Abstract

This study reports the synthesis, characterization and applicability of surface-modified biochar, an eco-friendly and economic adsorbent for the removal of highly toxic hexavalent chromium from drinking water at a pH suitable for drinking water. The acid modification of the pristine biochar prepared by the pyrolysis of rice husk substantially enhanced the carbon content percentage by 25.29% and active sites by 10 times in the acid-modified biochar and produced a BET surface area of 142.78 ± 2.57 m2 g−1. Furthermore, the alteration of the surface of pristine biochar resulted in the substantial increase in C=C, C=O, C–O, phenolic and alcoholic –OH bonds on the surface of the biochar which further facilitated the adsorption of Cr. The batch adsorption study was carried out to comprehend the process of adsorption. The Freundlich isotherm model has been found to be describing the adsorption process most precisely. The maximum adsorption capacity has been found to be 4109 μg g−1 at 30 °C and 4536 μg g−1 at 50 °C from the analysis of approximate adsorption site energy distribution function. The analysis of approximate adsorption site energy distribution function further showed the availability of more energetic sites to the adsorbate Cr(VI) oxyanions at higher temperatures. Further, the endothermic nature of the adsorption apart from the experimental outcomes has been evinced from the D–R isotherm model and from the values of ∆G° and ∆H°. The negative values of ∆G° at all the experimental temperatures indicate the spontaneity of the adsorption process. Furthermore, the values of ∆G° more than − 20 kJ mole−1 indicate the physisorption of Cr(VI) oxyanions on the adsorbent surface.

Graphical abstract

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Contamination of groundwater by various contaminants has been a matter of concern all over the globe in the past and present centuries. Water contaminants can easily cause mass poisoning as the entire human civilization is dependent on water. Besides, several water contaminants have severely threatened the aquatic ecosystem as well. Chromium is one such egregious water contaminant that has raised its gruesomeness and posed a serious threat to the human civilization. In general, in the surface and groundwater, chromium is present in +III and +VI oxidation states, while Cr(VI) is known to be highly mobile because of its weak adsorption onto the adsorbate surface (Wu et al. 2013; Zheng et al. 2015) and very toxic to humans (Sugashini and Begum 2013). Whereas, Cr(III) is comparatively immobile and 10–100 times less toxic than Cr(VI) (Robles-Camacho and Armienta 2000; Villalobos-Aragón et al. 2012). Cr(III) is considered to be poorly soluble in aqueous solution and not permeable to the living cells, whereas, Cr(VI) is highly soluble in the aqueous medium, permeable to the living cells probably due to its resemblance to the sulfate ions (Saikia et al. 2014), and highly reactive toward the living cells (Naz 2017). Ingestion of Cr(VI)-rich water for a prolonged time could cause gastro-intestinal malfunctioning, liver diseases, cytotoxicity, hemotoxicity, and moreover, Cr(VI) is well known for its mutagenic and carcinogenic activities (Costa 1997; Barceloux and Barceloux 1999; Saikia et al. 2014; Naz et al. 2016). In India, for effluent discharges, the maximum tolerable limit of hexavalent Cr in inland surface water and public sewers has set to be 100 ppb and 2 ppm, respectively, by the MOEFCC, Government of India, whereas for drinking water, the maximum permissible limit for total chromium has been set to be 50 ppb by Bureau of Indian Standards, WHO, and USEPA (IS 10500 2009; World Health Organization 2011).

Apart from the geogenic sources, the anthropogenic sources like the tannery industries, chrome steel manufacturing units, paint and pigment (such as lead chromate) production units, chromium wood preservative manufacturing unit, chromium mining and smelting industries contribute an enormous amount of chromium into the environment (Oliveira 2012; Cheng et al. 2014). The chromium content released into the environment can pollute the surface water either directly or indirectly. The scenario becomes even worse when it reaches the groundwater underneath the earth. Contamination of chromium in groundwater can easily act as a mass poisoning agent as millions of people find it as the sole source of drinking water. One such case could be seen in the Indian state of Odisha where the Sukinda chromite mines have been contributing chromium to the groundwater for several years. Leaching of Cr from the mining overburden at the rainy seasons contaminates the groundwater present underneath the mining area (Dhakate et al. 2008; Samuel et al. 2012). The concentration of Cr(VI), the most toxic form of Cr, in groundwater of the Sukinda mining area has been recorded as high as 1.35 ppm (Naz et al. 2016)! Therefore, the urge is to provide Cr-free drinking water to the dwellers of the chromium-affected areas. To provide safe groundwater to the comparatively economically backward people of chromium-affected areas like the Sukinda mining area, an eco-friendly and cost-effective technology for the household drinking water treatment process has to be developed.

Adsorption of water contaminant from water by various adsorbents has been an age-old technique and often is considered to be an apt, eco-friendly and cost-effective way to treat the drinking water. However, the choice of suitable adsorbent is the key to achieve a fruitful adsorption practice. Along with the other agro-industrial wastes like sugarcane bagasse, vegetable peels, tree leaves and barks, rice husk has extensively been used as adsorbent for the distillation of water from the water contaminants. Moreover, these are also considered as the low-cost and eco-friendly adsorbents. However, these green adsorbents in its primitive states can hardly adsorb a substantial amount of adsorbates from water, and therefore, it requires some physicochemical treatment to enhance the adsorption capacities of these adsorbents. Although surface modification of these adsorbents by physicochemical treatments has been proven fruitful in many cases like the adsorption of industrial dyes, organic matters, pesticides, (Bhatnagar and Sillanpää 2010; Chowdhury et al. 2011; Chakraborty et al. 2011), we have not found it suitable for adsorption of Cr from water. Synthesis of biochar from the green agro-industrial wastes and its subsequent application as adsorbent could help us to get rid of the problem. Biochar, a carbon-rich byproduct synthesized through pyrolysis of biomass at relatively low temperature (300–700 °C) in an environment with limited oxygen, is considered as a low-cost, eco-friendly and economic adsorbent and has successfully been utilized to adsorb various water contaminants like dye, organic matter, pesticides, fluoride, nitrate-phosphate, heavy metals from water with a greater proficiency than that of the raw agro-industrial wastes (Liu et al. 2015b; Rajapaksha et al. 2016). It has also been used to decontaminate the air as well. Moreover, surface modification of the biochar by a feasible chemical process like acid treatment further enhances the adsorption capacity of the biochar by incorporating highly active –COOH, C=O, C–O, phenolic and alcoholic –OH functional groups on the surface of the biochar. These functional groups eventually become the nucleation sites for the adsorbates like the heavy metals (Liu et al. 2015b; Rajapaksha et al. 2016). Furthermore, the surface modification of biochar is supposed to increase the active surface area of the pristine biochar enabling it to offer more sites for the adsorbate molecules to get adsorbed (Liu et al. 2015b). In this study, we report the synthesis of biochar from agro-industrial waste rice husk and subsequent surface modification by acid treatment and henceforth the utilization of the eco-friendly and low-cost acid-modified biochar (AMB) for the adsorption of Cr(VI) from drinking water. In addition, this study includes an elaborative adsorption isotherm, kinetic and thermodynamic study to elucidate the science lying behind the entire adsorption process. The approximate adsorption site energy distribution function has also been analyzed to realize the energetically heterogeneous nature of the AMB surface.

Experimental section

Materials and reagents

Rice husk was collected from the rice mills of Bhagalpur, Bihar, India. Sulfuric acid (H2SO4) (assay 98%) and sodium bicarbonate (NaHCO3) were procured from RANKEM, India. Hydrochloric acid (HCl) (assay 35%), sodium hydroxide (NaOH), potassium dichromate (K2Cr2O7) and ferrous sulfate heptahydrate (FeSO4.7H2O) were procured from Merck India. All the chemicals utilized were of analytical grade and used without any further purifications. Deionized (DI) water had been used throughout the study for preparing all the reagents and solutions.

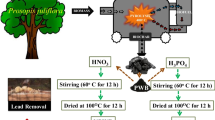

Synthesis of biochar from rice husk

The as-procured rice husk was first sieved with a mechanical sieving machine to select only the rice husk with length ranging in between 3 and 4 mm. Five hundred grams of the sieved rice husk was then washed thoroughly with 3 L of distilled water to remove any kind of dirt and debris adhering to the rice husk. Afterward, the washed rice husk was dried in open air and stored in an airtight polythene zipper sack for further use. The cleaned and dried rice husk was subsequently placed in a 100-mL silica crucible with a lid on the top and kept in a muffle furnace at 520 °C for 2 h. After cooling, the black-colored biochar was collected and stored in another airtight polythene zipper sack for further use.

Synthesis of acid-modified of biochar (AMB)

The as-prepared biochar was first pulverized with a porcelain mortar pestle and sieved with a 1-mm sieve. Each gram of crushed biochar was mixed vigorously with 50 mL of 8 M H2SO4 by a magnetic stirrer for 6 h and then placed in a 100-mL stainless steel Teflon liner autoclave and heated at 140 °C for 2 h in a hot air oven. This process, firstly, increases the carbon content in the biochar by lowering down the metal content present in the biochar, and secondly, it incorporates an enormous number of active sites on the surface of the biochar which act as a nucleation site for the adsorbates as discussed earlier. The as-modified AMB was washed with copious amount of DI water to remove every trace of H2SO4 from the AMB. It was then oven-dried at 110 °C for 12 h and stored in an airtight polythene zipper sack.

Estimation of loss on ignition (LOI) and ash content in rice husk

The LOI is the measure of the content of volatile organic carbon (VOC) in a biomass (Kalderis et al. 2008). The high value of LOI indicates the presence of a higher amount of organic carbon in the biomass. The LOI was estimated initially by taking a certain amount of clean rice husk in a clean and dry silica crucible (mass of the crucible: mc) and placing that in a horizontal tube furnace at 110 °C for 6 h to demoisturize the rice husk. After measuring the mass of the crucible with the demoisturized rice husk (mi), the crucible was again heated at 550 °C for 2 h in the air at the horizontal tube furnace. After getting cooled, the crucible with rice husk residue was weighted (mf) and the LOI was estimated by using the following formula:

The ash content was also estimated by heating a certain amount of demoisturized rice husk at 700 °C for 2 h in the air in a horizontal tube furnace. The percentage of loss of mass due to heating at 700 °C gives a measure of the ash content in the rice husk sample. Further, the fixed carbon content was estimated by subtracting the ash content from the LOI.

Estimation of active sites on the AMB surface

The estimation of active sites present on the AMB surface was carried out by following the Boehm’s titration method (Boehm 1994; Shaffer et al. 1998). In actuality, it is a measure of the carboxylic (–COOH) and total acidic groups present in the surface of AMB. Briefly, 5 mg of AMB was added separately to 20 mL of 0.05 M NaOH and NaHCO3 solutions and stirred vigorously with a magnetic stirrer at 600 rpm for 48 h. Subsequently, the AMB was filtered out from the solution with 0.22-μm PVDF membrane filter papers and 10 mL of 0.05 M HCl was added to 10 mL of each filtrate. The excess amount of acid was titrated with 0.05 M NaOH. It is assumed that the NaHCO3 reacts only with the –COOH groups present on the AMB surface and lays bare a quantitative estimation of the –COOH groups. On the other hand, NaOH reacts with all the acidic groups present in the AMB and thus provides an estimation of the total acidic group present in the samples.

Characterization of AMB

The surface morphology of the AMB was investigated with a field emission scanning electron microscope (FESEM supra 55-Carl Zeiss), and the elemental composition was investigated by the energy-dispersive X-ray spectroscopy (EDS) analysis with an EDS machine (Oxford Instruments) attached to the FESEM machine. The chemical groups present in the samples were probed with Fourier transform infrared spectroscopy (FTIR) from 400 to 4000 cm−1 at room temperature (FTIR, PerkinElmer FTIR Spectrophotometer). The BET surface area of the AMB was estimated by nitrogen adsorption isotherm at − 196.018 °C temperature with micromeritics 3 Flex version 3.02. The zero point charge (pHzpc) of the AMB was estimated by the method described by Deng et al. (2010). Briefly, 30 mg of AMB was added to 10 mL of boiled DI water (DI water was boiled essentially to eliminate the dissolved CO2 from the water) and stirred at 600 rpm with a magnetic stirrer for 48 h. After that, the AMB was separated from the solution and the pH of the filtrate was measured with a digital pH meter (Hanna Instruments HI 98127). The room temperature zeta potential of the AMB in the DI water medium was estimated by a zeta potential analyzer (Zeta Meter system 4).

Adsorption study

The batch adsorption studies were carried out with different initial Cr(VI) concentrations, AMB doses, times, temperatures, and with the presence of competing materials like iron, sulfate, and bicarbonate. A Cr(VI) stock solution of 100 ppm was prepared by dissolving 28.27 mg of K2Cr2O7 in 50 ml of DI water, and then, the final volume of the solution was made up to 100 mL by adding DI water. Cr(VI) solution of different strength was obtained by appropriate dilution. The pH of the solution was not varied because either an acidic or an alkaline pH which although could enhance the adsorption efficiency, will not be suitable for drinking either. The measurement of aqueous Cr(VI) was carried out by a computerized atomic absorption spectroscopy machine (AAS-GBC Avanta PM).

Firstly, to estimate the equilibrium dose of AMB for the adsorption of 30 mL 750 ppb aqueous Cr(VI) solution, 5, 10, 15, 20, 25 and 30 mg of AMB were added individually to 30 mL 750 ppb aqueous Cr(VI) solution, and it was stirred with a magnetic stirrer at 500 rpm for 3 h at 30 °C. Afterward, the solutions were filtered and the remaining Cr(VI) concentrations were measured with AAS. The equilibrium contact time was estimated by carrying out the adsorption study of 30 mL 750 ppb aqueous Cr(VI) solution with the equilibrium AMB dose for 15, 30, 45, 60, 90, 120, 150 and 180 min. The effect of different Cr(VI) dose on the efficiency of the adsorption process was investigated by adding the equilibrium AMB dose to 30 mL aqueous Cr(VI) solutions with different strengths: 250, 500, 750, 1000, 2000 and 5000 ppb and stirring at 500 rpm for estimated equilibrium contact time. The effect of different solution temperatures (30, 40 and 50 °C) on the efficiency of removal of Cr(VI) was assessed by conducting the aforementioned experiments at 30, 40 and 50 °C temperatures. How the presence of FeSO4 and HCO3− affects the overall Cr(VI) removal efficiencies was investigated by preparing 30 mL aqueous solution with 100, 200 and 300 ppb of aqueous FeSO4͘ 7H2O and 750 ppb of Cr(VI) and by preparing 30 mL of aqueous solutions containing 100, 200 and 300 ppm of HCO3− and 750 ppb Cr(VI) solutions; in each case, equilibrium adsorbent dose for Cr(VI) was added and stirred for equilibrium contact time at 500 rpm. The removal percentage (R%) of Cr(VI) has been calculated by the following formula:

Further, the amount of Cr(VI) adsorbed per unit mass of adsorbent at equilibrium \(q_{\text{e}}\) (expressed in μg g−1) has been estimated by the following equation:

where C0, Ce, m and V represent the initial Cr(VI) concentration (in ppb or μg L−1), the equilibrium Cr(VI) concentration (in ppb or μg L−1), the mass of adsorbent used (in mg) and the volume of the solution (in mL), respectively.

Principles of adsorption, adsorption isotherm, adsorption site energy distribution, adsorption kinetics and adsorption thermodynamics

Adsorption is a physical or a chemical or a combination of both the physical and chemical process where the adsorbate molecules get attached to the surface of the adsorbate (Sarkar and Paul 2016). It is a surface phenomenon, and for physical adsorption, the adsorbates adhere to the adsorbent with relatively weaker van der Waal’s force (Dąbrowski 2001; Sarkar and Paul 2016), whereas in chemical adsorption process, the adsorbates attach to the adsorbent surface by the formation of chemical bonds and thus the adhesion becomes more strong (Sarkar and Paul 2016). However, in the case of adsorption of Cr(VI) on the AMB surface, the physical adsorption is supposed to have occurred. The surface area and the porosity of the mesoporous AMB play an important role in adsorbing the adsorbates (Heuchel et al. 1993; Yan and Niu 2017) such as the Cr(VI) oxyanions. The pH of the aqueous solution is often considered as an important factor in determining the efficiency of adsorption. Furthermore, the pH of the aqueous solution determines the speciation of oxyanions of Cr(VI) in water. The equilibrium that exists between different forms of oxyanions of Cr(VI) is as follows (Ding et al. 2016):

The speciation of Cr(VI) in aqueous medium confirms the existence of its anionic forms at every pH. Therefore, the adsorption of Cr(VI) on at the AMB surface should not be favored at a pH > pHzpc, and various studies have evinced that the adsorption of Cr(VI) is achieved best at an acidic pH (~ 2) (Ullah et al. 2013; Ma et al. 2014; Soliemanzadeh and Fekri 2017). However, contradicting to this, studies have also laid bare the instances where the adsorption of Cr(VI) by rice husk-made biochar is highly favorable at pH higher than the pHzpc (Ding et al. 2016). It is worthy to note that the pH suitable for drinking water is 6.5–8.5 (IS 10500 2009); therefore, the pH cannot be set to 2, when treatment of potable water is concerned. Hence, it is worth to understand the interaction of oxyanions of Cr(VI) on AMB surface at a pH suitable for drinking water. The adsorption of oxyanions of Cr(VI) on the negatively charged AMB surface could be assumed to be occurring due to the anion–π interactions, i.e., the interaction between the anions and the non-covalent electron deficient aromatic rings (Schottel et al. 2008) present on the AMB (although the aromatic rings without electron deficiency can do the same as well). However, this could happen for the adsorbents with a copious number of aromatic rings in it.

Adsorption isotherm

The process of adsorption is frequently studied with the lights of various adsorption isotherm models like the Langmuir isotherm, Freundlich isotherm, Dubinin–Radushkevich (D–R) isotherm model. In this study, the isotherm analyses were carried out by conducting adsorption of Cr(VI) at different concentrations with the equilibrium dose of AMB for equilibrium time at 30, 40 and 50 °C temperatures. The isotherms investigated are as follows:

The common Langmuir isotherm equation is given by (Vasanth Kumar and Sivanesan 2007; Sarkar and Paul 2016):

The linear form of Langmuir isotherm reads as:

where qm and KL represent maximum adsorption capacity and Langmuir constant, respectively. \(K_{\text{L}}\) is, however, a parameter which is indeed dependent on temperature related to the energy of adsorption (Carter et al. 1995). The unit of KL should actually be expressed in L mole−1 (Liu 2009), but it has been expressed as L g−1(Kobya 2004; Malkoc and Nuhoglu 2007; Weng et al. 2008; Chowdhury et al. 2011; Prabhakar and Samadder 2018). In this study, KL will be expressed as L μg−1 which, however, could be approximated in terms of L mole−1 by multiplying KL (in L μg−1) with (molar mass of Cr (52) × 106 μg mole−1). The slope and intercept of the plot between \(\frac{1}{{q_{\text{e}} }}\) and \(\frac{1}{{C_{\text{e}} }}\) represent \(\frac{1}{{K_{\text{L}} q_{\text{m}} }}\) and \(\frac{1}{{q_{\text{m}} }}\). From the Langmuir isotherm, a dimensionless quantity RL could be derived \(\left( {R_{\text{L}} = \frac{1}{{1 + K_{\text{L}} C_{0} }}} \right)\), the value of which indicates the feasibility of the adsorption process. 0 < RL < 1 reveals a favorable adsorption condition, whereas RL > 1 indicates an unfavorable adsorption condition (Foo and Hameed 2010; Sun et al. 2015; Prabhakar and Samadder 2018).

The Freundlich isotherm and its linearized forms are given below: (Vasanth Kumar and Sivanesan 2007; Sarkar and Paul 2016):

The linearized form of Freundlich isotherm is as follows:

where KF and n represent, respectively, the Freundlich constant and a parameter related to the heterogeneity of the adsorbent surface. The slope and intercept of the plot between \({ \log }(q_{\text{e}} )\) and \({ \log }(C_{\text{e}} )\) represent \(\frac{1}{n}\) and \({ \log }(K_{\text{F}} )\) respectively. A typical value of n in between 1 and 10 generally indicates a favorable condition for adsorption (Prabhakar and Samadder 2018). Although it is believed that \(K_{\text{F}}\) itself is a composite of three individual parameters, viz. the \(q_{\text{m}}\), an isotherm constant K and n, and is expressed by Eq. 11 (Sheindorf et al. 1981; Carter et al. 1995), it is hardly possible to derive \(q_{\text{m}}\) and K from the common Freundlich isotherm equation as it is expressed unambiguously as a two-parameter isotherm.

The linear form of (D–R) isotherm reads as (Chakraborty et al. 2011):

where β and ε represent the D–R isotherm constant (mmole2 J−2) and the Polanyi potential (J mmole−1), respectively. The ε is given by

where R and T are the ideal gas constant (0.008314 kJ mole−1 K−1) and the temperature in the Kelvin scale, respectively. The value of β provides an idea about the mean free energy \((\epsilon = \frac{1}{{\sqrt {2{\beta}}}} )\) of the adsorption process. The value of ϵ indicates the nature of the adsorption process, whether it is a physical adsorption (ϵ < 8 kJ mole−1) or a chemical adsorption process (ϵ ~ 8–16 kJ mole−1) (Chakraborty et al. 2011). The slope and intercept of the plot between \(\ln \left( {q_{\text{e}} } \right)\) versus \(\varepsilon^{2}\), respectively, represent β and \(\ln \left( {q_{\text{m}} } \right)\).

Adsorption site energy distribution

The approximate adsorption site energy distribution functions could be derived from the adsorption isotherms based on the condensation approximation as proposed by Cerofolini (1974), Kumar et al. (2011). The approximate site energy distribution functions are generally, not normalized and are expressed in terms of isotherm parameters (Carter et al. 1995). For each approximate adsorption site energy distribution functions, the area covered under the distribution function is governed by \(q_{\text{m}}\), the position of the distributions in energy axis is controlled by the adsorption isotherm constant, and the spread of the distribution functions is destined by the parameter related to the heterogeneity of the adsorbent surface, i.e., n (Carter et al. 1995; Kumar et al. 2011). The equilibrium Cr(VI) concentration, Ce, could now further be expressed under the assumptions of Cerofolini approximation and in terms of the energy of adsorption as:

or

where CS represents the maximum solubility of the solute in the solvent at a certain temperature and pressure. E is the difference between the solute and solvent adsorption energies for a certain site. ES denotes the value of adsorption energy corresponding to \(C_{\text{e}} = C_{\text{S}}\). Clearly, it is the lowest physically realizable adsorption energy. The magnitude of ES is dependent merely on the solute; the adsorbent has no role to play in it (Carter et al. 1995; Kumar et al. 2011).

Now, the approximate adsorption site energy distribution function F(E*) could be obtained by differentiating each adsorption isotherms (a function of E*) with respect to E*:

For a non-normalized site energy distribution function, the value of \(q_{\text{m}}\) could be estimated by integrating the site energy distribution function from \(E_{ \text{min} }^{ *}\) to \(E_{ \text{max} }^{ *}\) as given in Eq. 17, where \(E_{ \text{min} }^{ *}\) and \(E_{ \text{max} }^{ *}\) represent the experimentally derived lowest and highest values of E* for a given temperature, respectively.

Adsorption kinetics

The adsorption kinetics could be assessed with the Lagergren model (Eqs. 18–19) based on the pseudo-first-order kinetic model (Addo Ntim and Mitra 2012) and with the Ho and McKay model based on the pseudo-second-order kinetic model (Eqs. 20–22) (Hang et al. 2012; Ntim and Mitra 2012). The Lagergren model kinetic model is given by:

Integrating Eq. 18, we can derive:

where qt and k1 represent, respectively, the mass of adsorbate (Cr(VI)) adsorbed per unit mass of adsorbent (AMB) and the pseudo-first-order reaction rate constant. The term \(\ln \left( {q_{\text{e}} } \right)\) is actually the constant of integration. However, the intercept of the plot between \(\ln \left( {q_{\text{e}} - q_{t} } \right)\) and \(\ln \left( {q_{\text{e}} } \right)\) gives the value of k1.

Further, the Ho and McKay kinetic model is given by:

The integral form of Eq. 20 reads as

Rearranging Eq. 21 (multiplying the inverse of Eq 21 with t), the following is obtained

where k2 is the pseudo-second-order reaction rate constant. \(\frac{1}{{q_{\text{e}} }}\) is the constant of integration. The value of k2 can be determined from the plot between \(\frac{t}{{q_{t} }}\) and t.

The adsorption kinetics could well be comprehended from a mechanistic insight as well. For a rigorously agitated batch adsorption system, the diffusive mass transfer could be related to a diffusion coefficient which would fit the adsorption rate data obtained from experiments. An adsorption process is said to be a diffusion-controlled process should the adsorption rate depends on the rate at which the adsorbate and adsorbent diffuse toward each other (Fierro et al. 2008). The likeliness of intraparticle diffusion is investigated by the intraparticle diffusion model which is given by (Fierro et al. 2008; Chen et al. 2014a)

where \({k}_{\text{dif}}\) is the intraparticle diffusion rate constant and I is the constant related to the boundary layer thickness. The slope and intercept of the plot between \(q_{t}\) and \(t^{{\frac{1}{2}}}\), commonly known as the Weber–Morris plot, represent the \(k_{\text{dif}}\) and I, respectively.

Adsorption thermodynamics

The change in Gibbs free energy (∆G°) for the adsorption is representative to the spontaneity of the adsorption process, a negative value of which reflects an energetically more favorable adsorption. The ∆G° is given by (Liu 2009; Liu et al. 2015a)

where R, T and κc are the ideal gas constant, the temperature in Kelvin scale and a dimensionless thermodynamic equilibrium coefficient, respectively. The determination of κc from adsorption studies is often tricky and could be misleading (Liu 2009). However, the change in Gibbs’s free energy is related to the change in the enthalpy (∆H°) and in the entropy (∆S°) and is given by:

κc could approximately be represented by the Langmuir constant KL when a diluted solution with charged adsorbate is concerned (Weng et al. 2008; Liu 2009).

Results and discussion

Characterization

Analysis of the moisture content, LOI, ash content and fixed carbon content of the as-collected rice husk reveals that it contained 1.5% moisture, 77.5% VOC, 12% ash and 9% fixed carbon. The estimated active sites present on the surface of the biochar and AMB were ~ 1021 g−1 and ~ 1022 g−1, respectively. The increase in the number of active sites present on the AMB surface has been observed clearly due to the strong acid treatment process.

The FESEM micrographs (Fig. 1a and c) show the arbitrarily shaped granules of the biochar and the AMB, respectively. From the FESEM micrographs, it is evident that the acid treatment has not produced any visible deformations to the biochar particles. However, the presence of few highly porous particles could be observed in both the cases (Fig. 1b and d). The formation of such a porous structure could have been caused due to the ejection of gas from the core of rice husk in the time of pyrolysis. The alteration caused in the elemental composition can be observed from the EDS spectrum of the pristine biochar and AMB (Fig. 1e, f). The treatment of biochar with strong H2SO4 has substantially diminished the metal content by digesting the metallic constituents which further causes a substantial enrichment of carbon in the biochar, thus making it a more suitable adsorbent. The elemental compositions along with the corresponding weight percentages of the pristine biochar and AMB as analyzed by the EDS study are given in Supplementary Table 1. The presence of sulfur in the AMB could be considered to have appeared due to the addition of sulfates to the AMB due to the treatment with H2SO4. Further, the functional groups present in the biochar and AMB samples were analyzed from the FTIR spectra of the pristine biochar and AMB (Fig. 1g). The intense and broad peak within 1700–1600 cm−1 in AMB sample is representative to the C=O (carboxylic acid group) and C=O stretching in aromatic ring overlapped with the aromatic C=C bonds (Malkoc and Nuhoglu 2007; Xu et al. 2013). Compared to the less intense peak ca. 1600 cm−1 in pristine biochar, it, clearly evinces the substantial enhancement of C=O groups in the AMB due to the modification of the surface by strong acid. The peaks ca. 1100 cm−1 in both the samples represent the C–O–C symmetric stretching characteristic to the cellulose and hemicellulose (Lee et al. 2010) present in the materials. However, broadening and intensification of the peak ca. 1100 cm−1 in AMB can be observed due to the incorporation of phenolic and alcoholic –OH bonds (Qiu et al. 2015) into the sample due to the vigorous acid functionalization process. The peaks at 814 cm−1 for pristine biochar and the peak at 797 cm−1 for AMB sample roots from the aromatic C–H out of the plane vibration (Lee et al. 2010). The aromatic structure is believed to produce π-electrons which can bond with heavy metal ions strongly (Chen et al. 2014b). The distinct and sharp peak at 1401 cm−1 in pristine biochar represents the –CH2-structures that originate due to the decomposition of hydrocarbon chains and reduction of oxygen functional groups due to the temperature involved in the pyrolysis process (Chen et al. 2014b). However, a complete omission of this peak can be observed in the case of AMB. The prominent peak at 466 cm−1 in AMB represents the bending mode vibration of SiO2 (Tran et al. 2013). Finally, the prominent peaks at 3127 and 3404 cm−1 represent the asymmetric O–H vibration of water molecules present in them (Samsuri et al. 2013).

The BET surface area measured for the AMB was 142.78 ± 2.57 m2 g−1 (See Fig. S1) which is quite high compared to the other biochar made of animal manure, waste paper, bone dregs, water weeds, grass, fruit bunch (Xu et al. 2013; Samsuri et al. 2013; Liu et al. 2015b). Moreover, the BET surface area of AMB is even 5–6 times higher than that of typical pristine biochar made of rice husk which again evinces the superiority of AMB over the pristine biochar as an adsorbent. The surface charge neutrality can be obtained for AMB at a pH of 4.10 which probably indicates that at a pH more than 4.10, it would cause the abundance of negative charges on the surface of the AMB in the aqueous solution. The zeta potential measured for the AMB in aqueous solution (pH ~ 7) at 30 °C showed a value of − 99.52 μS cm−1 which again confirms the existence of negative charges on the surface of the AMB at a pH more than 4.10.

Analysis of the adsorption process

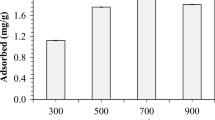

The equilibrium dose of AMB determined for treating 30 mL 750 ppb Cr(VI) solution was 20 mg, and a time period of 2 h was determined to be the equilibrium time for adsorption with the same amount of Cr(VI) solution and 20 mg dose of AMB at 30 °C (Fig. 2a). It has been found that a dose of 20 mg AMB can adsorb about 76% of Cr(VI) after 2 h, but after this period of time, no significant change in adsorption of Cr(VI) was observed. After the adsorption of Cr(VI) or any other adsorbate up to a certain level by an adsorbent, the concentration of Cr(VI) or any other adsorbate in the bulk solution gets reduced substantially which probably could not further support the transfer of adsorbate mass to the adsorbate–solution interface. Moreover, from the simple Fick’s law, it could be said that at a certain time t the amount of mass of a substance diffusing through a surface perpendicular to the direction of diffusion is proportional to the concentration gradient of the substance (Mostinsky 2011). Thus, when the concentration of Cr(VI) in bulk solution at a particular temperature falls down below a certain minimum (cutoff level), the mass flux (of Cr(VI)) to the adsorbate/solution interface practically becomes insignificant, and no further enhancement in the removal of Cr(VI) will be observed.

The increase in the solution temperature has been found to be very effective for the enhancement of the removal percentage.

By using the as-determined equilibrium AMB dose and adsorption time, further experiments were carried out to establish the adsorption isotherms, kinetic studies and to estimate the change in Gibb’s free energy that occurred during the process of adsorption. For all the solutions with different initial aqueous Cr(VI) concentrations and 20 mg of AMB dose, maximum removal was observed at a temperature of 50 °C (Fig. 2b). This advocates the endothermic nature of the adsorption of Cr(VI) on AMB. Furthermore, it is assumed that with the increase in solution temperature, the kinetic energy of the adsorbate molecules also increases which further led the adsorbate molecules to overcome the diffusion barrier (Bhatt et al. 2012; Sarkar et al. 2018) to come at the vicinity of the adsorbents and thereby get adsorbed. The decrease in the removal percentage of Cr(VI) by 20 mg of AMB with the increase in initial Cr(VI) concentrations at all the temperatures studied is also clear from Fig. 2b. However, in contrast, the value of qe increases with the increase in the initial Cr(VI) concentrations. This is expected as the higher concentration gradient of Cr(VI) prevailing in the solutions with higher initial Cr(VI) concentrations enhances the mass flux of Cr(VI) to the adsorbate/solution interface which further results in a higher degree occupancy of the adsorption sites by the adsorbate molecules.

To get an idea on the adsorption process, the linear forms of Langmuir, Freundlich and D–R isotherms have been plotted (Fig. 3) and the outputs from the respective isotherms have been analyzed (summarized in Supplementary Table 2).

a The linear Langmuir isotherm plot for the adsorption data obtained at 30, 40 and 50 °C. The linear fit of Langmuir isotherm for b 30 °C, c 40 °C and d 50 °C. e The linear Freundlich isotherm plots the adsorption data obtained at 30, 40 and 50 °C. The linear fit of Freundlich isotherm for f 30 °C, g 40 °C and h 50 °C. i The linear D–R isotherm plots the adsorption data obtained at 30, 40 and 50 °C. The linear fit of D–R isotherm for j 30 °C, k 40 °C and l 50 °C. (For all experiments C0 varied, t = 2 h; AMB dose = 20 mg 30 mL−1)

Although the experimental data fit extremely well with the linear form of the Langmuir isotherm, and the values of RL calculated for 750 ppb initial Cr(VI) concentration indicate a favorable circumstance for adsorption, the values of qm decreases with the increase of temperature which clearly disobeys the endothermic nature of the as-studied adsorption process. Therefore, it can be concluded that the Langmuir isotherm model fails to explain the adsorption process studied in this case. This is quite expected as the carbonaceous AMB contains energetically heterogeneous surface for adsorption which certainly disobeys one of the key assumptions of the Langmuir isotherm model which necessitates a homogeneous adsorbent surface for adsorption (Carter et al. 1995).

The D–R isotherm analysis clearly shows the endothermic nature of the adsorption process with a qm increasing with the increase in solution temperature in accordance with the endothermic nature. The values of ε ≪ 8 kJ mole−1 suggest physical adsorption of aqueous Cr(VI) on the AMB. However, the values of R2 prevent this model to be considered as the best one for describing the adsorption phenomena. However, it is also said that only a statistical parameter like R2 cannot be trustworthy in understanding the entire adsorption process, which indeed is very complex in nature (Liu 2009).

Fitting of the experimental data in the linear form of Freundlich isotherm gives a high degree of correlation and the values of n at every temperature point toward a favorable adsorption condition. Moreover, the value of KF increases with the increase in solution temperature confirming the endothermic nature of the adsorption process studied here. Therefore, it can be assumed that the adsorption process is best described by the Freundlich isotherm model, and thus, in this particular study it can be considered that multiple layers of Cr molecules form on the AMB surface during the adsorption process.

As, in this study, the Freundlich isotherm model has been found to be the most appropriate one to describe the adsorption of Cr(VI) on AMB, the approximate adsorption site energy distribution function F(E*) has been derived using the Freundlich isotherm equation and reads as (Carter et al. 1995):

The variation of adsorption site energy E* with the \(q_{\text{e}}\) s at different temperatures has been laid bare in Fig. 4a, and from this figure, it is evident that the site energy falls down exponentially with the increase in \(q_{\text{e}}\) which further suggests that the oxyanions of Cr(VI) first occupy the adsorption sites with higher energies at lower initial concentrations and then spread to the sites with lower energies at higher concentrations of Cr(VI) (Yan and Niu 2017). Furthermore, the increase in temperature enhances the adsorption site energies substantially and thereby provides higher energy sites to the oxyanions of Cr(VI) to occupy and which further, as a consequence, boosts the overall adsorption proficiency up. Thus, it could now be assumed that the increment in working temperature ameliorates the overall adsorption proficiency by enhancing the adsorption site energies of AMB along with providing the adsorbates (oxyanions of Cr(VI)) sufficient energies to overcome the diffusion barrier that screens the oxyanions of Cr(VI) from the AMB as discussed earlier. The rightward spread of F(E*) could also be found to have extended with the increase in the working temperature (Fig. 4b) which again confirms the enhancement in adsorbent surface heterogeneity as it had been found from Freundlich isotherm adsorption analysis. The exponential nature of the F(E*) derived using the Freundlich isotherm equation can easily be observed from the extrapolated approximate adsorption site energy distribution for the adsorption of Cr(VI) on AMB over a wide range of E* (Fig. 4c). The values of \(q_{\text{m}}\) at different experimental temperatures have been determined by integrating F(E*) within the experimentally determined minimum and maximums of E*, and it has been found that at 30 °C, \(q_{\text{m}}\) attains a value of 4109 μg g−1, whereas, as expected, at 40 and 50 °C it turns out to be 4340 μg g−1 and 4536 μg g−1, respectively. It is, however, at this point, interesting to note that with this procedure, the values of \(q_{\text{m}}\) could easily be determined which in fact, is hardly possible from the analysis of the Freundlich isotherm model.

a Variation of E* with qe at different temperatures, b the plot of approximate adsorption site energy distribution for the adsorption of Cr(VI) on AMB over the experimentally estimated E* at different temperatures, c extrapolated approximate adsorption site energy distribution for the adsorption of Cr(VI) on AMB over a wide range of E*; inset: same within the experimentally estimated E*

The kinetics of the adsorption process has been investigated using the integral form of the pseudo-first-order and pseudo-second-order kinetic models (Fig. 5a and b). The worked-out values of the parameters involved in each of the kinetic models are summarized in Table 1. Although the value of R2 for the pseudo-first-order kinetic model plot shows a good degree of fitting, a substantial deviation in the values of the \(q_{{{\text{e}}_{\text{calculated}} }}\) and \(q_{{{\text{e}}_{\text{experimental}} }}\) indicates that the adsorption of Cr(VI) on the AMB does not obey the pseudo-first-order kinetic model, whereas, with R2 = 0.99 and only a meager 7% deviation in the values of \(q_{{{\text{e}}_{\text{experimental}} }}\) and \(q_{{{\text{e}}_{\text{calculated}} }}\) the pseudo-second-order kinetic model could be assumed to be the kinetic model followed by the adsorption of Cr(VI) on AMB at 30 °C.

Further, to probe the role of intraparticle diffusion in controlling the rate of the adsorption process, the Weber–Morris plot has been plotted (Fig. 5c). The Weber–Morris plot clearly shows a couple of distinct regions in it. At the initial phase, the \(q_{\text{e}}\) versus \(t^{{\frac{1}{2}}}\) plot represents a straight line with a steeper slope (57.27). This indicates the occurrence of intraparticle diffusion as the rate-limiting step. This is expected as the AMB contains numerous pores and interstices within it and the adsorbate molecules/ions (such as oxyanions of Cr(VI)) diffuse into these spaces quite easily and eventually get adsorbed. The steeper slope also reveals a higher value of intraparticle diffusion coefficient, whereas, in the later stage, another straight line could be observed with a gentler slope (5.20). At this period, the pores and interstices within the AMB almost get filled with the adsorbate ions and they try to diffuse to the pores having the smallest dimensions in AMB, which indeed is very difficult to execute. At this point, the adsorption of oxyanion of Cr(VI) also reaches its equilibrium.

The thermodynamic parameters studied are summarized in Table 2. As the Langmuir model was found inappropriate to describe the adsorption process, the values of KL are worth nothing for the calculation of κc. Therefore, considering the low concentration of oxyanions of Cr(VI), the ratio between the Cr(VI) adsorbed on the AMB and the Cr(VI) that remained in the solution at equilibrium can approximate κc (Liu 2009; Chowdhury et al. 2011).

The negative value of ∆G° shows the spontaneity of the adsorption process at all the temperatures (Liu 2009; Chowdhury et al. 2011). Furthermore, the decrease in the values of ∆G° with the increment of temperature evinces the endothermic nature of the adsorption process, i.e., adsorption of Cr(VI) on AMB is favored at higher temperatures. Moreover, the positive value of ∆H° also vindicates the endothermic nature of the adsorption process (Sharma 2001; Al-Sou’od 2012). The endothermic nature may be explained by the requirement of energy for the dehydration of highly water-soluble Cr(VI) for getting adsorbed on the AMB surface (Al-Sou’od 2012). However, all the values of ∆G° determined in this study are less negative than − 20 kJ mole−1, and thus, it implies a physical adsorption process (Weng et al. 2008). The positive value of entropy indicates the feasibility of adsorption and denotes the increased randomness at the adsorbate/adsorbent interface during the adsorption process (Malkoc and Nuhoglu 2007; Al-Sou’od 2012).

Effect of FeSO4 and bicarbonates on the removal percentage of Cr(VI)

The interfering effects of metals and ions like iron, sulfate (as FeSO4) and bicarbonate (as NaHCO3) on the removal of Cr(VI) have been investigated, and it has been found that the presence of FeSO4 and HCO3− diminishes the removal efficacy of Cr(VI) by AMB (Fig. 6). This is probably because of the increased competition among the ions for the limited adsorption sites present on the AMB.

A comparison of the different adsorbents used to remove Cr(VI) from water is given in Table 3. However, it must be kept in mind that considering an adsorbent advantageous over the others merely on the basis of maximum adsorption capacity would be erroneous. The maximum adsorption capacity generally attains a higher value when the initial concentrations of the adsorbates are kept high. So, it is no wonder to observe a high qm when 10–100 ppm of Cr(VI) is treated rather than few ppb to 10 ppm. From Eq. 7, \(q_{\text{m}}\) could easily be found to have maximized when the \(q_{\text{e}}\) s increase for a certain KL. The same trend could also be observed from the integral of F(E*)-derived from Freundlich isotherm equation (integral of Eq. 26), where lower values of E*s which could be obtained from higher \(q_{\text{e}}\)s, maximize the \(q_{\text{m}}\).

Conclusion

In this study, rice husk, a cost-effective agro-industrial waste and available in plenty, has been utilized to prepare biochar. The biochar prepared from rice husk was found to be containing 77.5% of VOC. Furthermore, an instance modification of the as-prepared biochar with H2SO4 increased the percentage of carbon content in the biochar and introduced almost 10 times more active sites on the surface of each gram of biochar. Application of the AMB for the adsorption of Cr(VI) from the groundwater at a pH ~ 7 has been proven effective, especially at higher temperatures. The adsorption of Cr(VI) on AMB surface has been considered to have been assisted by the anion–π interaction on the AMB surface. Almost 77% of 750 ppb Cr(VI) has been found adsorbed by 20 mg of AMB within 2 h at 30 °C, whereas the removal percentage reached 86 when the temperature was set at 50 °C with an adsorption capacity of 963 μg g−1. From the study of the adsorption isotherms, the Freundlich isotherm model was found to be suitable for describing the adsorption of Cr(VI) on AMB. The estimated values of KF and n indicate a favorable adsorption process at all the temperatures (30–50 °C). The energetically heterogeneous nature of the AMB has been confirmed analyzing the approximate site energy distribution function. Using the approximate site energy distribution function derived from the Freundlich isotherm model, the maximum adsorption capacity of the AMB has also been estimated and found to be 4109 μg g−1 at 30 °C and 4536 μg g−1 at 50 °C. A spontaneous and endothermic physisorption process was also evinced from the thermodynamic studies. Furthermore, the presence of other competing chemicals in water such as FeSO4 and bicarbonates has been found to play a detrimental role in the overall removal percentage of Cr(VI).

References

Al-Sou’od K (2012) Adsorption isotherm studies of chromium (VI) from aqueous solutions using Jordanian pottery materials. APCBEE Proc 1:116–125. https://doi.org/10.1016/j.apcbee.2012.03.020

Barceloux DG, Barceloux D (1999) Chromium. J Toxicol Clin Toxicol 37:173–194. https://doi.org/10.1081/CLT-100102418

Bhatnagar A, Sillanpää M (2010) Utilization of agro-industrial and municipal waste materials as potential adsorbents for water treatment—a review. Chem Eng J 157:277–296. https://doi.org/10.1016/j.cej.2010.01.007

Bhatt AS, Sakaria PL, Vasudevan M et al (2012) Adsorption of an anionic dye from aqueous medium by organoclays: equilibrium modeling, kinetic and thermodynamic exploration. RSC Adv 2:8663. https://doi.org/10.1039/c2ra20347b

Boehm HP (1994) Some aspects of the surface chemistry of carbon blacks and other carbons. Carbon 32:759–769. https://doi.org/10.1016/0008-6223(94)90031-0

Carter MC, Kilduff JE, Weber WJ (1995) Site energy distribution analysis of preloaded adsorbents. Environ Sci Technol 29:1773–1780. https://doi.org/10.1021/es00007a013

Cerofolini GF (1974) Localized adsorption on heterogeneous surfaces. Thin Solid Films 23:129–152. https://doi.org/10.1016/0040-6090(74)90235-1

Chakraborty S, Chowdhury S, Das Saha P (2011) Adsorption of crystal violet from aqueous solution onto NaOH-modified rice husk. Carbohydr Polym 86:1533–1541. https://doi.org/10.1016/j.carbpol.2011.06.058

Chen N, Feng C, Li M (2014a) Fluoride removal on Fe–Al-impregnated granular ceramic adsorbent from aqueous solution. Clean Technol Environ Policy 16:609–617. https://doi.org/10.1007/s10098-013-0659-6

Chen T, Zhang Y, Wang H et al (2014b) Influence of pyrolysis temperature on characteristics and heavy metal adsorptive performance of biochar derived from municipal sewage sludge. Bioresour Technol 164:47–54. https://doi.org/10.1016/j.biortech.2014.04.048

Cheng H, Zhou T, Li Q et al (2014) Anthropogenic chromium emissions in China from 1990 to 2009. PLoS One 9:e87753. https://doi.org/10.1371/journal.pone.0087753

Chowdhury S, Chakraborty S, Saha P (2011) Biosorption of basic green 4 from aqueous solution by Ananas comosus (pineapple) leaf powder. Colloids Surf B Biointerfaces 84:520–527. https://doi.org/10.1016/j.colsurfb.2011.02.009

Costa M (1997) Toxicity and carcinogenicity of Cr(VI) in animal models and humans. Crit Rev Toxicol 27:431–442. https://doi.org/10.3109/10408449709078442

Dąbrowski A (2001) Adsorption—from theory to practice. Adv Colloid Interface Sci 93:135–224. https://doi.org/10.1016/S0001-8686(00)00082-8

Deng X, Lü L, Li H, Luo F (2010) The adsorption properties of Pb(II) and Cd(II) on functionalized graphene prepared by electrolysis method. J Hazard Mater 183:923–930. https://doi.org/10.1016/j.jhazmat.2010.07.117

Dhakate R, Singh VS, Hodlur GK (2008) Impact assessment of chromite mining on groundwater through simulation modeling study in Sukinda chromite mining area, Orissa, India. J Hazard Mater 160:535–547. https://doi.org/10.1016/j.jhazmat.2008.03.053

Ding D, Ma X, Shi W et al (2016) Insights into mechanisms of hexavalent chromium removal from aqueous solution by using rice husk pretreated using hydrothermal carbonization technology. RSC Adv 6:74675–74682. https://doi.org/10.1039/C6RA17707G

Fierro V, Torné-Fernández V, Montané D, Celzard A (2008) Adsorption of phenol onto activated carbons having different textural and surface properties. Microporous Mesoporous Mater 111:276–284. https://doi.org/10.1016/j.micromeso.2007.08.002

Foo KY, Hameed BH (2010) Insights into the modeling of adsorption isotherm systems. Chem Eng J 156:2–10. https://doi.org/10.1016/j.cej.2009.09.013

Hang C, Li Q, Gao S, Shang JK (2012) As(III) and As(V) adsorption by hydrous zirconium oxide nanoparticles synthesized by a hydrothermal process followed with heat treatment. Ind Eng Chem Res 51:353–361. https://doi.org/10.1021/ie202260g

Heuchel M, Jaroniec M, Gilpin RK et al (1993) Energetic heterogeneity of reference carbonaceous materials. Langmuir 9:2537–2546. https://doi.org/10.1021/la00034a011

IS 10500 (2009) Draft Indian Standard drinking water—specification (second revision of IS 10500)

Kalderis D, Bethanis S, Paraskeva P, Diamadopoulos E (2008) Production of activated carbon from bagasse and rice husk by a single-stage chemical activation method at low retention times. Bioresour Technol 99:6809–6816. https://doi.org/10.1016/j.biortech.2008.01.041

Kobya M (2004) Removal of Cr(VI) from aqueous solutions by adsorption onto hazelnut shell activated carbon: kinetic and equilibrium studies. Bioresour Technol 91:317–321. https://doi.org/10.1016/j.biortech.2003.07.001

Kumar KV, Monteiro de Castro M, Martinez-Escandell M et al (2011) A site energy distribution function from Toth isotherm for adsorption of gases on heterogeneous surfaces. Phys Chem Chem Phys 13:5753. https://doi.org/10.1039/c0cp00902d

Lee JW, Kidder M, Evans BR et al (2010) Characterization of biochars produced from cornstovers for soil amendment. Environ Sci Technol 44:7970–7974. https://doi.org/10.1021/es101337x

Liu Y (2009) Is the free energy change of adsorption correctly calculated? J Chem Eng Data 54:1981–1985. https://doi.org/10.1021/je800661q

Liu C-H, Chuang Y-H, Chen T-Y et al (2015a) Mechanism of arsenic adsorption on magnetite nanoparticles from water: thermodynamic and spectroscopic studies. Environ Sci Technol 49:7726–7734. https://doi.org/10.1021/acs.est.5b00381

Liu W-J, Jiang H, Yu H-Q (2015b) Development of biochar-based functional materials: toward a sustainable platform carbon material. Chem Rev 115:12251–12285. https://doi.org/10.1021/acs.chemrev.5b00195

Ma Y, Liu W-J, Zhang N et al (2014) Polyethylenimine modified biochar adsorbent for hexavalent chromium removal from the aqueous solution. Bioresour Technol 169:403–408. https://doi.org/10.1016/j.biortech.2014.07.014

Malkoc E, Nuhoglu Y (2007) Determination of kinetic and equilibrium parameters of the batch adsorption of Cr(VI) onto waste acorn of Quercus ithaburensis. Chem Eng Process—Process Intensif 46:1020–1029. https://doi.org/10.1016/j.cep.2007.05.007

Mohan D, Singh KP, Singh VK (2005) Removal of hexavalent chromium from aqueous solution using low-cost activated carbons derived from agricultural waste materials and activated carbon fabric cloth. Ind Eng Chem Res 44:1027–1042. https://doi.org/10.1021/ie0400898

Mostinsky IL (2011) Diffusion. Thermopedia: a guide to thermodynamic head and mass transfer and fluids engineeding, 11. https://doi.org/10.1615/AtoZ.d.diffusion_coefficient

Naiya TK, Das SK (2016) Removal of Cr(VI) from aqueous solution using fly ash of different sources. Desalin Water Treat 57:5800–5809. https://doi.org/10.1080/19443994.2014.1003611

Naz A (2017) Risk assessment of chromium in the chromite mine water and its. Indian Institute of Technology(Indian School of Mines), Dhanbad

Naz A, Chowdhury A, Mishra BK, Gupta SK (2016) Metal pollution in water environment and the associated human health risk from drinking water: a case study of Sukinda chromite mine, India. Hum Ecol Risk Assess An Int J 22:1433–1455. https://doi.org/10.1080/10807039.2016.1185355

Nethaji S, Sivasamy A (2014) Removal of hexavalent chromium from aqueous solution using activated carbon prepared from walnut shell biomass through alkali impregnation processes. Clean Technol Environ Policy 16:361–368. https://doi.org/10.1007/s10098-013-0619-1

Ntim SA, Mitra S (2012) Adsorption of arsenic on multiwall carbon nanotube–zirconia nanohybrid for potential drinking water purification. J Colloid Interface Sci 375:154–159. https://doi.org/10.1016/j.jcis.2012.01.063

Oliveira H (2012) Chromium as an environmental pollutant: insights on induced plant toxicity. J Bot 2012:1–8. https://doi.org/10.1155/2012/375843

Prabhakar R, Samadder SR (2018) Low cost and easy synthesis of aluminium oxide nanoparticles for arsenite removal from groundwater: a complete batch study. J Mol Liq 250:192–201. https://doi.org/10.1016/j.molliq.2017.11.173

Qiu M, Sun K, Jin J et al (2015) Properties of the plant- and manure-derived biochars and their sorption of dibutyl phthalate and phenanthrene. Sci Rep 4:5295. https://doi.org/10.1038/srep05295

Qurie M, Khamis M, Manassra A et al (2013) Removal of Cr(VI) from aqueous environments using micelle-clay adsorption. Sci World J 2013:1–7. https://doi.org/10.1155/2013/942703

Rai MK, Giri BS, Nath Y et al (2018) Adsorption of hexavalent chromium from aqueous solution by activated carbon prepared from almond shell: kinetics, equilibrium and thermodynamics study. J Water Supply Res Technol. https://doi.org/10.2166/aqua.2018.047

Rajapaksha AU, Chen SS, Tsang DCW et al (2016) Engineered/designer biochar for contaminant removal/immobilization from soil and water: potential and implication of biochar modification. Chemosphere 148:276–291. https://doi.org/10.1016/j.chemosphere.2016.01.043

Robles-Camacho J, Armienta M (2000) Natural chromium contamination of groundwater at León Valley, México. J Geochemical Explor 68:167–181. https://doi.org/10.1016/S0375-6742(99)00083-7

Saikia SK, Gupta R, Pant A, Pandey R (2014) Genetic revelation of hexavalent chromium toxicity using Caenorhabditis elegans as a biosensor. J Expo Sci Environ Epidemiol 24:180–184. https://doi.org/10.1038/jes.2013.66

Samsuri AW, Sadegh-Zadeh F, Seh-Bardan BJ (2013) Adsorption of As(III) and As(V) by Fe coated biochars and biochars produced from empty fruit bunch and rice husk. J Environ Chem Eng 1:981–988. https://doi.org/10.1016/j.jece.2013.08.009

Samuel J, Paul ML, Pulimi M et al (2012) Hexavalent chromium bioremoval through adaptation and consortia development from Sukinda chromite mine isolates. Ind Eng Chem Res 51:3740–3749. https://doi.org/10.1021/ie201796s

Sarkar A, Paul B (2016) The global menace of arsenic and its conventional remediation—a critical review. Chemosphere 158:37–49. https://doi.org/10.1016/j.chemosphere.2016.05.043

Sarkar A, Sarkar A, Paul B, Khan GG (2018) Fabrication of one dimensional MnO2–TiO2 nano-heterostructures for enhanced hole mediated oxidation of As(III) in potable water. ChemCatChem 10:4369–4379. https://doi.org/10.1002/cctc.201800915

Schottel BL, Chifotides HT, Dunbar KR (2008) Anion–π interactions. Chem Soc Rev 37:68–83. https://doi.org/10.1039/B614208G

Shaffer MSP, Fan X, Windle AH (1998) Dispersion and packing of carbon nanotubes. Carbon 36:1603–1612. https://doi.org/10.1016/S0008-6223(98)00130-4

Sharma YC (2001) Effect of temperature on interfacial adsorption of Cr(VI) on wollastonite. J Colloid Interface Sci 233:265–270. https://doi.org/10.1006/jcis.2000.7232

Sharma YC, Srivastava V (2011) Comparative studies of removal of Cr(VI) and Ni(II) from aqueous solutions by magnetic nanoparticles. J Chem Eng Data 56:819–825. https://doi.org/10.1021/je100428z

Sheindorf C, Rebhun M, Sheintuch M (1981) A Freundlich-type multicomponent isotherm. J Colloid Interface Sci 79:136–142. https://doi.org/10.1016/0021-9797(81)90056-4

Soliemanzadeh A, Fekri M (2017) The application of green tea extract to prepare bentonite-supported nanoscale zero-valent iron and its performance on removal of Cr(VI): effect of relative parameters and soil experiments. Microporous Mesoporous Mater 239:60–69. https://doi.org/10.1016/j.micromeso.2016.09.050

Sugashini S, Begum KMMS (2013) Optimization using central composite design (CCD) for the biosorption of Cr(VI) ions by cross linked chitosan carbonized rice husk (CCACR). Clean Technol Environ Policy 15:293–302. https://doi.org/10.1007/s10098-012-0512-3

Sun L, Chen D, Wan S, Yu Z (2015) Performance, kinetics, and equilibrium of methylene blue adsorption on biochar derived from eucalyptus saw dust modified with citric, tartaric, and acetic acids. Bioresour Technol 198:300–308. https://doi.org/10.1016/j.biortech.2015.09.026

Tran TN, Van Anh Pham T, Le Phung ML et al (2013) Synthesis of amorphous silica and sulfonic acid functionalized silica used as reinforced phase for polymer electrolyte membrane. Adv Nat Sci Nanosci Nanotechnol 4:045007. https://doi.org/10.1088/2043-6262/4/4/045007

Ullah I, Nadeem R, Iqbal M, Manzoor Q (2013) Biosorption of chromium onto native and immobilized sugarcane bagasse waste biomass. Ecol Eng 60:99–107. https://doi.org/10.1016/j.ecoleng.2013.07.028

Vasanth Kumar K, Sivanesan S (2007) Sorption isotherm for safranin onto rice husk: comparison of linear and non-linear methods. Dye Pigment 72:130–133. https://doi.org/10.1016/j.dyepig.2005.07.020

Villalobos-Aragón A, Ellis AS, Armienta MA et al (2012) Geochemistry and Cr stable isotopes of Cr-contaminated groundwater in León valley, Guanajuato, México. Appl Geochemistry 27:1783–1794. https://doi.org/10.1016/j.apgeochem.2012.02.013

Weng C-H, Sharma YC, Chu S-H (2008) Adsorption of Cr(VI) from aqueous solutions by spent activated clay. J Hazard Mater 155:65–75. https://doi.org/10.1016/j.jhazmat.2007.11.029

World Health Organization (2011) Guidelines for drinking-water quality. World Health Organization, Geneva

Wu Q, Zhao J, Qin G et al (2013) Photocatalytic reduction of Cr(VI) with TiO2 film under visible light. Appl Catal B Environ 142–143:142–148. https://doi.org/10.1016/j.apcatb.2013.04.056

Xu X, Cao X, Zhao L (2013) Comparison of rice husk- and dairy manure-derived biochars for simultaneously removing heavy metals from aqueous solutions: role of mineral components in biochars. Chemosphere 92:955–961. https://doi.org/10.1016/j.chemosphere.2013.03.009

Yan B, Niu CH (2017) Modeling and site energy distribution analysis of levofloxacin sorption by biosorbents. Chem Eng J 307:631–642. https://doi.org/10.1016/j.cej.2016.08.065

Zheng S, Jiang W, Rashid M et al (2015) Selective reduction of Cr(VI) in chromium, copper and arsenic (CCA) mixed waste streams using UV/TiO2 photocatalysis. Molecules 20:2622–2635. https://doi.org/10.3390/molecules20022622

Acknowledgements

All the authors are thankful to IIT(ISM) Dhanbad for providing the research facilities. A. Sarkar acknowledges MHRD, Government of India, for providing financial support through IIT(ISM) JRF contingency. A. Sarkar and A. Ranjan are thankful to Dr. S.R. Samadder, Prof. S.K. Maiti, Dr. A. Sinha, Dr. A. Kumar, Mrs. P. Saha, Mr. D. Raj and Mr. R. Prabhakar of Department of Environment Science & Engineering, IIT(ISM), for their assistance.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Sarkar, A., Ranjan, A. & Paul, B. Synthesis, characterization and application of surface-modified biochar synthesized from rice husk, an agro-industrial waste for the removal of hexavalent chromium from drinking water at near-neutral pH. Clean Techn Environ Policy 21, 447–462 (2019). https://doi.org/10.1007/s10098-018-1649-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10098-018-1649-5