–267s

Kuno A, Sbimizu D, Kaneko S, Koyama Y, Yoshida S, Kohayashi H, Hayashi K, Taira K, Kusakabe I (1998) PCR cloning and expression of the F/10 family xylanase gene from Streptomyces olivaceoviridis E-86. J Ferment Bioeng 86:434–439

Leathers TD (2003) Bioconversions of maize residues to value-added co-products using yeast-like fungi. FEMS Yeast Res 3:133–140

Lee RC, Hrmova M, Burton RA, Lahnstein J, Fincher GB (2003) Bifunctional family 3 glycoside hydrolases from barley with α-l-arabinofuranosidase and β-d-Xylosidase activity: characterization, primary structures, and COOH-terminal. J Biol Chem 278:5377–5387

Mai V, Wiegel J, Lorenz W (2000) Cloning, sequencing, and characterization of the bifunctional xylosidase–arabinosidase from the anaerobic thermophile Thermoanaerobacter ethanolicus. Gene 247:137–143

Manelius A, Dahlberg L, Holst O (1994) Some properties of a thermostable β-xylosidase from Rhodothermus marinus. Appl Biochem Biotechnol 44:39–48

Margolles A, de los Reyes-Gavilán CG (2003) Purification and functional characterization of a novel α-l-arabinofuranosidase from Bifidobacterium longum B667. Appl Environ Microbiol 69:5096–5103

Margolles-Clark E, Tenkanen M, Nakari-Setala T, Penttila M (1996) Cloning of genes encoding α-l-arabinofuranosidase and β-xylosidase from Trichoderma reesei by expression in Saccharomyces cerevisiae. Appl Environ Microbiol 62:3840–3846

Marlatt C, Ho C-T, Chien M (1992) Studies of aroma constituents bound as glycosides in tomato. J Agric Food Chem 40:249–252

Martinez-Anaya MA, Devesa A (eds) (1999) Enzymes and sourdough starters govern bread and dough quality: influence on dough-bread pentosans. In: Abstracts of the 17th ICC Conference of the Cereal Across the Continents, Instituto de Agroquimica Tecnologia de Alimentos, Valencia p 168

Mateo JJ, Jimènez M (2000) Monoterpenes in grape juice and wines. J Chromatogr A 881:557–567

Mathlouthi N, Saulnier L, Quemener B, Araier L (2002) Xylanase and β-glucanase and other side enzymatic activities have greater effects on the viscosity of several feedstuffs than xylanase and β-glucanase used alone or in combination. J Agric Food Chem 50:5121–5127

Matsumura K, Obata H, Hata Y, Kawato A, Abe Y, Akita O (2004) Isolation and characterization of a novel gene encoding α-l-arabinofuranosidase from Aspergillus oryzae. J Biosci Bioeng 98:77–84

Matte A, Forsberg CW (1992) Purification, characterization, and mode of action of endoxylanases 1 and 2 from Fibrobacter succinogenes S85. Appl Environ Microbiol 58:157–168

Matuso N, Kaneko S, Kuno A, Kobayashi H, Kusakabes I (2000) Purification, characterization and gene cloning of two α-l-arabinofuranosidases from Streptomyces chartreusis GS901. Biochem J 346:9–15

Mc Cleary BV, Harrington J, Allen H (1988) Enzymic solutions to polysaccharide related industrial problems. In: Phillips GO, Williams PA, Wedlock DJ (eds) Gums and stabilizers for the industry. IRL Press, Oxford, pp 51–62

Miyanaga A, Koseki T, Matsuzawa H, Wakagi T, Shoun H, Fushinobu S (2004) Crystal structure of a family 54 α-l-arabinofuranosidase reveals a novel carbohydrate binding module that can bind arabinose. J Biol Chem 279:44907–44914

Miyazaki K (2005) Hyperthermophilic α-l-arabinofuranosidase from Thermotoga maritima MSB8: molecular cloning, gene expression, and characterization of the recombinant protein. Extremophiles 9:399–406

Morales P, Sendra JM, Pèrez-González JA (1995) Purification and characterization of an arabinofuranosidase from Bacillus polymyxa expressed in Bacillus subtilis. Appl Microbiol Biotechnol 44:112–117

Morrison IM (1982). The degradation of isolated hemicellulose and lignin-hemicellulose complexes by cell free, rumen hemicellulase. Carbohydr Res 101:93–100

Patterson JA (1989) Prospects for establishment of genetically engineered microorganisms in the rumen. Enzyme Microb Technol 11:187–189

Pilnik W (1982) Enzymes in the beverage industry. In: Dupuy P(ed) Use of enzymes in food technology, Lavoisier, Paris, pp 425–449

Piston SM, Voragen AG, Beldman G (1996) Stereochemical course of hydrolysis catalyzed by arabinofuranohydrolases. FEBS Lett 398:7–11

Rahman SAKM, Kato K, Kawai S, Takamizawa K (2003) Substrate specificity of the α-l-arabinofuranosidase from Rhizomucor pusillus HHT-1. Carbohydr Res 338:1469–1476

Rémond C, Ferchichi M, Aubry N, Plantier-Royon R, Portella C, O’Donohue MJ (2002) Enzymatic synthesis of alkyl arabinofuranosides using a thermostable α-l-arabinofuranosidase. Tetrahedron Lett 43:9653–9655

Rémond C, Plantier-Royon R, Aubry N, Maes E, Bliardc C, O’Donohue MJ (2004) Synthesis of pentose-containing disaccharides using a thermostable α-l-arabinofuranosidase. Carbohydr Res 339:2019–2025

Roche N, Berna P, Desgranges C, Durand A (1995) Substrate use and production of α-l-arabinofuranosidase during solid-state culture of Trichoderma reesei on sugar beet pulp. Enzyme Microb Technol 17:935–941

Romboust FM, Voragen AGJ, Searle-van Leenwen MF, Geraeds CCJM, Schols HA, Pilnik W (1988) The arabinanases of Asperigillus niger—purification and characterization of two α-L- arabinofuranosidase and an endo-1,5-α-l-arabinanase. Carbohydr Polym 9:25–47

Rye CS, Withers SG (2000) Glycosidase mechanisms. Curr Opin Chem Biol 4:573–580

Saha BC (2000) α-l-Arabinofuranosidases: biochemistry, molecular biology and application in biotechnology. Biotech Adv 18:403–423

Saha BC (2003) Hemicellulose bioconversion. J Ind Microbiol Biotechnol 30:279–291

Saha BC, Bothast RJ (1998) Purification and characterization of a novel thermostable α-l-arabinofuranosidase from a color–variant strain of a Aureobasidium pullulans. Appl Environ Microbiol 64:216–220

Sakamoto T, Kawasaki H (2003) Purification and properties of two type-B α-l-arabinofuranosidases produced by Penicillium chrysogenum. Bioch et Biophy Acta 1621:204–210

Sakamoto T, Thibault J-F (2001) Exo-Arabinanase of Penicillium chrysogenum able to release arabinobiose from α-1,5-l-Arabinan. Appl Environ Microbiol 67:3319–3321

Sanai K, Seri K, Inoue S (1997) Inhibition of sucrose digestion and absorption by l-arabinose in rats. Nihon Eiyou Syokuryougaku Kaishi (in Japanese) 50:133–137

Schwab W, Scheller G, Schreier P (1990) Glycosidically bound aroma components from sour cherry. Phytochemistry 29:607–612

Seri K, Sanai K, Matsuo N, Kawakubo K, Xue C, Inoue S (1996) l-arabinose selectively inhibits intestinal sucrase in uncompetitive manner and reduces glycemic response after sucrose ingestion in animals. Metabolism 45:1368–1374

Shallom D, Belakhov V, Solomon D, Gilead-Gropper S, Baasov T, Shoham G, Shohama Y (2002) The identification of the acid-base catalyst of α-arabinofuranosidase from Geobacillus stearothermophilus T-6, a family 51 glycoside hydrolase. FEBS Lett 514:163–167

Shin H-Y, Park S-Y, Sung JH, Kim D-H (2003) Purification and characterization of α-l-arabinopyranosidase and α-l-arabinofuranosidase from Bifidobacterium breve K-110, a human intestinal anaerobic bacterium metabolizing ginsenoside Rb2 and Rc. Appl Environ Microbiol 69:7116–7123

Skjat M, Kuppinen S, Kofod LV, Fulsang C, Pauly M, Dalofe H, Anderson LN (2001) Functional cloning of an endo-arabinanase from Aspergillus aculeatus and its heterologous exptression in A. oryzae and tobacco. Mol Genet Genomics 265:913–921

Sknchez-Torres P, GonzBlez-Candelas L, Ramón D (1996) Expression in a wine yeast strain of the Aspergillus niger abfB gene. FEMS Microbiol Lett 145:189–194

Sørensen HR, Pedersen S, Viksø-Nielsen A, Meyer AS (2005) Efficiencies of designed enzyme combinations in releasing arabinose and xylose from wheat arabinoxylan in an industrial ethanol fermentation residue. Enzyme Microb Technol 36:773–784

Sozzi GO, Greve LC, Prody GA, Labavitch JM (2002) Gibberellic acid, synthetic auxins, and ethylene differentially modulate α-l-arabinofuranosidase activities in antisense 1-aminocyclopropane-1-carboxylic acid synthase Tomato Pericarp Discs. Plant Physiol 129:1330–1340

Spagna G, Andreani F, Salatelli E, Romagnoli D, Casarini D, Pifferi PG (1998) Immobilization of the glycosidases: α-l-arabinofuranosidase and β-d-glucopyranosidase from Aspergillus niger on a chitosan derivative to increase the aroma of wine. Part II. Enzyme Microb Technol 23:413–421

Spagna G, Barbagalloa RN, Grecob E, Manentib I, Pifferi PG (2002) A mixture of purified glycosidases from Aspergillus niger for oenological application immobilised by inclusion in chitosan gels. Enzyme Microb Technol 30:80–89

Takao M, Akiyama K, Sakai T (2002) Purification and characterization of thermostable endo-1,5-α-l-Arabinase from a strain of Bacillus thermodenitrificans. Appl Environ Microbiol 68:1639–1646

Tsujibo H, Takada C, Wakamatsu Y, Kosaka M, Tsuji A, Miamuto K, Inamori Y (2002) Cloning and expression of an arabinofuranosidase (STX- IV) Streptomyces thermoviolaceus OPC-520, and characterization of the enzyme. Biosci Biotechnol Biochem 66:434–438

Tuncer M, Ball AS, Robb A, Wilson MT (1999) Optimization of extracellular lignocellulolytic enzyme production by a thermophilic actinomycete Thermomonospora fusca BD2. Enzyme Microb Technol 25:38–47

Tuncer M (2000) Characterization of β-xylosidase and α-l-arabinofuranosidase activities from Thermomonospora Fusca BD25. Turk J Biol 24:753–767

Tuncer M, Ball AS (2003) Purification and partial characterization of α-l-arabinofuranosidase produced by Thermomonospora fusca. Folia Microbiol 48:168–172

Tuncer M, Ball AS (2003) Co-operative actions and degradation analysis of purified xylan-degrading enzymes from Thermomonospora fusca BD25 on oat-spelt xylan. J Appl Microbiol 94:1030–1035

Utt EA, Eddy CK, Keshav KF, Ingram LO (1991) Sequencing and expression of the Butyrivibrio fibrisolvens xylB gene encoding a novel bifunctional protein with β-d-xylosidase and α-l-arabinofuranosidase activities. Appl Environ Microbiol 57:1227–1234

Van laere KMJ, Beldman G, Voragen GJ (1997) A new arabinofuranohydrolase from Bifidobacterium adolescentis able to remove arabinosyl residue from double substituated xylose units in arabinoxylan. Appl Microbiol Biotechnol 47:231–235

Van Laere KMJ, Voragen CHL, Kroef T, Van den Broek LAM, Beldman G, Voragen AGJ (1999) Purification and mode of action of two different arabinoxylan arabinofuranohydrolases from Bifidobacterium adolescentis DSM 20083. Appl Microbiol Biotechnol 51:606–613

Viikari L, Kantelinen A, Sundquist J, Linko M (1994) Xylanases in bleaching-from an idea to the industry. FEMS Microbiol Rev 13:335–350

Vincent P, Shareck F, Dupont C, Morosoli R, Kluepfel D (1997) New α-l-arabinofuranosidase produced by Streptomyces lividans: cloning and DNA sequence of the abfB gene and characterization of the enzyme. Biochem J 322:845–852

Voragen AGJ, Rombouts FM, Searle-van leeuwen MF, Schols HA, Pilnik W (1988) The degradation of arabinans by endoarabinanase and arabinofuranosidases purified from Aspergillus niger. Food Hydrocolloids 1:423–437

Vorin SG, Baumes RL, Bitteur SM, Gunata ZY, Bayonove CL (1990) Novel monoterpene disaccharide glycosides of Vitis vinifera grapes. J Agric Food Chem 38:1373–1378

Wakabayashi C, Hasegawa H, Murata J, Saiki I (1997) In vivo antimetastatic action of ginseng protopanaxadiol saponins is based on their intestinal bacterial metabolites after oral administration. Oncol Res 9:411–417

Ward OP, Moo-Young M (1989) Degradation of cell wall and related plant polysaccharides. Crit Rev Biotechnol 8:237–274

Weaver J, Whitehead TR, Cotta MA Valentine PC, Salyers AA (1992) Genetic analysis of a locus on the Bacteroides ovatus chromosome which contains xylan utilization genes. Appl Environ Microbiol 58:2764–2770

Whitaker JR (1984) Pectic substances, pectic enzymes and haze formation in fruit juices. Enzyme Microb Technol 6:341–349

Winterhalter P (1990) Bound terpenoids in the juice of the purple passion fruit (Passiflora edulis Sims). J Agric Food Chem 38:452–455

Wu P, Kuo M-C, Hartman TG, Rosen RT, Ho C-T (1991) Free glycosidically bound aroma compounds in pineapple (Ananas comosus L. Merr.). J Agric Food Chem 39:170–172

Yannai T, Sato M (2000) Purification and characterization of novel α-l-arabinofuranosidase form Pichia capsulata X91. Biosci Biotechnol Biochem 64:1181–1188

Zaldivar J, Nielsen J, Olsson L (2001) Fuel ethanol production from lignocellulose:a challenge for metabolic engineering and process integration. Appl Microbiol Biotechnol 56:17–34

Zechel DL, Withers SG (2000) Glycosidase mechanisms: anatomy of a finely tuned catalyst. Acc Chem Res 33:11–18

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Numan, M.T., Bhosle, N.B. α-l-Arabinofuranosidases: the potential applications in biotechnology. J IND MICROBIOL BIOTECHNOL 33, 247–260 (2006). https://doi.org/10.1007/s10295-005-0072-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10295-005-0072-1