Abstract

Electrical motors use about 30–80% of total industrial energy for some selected countries around the world. Experiences from other countries show that government intervention in the form of regulations such as mandatory and voluntary approaches can save huge amount of energy along with the reduction of emissions associated with energy savings. In this paper, use of high efficient motors to replace standard motors to save energy have been quantified and presented. Emission reductions associated with the energy savings have been estimated and presented as well. Based on estimation, it has been found that 15,111, 6507 and 4295 MWh of energy can be saved for 50, 75 and 100% motor loadings, respectively, for using high efficient motors. These savings will correspond to US$ 967,074, US$ 416,461 and US$ 274,892 savings for 50, 75 and 100 motor loadings, respectively, by replacing standard motors with high efficiency motors. It was also found that 7,562,070 kg of CO2, 45,266 kg of SO2, 21,326 kg of NO x and 4,599 kg of CO could be avoided by using energy efficient motors for 50% load. It was also found that payback period for implementing high efficient motors are in the range from 1.22 to 6.05, which is economically very viable for motor loadings of 50%.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

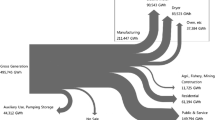

Electric motors have broad applications in areas such as industry, business, public service and household electrical appliances, powering a variety of equipment including wind blowers, water pumps, compressors and machine tools as can be seen in Fig. 1. In industrially developed nations and large developing nations, electric motors account for a considerable proportion of total national power consumption (APEC 2008).

Share of motor energy use by type of end-use, in the industrial sector in EU (De Almeida et al. 2003)

Energy use performances and energy efficiencies of the industry have also been studied in different surveys in many countries (Ozturk 2005; Christoffersen et al. 2006; Subrahmanya 2006). In Slovenia, industrial sector uses about 52% of total electrical energy (Al-Mansour et al. 2003). In Turkey, about 35% of total energy is used in industrial sector (Onut and soner 2007). Approximately, half of UK’s generated electricity is used to drive electrical motors. This means that efficiency improvements to electrical machines can have a very large impact on energy use (Mecrow and Jack 2008). Motor driven systems account for approximately 65% of the electricity used by EU industry (Anon 2004). In Jordan, industrial sector uses about 31% of total energy (Al-Ghandoor et al. 2008). In Malaysia, about 48% of total industrial energy used by industrial motors is as shown in Table 1 (Saidur et al. 2009a, b). In many industrialized countries, more than 70% of the total produced energy is used by electric motors. Share of electric motor energy use for some selected countries is shown in Table 1. Therefore, the cost of energy to operate motors has become a real concern for industries. On the other hand, the concern for the environment particularly through the emission of green-house gases and other pollutants has prompted the regulators of utilities to enforce alternative measures to meet load growth, instead of building additional power stations (Akbaba 1999). Comprehensive literatures in energy electrical motors’ energy savings, policy, and technology can be found in a handbook written by Nadel et al. (2002).

The energy that electric motors used in plants is about 65% of the total energy consumption in Turkey. Therefore, it is important to choose ‘high efficiency’ motors in plants to reduce industrial energy use and emission reductions (Kaya et al. 2008). Many countries around the world already implemented energy efficiency standards; many are in the process of developing them as can be seen in Table 2. It may be mentioned that energy can be saved using technology such as use of variable speed drive, use of capacitor banks to improve power factor, by regular maintenance of equipments/machineries and by implementing energy efficiency regulations such as voluntary, mandatory approaches, incentives and energy guide labels. However, focus of this paper is to quantify energy savings, bill savings and emission reductions for electric motors using high efficient motors (i.e. using energy efficiency regulations)

Mahlia et al. (2002, 2004) carried out some works about the energy savings potential by implementing energy efficiency standards for room air conditioners and household refrigerator-freezers in Malaysia. De Almeida et al. (2003), Garcia et al. (2007), Yanti and Mahlia (2009) and many others carried out some works on motor energy efficiency standards. Lu (2007) developed energy efficiency standards for central air conditioners for China and reported potential energy savings and environmental benefits of energy efficiency standards. Lu (2006a, b) developed energy efficiency standards for refrigerator-freezers in China and reported potential energy savings and environmental benefits of energy efficiency standards.Wiel and McMahon (2005) wrote a comprehensive guidebook about global standards and labels for appliances. However, there is no such work for industrial motors in Malaysia. This study will fill that gap and it is expected that this study will be useful for policy makers of Malaysia and ASEAN regions, researchers and industrial energy users. Moreover, this study will create strong awareness about electric motor energy savings and emission reductions.

Global status of electric standards and labels

Many countries already developed energy efficiency standards and labels and many are in the process of developing them. A summary of present status of standards and labels is shown in Table 2.

Minimum efficiency requirements or minimum energy performance standards (MEPS) are a powerful tool to force market transformation, as it can be seen in Fig. 2.

Effects on motor market of mandatory MEPS and efficiency class labelling (De Almeida et al. 2002)

Energy savings by using a high efficiency motor

A high efficiency motor (HEM) uses low loss materials to reduce core and copper losses. Therefore, it generates less heat and requires smaller and more energy efficient cooling fans. The most popular is demand-side management, one aspect of which is to improve efficiency to offset load growth. These facts have led electric-motor manufacturers to seek methods for improving the motor efficiency, which resulted in a new generation of electric motors that are known as energy-efficient electric motors. Several leading electric motor manufacturers, mainly in USA and Europe, have developed product lines of energy-efficient electric motors (Akbaba 1999).

Historically, the primary goal in motor manufacture has been to reduce production costs while preserving available power. A motor can be made more efficient by improvements in design: magnetic cores with plates made of ferrosilicon alloys, better-filled slots using more copper, larger rotor conductors, and improvements in air-gaps, core heads, fans and bearings, and in the dimensional design. High-efficiency motors typically cost 10–25% more than standard ones (Garcia et al. 2007; CLASP 2009). Malaysian policy on the classification of motor is based on CEMEP classification. In rating motors for high efficiency standards in Malaysia, Suruhanjaya Tenaga (Energy Commission of Malaysia) has adopted the EU’s EFF1 level as the threshold, i.e. all motors with efficiency level equal to or above the EFF 1 level efficiencies are to be classified as high efficiency motor (HEM).

The aim is to make the industry realize that EFF 2 and EFF 3 motors use more energy than EFF 1 motors. Motor manufacturers representing 80% of the motor sales in Malaysia have agreed and participated in the high efficiency electric motor agreement (HEEMA) to support the Suruhanjaya Tenaga’s initiative to promote greater use of HEMs. To encourage use/sales of high efficient motors, Malaysian government prodived following incentives:

-

1.

For companies providing energy conservation services:

-

Pioneer Status with tax exemption of 70% of statutory income for a period of 5 years; or

-

Investment Tax Allowance of 60% on the qualifying capital expenditure incurred within a period of 5 years with the allowance deducted in each year of assessment be set-off against 70% of statutory income; and

-

Import duty and sales tax exemption for equipment used in the related project, which are not produced locally. Equipment purchased from local manufacturers is given sales tax exemption .

-

-

2.

For Companies which incur capital expenditure for conserving energy for own consumption:

-

Import duty and sales tax exemption for equipment used in energy conservation, which are not produced locally.

-

Equipment purchased from local manufacturers is given sales tax exemption.

-

Applications made to Chairman of Energy Commission.

-

Mathematical formulations to estimate energy savings using HEMs

Annual energy savings (AES) attained by replacing standard efficient motors with high energy efficient motors can be estimated using the methodology described in Garcia et al. (2007):

Annual bill savings associated with the above energy savings can be calculated as:

where, AES is the annual energy savings (kWh), Savings = expected annual bill savings (US$), P is the motor rated power (kW), L is the load factor (percentage of full load), hr is the annual operating hours, C is the average energy cost (US$/kWh), EEstd is the standard motor efficiency rating (%) and EEhem is the energy-efficiency of high efficiency motor (%).

Total number of motors with the capacities has been collected from Saidur et al. 2009a. Motor usage time at different percentage of loadings is shown in Table 3.

Formulations of emission reductions associated with the energy savings

Emission estimation associated with the electricity generation by burning fossil fuels can be expressed by the following equation (Mahlia 2002):

where EM i is the total emission for unit of electricity generation (kg), \( {\text{Em}}_{p}^{n} \)is the fossil fuel emission for a unit of electricity generation of fuel type n (kg), EP i is the electricity production in year i (GWh), \( {\text{PE}}_{i}^{n} \) is the percentage of electricity generation in year i of fuel type n.

Tables 4 and 5 show input data needed to estimate amount of emissions that can be reduced due to energy savings for using energy efficient motors.

Mathematical formulations of payback period

A simple payback period for different energy saving strategies can be calculated using Eq. 4.

Input data needed to estimate energy savings and payback period for different percentage of motor loadings are shown in Tables 6 and 7. Average usage hours have been collected from energy audit survey data. Efficiency of standard and high efficiency motors have been collected from Garcia et al. (2007). Incremental costs associated with the usage of high efficiency motor have been collected from Garcia et al. (2007). It should be noted here that there is no comprehensive work on motors in Malaysia, so these data have been used to provide some insight into the amount of energy and energy costs can be saved along with emission reductions. Moreover, motors are manufactured, sold and used around the world, so data from other countries have also been used in this estimation.

Results and discussions

Using data in Tables 4, 5, 6 and 7 and Eqs. 1–3, energy savings, bill savings and emission reductions associated with energy savings for using high efficient electric motors have been estimated and presented in Figs. 3 and 4 and Tables 8, 9 and 10.

It has been found that more energy and electrical bill can be saved for 50% of motor loadings. Using data from Fig. 3 and Eq. 4, energy savings and payback period for using high efficient motor have been estimated and presented in Tables 8 and 9, respectively. From Table 9, it has been found that payback periods for using high efficient motors particularly for 50% are economically very viable as there are huge savings potentials at this loading. Table 10 shows that huge amount of emission can be reduced associated with electrical motor energy savings. It may be mentioned that this savings are shown for about 111 industries in Malaysia. However, there are many industries and they use number of electric motors for different industrial processes. If savings are estimated for total motor populations in Malaysia, a sizeable amount of energy and emission reductions can be achieved through this policy measures. De Almeida et al. (2003) reported that 47 TWh can be saved in industry and 14 TWh in the services sector for using high efficient motors. Akbaba (1999) reported that using an energy efficient motor will save about 79 MWh per year in Bahrain. Cheek and Pillay (1997) mentioned that about 650 MWh energy can be saved annually for motor systems in petrochemical industry. De Keulenaer et al. (2004) projected that implementation of energy efficient motor can save 202 billion kWh of energy in EU industries.

Conclusions

Following conclusions can be drawn from this study:

-

(a)

The study found that a substantial amount of energy and utility bills can be saved if high efficiency motors are used for industrial motors.

-

(b)

It has been found that the payback period for using energy efficient motors is reasonable (i.e. within 1–3 years).

-

(c)

The study also estimated that emissions can be substantially reduced by applying energy efficient motors.

-

(d)

Along with energy efficiency standard, energy guide label which provide information about the efficiency level of a motor should be established and its impact on energy and emission reductions can be analyzed. Education and information dessimation through mass media may certainly play important role in creating awareness about the benefit of energy efficient products.

References

Akbaba M (1999) Energy conservation by using energy efficient electric motors. Appl Energy 64(1–4):149–158

Al-Ghandoor A, Al-Hinti I, Jaber JO, Sawalha SA (2008) Electricity consumption and associated GHG emissions of the Jordanian industrial sector: empirical analysis and future projection. Energy Policy 36(1):258–267

Al-Mansour F, Merse S, Tomsic M (2003) Comparison of energy efficiency strategies in the industrial sector of Slovenia. Energy 28(5):421–440

Anon (2004) Variable speed driven pumps, best practice guide, automation instrumentation and control laboratory technology, www.gambica.org.uk, Accessed 31 Dec 2008

APEC (2008) Electric motors—alignment of standards and best practice programmes within APEC, final report

Bouzidi F (2007) Energy savings on single-phase induction motors under light load conditions. MS thesis, University of Nevada Las Vegas, USA

Cheek KF, Pillay P (1997) Impact of energy efficient motors in the petrochemical industry. Electr Power Syst Res 42(1):11–15

Christoffersen LB, Larsen A, Togeby M (2006) Empirical analysis of energy management in Danish industry. J Clean Prod 14(5):516–526

CLASP (2009) Collaborative labeling and appliance standards programs homepage, http://www.clasponline.org

De Almeida AT, Ferreira FJTE, Busch JF, Angers P (2002) Comparative analysis of IEEE 112-B and IEC 34–2 efficiency testing standards using stray load losses in low-voltage three-phase, cage induction motors. IEEE Trans Ind Appl 38(2):608–614

De Almeida AT, Fonseca P, Bertoldi P (2003) Energy-efficient motor systems in the industrial and in the services sectors in the European Union: characterisation, potentials, barriers and policies. Energy 28(6):673–690

De Keulenaer H, Belmans R, Blaustein E, Chapman D, De Almeida A, De Wachter B, Radgen P (2004) Energy-efficient motor-driven systems. EU-sponsored programme. European Copper Institute, Brussels

Garcia AGP, Szklo AS, Schaeffer R, McNeil MA (2007) Energy-efficiency standards for electric motors in Brazilian industry. Energy Policy 35(6):3424–3439

Kaya D, Yagmur EA, Yigit KS, Kilic FC, Eren AS, Celik C (2008) Energy efficiency in pumps. Energy Convers Manag 49(6):1662–1673

Lu B (2006) Energy usage evaluation and condition monitoring for electric machines using wireless sensor networks. PhD thesis, Georgia Institute of Technology, USA

Lu W (2006b) Potential energy savings and environmental impact by implementing energy efficiency standard for household refrigerators in China. Energy Policy 34(13):1583–1589

Lu W (2007) Potential energy savings and environmental impacts of energy efficiency standards for vapor compression central air conditioning units in China. Energy Policy 35(3):1709–1717

Mahlia TMI (2002) Emissions from electricity generation in Malaysia. Renew Energy 27(2):293–300

Mahlia TMI, Masjuki HH, Choudhury IA (2002) Potential electricity savings by implementing energy labels for room air conditioner in Malaysia. Energy Convers Manag 43(16):2225–2233

Mahlia TMI, Masjuki HH, Saidur R, Amalina MA (2004) Cost-benefit analysis of implementing minimum energy efficiency standards for household refrigerator-freezers in Malaysia. Energy Policy 32(16):1819–1824

Mecrow BC, Jack AG (2008) Efficiency trends in electric machines and drives. Energy Policy 36(12):4336–4341

Nadel S, Elliott RN, Shepard M, Greenberg S, Katz G, De Almeida AT (2002) Energy-efficient motor systems: a handbook on technology, program, and policy opportunities, 2nd edn. American Council for an Energy-Efficient Economy, Washington, D.C.

Nesbitt L (2008) The impact of industry characteristics on the diffusion of adjustable speed motors across manufacturing industries. MA thesis, University of Denver, USA

Onut S, Soner S (2007) Analysis of energy use and efficiency in Turkish manufacturing sector SMEs. Energy Convers Manag 48(2):384–394

Ozturk HK (2005) Energy usage and cost in the textile industry: a case study for Turkey. Energy 30(13):2424–2446

Prakash V, Baskar S, Sivakumar S, Sri Krishna K (2008) A novel efficiency improvement measure in three-phase induction motors, its conservation potential and economic analysis. Energ Sustain Dev 12(2):78–87

Saidur R, Rahim NA, Ping HW, Jahirul MI, Mekhilef S, Masjuki HH (2009a) Energy and emission analysis for industrial motors in Malaysia. Energy Policy 37(9):3650–3658

Saidur R, Rahim NA, Masjuki HH, Mekhilef S, Ping HW, Jamaluddin MF (2009b) End-use energy analysis in the Malaysian industrial sector. Energy 34(2):153–158

Sterling CA (1996) Prevalence of components necessary for electrical demand side management savings persistence in the Albertan Industrial market sector. MS thesis, University of Alberta, Canada

Subrahmanya MHB (2006) Labour productivity, energy intensity and economic performance in small enterprises: a study of brick enterprises cluster in India. Energy Convers Manag 47(6):763–777

Tolvanen J (2008a) Saving energy with variable speed drives. World Pumps 32–33

Tolvanen J (2008b) LCC approach for big motor-driven systems savings. World Pumps 24–27

Wiel S, McMahon JE (2005) Energy-efficiency labels and standards: a guidebook for appliances, equipment, and lighting, 2nd ed. www.clasponline.org/files/Guidebook_2ndEdition.pdf 10/05/2005

Yanti PAA, Mahlia TMI (2009) Considerations for the selection of an applicable energy efficiency test procedure for electric motors in Malaysia: lessons for other developing countries. Energy Policy 37(9):3467–3474

Yuejin Z (2007) General situation of energy conservation standards for china’s motor system. Energy Efficiency in Motor Driven Systems EEMODS 2007 to be held in Beijing, China, from June 10–13

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Saidur, R., Mahlia, T.M.I. Impacts of energy efficiency standard on motor energy savings and emission reductions. Clean Techn Environ Policy 13, 103–109 (2011). https://doi.org/10.1007/s10098-009-0275-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10098-009-0275-7