Abstract

Lipid production is an important indicator for evaluating microalgal species for biodiesel production. In this study, a new green microalga was isolated from a salt lake in Egypt and identified as Asteromonas gracilis. The main parameters such as biomass productivity, lipid content, and lipid productivity were evaluated in A. gracilis, cultivated in nutrient-starved (nitrogen, phosphorous), and salinity stress as a one-factor-at-a-time method. These parameters in general did not vary significantly from the standard nutrient growth media when these factors were utilized separately. Hence, response surface methodology (RSM) was assessed to study the combinatorial effect of different concentrations of the abovementioned factor conditions and to maximize the biomass productivity, lipid content, and lipid productivity of A. gracilis by determining optimal concentrations. RSM optimized media, including 1.36 M NaCl, 1 g/L nitrogen, and 0.0 g/L phosphorus recorded maximum biomass productivity, lipid content, and lipid productivity (40.6 mg/L/day, 39.3%, and 15.9 mg/L/day, respectively) which agreed well with the predicted values (40.1 mg/L/day, 43.6%, and 14.6 mg/L/day, respectively). Fatty acid profile of A. gracilis was composed of C16:0, C16:1, C18:0, C18:3, C18:2, C18:1, and C20:5, and the properties of fuel were also in agreement with international standards. These results suggest that A. gracilis is a promising feedstock for biodiesel production.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Microalgae are considered one of the most promising candidates for large-scale global biodiesel production due to their high photosynthetic efficiency and lipid content (Sforza et al. 2012). Biodiesel is a biofuel obtained from transesterification of fat or oil from the biological resources (Yilancioglu et al. 2014). Lipid production by microalgae is controlled by different culturing conditions such as nitrogen deficiency (Mujtaba et al. 2012), phosphate limitation (Feng et al. 2012), carbon source (Zhao et al. 2012), salinity stress (Kaewkannetra et al. 2012), iron content (Lin et al. 2012), and light intensity (Sousa et al. 2012). In addition, the level of lipid accumulation is influenced by growth cycle culturing time and species as well as strain specific (Yeh and Chang 2012). All of these factors influence the growth rate and lipid production by microalgae. Sufficiency of phosphorus and nitrogen in microalgae increases the rate of carbon dioxide fixation by seven to ten times, but their deficiency in most microalgae results in diminished photosynthetic capability, altered lipid metabolism, and an increase in their accumulation of triacylglycerol (Nascimento et al. 2013; Fan et al. 2014). Transesterification with acid or base catalyst was used to convert triacylglycerol to biodiesel (Rippka et al. 1979). Nitrogen limitation is associated to increase in lipid content by various species, followed by iron and phosphate. For instance, the lipid content in Chlorella sp. was stated to rise by 40–64% when cultivated in nitrogen deficient and iron increased media (Liu et al. 2008; Feng et al. 2012; Mujtaba et al. 2012). On the other hand, the high salt concentrations cause a biochemical and bioenergetic changes in microalgal cells (Mittal et al. 2012) such as increasing in biopolymer production rates and catabolism of the lipid, alterations in the rates of processes of energy yielding, and changes in permeability of membrane with interruption of ion homeostasis (Alyabyev et al. 2007). Various species of microalgae can be stimulated to accumulate high contents of lipid, although the average lipid content differs between 1 and 70%; few microalgal species may reach 90% under certain conditions (Chisti 2007; Li et al. 2008). Improvement of lipid production in the microalgae by scheming the conditions of cultivation is equally essential as the selection of microalgae for high lipid-producing algae (Duong et al. 2012). In these conditions, response surface methodology is one of the appropriate and efficient methods for optimizing the media conditions to maximize biomass and lipid productivity in microalgae (Yang et al. 2014). As well, it has more benefits such as less time consuming with a minimum number of experiments and assessing the effective factors and their interaction on the responses than the traditional methodologies. Numerous microalgae have been defined as lipid-rich species for their hydrocarbons and other oils. Biodiesel production by microalgal species may be the only way to produce adequate automotive fuel to replace existing petro-diesel usage (Chisti 2007). The total lipid content as well as the fatty acid proportion are important parameters for biodiesel production (Griffiths and Harrison 2009). Generally, the biodiesel that produced lipids and fatty acid methyl ester of microalgae was observed to be in conformity with the standards of biodiesel (Nascimento et al. 2013). Moreover, a good biodiesel should agree with the standard of cetane number, which refers to the good ignition quality, low pollutant content, a suitable cold filter plugging point, and at the same time, correct viscosity and density (Gopinath et al. 2009). Asteromonas gracilis Artari is a green motile unicellular wall-less halotolerant alga that can grow in wide range habitat. A. gracilis has high tolerance to salt, light, and temperature. It is considered as a new record in Egypt and easy in cultivation and has high growth rate and lipid content (Ben-Amotz and Grunwald 1981).

Whereas, in the case of green algae, no or little information is available regarding lipid enhancement for biodiesel production by A. gracilis, hence, this study was designed to improve the biomass, lipid content, and lipid productivity by A. gracilis using response surface methodology based on the Box-Behnken design and to evaluate the biodiesel fuel properties by analyzing the profile of fatty acid. To the best of our information, this is the first extensive report that expressing the media optimization methodology improved the biomass, lipid content, and lipid productivity in A. gracilis and it could be utilized as a biodiesel feedstock for the production of biodiesel.

Materials and Methods

Alga Strain and Growth Conditions

Marine green microalga Asteromonas gracilis was isolated from a salt lake in Alexandria (El-Agamy), which may be considered as a new record in Egypt. A. gracilis was grown in Modified Johnsons Medium (J/l) (Borowitzka 1988) in 300-ml Erlenmeyer’s flask under constant illumination of 48.4 μmole/m2/s1, and the cultures were gassed with sterile air provided by air pump at 25 °C. The pH of the medium was also adjusted to pH 7.5 with 0.1 M HCl or 0.1 M NaOH.

Cultivation of Microalgae in Nutrient Stress

The conditions of nutrient stress, like the starvation of nitrogen and phosphorous, were applied by excluding the nitrogen (NaNO3, −100%) and phosphorous (KH2PO4, −100%) sources in Modified Johnsons Medium. Osmotic stress was also created in the Modified Johnsons Medium by the addition of 3 M NaCl. In the control culture, original Asteromonas media was used and all the applications were repeated in triplicate.

Determination of Biomass and Lipid Productivity

A. gracilis cells were harvested at the end of the logarithmic phase (day 9), and they were dried at 105 °C until the constant dry cell weight was obtained. Dried cells were reweighed and calculated gravimetrically (the growth was expressed as dry cell weight). The total lipid was extracted using methanol/chloroform (2:1) according to the method of Drevon and Schmitt (1964). The phosphovanilin reagent consisted of phosphoric acid, vanillin, and ethanol solution. About 0.1 ml of the previous extract was transferred to a dry glass tube, and 3 ml of H2SO4 was added and left in boiling water bath for 10 min. After hydrolysis, 1.5 ml phosphovanilin reagent was added to 0.05 ml of hydrolyaste, mixed well, and incubated at 37 °C for 10 min. The absorbance of characteristic pale pink color was measured at 530 nm.

Biomass productivity and lipid productivity were calculated from the initial and final cell dry weight as the following equations (Griffiths and Harrison 2009):

where B1 and B2 indicate dry cell weight of initial and final biomass concentration, respectively, (T2-T1) represents the time interval. All the experiments were carried out in triplicate and the data were expressed as mean ± standard error. The data obtained were subjected to one-way analysis of variance (ANOVA), using the SPSS statistical package. For comparison of the means, the Duncan’s multiple range tests (p < 0.05) were used.

Experimental Design for Response Surface Methodology

The statistical experimental design by RSM is being generally used by researchers for improved production of metabolites (Montgomery 2005; Myers and Montgomery 2002). Box-Behnken experimental design (BBD) with three factors and three levels was used to optimize the conditions of growth media using NaCl (A), nitrogen (B), and phosphorus (C) as independent variables for the biomass productivity, lipid content, and lipid productivity using Design Expert Software Version 7.0.0 (Stat-Ease Inc., Minneapolis, USA). The full design consisted of 17 experimental runs at three coded levels, low (−1), medium (0), and high (+1) which corresponds to NaCl (1.25, 2.13, 3 M), NaNO3 (0, 0.5, 1 g/L), and KH2PO4 (0, 0.02, 0.04 g/L), respectively, with 5 replicates at the center point to estimate the experimental error.

A second-order polynomial equation was used to express the mutual interaction among the variables and their corresponding optimum levels. The general form of this equation is as follows:

where Y is the predicted response, βo is the intercept term, βi, βii, and βij are the linear, quadratic, and interaction effects, respectively, Xi and Xj are the factor independent variables (regression coefficient of the model), and ε is the error.

Statistical Analysis of the Data

Multiple regression analysis was used for analysis of the experimental data obtained from the Box-Behnken design to determine the significant differences (p ≤ 0.05) in responses at various conditions. The 3D surface plots were generated for visualization of the relationships between the responses and the independent variables and to determine the optimum conditions. The best fit of the model was determined based on the coefficient of determination (R 2), and ANOVA as well as its statistical significance were checked by F test quadratic polynomial equations that were attained by holding one of the independent variables at a constant value and changing in the other variable level.

Validation of the Optimized Conditions and Predictive Model

Triplicate experiments were carried out under the optimized conditions gotten by the methodology of Derringer’s desired function (Derringer and Suich 1980) to verify the optimized conditions. The predicted and actual values were compared to determine the accuracy and validity of the model.

Fatty Acid Profiling of A. gracilis

Direct acid esterification of the algal dry biomass (control culture) was performed to produce fatty acid methyl esters according to Vicente et al. (2009, 2010), with some modification. Algal biomass was dried at 50 °C. The dry algal biomass (0.5 g) was suspended in 40 ml of the mixture (methanol/chloroform/conc. HCl) (2:1:1) and left overnight at 40 °C with shaking at 120 rpm. The fatty acid methyl esters were extracted by n-hexane and analyzed using gas chromatography-mass spectrometer (GC-MS), Agilent Model 7890A-5975B [Column, DB 5 ms, Agilent form (30 m × 250 μm × 0.25 μm)] in the Unit of Analytical Chemistry, Department of Chemistry, Faculty of Science, Assiut University. The column was initially maintained for 2 min at 40 °C, and then, the temperature was increased to 50 °C at a rate of 4 °C/min and held for 3 min, then increased to 150 °C at a rate of 10 °C/min and held for 3 min, then increased to 220 °C at a rate of 10 °C/min and held for 6 min, finally increased to 280 °C at a rate of 15 °C/min and held for 10 min. Helium (purity 99.999%) was used as the carrier gas with a flow rate of 0.5 ml/min for 10.9 min, then 1 ml/min per min to 1 ml/min for 30 min. Electron impact ionization mass spectrometry (EI-MS) was used to detect the m/z value of the separated fatty acid compound. The mass spectrum data of each peak of the chromatogram were compared with the Willey 9 and NIST library for the identification of the fatty acid compound. The relative percentage of fatty acids was calculated by the area normalization method.

Evaluation of Biodiesel Fuel Properties

The fuel properties of A. gracilis (control culture) such as cetane number (CN), iodine value (IV), saponification value (SV), kinematic viscosity (υ), higher heating value (HHV), and oil density (ρ) were obtained from its fatty acid methyl ester profile using the following equations (Ramos et al. 2009; Klopfenstein 1982). Specifications of biodiesel fuel are given by the international standards such as EN 14214 in Europe and ASTM D6751-02 in the USA (Hoekman et al. 2012).

where N is the percentage of each fatty acid methyl ester, M and D are the molecular weight and number of double bonds of corresponding fatty acid, respectively.

Results and Discussion

Effects of Salinity Stress and Nutrient Starvation on Biomass Productivity, Lipid Content, and Lipid Productivity of A. gracilis

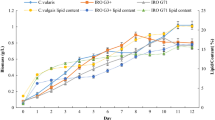

Biomass and lipid productivity are the main parameters to figure out the best strain for the production of biodiesel. Lipid contents in microalgae can be enhanced by different strategies like salinity stress, nitrogen starvation, and nutrient supplementation (Karpagam et al. 2015). The effect of salinity stress as well as NaNO3 and KH2PO4 starvation on the biomass, lipid content, and lipid productivity was recorded in Table 1. In general, the salinity stress and nutrient starvation increased the lipid content and productivity compared to the control culture. The results revealed that among these stresses, the nitrogen starvation induced relatively higher accumulation in lipid content and productivity (29.26% and 10.21 mg/L/day, respectively). These results are in agreement with Yeesang and Cheirsilp (2011) who reported that algal cells accumulate lipids under nitrogen-deficient conditions. On the other hand, Li et al. (2010) found that the phosphorus limitation as well leads to lipid accumulation in Scenedesmus sp. The stimulation of lipid production by salinity stress would lead to increase in the viscosity of plasma membrane and turgor pressure of the plant or algal cell and thereby inhibiting the water efflux from the cell for its adaptation (Reed and Walsby 1985). Furthermore, salinity stress could cause the synthesis of osmoregulants rather than the other cellular components and which may increase the level of tolerance to salinity stress by aiding the different functions such as carbon and nitrogen storage and stabilization of sub-cellular structure in microalgae and plants (Kalsoom et al. 2013; Battah et al. 2013). Many reports have suggested that lipid biosynthesis might be involved in the protection against stressful environments (Sheehan et al. 1998; Timmins et al. 2009). Biomass productivity was also examined during the salinity stress and nutrient starvation and found to be decreased in NaCl (36.78 mg/L/day) stress, nitrogen (34.9 mg/L/day), and phosphorus (36.1 mg/L/day) starvation than the control (38.87 mg/L/day). Therefore, the accumulation of high lipid content is ordinarily accompanied by low biomass productivity in case of the treatment by nutrient starvation or salinity stress. Converti et al. (2009) showed that a gradual decrease in the growth of Nannochloropsis oculata accompanied by almost a duplication of the lipid content was observed when the nitrogen was eliminated from the media. The common conclusion about deficiency of nutrients such as nitrogen for microalgae is that nitrogen deficiency can improve lipid content, but significantly reduce biomass productivity, eventually resulting in a slight increase or even a decrease in lipid productivity (Breuer et al. 2012).

Optimization of the Culture Conditions by Box-Behnken Design

Since salinity stress and nutrient starved media resulted in only marginal increase in lipid content and productivity and decrease in biomass productivity compared to the standard nutrient growth media as shown in Table 1, the combined effect of the above mentioned factors for optimum biomass, lipid content, and lipid productivity was designed through a Box-Behnken design (BBD). In order to fit the experimental results obtained based on Box-Behnken design and the three process variables to develop empirical models in order to express the true relationship between the independent variables and responses, a second-order polynomial mathematical equation was developed. In the current study, based on BBD, all 17 designed experiments were conducted with various combinations of three independent parameters such as sodium chloride, nitrogen, and phosphorus at three various levels, low (−1), medium (0), and high (+1) to study the combinatorial effects of these factors on biomass productivity, lipid content, and lipid productivity of A. gracilis. The independent variables and their coded levels that used for this study as well as a BBD matrix of independent variables in coded units with actual and predicted values for biomass productivity, lipid content, and lipid productivity are shown in Table 2. Multiple regression analysis was used for the analysis of results. Maximum biomass and lipid productivity (58.8 and 14.8 mg/L/day) were obtained under the conditions of media concentrations of NaCl 3 M, nitrogen 1 g/L, and phosphorus 0.02 g/L. While the media concentration of NaCl 3 M, nitrogen 0.5 g/L, and phosphorus 0.04 g/L provided the lowest biomass and lipid productivity (10.9 and 6.8 mg/L/day), respectively, on the other hand, the maximum lipid content was recorded at NaCl 1.25 M, nitrogen 0.5 g/L, and phosphorus 0 g/L. The final models obtained by backward elimination of insignificant variables in terms of code factors were given as follows:

where A: NaCl (M), B: nitrogen (gl−1), C: phosphorus (gl−1).

It is necessary to conduct ANOVA to determine whether the quadratic model is significant or not. ANOVA for the response surface quadratic model was tabulated in Table 3. The p values were used for examining a significance of each coefficient, that in turn were needed to comprehend the mutual interaction pattern between the test variables. Murthy et al. (2000) reported that when p values are low, this indicates that the process parameters are more significant and efficient. In our study, the model p value was smaller than 0.01 in case of all responses; these results indicated that the model was appropriate for use in this study. The failure of a model to explain the experimental data in experimental domain at a point, which are not comprised in the analysis of regression, was measured by the test of lack of fit (Sharma et al. 2009). This test is required to be non-significant to signify the model. In the current investigation, the p value of “lack of fit” of biomass productivity, lipid content, and lipid productivity was 0.197, 0.785, and 0.963 (p > 0.05), respectively. These values indicated that “lack of fit” was insignificant relative to pure error as well as the equation of a model was appropriate to predict biomass productivity, lipid content, and lipid productivity under any groups of variable combination. The F test was used to perform the statistical significance of polynomial equations. The model F value of 11.54, 25.43, and 8.31 (p < 0.01) for biomass productivity, lipid content, and lipid productivity, respectively, as well, the non-significant lack of fit implies that most of the variation in the responses can be explained by the regression equation and the developed quadratic models were significant (p ≤ 0.5) to predict all responses. Regression correlation coefficients and corresponding p values were tabulated in Table 4. The goodness of fit of this model was checked by the coefficient of determination (R 2), adjusted R 2, predicted R 2, and coefficient of variation. The R 2 gives the total variation proportion in the responses predicted by the model. The R 2 value indicates better accuracy of the model when it was close to 1.0 where it varies from 0 to 1.0. However, in some cases, the higher R 2 values may be resulted in the presence of large numbers of insignificant variables in the model and thereby it predicts poor response. Therefore, the adjusted R 2 was introduced which corrects R 2 value accordingly to the size of the sample and terms number in the model. The high values of R 2 (0.91, 96, and 0.88) for biomass productivity, lipid content, and lipid productivity, respectively, ensure a satisfactory fitting of the quadratic model in order to express the actual relationship between the independent variables and responses. As well as, the model could explain 91, 96, and 88% of the variability in the responses. The adjusted R 2 should be close to R 2 value, and the larger difference between R 2 and adjusted R 2 indicated cautionary that the content of the model has too many insignificant terms (Haaland 1989). In this study, the value of R 2 adjusted (0.83, 0.92, and 0.86 for biomass productivity, lipid content, and lipid productivity, respectively) was also high and gives a high correlation between the actual and predicted values as well as confirming the model validity. The R 2 predicted measures how good the model predicts the values of the response. The R 2 predicted and R 2 adjusted should be within 0.2 close to each other to be in reasonable agreement (Kazemi-Beydokhti et al. 2015). The values of R 2 predicted (0.64, 0.83, and 0.66 for biomass productivity, lipid content, and lipid productivity, respectively) are in a sensible covenant with the values of R 2 adjusted and indicate that the model was used to explain the data well. The signal to noise ratio was measured by adequate precision, and its value can be predicted by statistical analysis. A ratio greater than 4 is desired and shows adequate model discrimination (Haaland 1989). In the current study, the ratio of adequate precision is 10.95, 15.51, and 8.05 for biomass productivity, lipid content, and lipid productivity, respectively, which indicates a suitable signal; thus, the model can be applied to navigate the space of design. The variation coefficient (CV) is the standard error of the estimate ratio to the mean value of observed response. Sen and Swaminathan (2004) reported that, in general, the higher the CV value, the lower is the reliability of the experiment while low CV value predicts reliability and accuracy of the experiments conducted. The value coefficient of variation in this study was found to be 13.8, 10.4, and 11.33% of biomass productivity, lipid content, and lipid productivity, respectively, indicating a greater degree of precision (Table 4).

Effect of Interactive Variables

Three factors such as NaCl, NaNO3, and KH2PO4 at three-level Box-Behnken design were used to examine the process variables on the biomass and lipid productivity of A. gracilis. The 3D response surface plot is a graphical representation of the regression equation. It is plotted to examine the interactive effects between the two factors and keeping the third factor constant (in turn its central level), and also to determine the optimal level of each variable for a maximal response (Yetilmezsoy et al. 2009) (Figs. 1 and 2). Figure 1a shows the effects of NaCl and NaNO3 levels separately and their mutual interaction on biomass productivity. The increase in concentrations of NaNO3 enhanced the biomass productivity, but it was almost constant when NaCl concentrations were increased at a fixed KH2PO4 concentration. ANOVA analysis showed that nitrogen was the high statistically significant effect on the biomass productivity (p = 0.01). Figure 1b indicates that the increase in concentrations of KH2PO4 enhanced the biomass productivity initially, but then, with increasing its concentrations further, which exceed 0.03 gl−1, the biomass productivity could decrease. The reversible trend occurred in the case of NaNO3 concentrations at a fixed NaCl concentration. The highest response value was observed at 0.03 and 1 gl−1 of KH2PO4 and NaNO3, respectively. In this respect, Shen et al. (2015) reported that the highest biomass productivity was observed under sufficient phosphorus conditions. Both nitrogen and phosphorus showed positive effects in linear terms, but a negative effect was observed with phosphorus in its quadratic terms. The biomass productivity was increased when KH2PO4 and NaCl concentrations were increased at a fixed NaNO3 concentration (Fig. 1c). This indicates that the interaction between KH2PO4 and NaCl did have a significant effect on biomass productivity under phosphorus sufficiency. Figure 2a–c shows the influence of process variables on the lipid productivity of A. gracilis. The lipid productivity was increased when NaCl and nitrogen concentrations were increased at a constant phosphorus concentration, then reduced by increasing the concentrations of NaCl (Fig. 2a).

The effect of nitrogen and phosphorus concentrations on the lipid productivity at a NaCl concentration of 2.13 M is provided in Fig. 2b. At first, an increase in lipid productivity was observed with the increasing of nitrogen and phosphorus concentration. However, the trend was reversed when the concentrations of phosphorus reached a certain value. It could be seen from Fig. 2b and Table 4 that lipid productivity was affected significantly by nitrogen concentration. There was evidence to propose that the deficiency of nitrogen could stimulate the accumulation of lipids (Welter et al. 2013). However, this phenomenon was not observed under the applied experimental conditions, whereas NaNO3 had a positive effect on lipid productivity (Table 4) (Yang et al. 2014). Furthermore, although the lipid productivity was increased with the increasing nitrogen concentration, the NaNO3 contribution was low (1.9%) (Table 4). These results are in agreement with El-Sheekh et al. (2013) who stated that nitrogen starvation reduced the lipid productivity due to the inhibition of growth, although the lipid content increased for about 50 %. Figure 2c represents the effects of NaCl and phosphorus concentration individually and their mutual interactions on the lipid productivity of A. gracilis at a constant nitrogen concentration of 0.5 gl−1. At the designed range of NaCl concentration from 1.25 to 3 M, the lipid productivity resulted in a linear increase in phosphorus concentration and then reduced. It can be concluded that lipid productivity was affected by the combination of NaCl and phosphorus concentration. From ANOVA analysis of lipid productivity, it can infer that nitrogen exhibited the most important factor (p = 0.004) followed by NaCl (p = 0.057). NaCl showed a negative non-significant effect in linear terms (p > 0.05) but showed a negative significant effect in quadratic terms (p = 0.01). Nitrogen exhibited a positive significant effect, but phosphorus showed a non-significant negative effect in linear terms (p > 0.05) and a significant negative effect in quadratic terms (p = 0.006).

Experimental Validation of the Optimized Conditions

In order to confirm the predicted results, the culture of A. gracilis was studied using the optimized nutrient levels. The optimum conditions for the selected parameters were predicted using desirability function criteria available in the design expert software. The maximum predicted biomass productivity, lipid content, and lipid productivity could be achieved with NaCl concentration of 1.36 M, nitrogen concentration of 1 g/L, and phosphorus concentration of 0 g/L. Triplicate experiments were performed under the above-mentioned optimized conditions and the mean values of actual data were compared with the predicted data. The mean values of biomass productivity, lipid content, and lipid productivity were 40.6 ± 3.1 mg/L/day, 39.3 ± 2.6%, and 15.9 ± 0.95 mg/L/day agreeing well with the predicted values 40.1 ± 3.9 mg/L/day, 43.6 ± 4.5%, and 14.6 ± 1.51 mg/L/day, respectively. The percentage prediction error was 1.2, 10.9, and 8.2% for the biomass productivity, lipid content, and lipid productivity, respectively. Consequently, the model developed was considered to be accurate and reliable for predicting the biomass productivity, lipid content, and lipid productivity from A. gracilis.

Fatty Acid Methyl Ester Analysis

The FAME composition analysis and properties of comparative fuel are very important for the selection of species for biodiesel production. In this study, the main fatty acids in A. gracilis were palmitoleic (C16:1 ω-7), palmitic (C16:0), linolenic (C18:3 ω-3), oleic (C18:1 ω-9), stearic (C18:0), linoleic (C18:2 ω-6), and eicosapentaenoic acid (EPA) (C20:5 ω-3). Among them, palmitic acid and oleic acid were accounted for the largest proportion (61%) of the total fatty acids present in the microalgal lipids (Fig. 3). These results were in agreement with Knothe (2009) who reported that the most common fatty acids of microalgal species are C16:0, C18:0, C18:1 ω-9, C18:2 ω-6, and C18:3 ω-3. Ördög et al. (2016) reported that the FAME profiles were similar in the three Chlorella strains—namely C. sp. MACC-438, C. minutissima MACC-452, and C. sp. MACC728 with the predominant fatty acids being C16:0 > C18:1 ω-9 > unidentified FAMEs > C18:2 ω-6 > C18:3 ω-3 > C18:0 which accounted for over 90% of the total FAME content. The fatty acid percentage in A. gracilis shows the total content of medium chain fatty acids such as C16 and C18 (Fig. 3) that ensures the suitability for the production of biodiesel as these fatty acids have better stability to oxidation (Mandotra et al. 2014). The percentage of total saturated fatty acids and monounsaturated in A. gracilis was 67.36%, while the polyunsaturated fatty acid percentage was 32.63% (Table 5). These results are in agreements with Karpagam et al. (2015) who reported that the total saturated fatty acids and monounsaturated in Coelastrella sp. M-60 was 67.8 ± 0.9%.

The algal fatty acid methyl esters were composed of more unsaturated fats, which are more appropriate for cold weather use due to a usually lower gel point (Belarbi et al. 2000).

Fuel Properties of Biodiesel

The properties of biodiesel fuel such as saponification value, cetane number, iodine value, higher heating value, kinematic viscosity, and oil density were tabulated in Table 5. These properties are confirmed by the concentration and type of the resultant fatty acid methyl esters (Knothe 2008). The saponification value (milligrams number of KOH required to saponify 1 g of oil) is used to calculate the cetane number of the fuel. The saponification value of A. gracilis was 193.7 mgKOHg−1oil, which is equal to Coelastrella sp. M60 (194.5 mgKOHg−1oil) (Karpagam et al. 2015). The cetane number of a fuel is related to the combustion delay time, which is the time between injection and combustion; in addition, the combustion quality increases with the increase in saturated fatty acid content in the oil, i.e., the cetane number increases in fuels with high amounts of saturated fatty acids (Nascimento et al. 2013). The higher the cetane number, the shorter the ignition delay time, and vice versa) Gopinath et al. 2009(. Cetane number was obtained in this study as 51.14 ensures the better combustion quality of the fuel, since the minimum limit for cetane number is 47 as per the international standard (ASTMD6751-02). Different microalgal species were screened by Islam et al. (2013) for biodiesel production; they reported that the cetane number of Biddulphia sp., Nannochloropsis oculata, and Extubocellulus was 52.5, 55.0, and 57.8, respectively, and these were the only species meeting the EN14214 and ASTM D6751-02 biodiesel standards. The iodine value is the measure of numbers of the double bond in the fatty acid (Nascimento et al. 2013). The iodine value of A. gracilis (103.7 g I2100 g−1) was compliant with the biodiesel standards and almost equal to Oocystis IA1 (110.0 g I2100 g−1) and Botyrococcus YA5 (111.2 g I2100 g−1) (Ogbonna and Ogbonna 2015). Viscosity is a significant fuel property regarding in-use biodiesel performance since it affected the operation of the injection equipment of fuel. Viscosity increases with increasing chain length of fatty acid and saturation degree (Hoekman et al. 2012). The kinematic viscosity value in this study was 3.69 mm2/s, which are compliant with the two-biodiesel standards. Furthermore, the density derived from fatty acid methyl esters of A. gracilis (0.88 g/cm3) was within the range of a standard value that has been set at 0.86–0.90 g/cm3 according to EN 14214. The fatty acid methyl ester-derived higher heating value of A. gracilis investigated was 39.6 (MJ/kg) which are equal to Botryococcus braunii (39.6 MJ/kg) and Desmodesmus brasiliensis (39.0 MJ/kg) (Islam et al. 2013). Hence, the biodiesel from A. gracilis having a relatively high content of polyunsaturated fatty acids attributes poor performance in the cold countries, but can be readily used in tropical regions due to its optimum cetane number, saponification value, and iodine value.

Conclusion

In this study, A. gracilis has been evaluated for biodiesel production, and the response surface methodology was applied to optimize the medium compositions for maximal biomass productivity, lipid content, and lipid productivity. The medium containing 1.34 M NaCl, 1 g/L nitrogen, and 0.0 g/L phosphorus was considered as the optimal medium, which enhanced biomass productivity, lipid content, and lipid productivity than the initial medium. Consequently, the fuel properties of biodiesel obtained from A. gracilis were found in concurrence with the International Standards (ASTMD6751-02 and EN 14214). Furthermore, the results confirmed that the response surface methodology was beneficial for improving the biomass productivity, lipid content, and productivity of the microalga, A. gracilis.

References

Alyabyev AJ, Loseva NL, Gordon LK, Andreyeva IN, Rachimova GG, Tribunskih VI, Ponomareva AA, Kemp RB (2007) The effect of changes in salinity on the energy yielding processes of Chlorella vulgaris and Dunaliella maritima cells. Thermochim Acta 458:65–70

Battah M, El-Ayoty Y, Abomohra AEF, El-Ghany SA, Esmael A (2013) Optimization of growth and lipid production of the chlorophyte microalga Chlorella vulgaris as a feedstock for biodiesel production. World Appl Sci J 28:1536–1543

Belarbi EH, Molina E, Chisti Y (2000) A process for high yield and scaleable recovery of high purity eicosapentaenoic acid esters from microalgae and fish oil. Enzym Microb Technol 26:516–529

Ben-Amotz A, Grunwald T (1981) Osmoregulation in the halotolerant alga Asteromonas gracilis. Plant Physiol 67:613–616

Borowitzka MA (1988) Algal growth media and sources of cultures. In: Borowitzka MA, Borowitzka LJ (eds) Micro-algal biotechnology. Cambridge University Press, Cambridge, pp 456–465

Breuer G, Lamers PP, Martens DE, Draaisma RB, Wijffels RH (2012) The impact of nitrogen starvation on the dynamics of triacylglycerol accumulation in nine microalgae strains. Bioresour Technol 124:217–266

Chisti Y (2007) Biodiesel from microalgae. Biotechnol Adv 25:294–306

Converti A, Casazza AA, Ortiz EY, Perego P, Del Borghi M (2009) Effect of temperature and nitrogen concentration on the growth and lipid content of Nannochloropsis oculata and Chlorella vulgaris for biodiesel production. Chem Eng Process Process Intensif 48:1146–1151

Derringer G, Suich R (1980) Simultaneous optimization of several response variables. J Qual Technol 12:214–219

Drevon B, Schmitt JM (1964) La reaction sulfophosphovanillique dans l’ét.ude des lipides seriques. Bull Trau Soc Pharm Lyon 8:173–178

Duong VT, Li Y, Nowak E, Schenk PM (2012) Microalgae isolation and selection for prospective biodiesel production. Energies 5:1835–1849

El-Sheekh M, Abomohra A, Hanelt D (2013) Optimization of biomass and fatty acid productivity of Scenedesmus obliquus as a promising microalga for biodiesel production. World J Microbiol Biotechnol 29:915–922

Fan J, Cui Y, Wan M, Wang W, Li Y (2014) Lipid accumulation and biosynthesis genes response of the oleaginous Chlorella pyrenoidosa under three nutrition stressors. Biotechnol Biofuels 7:1

Feng P, Deng Z, Fan L, Hu Z (2012) Lipid accumulation and growth characteristics of Chlorella zofingiensis under different nitrate and phosphate concentrations. J Biosci Bioeng 114:405–410

Gopinath A, Puhan S, Nagarajan G (2009) Relating the cetane number of biodiesel fuels to their fatty acid composition: a critical study. Proc Inst Mech Eng Part D J Automob Eng 223:565–583

Griffiths MJ, Harrison STL (2009) Lipid productivity as a key characteristic for choosing algal species for biodiesel production. J Appl Phycol 21:493–507

Haaland PD (1989) Experimental Design in Biotechnology. Marcel Dekker, New York

Hoekman SK, Broch A, Robbins C, Ceniceros E, Natarajan M (2012) Review of biodiesel composition, properties, and specifications. Renew Sust Energ Rev 16:143–169

Islam MA, Magnusson M, Brown RJ, Ayoko GA, Nabi MN, Heimann K (2013) Microalgal species selection for biodiesel production based on fuel properties derived from fatty acid profiles. Energies 6:5676–5702

Kaewkannetra P, Enmak P, Chiu TY (2012) The effect of CO2 and salinity on the cultivation of Scenedesmus obliquus for biodiesel production. Biotechnol Bioprocess Eng 17:591–597

Kalsoom U, Boyce MC, Bennett IJ, Veraplakorn V (2013) Simultaneous determination of key Osmoregulants in halophytes using HPLC–ELSD. Chromatographia 76:1125–1130

Karpagam R, Raj KJ, Ashokkumar B, Varalakshmi P (2015) Characterization and fatty acid profiling in two fresh water microalgae for biodiesel production: lipid enhancement methods and media optimization using response surface methodology. Bioresour Technol 188:177–184

Kazemi-Beydokhti A, Azizi Namaghi H, Asgarkhani H, Zeinali Heris S (2015) Prediction of stability and thermal conductivity of SnO2 nanofluid via statistical method and an artificial neural network. Braz J Chem Eng 32:903–917

Klopfenstein W (1982) Estimation of cetane index for esters of fatty acids. J Am Oil Chem Soc 59:531–533

Knothe G (2008) Designer Biodiesel: Optimizing Fatty Ester Composition to Improve Fuel Properties. Energy Fuel 22:1358–1364

Knothe G (2009) Improving biodiesel fuel properties by modifying fatty ester composition. Energy Environ Sci 2:759–766

Li X, Hu HY, Gan K, Sun YX (2010) Effects of different nitrogen and phosphorus concentrations on the growth, nutrient uptake, and lipid accumulation of a freshwater microalga Scenedesmus sp. Bioresour Technol 101:5494–5500

Li YQ, Horsman M, Wang B, Wu N, Lan CQ (2008) Effects of nitrogen sources on cell growth and lipid accumulation of green alga Neochloris oleoabundans. Appl Microbiol Biotechnol 81:629–636

Lin Q, Gu N, Lin J (2012) Effect of ferric ion on nitrogen consumption, biomass and oil accumulation of a Scenedesmus rubescens-like microalga. Bioresour Technol 112:242–247

Liu ZY, Wang GC, Zhou BC (2008) Effect of iron on growth and lipid accumulation in Chlorella vulgaris. Bioresour Technol 99:4717–4722

Mandotra SK, Kumar P, Suseela MR, Ramteke PW (2014) Freshwater green microalga Scenedesmus abundans: a potential feedstock for high quality biodiesel production. Bioresour Technol 156:42–47

Mittal S, Kumari N, Sharma V (2012) Differential response of salt stress on Brassica juncea: photosynthetic performance, pigment, proline, D1 and antioxidant enzymes. Plant Physiol Biochem 54:17–26

Montgomery DC (2005) Design and analysis of experiments, sixth edn. Wiley, Hoboken

Mujtaba G, Choi W, Lee CG, Lee K (2012) Lipid production by Chlorella vulgaris after a shift from nutrient-rich to nitrogen starvation conditions. Bioresour Technol 123:279–283

Murthy MSRC, Swaminathan T, Rakshit SK, Kosugi Y (2000) Statistical optimization of lipase catalyzed hydrolysis of Methyloleate by response surface methodology. Bioprocess Eng 22:35–39

Myers RH, Montgomery DC (2002) Response surface methodology: process and product optimization using designed experiments, 2nd edn. New York, Wiley

Nascimento IA, Marques SSI, Cabanelas ITD, Pereira SA, Druzian JI, De Souza CO, Vich DV, De Carvalho GC, Nacimento MA (2013) Screening microalgae strains for biodiesel production: lipid productivity and estimation of fuel quality based on fatty acid profiles as selective criteria. Bioenerg Res 6:1–13

Ogbonna IO, Ogbonna JC (2015) Isolation of microalgae species from arid environments and evaluation of their potentials for biodiesel production. Afr J Biotechnol 14:1598–1604

Ördög V, Stirk WA, Bálint P, Aremu AO, Okem A, Lovász C, Molnár Z, van Staden J (2016) Effect of temperature and nitrogen concentration on lipid productivity and fatty acid composition in three Chlorella strains. Algal Res 16:141–149

Ramos MJ, Fernandez CM, Casas A, Rodriguez L, Perez A (2009) Influence of fatty acid composition of raw materials on biodiesel properties. Bioresour Technol 100:261–268

Reed RH, Walsby AE (1985) Changes in turgor pressure in response to increases in external NaCl concentration in the gas-vacuolate cyanobacterium Microcystis sp. Arch Microbiol 143:290–296

Rippka R, Deruelles J, Waterbury JB, Herdman M, Stanier RY (1979) Generic assignments, strain histories and properties of pure cultures of cyanobacteria. J Gen Microbiol 111:1–61

Sen R, Swaminathan T (2004) Response surface modeling and optimization to elucidate and analyze the effects of inoculums age and size on surfactin production. Biochem Eng J 21:141–148

Sforza E, Bertucco A, Morosinotto T, Giacometti GM (2012) Photobioreactors for microalgal growth and oil production with Nannochloropsis salina: from lab-scale experiments to large-scale design. Chem Eng Res Des 90:1151–1158

Sharma P, Singh L, Dilbaghi N (2009) Optimization of process variables for decolorization of disperses yellow 211 by Bacillus subtilis using box-Beknken design. J Hazard Mater 169:1024–1029

Sheehan J, Dunahay T, Benemann J, Roessler P (1998) A look back at the US Department of Energy’s aquatic species program: biodiesel from algae; close-out report. National Renewable Energy Lab., Golden, CO. (US)

Shen XF, Liu JJ, Chu FF, Lam PK, Zeng RJ (2015) Enhancement of FAME productivity of Scenedesmus obliquus by combining nitrogen deficiency with sufficient phosphorus supply in heterotrophic cultivation. Appl Energy 158:348–354

Sousa C, de Winter L, Janssen M, Vermue MH, Wijffels RH (2012) Growth of the microalgae Neochloris oleoabundans at high partial oxygen pressures and sub-saturating light intensity. Bioresour Technol 104:565–570

Timmins M, Zhou W, Lim L, Thomas-Hall SR, Doebbe A, Kruse O, Hankamer B, Marx UC, Smith SM, Schenk PM (2009) The metabolome of Chlamydomonas reinhardtii following induction of anaerobic H2 production by sulphur deprivation. J Biol Chem 284:23415–23425

Vicente G, Bautista LF, Gutiérrez FJ, Rodríguez RA, Martínez V, Rodríguez-Frómeta RA, Ruiz-Vázquez RM, Torres-Martínez S, Garre V (2010) Direct transformation of fungal biomass from submerged cultures into biodiesel. Energy Fuel 24:3173–3178

Vicente G, Bautista LF, Rodríguez R, Gutiérrez FJ, Sádaba I, Ruiz-Vázquez RM, Torres-Martínez S, Garre V (2009) Biodiesel production from biomass of an oleaginous fungus. Biochem Eng J 48:22–27

Welter C, Schwenk J, Kanani B, Blargan JV, Belovicha JM (2013) Minimal medium for optimal growth and lipid production of the microalgae Scenedesmus dimorphus. Environ Prog Sustain Energy 4:937–945

Yang F, Long L, Sun X, Wu H, Li T, Xiang W (2014) Optimization of medium using response surface methodology for lipid production by Scenedesmus sp. Mar Drugs 12:1245–1257

Yeesang C, Cheirsilp B (2011) Effect of nitrogen, salt, and iron content in the growth medium and light intensity on lipid production by microalgae isolated from freshwater sources in Thailand. Bioresour Technol 102:3034–3040

Yeh KL, Chang JS (2012) Effects of cultivation conditions and media composition on cell growth and lipid productivity of indigenous microalga Chlorella vulgaris ESP-31. Bioresour Technol 105:120–127

Yetilmezsoy K, Demirel S, Vanderbei RJ (2009) Response surface modeling of pb (ii) removal from aqueous solution by Pistacia vera L.: box-Behnken experimental design. J Hazard Mater 171:551–562

Yilancioglu K, Cokol M, Pastirmaci I, Erman B, Cetiner S (2014) Oxidative stress is a mediator for increased lipid accumulation in a newly isolated Dunaliella salina strain. PLoS One 9:e91957

Zhao G, Yu J, Jiang F, Zhang X, Tan T (2012) The effect of different trophic modes on lipid accumulation of Scenedesmus quadricauda. Bioresour Technol 114:466–471

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

ESM 1

(DOCX 36 kb)

Glossary

- C16:0

-

palmitic acid.

- C16:1 ω-7

-

palmitoleic acid.

- C18:0

-

stearic acid.

- C18:1 ω-9

-

oleic acid.

- C18:2 ω-6

-

linoleic acid.

- C18:3 ω-3

-

linolenic acid.

- C20:5 ω-3

-

eicosapentaenoic acid (EPA).

- CN

-

cetane number.

- CV

-

variation coefficient.

- HHV

-

higher heating value (MJ/kg).

- IV

-

iodine value (g I2 100 g−1 fat).

- SV

-

saponification value (mg/KOH/g).

- ρ

-

oil density (gcm−3).

- υ

-

kinematic viscosity (mm2/s).

Rights and permissions

About this article

Cite this article

Fawzy, M.A. Fatty Acid Characterization and Biodiesel Production by the Marine Microalga Asteromonas gracilis: Statistical Optimization of Medium for Biomass and Lipid Enhancement. Mar Biotechnol 19, 219–231 (2017). https://doi.org/10.1007/s10126-017-9743-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10126-017-9743-y