Abstract

Landfilling is the main technology for municipal solid waste (MSW) disposal in Thailand. Semi-aerobic landfill and mechanical biological treatment (MBT) are the emerging options for MSW management. Nevertheless, their direct and indirect impacts on greenhouse gas (GHG) emissions are still unclear. In this study, life cycle analysis was used to analyze GHG emissions from three MSW management scenarios. For landfill options, three operating phases including transportation, landfill operation, and biodegradation from landfill were considered. The emissions from landfills operated under anaerobic and semi-aerobic conditions were evaluated using country-specific emission data. Meanwhile, MBT was considered with additional phases of refused derived fuel (RDF) production and transportation from landfill to power plant for electricity production. The results revealed a significant GHG emission reduction of 68% when replacing anaerobic landfills with semi-aerobic landfills. The use of RDF products in MBT options as power plant fuel could offset all emissions during their upstream phases yielding a positive impact in terms of GHG emission provided that the RDF was transported to power plants located within 150 km from the MBT plant. The study could be used to support the MSW management plan to achieve zero net emissions in the waste sector of the country.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Municipal solid waste (MSW) generation in Thailand accounted for 25.37 million tons in 2020, with an average per capita generation rate of 1.05 kg/day [1]. Similar to other developing countries, a rapid growth rate of population, urbanization, economic development, and changes in consumption patterns affected the waste generation increase in Thailand. Within the total amount of MSW generated, 31% was recycled and utilized, 36% was properly managed, 22% was improperly managed, and 11% was unmanaged. The majority of properly managed MSW was disposed of in sanitary landfills (84 sites, 4% of the total number of disposal sites) or controlled dumpsites (237 sites, 11%) whereas open dumpsites (1760 sites, 85%) predominated the improperly managed method. In 2021, the Thai government proposed an action plan for MSW management during 2022–2027 including closure or rehabilitation of unsanitary disposal sites as well as improvement of MSW management efficacy through increasing waste utilization for energy recovery [2].

Landfilling is the main MSW disposal technology in many countries around the world [3] including Thailand [4]. The conventional landfill is usually conceptualized as an anaerobic biochemical degradation process producing landfill gas (LFG) and leachate as the major product [5]. Landfill gas is generated as a result of physical, chemical, and biological processes. The biodegradation of MSW in anaerobic landfills generates LFG mainly composed of two major greenhouse gases (GHG), i.e., methane (CH4) and carbon dioxide (CO2). In Asian developing countries, the major portion of MSW generated is predominated by food waste with high moisture content [6]. Moreover, warm temperatures and intensive precipitation during the rainy season in a tropical climate also help to promote gas production in landfills [7]. In Thailand, CH4 emission from MSW disposal on land accounted for 5,346 GgCO2 eq, or about 1.7% of the national total emission in 2013 [8]. Following the Paris agreement, Thailand has already submitted its Intended National Determined Contribution (INDC) in 2015 to reduce its GHG emission by 20–25% from the project business as usual level by 2030 [8].

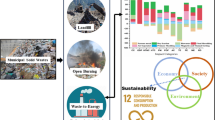

There are varieties of MSW management options to mitigate GHG emissions from landfills, e.g., material recovery for composting, incineration, or waste to energy [9]. Nevertheless, those options should be considered appropriately under local conditions. In Thailand, there are two emerging MSW management technologies recently considered as possible options to help mitigate GHG emissions from the waste sector. One option is the improvement of MSW disposal conditions using a semi-aerobic (SM) or the Fukuoka landfill method initiated in Japan by Fukuoka City and Fukuoka University [10]. The other option is the utilization of MSW as an alternative fuel at power plants or industrial facilities. This option is promoted provided that there is still insufficient development of MSW-specific incineration facilities in the country. Both technologies have already been implemented in the field or full-scale operation in Thailand.

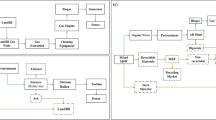

The SM landfill technology has already been successfully implemented in Thailand in some municipalities. Figure 1 shows schematics of anaerobic or conventional (CT) and SM landfill cells and sizing of leachate collecting pipe applied in the MSW disposal area of a municipality in Thailand [11]. Meanwhile, mechanical biological treatment (MBT) is used to improve MSW properties for its utilization as refuse-derived fuel (RDF). The mechanical process aims at the segregation of recyclable materials through a combination of sorting, separation, shredding, and screening processes. It is also used for the preparation of organic wastes for the biological process. The biological process, e.g., composting, and anaerobic digestion has the main objective to stabilize the organic fraction of MSW. The residuals from mechanical and biological processes are further proceeding to the final disposal step, e.g., landfill. Recently, there are currently several full-scale MBT facilities in operation in Thailand. One of them is the windrow pile typed MBT operating at Phitsanulok municipality (Fig. 2) with its detailed performance reported elsewhere in the literature [12].

Theoretical consideration

The application of SM landfill could mitigate GHG emissions through the promotion of aerobic conditions in the landfill. In an SM landfill, the air is introduced from the leachate collecting pipe, which was partially filled with leachate. Natural air was driven by the temperature difference between the inside of the waste cell and ambient air. The air penetration support improves waste stabilization and leachate qualities due to the enhancement of aerobic biodegradation [13]. The Intergovernmental Panel on Climate Change (IPCC) has proposed a CH4 correction factor (MCF) of 0.5 for SM landfills in the ‘Guideline for National Greenhouse Gas Inventories’ [14] suggesting that an SM landfill would produce one-half of the CH4 produced by an equally-sized anaerobic landfill. Nevertheless, previous research investigations suggest that the successful development of SM conditions in the landfill could significantly lower CH4 production than the proposed MCF value [15, 16].

The application of MBT, on the other hand, helps to divert the majority of MSW from landfill disposal. The use of mechanical and biological treatment transforms the waste into RDF which is further utilized in the energy recovery process. However, there can still be GHG emissions from the MBT process, especially during biological treatment depending on the effectiveness of the air supply during aerobic biological treatment. In the IPCC guideline [14], there are no default emission factors proposed for the MBT process, therefore, the emissions could be determined from the measurements at the operating facilities. For instance, Clemens and Cuhls [17] reported CH4 and N2O emission rates of 6 × 103–1.2 × 104 g/t waste and 1.44–378 g/ t waste during the measurements at four mechanical-oriented MBT facilities in Europe. Nevertheless, the emissions can be varied significantly depending on the types of process used. In developing countries, natural biological treatment process such as windrow pile was considered due to their low operating cost. Without mechanical aeration, airflow was naturally drafted into the waste pile from the temperature difference between the interior of the MSW layer and outside ambient air. Moreover, ambient air penetration could also occur at the pile surface. The introduction of air into the MSW layer promotes aerobic microbial activities responsible for the decomposition of organic wastes. Nevertheless, high CH4 emissions from deep windrow piles could occur temporally when operated in tropical Asian conditions due to high moisture retention within the waste matrix [12].

Despite the technologies being used for the improvement of MSW management have been identified, their efficacies in mitigating greenhouse gas are still unclear especially in the context of their application locally. To evaluate the overall impact along the MSW management stream, a life cycle assessment (LCA) has been proposed for comparing different waste management scenarios under appropriate assumptions and boundaries [18]. Using LCA to waste management, it is also possible to qualify and quantify the impact of gas emissions and various substances derived from the whole system. There were various studies focused on the impact of GHG emissions from several technologies to compare the impact on the environment. Table 1 summarizes GHG emissions from different waste management processes reported in the literature. Among them, waste disposal in landfill generally yields higher GHG emissions but other treatment processes may also contribute significant emissions. High variations of emissions, up to several orders of magnitude, were reported even for the same waste treatment category due to the differences in process design and operation. In some cases, there were both positive and negative values of GHG emissions reported such as anaerobic digestion and MBT due to the presence or absence of product utilization, e.g., biogas and RDF recovery for electricity generation. Therefore, the selection of appropriate waste management processes under local conditions would be important to achieve real GHG emission reduction.

Kristanto et al. [20] proposed the treatment of 150 t/d of MSW via composting, 80 t/d via material recovery facilities, 500 t/d via anaerobic digestion, and 390 t/d for controlled landfill disposal as the best scenario for GHG emission reduction for an Indonesian city. Devadoss et al. [29] compared GHG emission reduction potential between recycling-focused and incineration-focused strategies for Pakistan and proposed 23% for recycling, 10% for anaerobic digestion, and 67% for the sanitary landfill with energy recovery as the most effective option. In contrast, Liu et al. [30] found that incineration led to a substantial decrease in GHG emissions due to its highest energy recovery rate as compared to composting and anaerobic digestion options for China. Inazumi et al. [31] applied the LCA methodology to the waste disposal stream of Bangkok (the capital city of Thailand) and found resource sorting and compost treatment as the best scenario for reducing GHG emissions. Nevertheless, the study did not include the consideration of MSW utilization as RDF. From the literature, there is still a lack of information on the impact of applying emerging technologies such as SM landfill and MBT on GHG emissions in developing countries, especially in tropical Asian conditions.

Therefore, this study aims to investigate life cycle GHG emissions from the implementation of specific technologies, i.e., SM landfill and MBT for preparation of RDF from MSW and its utilization for electricity production. Their efficacies in mitigating GHG emissions are compared to that of an anaerobic landfill used as a base-case scenario.

Methodology

Basic information and system boundary

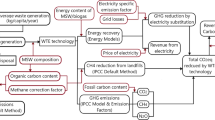

This study employed the LCA technique to evaluate GHG emission by comparing MSW management in CT (anaerobic) landfill, improvement of final disposal facilities in SM landfill, and application of MBT for preparation of RDF and utilization in the power plant for electricity production. Basic information used in the determination of GHG emissions in this study is described as follows.

The GHG potential of the MSW management system at each step along the life cycle stream of MSW management was evaluated. MSW considered includes waste generated and collected from the residential and commercial areas of the Phitsanulok municipality area (Fig. 3). The functional unit of this study is 1 ton of dry MSW treated. The CT landfill as final disposal is used as the base case scenario and compared to SM landfill and MBT scenarios. The life cycle GHG emission helps to demonstrate how the selection of waste management scenario affects the GHGs emission across the entire life cycle of the waste management stream and how GHGs emissions can be mitigated by those waste management options. The LCGHGs result will support the decision-making of the authorities to consider the selection of appropriate MSW management strategy to achieve the GHG emission reduction goal. The optimal MSW management option would also contribute to environmental sustainability that supports the national policy.

Two MSW management technologies were considered to mitigate GHG emissions, i.e., SM landfill and MBT operations. The SM landfill which has been implemented in a municipality in Thailand [11] was considered for its application at Phitsanulok municipality. The SM and CT landfill cells were constructed to evaluate their performance in MSW disposal and corresponding GHG emissions. For the SM landfill cell, the main leachate collection pipe with a 0.50 m diameter (Fig. 1) was installed and connected with two vertical gas vents (0.30 m diameter). All the pipeline was covered by large-sized (0.05 m) gravels. To promote the convective air into the waste layer. On the other hand, the CT landfill cell was constructed with a 0.3 m diameter of leachate collection pipe (Fig. 1) and without a ventilation pipe. The size of the gravel surrounding the pipe is smaller than 0.05 m in diameter. Surface emission from both landfill cells was used to derive EF used in the LCA.

MBT operation at Phitsanulok municipality is considered in the MBT scenario. The site received MSW from Phitsanulok municipality and a nearby area of about 100 tons/day. The MSW was transferred to the site where MSW was managed in various steps (Fig. 2). In the first step, MSW was de-bagging and homogenized by using a rotating drum. After that, homogenized MSW was piled on the palate plates and left for several months. During that period, passive aeration was naturally promoted for waste stabilization (biological process). After the treatment, stabilized MSW was transferred to a mechanical separation facility which used to produce RDF. The separation processes consist of the trommel, disc screen, wind separation, and magnetic separation. The remaining residuals from these separation processes were disposed of in the landfill or utilized as soil conditioners.

System boundaries and scenario setup

System boundaries delineate which processes are included and excluded in the study. There are 3 scenarios in this study. Figure 4 shows the system boundaries of all scenarios. The evaluation of GHG emission in this study aims to compare 3 scenarios, i.e., “CT Landfill” represents conventional (anaerobic) landfill as the current practice of MSW management, and "SM Landfill” represents semi-aerobic landfill following the proposed national strategy to improve solid waste disposal condition and “MBT” represents a diversion of MSW from final disposal through MBT operation for utilization as RDF for electricity production. The GHG emissions are considered in terms of tons of CO2 equivalent per ton dry weight (t CO2eq/ t dry wt.)

Scenario I: CT landfill

The CT landfill scenario is set up to evaluate the life cycle of GHG emissions from MSW collection to its final disposal in a conventional anaerobic landfill. The MSW is collected from households and transported to the landfill site using waste trucks. The collection capacity of six-wheeled waste trucks is 4–6 tons of waste. This type of truck uses diesel and compressed natural gas (CNG). The gas emission from fuel consumption is counted. After the waste was delivered to the site, the excavator and front-end loading trucks are managing the area of waste tipping. In parallel, electricity is used for operating the waste-scale building and office use. After the waste was landfilled, anaerobic biodegradation of MSW takes place. The CH4 emission from anaerobic biodegradation was calculated by using country-specific EF derived from an anaerobic landfill cell [11]. The emission of CO2 from biogenic wastes during landfill biodegradation is not accounted it is considered carbon neutral.

Scenario II: SM landfill

Scenario II is set up to analyze the life cycle of GHG emissions from MSW collection to its final disposal in the SM landfill. The management steps of scenario II on waste transportation and landfill operation are the same as those of scenario I. However, GHG emission from the biodegradation process was determined using country-specific EF derived from an SM landfill cell [11].

Scenario III: MBT

Scenario III is set up to evaluate the GHG emission and fuel consumption from the MBT process. The MSW collection and transportation from sources to the landfill site are the same as in scenario I. However, the management of MSW at the site is different. The MSW was de-bagged and homogenized then piled into a windrow shape. Therefore, the GHG emission from heavy machines is different from the landfill operation. Moreover, the processed waste after several months of biodegradation will transfer to the mechanical separation facility to produce RDF. During this stage, GHG emission was accounted for in the biodegradation process using CH4 and N2O EFs derived from the MBT windrow pile treatment determined in our previous study [12]. The fuel and electricity consumption in the separation facility were accounted for. The materials removed at this step were mostly inorganic components therefore the GHG emission from their disposal was negligible. From the operation of the MBT plant, 1 ton of raw MSW can produce 0.28 tons of RDF (Fig. 2). After MBT processes, the produced RDF was transported to a power plant using trailer trucks. The power plants located within 300 km distance from Phitsanulok municipality which can utilize RDF produced from MSW were the targeted RDF users. The GHG emission from fuel consumption during RDF transportation was accounted for. The RDF was then used as an alternative fuel to produce electricity instead of fossil fuel. The combustion of RDF to produce electricity was determined. While the GHG emission saving from substituted fuel was accounted for using EF for electricity production for the national grid in Thailand.

Each scenario assumed the same MSW characteristics as those of the reference sites so the pre-determined CH4 EF reported in the literature [11, 12] is directly applied. The average distance to collect the MSW from its sources to the landfill site was set at 50 km which covered the collection and transportation of collected MSW to the Phitsanulok municipality MSW management site. In the MBT scenarios, the transportation of RDF to power plants located within 100, 200, and 300 km distance from the MBT plant was considered (Fig. 5).

Life cycle GHG emission of different MSW management options

To quantify the total GHG emissions of each scenario, the following equations are used.

Scenario I: CT landfill

where TECT = Total GHG emission from all stages operated under CT landfill scenario (t CO2eq/ t dry wt.), Etran1 = GHG emission from the transportation of MSW from its sources to landfill site (t CO2eq/t dry wt.), ELF operates = GHG emission from landfill operation (t CO2eq/t dry wt.), Edegrade CT = CH4 emission from biodegradation process under anaerobic condition (t CO2eq/t dry wt.)

where FCtran1, diesel = Diesel consumption of MSW transportation from sources to landfill site (L/km/t dry wt.), Disttran1 = Distance between MSW sources to the landfill site (km), NCVdiesel = Net calorific value for diesel (GJ/L), EFdiesel = Emission factor for diesel (tCO2eq/GJ), FCtran1, CNG = CNG consumption of MSW transportation from sources to landfill site (kg/km/t dry wt.), 3.63 = Conversion factor (1 scf = 3.63 kg of CNG), EF CNG = Emission factor for CNG (tCO2eq/scf)

where FCLF operate = Fuel consumption used for landfill operation, use only diesel (L/t dry wt.), ECLF operate = Electricity consumption for landfill operation (MWh), EFEL = Emission factor for grid electricity generation (t CO2eq/MWh)

where EFCH4, CT = CH4 emission factor from biodegradation process derived from CT landfill cell (t CH4/t dry wt.), GWPCH4 = CH4 Global Warming Potential ( – ).

Scenario II: SM-landfill

where TESM = Total GHG emission from all stages operated under SM landfill scenario (t CO2eq/ t dry wt.), Edegrade SM = CH4 emission from biodegradation under SM condition (t CO2eq/t dry wt.)

where EFCH4, SM = CH4 emission factor from biodegradation process derived from SM landfill cell (t CH4/t dry wt.)

Scenario III: MBT

where TE MBT = Total GHG emissions from all stages under MBT scenario (t CO2eq/ t dry wt.), Etran1 = GHG emission from the transportation of MSW from its sources to MBT plant (t CO2eq/t dry wt.), EMBT operate = GHG emission from the operation of MBT (t CO2eq/ t dry wt.), Edegrade WD = GHG emission from the biodegradable process from windrow pile (t CO2eq/ t dry wt.), ERDF prod = GHG emission from RDF production at separation facility (t CO2eq/ t dry wt.), Etran2 = GHG emission from the transportation of RDF from MBT plant to power plants (t CO2eq/ t dry wt.), ERDF comb = GHG emission from RDF utilization (combustion) at power plants (t CO2eq/ t dry wt.), Eelec sub = GHG emission from electricity which substitutes by RDF utilization (t CO2eq/ t dry wt).

where FC MBT operate = Fuel consumption used for MBT operation, only diesel used (L/t dry wt.), ECMBT Operate = Electricity consumption used for MBT operation (MWh)

where EFCH4, windrow, \(EF_\text{N2O, windrow}\) = CH4, N2O emission factors from the biodegradation process of windrow MBT (t CH4/t dry wt. or t N2O/t dry wt.), GWPN2O = N2O Global Warming Potential (-)

where FCRDF = Fuel consumption of RDF production process, use only diesel (L), EC RDF = Electricity consumption of RDF production process (MWh)

where FC tran2, diesel = Diesel Consumption of RDF transportation by trailer truck from separation facility to power plants (L/km/t dry wt.), Distance Tran2 = Distance from separation facility to power plants (km).

where MSWDW = Amount of MSW in dry wt. (t dry wt.), Fraction of RDF produced by 1 t of dry MSW (0.28), EFRDF comb = Emission factor of RDF combustion (CO2eq/ t dry wt.)

where LHVRDF = Low heating value of RDF (MJ/kg), EFEL = Emission factor of electricity generation (t CO2eq/MWh).

Table 2 shows the values of parameters used for the determination of GHG emissions at different stages of the compared scenarios.

Results and discussion

GHG emission from CT landfill scenario

The GHG emissions from the CT landfill scenario consist of emissions from transportation, landfill operation, and biodegradation. The collection trucks delivered MSW from its sources to the Phitsanulok MSW management site which is used as a landfill site in this scenario with an average traveling distance of 50 km by consuming diesel and CNG at 0.206 L/km/t dry wt. and 0.108 kg CNG/km/t dry wt., respectively. Thus, the GHG emission in the transportation stage was determined as 0.029 t CO2eq/t dry wt.

At the landfill site, MSW arrived and the waste truck proceeded to the weighing station. Then, it dumped the waste at the disposal area using landfill machines such as an excavator and front-end loading to process the waste. GHG emission was determined by using the consumption of fossil fuel (diesel) and electricity consumption in those processes. Diesel was used for heavy machines and electricity was used for scale and office buildings, respectively. The GHG emission from landfill operation was determined as 0.007 t CO2eq/t dry wt.

GHG emissions from biodegradation consist of CH4 emissions which took place under anaerobic conditions. The CH4 EF derived from the CT landfill cell was determined as 0.0147 t CH4/ t dry wt. or 0.366 t CO2eq/t dry wt. As a result, total GHG emission from the CT landfill scenario was 0.402 t CO2eq/t dry wt. in which GHG from biodegradation contributed over 90% of total emissions.

GHG emission from semi-aerobic landfill scenario

The GHG emission from transportation and landfill operation in this SM landfill scenario is similar to that of the CT landfill. Therefore, the GHG emission from transportation and landfill operation of the SM landfill was 0.029 t CO2eq/t dry wt. and 0.007 t CO2eq/t dry wt., respectively. However, the CH4 EF from the biodegradation process from the SM landfill was 0.00364 t CH4/t dry wt. Therefore, GHG emission from biodegradation of the SM landfill scenario was 0.091 t CO2eq/t dry wt. Total GHG emission from the SM landfill scenario was determined as 0.127 t CO2eq/t dry wt.

GHG emission from MBT scenarios

MSW transportation from sources to the Phitsanulok MSW management site which was used as the treatment location in the MBT scenarios was similar to other scenarios so GHG emission in the transportation stage was the same (0.029 t CO2e/t dry wt). During the MBT operation, MSW was debagged, homogenized, transferred to the biological treatment, and formed into windrow piles. From the study conducted at this representative site, fuel (diesel) and electricity consumption during MBT operation were reported as 7.76 L/t dry wt. and 0.425 kWh/ t dry wt., respectively [32]. The fuel consumption in the MBT process is comparatively higher than that in landfills mainly due to de-bagged and homogenizing processes. As a result, the GHG emission from the operation phase for MBT was 0.020 t CO2eq/t dry wt. or 2.86 times that in the landfill scenarios.

The windrow pile is served for biological treatment in the MBT scenario. From our previous study [12], the CH4 EF derived from the windrow piles operated at the Phitsanulok municipality was 0.007 t CH4/t dry wt. or 0.175 t CO2eq/t dry wt. This EF for the MBT process lies between those reported for CT and SM landfills [11] as the naturally ventilated windrow pile turns into an anaerobic condition periodically with higher CH4 emissions observed during wet months along the biodegradation period [12].

The additional phase to produce RDF and send it to the power plants is only considered in the MBT scenarios. After MSW biodegradation, biologically treated wastes were moved to the separation facility to produce the RDF. The separation process consists of mechanical separation steps which consumed fossil fuel and electricity. For the RDF production, diesel was consumed at 15.50 L/t dry wt. of input waste. Together with that, electricity was used at 0.06 MWh/t dry wt. The RDF production process, therefore, emitted 0.079 t CO2eq/t dry wt. In the last step, RDF was transported to targeted power plants by using trailer trucks which consumed 0.021 L/km/t of RDF which equals 0.066 L/km/t dry wt. of input MSW. Provided that the transport distances between the MBT plant and the power plant were varied at 100, 200, and 300 km, the GHG emissions from the transportation of RDF were determined as 0.135, 0.271, and 0.406 t CO2eq/t dry wt.

At the power plants, the RDF was used to substitute fossil fuel (coal) to generate electricity. The CO2 EF of RDF combustion is 902 kgCO2/t RDF. So, 1 t dry MSW could emit CO2 of 0.253 t CO2eq/t dry wt. However, the GHG emission avoidance from the RDF substitution of fossil fuels should also be considered. The RDF which contained a low heating value of about 17.21 MJ/kg could generate electricity at 1.34 MWh that equal to GHG emission of about 0.759 t CO2eq/t dry wt. As a result, net GHG emissions for the MBT scenarios with transportation distance of 100, 200, and 300 km of – 0.068, + 0.068, and + 0.203 t CO2eq/t dry wt. was determined.

Based on the above calculation, the comparison of GHG emissions from different MSW disposal scenarios is shown in Fig. 6.

Comparison of GHG emissions from different MSW management scenarios

In the previous session, GHG emissions from the whole process were determined for all scenarios. The results indicate that the major source of GHG emissions was biodegradation for landfill scenarios and biodegradation of MSW, transportation, and combustion of RDF in the MBT scenarios. When the SM landfill was applied instead of the CT landfill, the life cycle GHG emission of MSW management could be reduced by 68% mainly due to the presence of the aerobic condition in the SM landfill. These results suggested the potential of applying this technology to mitigate GHG emissions in MSW management. Comparing them, the operation procedures of the CT and SM landfills are similar and any additional operation is not required for the SM landfill, but the SM landfill only requires larger drainage pipes and vent pipes installation during its construction phase. It means only higher initial investment costs would be required. This additional cost could be subsidized by the mitigation of emission (carbon credit) scheme. The SM landfill also emitted lower organic pollution through leachate and odorous gas compared to the CT landfill. Therefore, the leachate treatment cost of the SM landfill should be lower than that of the CT landfill. As a result, additional co-benefit would be expected from the implementation of the SM landfill.

In the case of MBT scenarios, higher GHG emissions than that of the SM landfill but lower than that of the CT landfill would be expected from its operation if only MSW transport, MBT operation, and biodegradation are considered and RDF utilization is not practiced. This would be the case when MBT technology is utilized as landfill pre-treatment of MSW. However, it would come with additional space required for the installation of MBT windrow piles. So, MBT for landfill pre-treatment should be considered only when the land area of the MSW management site is sufficiently available. When MBT was applied for RDF production and utilization for energy recovery, its total GHG emissions are higher than that of the CT landfill but negative emissions can be expected from the utilization of RDF to replace fossil fuels used for electricity production (Fig. 6). Nevertheless, it would happen when the transportation of RDF to the power plants is limited within a certain distance, e.g., 150 km in this study. At a shorter transportation distance of 100 km, it will result in net emission of – 0.068 t CO2eq/t dry wt. or a 117% reduction from the baseline scenario. As transportation distance from the MBT plant to targeted power plants was increased to 200 and 300 km, positive emissions were determined but emission reductions of 87% and 50% from the baseline scenario were still achieved. Therefore, utilization of RDF produced from Phitsanulok municipality at power plants located in the surrounding area within 300 km from the MBT plant would result in a positive impact in terms of GHG emission compared to the disposal of untreated MSW in the conventional landfill. However, the selection of power plants with shorter transportation distances within 150 km from the MBT plant would help to achieve net zero or negative emissions from MSW management in this case study. In addition to the GHG emission reduction benefit, the use of RDF for electricity production reduces the consumption of fossil fuel, a non-renewable resource, at those power plants. Moreover, the diversion of the majority of MSW from the landfill through the MBT process with only < 10% of residual waste to be deposited helped extend the landfill lifetime of the studied site from 16 years to more than 40 years [39].

Conclusion

LCA methodology was used to evaluate GHG emissions by implementing different MSW management options including CT landfill, SM landfill, and MBT for recovery of RDF and its utilization in power plants located within 300 km distance from the MBT plant. Total GHG emissions of CT and SM landfill scenarios were 0.402 and 0.127 t CO2eq/ t dry wt. whereas they were ranging from – 0.068 to 0.203 t CO2eq/t dry wt. of MSW input for MBT scenarios with 100 to 300 km transportation distance, respectively. Improvement of landfill disposal from anaerobic to SM conditions would reduce GHG emissions by 68% while conversion of MSW to RDF through the MBT process would reduce GHG emission by only 43% but its further utilization in the power plant located at 100, 200, and 300 km from the MBT plant would yield a total reduction of 117%, 87% and 50% from the same baseline. In addition to GHG mitigation, SM landfill also provides co-benefit in reducing leachate and odor pollution whereas the MBT option helps to reduce the use of fossil fuel for electricity production and extend landfill lifetime.

Data availability

The data that support the findings of this study are available from the corresponding author, [CC], upon reasonable request.

References

PCD, 2021. Municipal Solid Waste Situation in Thailand in 2020, Pollution Control Department, Ministry of Natural Resources and Environment, Thailand (In Thai).

PCD, 2021. Action Plan for Municipal Solid Waste Management, Pollution Control Department, Ministry of Natural Resources and Environment, Thailand (In Thai).

Kaza S, Yao L, Bhada-Tata P, Van Woerden F (2018) What a Waste 2.0: A Global snapshot of solid waste management to 2050. World Bank, Washington DC

Chiemchaisri C, Visvanathan C (2008) Greenhouse gas emission potential of the municipal solid waste disposal sites in Thailand. J Air Waste Manag Assoc 58:629–635

Omar H, Rohani S (2015) Treatment of landfill waste, leachate and landfill gas: a review. Front Chem Sci Eng 9(1):15–32

Asian Institute of Technology, 2004. Municipal Solid Waste Management in Asia, Asian Regional Research Program on Environmental Technology (ARRPET), Thailand.

Chiemchaisri C, Chiemchaisri W, Kumar S, Hettiaratchi JPA (2007) Solid waste characteristics and their relationship to gas production in tropical landfill. Environ Monit Assess 135:41–48

Office of natural resources and environmental policy and planning (2018) Thailand’s third national communication. Ministry of Natural Resources and Environment, Thailand

Yaman C, Anil I, Alagha O (2020) Potential for greenhouse gas reduction and energy recovery from MSW through different waste management technologies. J Clean Prod 264:121432

PCD, 2020. Guidelines for the Planning, Design and Operation of Semi-aerobic Landfill, Ministry of Natural Resources and Environment, Thailand (In Thai).

Sutthasil N, Chiemchaisri C, Chiemchaisri W, Wangyao K, Endo K, Ishigaki T, Yamada M (2018) The effectiveness of passive gas ventilation on methane emission reduction in a semi-aerobic test cell operated in the tropics. Waste Manag 87:954–964

Sutthasil N, Chiemchaisri C, Chiemchaisri W, Ishigaki T, Ochiai S, Yamada M (2020) Greenhouse gas emission from window pile for mechanical biological treatment of municipal solid waste in tropical climate. J Mater Cycles Waste Manag 22:383–395

Huang Q, Yang Y, Pang X, Wang Q (2008) Evolution on qualities of leachate and landfill gas in the semi-aerobic landfill. J Environ Sci 20:499–504

IPCC, 2006. IPCC Guidelines for National Greenhouse Gas Inventory. IGES, Japan.

Aziz SQ, Aziz HA, Yusoff MS, Bashir MJK (2010) Leachate characterization in semi-aerobic and anaerobic sanitary landfills: a comparative study. J Environ Manag 91:2608–2614

Sutthasil N, Chiemchaisri C, Chiemchaisri W, Wangyao K, Towprayoon S, Endo K, Yamada M (2014) Comparison of solid waste stabilization and methane emission from anaerobic and semi-aerobic landfills operated in tropical condition. Environ Eng Res 19:261–268

Clemens J, Cuhls C (2003) Greenhouse gas emissions from mechanical and biological waste treatment of municipal waste. Environ Technol 24(6):745–754

Xu C, Yang JX, Wand RS (2000) Life cycle assessment for municipal solid waste treatment and utilization. J Environ Sci 12(2):225–231

Liamsanguan C, Gheewala SH (2008) The holistic impact of integrated solid waste management on greenhouse gas emissions in Phuket. J Clean Prod 16:1865–1871

Kristanto GA, Koven W (2019) Estimating greenhouse gas emissions from municipal solid waste management in Depok, Indonesia. City Environ Interact 4:100027

Wang K, Nakakubo T (2020) Comparative assessment of waste disposal systems and technologies with regard to greenhouse gas emissions: a case study of municipal solid waste treatment options in China. J Clean Prod 260:120827

Chaya W, Gheewala SH (2007) Life cycle assessment of MSW-to-energy schemes in Thailand. J Clean Prod 15:1463–1468

Chen TC, Lin CF (2008) Greenhouse gases emissions from waste management practices using life cycle inventory model. J Hazard Mater 155:23–31

Thuppahige RTW, Gheewala SH, Babel S (2022) Environmental impact of organic fraction of municipal solid waste treatment by composting in Sri Lanka. J Mater Cycles Waste Manag 24:189–199

Grosso M, Dellavedova S, Rigamonti L, Scotti S (2016) Case study of an MBT plant producing SRF for cement kiln co-combustion, coupled with a bioreactor landfill for process residues. Waste Manag 47:267–275

Montejo C, Tonini D, Márquez MC, Astrup TF (2013) Mechanical biological treatment: performance and potentials. An LCA of 8 MBT plants including waste characterization. J Environ Manag 128:661–673

Tyagi VK, Kapoor A, Arora P, Banu JR, Das S, Pipesh S, Kazmi AA (2021) Mechanical-biological treatment of municipal solid waste: case study of 100 TPD Goa plant, India. J Environ Manag 292:112741

Liamsanguan C, Gheewala SH (2008) LCA: A decision support tool for environmental assessment of MSW management systems. J Environ Manag 87:132–138

Devadoss PSM, Pariatamby A, Bhatti MS, Chenayah S, Hamid FS (2021) Strategies for reducing greenhouse gas emissions from municipal solid waste management in Pakistan. Waste Manag Res 39:914–927

Liu Y, Sun W, Liu J (2017) Greenhouse gas emissions from different municipal solid waste management scenarios in China: based on carbon and energy flow analysis. Waste Manag 68:653–661

Inazumi S, Ohtsu H, Shiotani T (2011) Environmental assessment and accounting for the waste disposal stream in Bangkok, Thailand. J Mater Cycles Waste Manag 13:139–149

Menikpura, S.N.M., Sang-arun, J., Bengtsson, M., 2012. Mechanical Biological Treatment as a solution for mitigating greenhouse gas emission from landfills in Thailand. Proceedings of the ISWA World Solid Waste Congress 2012, 17–19 September 2012, Florence, Italy.

Siam Cement Group, 2018. Plant record of fuel (diesel) consumption for RDF transportation, personnel communication.

Chanchampee, P., 2010. Method for Evaluation of Waste Management in Thailand in Consideration of Policy, Environmental Impact and Economics. Ph.D. Thesis, Technische Universität Berlin, Germany.

Phitsanulok Municipality, 2015. Plant record of fuel (diesel) and electricity consumption of RDF production process, personnel communication.

IPCC, 2014. Climate change 2014: synthesis report. contribution of working groups I, II and III to the fifth assessment report of the intergovernmental panel on climate change. IPCC, Switzerland.

USEPA, 2017. Emission factors for greenhouse gas inventories. Available Source: https://www.epa.gov/sites/production/files/2018-03/documents/ emission-factors_mar_2018_0.pdf, November 9, 2019.

TGO, 2018. Thailand grid emission factor for ghg reduction project/ activity. Available Source: http://ghgreduction.tgo.or.th/images/Grid_ Emission_Factor_2559_-_Finalised.pdf, November 9, 2019.

Phitsanulok Municipality, 2019. Management of solid waste disposal center, Phitsanulok municipality, personal communication.

Acknowledgements

This research was carried out in collaboration between Kasetsart University (KU), King Mongkut's University of Technology (KMUTT), Thailand, and the National Institute for Environmental Studies (NIES), Japan.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Sutthasil, N., Chiemchaisri, C., Chiemchaisri, W. et al. Life cycle greenhouse gas emissions of emerging municipal solid waste management options: a case study in Thailand. J Mater Cycles Waste Manag 25, 662–673 (2023). https://doi.org/10.1007/s10163-022-01584-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10163-022-01584-6