Abstract

To explore the effects of temperature and percolation velocity on the migration and deposition characteristics of different silica powder in saturated porous media under continuous injection conditions, migration-deposition tests were conducted for four combinations of particle sizes at different temperatures (5 °C, 15 °C, 25 °C, 35 °C) and different flow rates (0.032 cm/s, 0.063 cm/s, 0.095 cm/s), and deposition pictures were obtained under the microscope. The analytical solution of the convective dispersion equation of first-order deposition dynamics is demonstrated to be able to describe the penetration curve of suspended particles. With increasing seepage velocity and temperature, the sedimentation coefficient and longitudinal dispersion coefficient increase. The test results showed that the higher the temperature was, the lower the peak relative concentration of the effluent particles at the same percolation rate; the faster the flow rate was, the higher the peak relative concentration of the effluent particles at the same temperature, and both higher temperature and faster flow rate accelerated the migration of particles so that the pore ratio corresponding to the peak concentration was reduced. The effect of the two on the particles was the same; temperature was the main control factor in the test run at a low flow rate, and the effect of temperature was not obvious at a high flow rate. Thus, temperature and flow rate are important factors affecting the migration of suspended particles in saturated porous media.

Graphical Abstract

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

The study of migration and deposition characteristics of particles in saturated porous media is of great significance for many projects, such as oil extraction, groundwater recharge, groundwater contamination migration and nuclear waste disposal [1,2,3,4,5,6,7,8] and has been an important research topic in the field of environmental geotechnical engineering in recent years. The process of groundwater recharge often carries solid particles under the influence of physical and chemical effects and causes blockage inside the aquifer, thus affecting project efficiency or even hindering project operation. The physical factors affecting the particle transport process are mainly particle shape, particle size distribution, pore structure, particle concentration, percolation rate and temperature [9,10,11,12,13,14,15,16]. In practical projects such as groundwater heat pump systems, the recharge water temperature is higher in summer and lower in winter, different recharge water temperatures affect the migration process, the flow rate around the recharge well decreases rapidly with increasing distance from the well, and the recharge rates in different recharge wells are different, so it is important to study the effects of temperature and flow rate on the migration and deposition of suspended particles in saturated water-bearing sand layers and saturated aquifers.

Researchers have conducted related studies on the effects of temperature and flow rate on the migration of particles in porous media. Bai et al. [17] studied the vertical penetration of silica particles at three temperatures, 15 °C, 35 °C, and 55 °C, with one-dimensional sand column experiments and found that temperature is an important factor affecting the transport and deposition of suspended particles in porous media; other factors, such as particle velocity, dispersion and transport deposition coefficients, also contribute. Using the classical model of suspended particle migration, Xue Chuancheng et al. [18] found that temperature and pH are important factors affecting particle migration through indoor soil columns. When pH = 7 and T ≤ 30 °C, repulsion of suspended particles plays a dominant role, and when T > 30 °C, Brownian motion dominates. Jongmuk Won et al. [19] investigated the effect of kaolinite in different solutions (with different pH and ionic strength) and with different flow rates and found that the decrease in hydraulic conductivity was most significant at pH = 3 regardless of the flow rate. You et al. [20] investigated temperature-dependent variations in the forces acting on particles and showed that the effect of temperature on electrostatic force was greater than the effect on water viscosity, and they also found that geothermal reservoirs were more susceptible to particle migration than conventional oil fields and aquifers. Rosenbrand et al. [21] studied the migrations of particles in Berea sandstone and found that the higher the temperature and salt content was, the lower the permeabilities of aquifers and the more reversible the effects of temperature changes on permeability. Sandra et al. [22] investigated the stabilities of bentonite colloids at different temperatures by measuring the deposition rates and potentials and using DLVO theory to calculate the total interaction potentials between particles at different temperatures. These results showed that the stabilities of bentonite colloids increased with increasing temperature, but their surface potentials were not significantly affected. Sasidharan et al. [23] studied the penetration and deposition of nanocolloidal particles in porous media under different hydrodynamic and chemical conditions, and their results showed that the penetration curve exhibited a bimodal distribution as the ionic strength of the solution increased. Bennacer et al. [24] discovered that as flow velocity and particle size distribution increased, the longitudinal dispersion coefficient in the convective dispersion equation of deposition dynamics increased. To investigate the physical clogging of porous medium, Alen et al. [25] introduced suspended particles with a diameter of 1.740 m into a sand-filled column. The flow rate is found to have a significant impact on suspension retention. The retention of porous media from the column's entry is limited at low flow rates, resulting in a dramatic shift in the porous media's hydraulic characteristics. However, the hydraulic properties of more porous media is modified at high flow rates, not only at the inlet.

As mentioned above, many scholars have studied the migration and deposition of suspended particles in saturated porous media, but the effects of temperature or the percolation velocity of water on particle transport processes are usually considered separately, and few studies have been conducted under continuous injection conditions that are more in line with the real situation. In this paper, the effects of temperature and percolation velocity on the transport of suspended particles in porous media under continuous injection conditions was investigated by using a self-developed, one-dimensional sand percolation column for four particle size combinations at four different temperatures and three different percolation velocities. The impact of physical parameters such as temperature and seepage velocity on the migration properties of suspended particles were thoroughly investigated, as well as the variation of the deposition coefficient and dispersion coefficient at various temperatures and seepage velocity. The migration properties and mechanism of suspended particles in porous media are obtained, as well as the experimental basis for particle migration in porous media.

2 Experimental overviews

2.1 Experimental equipment

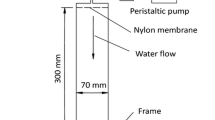

As shown in Fig. 1. The sand column is a 550-mm long, 60-mm inner diameter cylinder with a 9.17 ratio of length to inner diameter, so it can be regarded as a one-dimensional seepage test system. The sand column was equipped with a screen at both ends to ensure that seepage flow was evenly distributed throughout the column section and to prevent the natural sand from flowing out of the column during the test. Five equally spaced pressure sensors (P1, P2, P3, P4, P5) were installed on the surface of the sand column and were connected to an external data acquisition device to monitor the pressure changes occurring inside the sand column during the test. The entire sand column was placed in the high- and low-temperature test chamber for temperature control during the test, and an Espec (ESPEC) GPR-3 high- and low-temperature constant temperature and humidity temperature controller was used to ensure the stability of the four different temperatures (5 °C, 15 °C, 25 °C, 35 °C) during the entire test process. A precision peristaltic pump was used to transfer high purity deionized water from a water tank into the sand column so the percolation speed in the sand column was kept stable at three different speeds (0.032 cm/s, 0.063 cm/s, 0.095 cm/s) as required, and a flow meter was used to monitor the flow rate during the test. The test was conducted with a constant temperature heating magnetic stirrer during injection of the suspension, and the temperature was kept consistent with that in the sand column while continuously injecting the suspension. The turbidity of the suspended particles in the effluent was measured using a turbidimeter, and a metallographic microscope was used to observe clogging of the sand column after the test.

2.2 Experimental materials

Washed natural sand was used as the filling material of the sand layer, and the color of the natural sand was light yellow. Its chemical properties were stable, and it was hard and wear resistant. White silica micronized powder was used as the suspended particle material; it was nearly spherical in shape, it exhibited stable physical and chemical properties, and it was easy to observe after sampling. Based on engineering data and the experience of a previous study, the specific parameters of the selected natural sand and silica micronized powder are shown in Table 1. Four combinations of particle sizes were used for the tests: (1) natural sand 1 + silica micronized powder 1; (2) natural sand 1 + silica micronized powder 2; (3) natural sand 2 + silica micronized powder 1; and (4) natural sand 2 + silica micronized powder 2. The gradation curves of the natural sand and silica micronized powder in each group are shown in Fig. 2. And the roundness of silica powder is shown in Fig. 3.

2.3 Experimental process

The water temperature available for the GWHP unit is 12–22 °C in winter, while the water temperature is 18–35 °C in summer, and four temperatures of 5 °C, 15 °C, 25 °C, and 35 °C were selected as the test temperatures. The test flow rate is around 0.01 cm/s between different recharge wells according to the authors' previous related simulations [6], and three seepage rates of 0.032 cm/s, 0.063 cm/s, and 0.095 cm/s were selected as the test flow rates for the test. In the groundwater source heat pump and other projects, the particles that trigger recharge blockage are mainly concentrated above 10 μm, while 250 μm-500 μm and 1000 μm-2000 μm sand are selected for simulation according to the particle size distribution of the porous media in the ground [5]. Four different combinations of natural sands and particles with different particle sizes were selected for the 1D sand column tests, and migration-deposition tests were conducted at three different flow rates and at four different temperatures for each group of tests.

Before testing, the natural sand was repeatedly cleaned to remove suspended impurities, and the cleaned natural sand was put into an oven at 105 °C for 24 h. The natural sand was filled with the wet filling method, divided into 10 layers, the water surface of each layer was kept approximately 1 cm higher than the upper surface of the sand to ensure that the filled specimen was saturated, and the sand layer was properly pounded and compacted to ensure the uniformity of the sand layer during filling of layers. After the sand column was filled, it was put into the high- and low-temperature test chamber to prepare for the test. Before the start of each group of tests, deionized water was passed until the turbidity of the effluent was close to that of clear water (≤ 2 NTU). In order to perform more realistic simulations of the groundwater heat pump project in the backwater, tests used the continuous injection of the suspension. Before injecting the suspension, the stirrer was turned on to allow uniform distribution of particles and heating to the specified temperature. The volume of the suspension injected each time equaled the pore volume of the sand column, i.e., PV. Each group of tests started with the injection of the suspension, and the effluent was collected in a test tube every 3 − 5 s, providing a total of 70 tubes. The turbidity of the water sample was measured by a turbidity meter after 24 h, which was shaken evenly before measurement. To observe the blockage of the sand column after testing, a sampler was used to remove part of the sand column; it was placed into the temperature-controlled test chamber at − 20 °C for 24 h to ensure that the internal structure of the sand column was not disturbed after the test, and then cut pieces were removed and put under a microscope for observation.

Many studies have demonstrated that there is a strong correlation between the concentrations of suspended particles and turbidity [9, 16, 24]. In these experiments, a turbidimeter was used to measure the turbidity of the particles, and this was subsequently related to their concentration; thus, the concentration-turbidity relationships for 2 types of particles at 4 temperatures were measured before the study, as shown in Fig. 4. The results showed that the turbidities of the 2 types of silica microparticles selected for the experiment showed highly linear correlations between turbidity and concentration under the experimental conditions, and the turbidity was little affected by temperature. Therefore, it is reasonable to use this method in the experiments.

3 Analysis of test results

Reynolds number is a dimensionless number used to characterize the flow state of a fluid. When the Reynolds number is small, the viscous force has more influence on the flow field than the inertia force, and the fluid flow is stable and laminar. On the contrary, the inertia force has more influence on the flow field than the viscous force, and the fluid flow is more unstable. Reynolds number is defined as:

where ρ is the density of the fluid; u fluid is fluid velocity; L is characteristic length; μ is the viscosity coefficient of water. T is the Celsius temperature.

Reynolds number calculation results under test conditions are shown in Table 2, When the Reynolds number is less than 10.0 in groundwater dynamics, low speed movement occurs. The flow state of groundwater at this time is laminar movement dominated by viscous force, which is consistent with Darcy's law. we discovered that this experiment satisfies Darcy's law in earlier research. Local water, for example, flows through coarse sand with a particle size of D = 1 mm on average. The kinematic viscosity of 15 °C water is 0.1 m2/d, and the seepage velocity is predicted to be 200 m/d when the Re = 1. Darcy's law is obeyed in coarse sand when the seepage velocity < 200 m/d (the greatest flow velocity in the work is 82 m/d). In this study, most of the Re calculated in Table 2 are below 5. Therefore, the test in this study is consistent with Darcy's law.

To characterize the injection process, the pore volume ratio PV was used as the horizontal coordinate, and the relative concentration of suspended particles CR was used as the vertical coordinate [7,8,9,10, 13], as shown in Eqs. (3) and (4), respectively.

where VP is the pore volume of the sand layer, Vut is the volume of liquid injected per unit time, t is the time of injection of suspension, C is the outflow liquid particle concentration, C0 is the initial particle concentration in the liquid, and Vinj is the volume of injected water. The use of medium PV and CR as the horizontal and vertical coordinates can reduce the influence of the difference in pore space and pore flow rate of the sand layer on the comparability of test results.

3.1 Particle migration—deposition characteristics test penetration curve

The experimental results are shown in Fig. 5, where u is the percolation velocity of the sand column. The test results showed that the penetration curves all exhibited a pattern of increasing the maximum concentration, which was maintained for a period of time before decreasing. After continuous injection of the suspension, the penetration curve first showed a low turbidity zone close to the turbidity of clear water (2 NTU). With the passage of time, the particles accumulated in the sand column, and the turbidity of the effluent tended to rise gradually, reached the peak concentration at a certain time, started to decrease after maintaining the peak for a period of time, and finally converged to the turbidity of clear water again.

Figure 5 shows that, When the percolation rate was kept constant, an increase in temperature reduced the peak concentration of the effluent phase and made the pore volume corresponding to the starting particle concentration begin to rise, i.e., the outflow rate of the particles was accelerated. In fact, an increase in temperature increased the kinetic energies of particles, which intensified the collisions among suspended particles and between suspended particles and natural sand during migration and then intensified deposition. As the seepage velocity in the sand column increased, the hydrodynamic effects on the particles became increasingly obvious [11], and the effect of temperature on the particles was weakened at this time. In addition, the change in peak particle concentration caused by different temperature conditions was more obvious for the small particles, i.e., for the two groups 3 and 4.

Figure 5 shows that, These test results showed that regardless of the particle size and temperature, an increase in percolation velocity in the test sand column increased the hydrodynamic effect on the suspended particles; for particles of the same size, this significantly reduces the chance of adsorption and deposition, resulting in an increase in their effluent liquid phase to the peak concentration and a decrease in the pore volume ratio PV to reach the peak concentration. This was more evident in groups 1 and 2 because along with the increase in particle sizes of the porous media, the pore channels became wider, and the penetration of particles was carried out in larger macroscopic pores with larger hydrodynamic effects. In contrast, when the pore channels were narrower (groups 3 and 4), the flow rate variation had less effect on the effluent particle concentration, especially in group 3, for which the ratio of particle size to porous medium size was the largest. In addition, Fig. 5 shows that the migration velocities of particles in the sand column were slightly greater than the water flow velocity, the PV of the pore ratio, corresponding to the time when the peak concentration was reached, was less than 1.0, and the larger the flow velocity was, the smaller the PV. This is because the pore channels selected for particle migration within the percolating liquid were generally larger, the percolation velocities of these larger pore channels were greater than the migration velocities for the smaller pores, and the increase in flow velocity increased the hydrodynamic effect on the particles and sped up the migration process, which was ultimately reflected by the decrease in PV.

In order to more obviously see the influence of temperature on particle transport process under different test conditions, the corresponding peak concentration of suspended particles in outflow liquid phase under the combination of four different particle sizes at three flow rates and four temperatures is listed in Table 3 (u is the seepage velocity and T is the test temperature). The effect of temperature on the concentration peak was weaker and weaker with the increase of flow rate, and the third group was the most sensitive to the change of temperature at low flow rate. In the third group, when the temperature increased from 5 to 35 °C, the peak relative concentration of CR decreased from 0.219 to 0.095 with a difference of 0.124, while the difference was only 0.076 in the high flow rate test.

3.2 Penetration curve fitting analysis

Under the one-dimensional stable flow condition, the porous medium is assumed to be saturated, homogeneous, isotropic and incompressible. The flow in the pores conforms to Darcy's law. The deposition process of suspended particles is irreversible. Then, the convective dispersion equation of suspended particles in porous media is [24, 25]:

where C is the concentration of suspended particles; DL is the longitudinal dispersion coefficient; u is the seepage velocity; Kdep is sedimentation coefficient; t is time; x is the migration distance of suspended particles.

Hydrodynamic dispersion coefficient is a parameter describing the dispersion ability of porous media to a certain substance at a certain flow rate. It reflects the influence of groundwater flow process and pore structure characteristics on solute transport process in porous media at a macro level. Hydrodynamic dispersion coefficient includes mechanical dispersion coefficient and molecular diffusion coefficient. When the local water velocity is high, molecular diffusion can be ignored and only mechanical dispersion can be considered. Mechanical dispersion is divided into transverse dispersion and longitudinal dispersion, which respectively represent the dispersion phenomenon along the flow direction and vertical flow direction. The study in this paper is a one-dimensional test, and the concentration of substances injected on the transverse section is the same. Dispersion basically has no effect on the transverse aspect, so only the longitudinal dispersion coefficient is considered.

Initial conditions and boundary conditions are as follows:

where m is particle injection amount, Q is flow rate, and δ(t) is Dirac delta function.

Under the above initial conditions and boundary conditions, Wang et al. [26] derived the analytical solution of the convective dispersion equation:

The analytical solution is used to fit the penetration curve under different flow rates in OriginLab software, as shown in Fig. 6. The deposition coefficient Kdep and the longitudinal dispersion coefficient DL obtained by the fitting are summarized in Table 4. Figure 6 shows that the correlation between the experimental and theoretical curves is mostly strong, and the R2 is mostly above 0.9. However, the hysteresis phenomenon is common near the peak of the curve, because the theoretical equation assumes that the porous medium is homogeneous, but in reality, due to the different deposition conditions, particle shapes and force conditions, the sandy soil will show anisotropic mechanical behaviors. Moreover, some of the particles deposited in the porous media will undergo a re-detachment process, resulting in a hysteresis of the curve near the peak.

Figures 7 and 8 show the changes of sedimentation coefficient Kdep and dispersion coefficient DL in each group of tests. Figures 7 and 8 show that the sedimentation coefficient Kdep increases with the increase of temperature and seepage velocity, which is obviously the same as the law observed in Sect. 3.1, which proves the rationality of the test. When the maximum temperature T = 35 °C, the deposition coefficient changes most significantly with the velocity. In addition, Kdep in the first and second groups was significantly larger than that in the third and fourth groups. The analysis indicates that the cracks and depressions in the pore channels were wider when the particle size of the porous media was larger, which was conducive to the deposition of particles during the migration process. Table 4 shows that the longitudinal dispersion coefficient DL increases with the increase of seepage velocity under all conditions. In the second group of tests, the dispersion coefficient DL reached the minimum value in each group. The analysis shows that the particle size ratio between porous media and particles in the second group is the smallest, which increases the dispersion of particles.

3.3 Posttest microscopic observation map

The samples were taken out from the test tube after being frozen and observed under a microscope, as shown in Fig. 9. Figure 9a–c is the initial condition of porous media, and Fig. 9d–f is the morphology of particles deposited in the sand column. Obviously, particles are deposited during the migration of porous media. It can be seen that the surface of porous media is covered with white silica particles, which verifies the rationality of the experiment.

4 Discussion

The migration-deposition of suspended particles in a saturated porous medium is affected by many factors [27, 28], and the law shown represents a combination of these factors, which are influenced by the temperature and flow rate.

As seen from Figs. 5 and Table 3, regardless of particle sizes and flow rates, an increase in temperature reduces the peak outflow concentration. First, the viscosity of water is closely related to the temperature. With increasing temperature, the viscosity of water is reduced, and the particles are subject to lower resistance, which increases the settling of particles. However, it is known from Darcy's law that a decrease in viscosity accelerates the movement of the fluid, so the increase in temperature also accelerates the outflow of particles to a certain extent. Second, for particles larger than 10 μm, the temperature increase constitutes an increase in particle kinetic energy, which increases the collision frequencies among particles and between particles and natural sand; more particles are captured by the natural sand, and this ultimately reduces the particle outflow concentration.

When the percolation velocity increases, the particle concentration of the effluent also increases, and the analysis suggests that with a larger percolation velocity, the hydrodynamic force acting on the particles was larger and the deposition effect was smaller, thus increasing the effluent concentration. As seen from Table 3, the peak concentrations CR of groups (1) and (2) were close to 0.3 at higher flow rates, while the peak concentration CR was approximately 0.1 at lower flow rates, a difference of 0.2; the difference for groups (3) and (4) was only 0.1 under the same test conditions. Analysis suggests that the action of hydrodynamic forces on the particles was more obvious when the pore channels were wider (groups 1 and 2), because with more hydrodynamic action, the penetration of the particles occurred preferentially in the larger macroscopic pores; this further enhanced the hydrodynamic effects acting on the particles and increased the effluent particle concentration. Figure 5c, g, k shows that when the pore channel was narrow and the size ratio of particles to natural sand was large (group 3), an increase in flow rate led to only minimal hydrodynamic forces acting on particles because the main factor affecting the migration of particles at this time was the sieving and filtering [29] effect of natural sand on particles. Sieving and filtering action refers to a phenomenon in which large suspended particles cannot pass due to the small pores of the porous medium [30], which is closely related to the size ratio of particles to porous medium but also to the size distribution and shape of particles and the chemical composition of the percolating fluid.

Table 3 show that the peak concentrations spanning a temperature range of 5 °C to 35 °C were lowest for the four particle size combinations at u = 0.0945 cm/s, i.e., the effect of temperature on the relative peak concentration was less pronounced at higher percolation velocities. This analysis suggests that temperature was the main factor affecting particle migration at low percolation velocities in the sand column, and the hydrodynamic effect on the particles increased and hindered particle deposition as the flow velocity increased, which made the flow velocity the main controlling factor at this time.

In addition, the experimental results show that the velocity of particle migration within the sand column was slightly greater than the velocity of water flow, and the higher the flow velocity was, the higher the temperature and the more obvious the acceleration effect, which can be clearly seen from Fig. 5c, g, k. This analysis suggests that the pore channels selected for particle migration within the percolating liquid were generally larger, and the percolation velocities in these larger pore channels were greater than the migration velocities in small pores; the temperature increase raised the kinetic energy of particles and the increase in flow velocity increased the hydrodynamic effect acting on particles, both of which accelerated migration and were eventually reflected by a reduction in PV.

5 Conclusion

-

1.

The migration of particles in porous media is affected by both temperature and flow velocity. Differences in temperature and flow velocity significantly affect the migration patterns of particles in the saturated sand column, and the increase in temperature increases the kinetic energies of particles, which increases the collision frequency between particles and natural sand; more particles are captured by the natural sand medium, which ultimately reduces the outflow concentration of particles. The increase in flow velocity increases the hydrodynamic force acting on the particles, which inhibits the deposition of particles and increases the particle outflow concentration. This constitutes the joint effects of temperature and flow rate, and temperature is the main controlling factor at low flow rates. The effect of temperature becomes increasingly less important as the flow rate continues to increase.

-

2.

The velocities of particles migrating within the sand column are slightly greater than the velocity of water flow, and the higher the flow velocity is, the higher the temperature and the more obvious the acceleration effect. The pore channels selected for particle migration within percolating liquid are generally larger, and the percolation velocities in these larger pore channels are greater than the migration velocity in smaller pores; the temperature increase raises the kinetic energies of particles and the higher flow velocity increases the hydrodynamic effects acting on particles, both of which speed up migration and are eventually reflected in a reduction in PV value.

-

3.

The deposition coefficient and longitudinal dispersion coefficient will increase with the increase of seepage velocity, and the increase of temperature will significantly affect the deposition coefficient, which will increase, but the influence of temperature on the longitudinal dispersion coefficient is limited.

-

4.

The study used a combination of macroscopic and fine-scale methods to analyze the experimental results and found that the migration-deposition of suspended particles in saturated porous media is influenced by many factors in addition to temperature and flow rate, such as pore channels, particle sizes, and suspension concentration. The main controlling factors are different under different experimental conditions.

Abbreviations

- C :

-

Outflow liquid particle concentration

- C R :

-

Relative concentration of suspended particles

- C 0 :

-

Initial particle concentration in the liquid

- P V :

-

Pore volume ratio

- V inj :

-

Volume of injected water

- V P :

-

Pore volume of the sand layer

- V ut :

-

Volume of liquid injected per unit time

- T :

-

Temperature of the experiment

- t :

-

Time of injection of suspension

References

Chequer, L., Bedrikovetsky, P., Carageorgos, T., Badalyan, A., Gitis, V.: Mobilization of attached clustered colloids in porous media. J. Water Resour. Res. 55(7), 5696–5714 (2019)

Chrysikopoulos, C.V., Aravantinou, A.F.: Virus attachment onto quartz sand: Role of grain size and temperature. J. Environ. Chem. Eng. 2(2), 796–801 (2014)

Zheng, L., Pu, C., Xu, J., Liu, J., Zhao, X.: Modified model of porosity variation in seepage fluid-saturated porous media under elastic wave. J. Petrol. Explor. Prod. Technol. 6(4), 569–575 (2016)

Zhu, J.: A cell model of effective thermal conductivity for saturated porous media. Int. J. Heat Mass Transf. 138(AUG.), 1054–1060 (2019)

Xianze, C., Quansheng, L., Chengyuan, Z., Yisheng, H., Yong, F., Hongxing, W.: Land subsidence due to groundwater pumping and recharge: considering the particle-deposition effect in ground-source heat-pump engineering. Hydrogeol. J. 26(3) (2018)

Xianze, C., Yong, F., Hongxing, W., Shibing, H.: Ground environment characteristics during the operation of GWHP considering the particle deposition effect. J. Energy Build. 206 (2020)

Tang, Y., Yao, X., Chen, Y.: Experiment research on physical clogging mechanism in the porous media and its impact on permeability. J. Granular Matter 22(5), 1–14 (2020)

Ye, X., Cui, R., Du, X.: Mechanism of suspended kaolinite particle clogging in porous media during managed aquifer recharge. J. Granular Matter 57(5), 764–771 (2019)

Bai, B., Nie, Q., Zhang, Y., Wang, X., Hu, W.: Cotransport of heavy metals and SiO2 particles at different temperatures by seepage. J Hydrol. 597, 125771 (2021)

Dallmann, J., Phillips, C.B., Teitelbaum, Y., et al.: Impacts of suspended clay particle deposition on sand‐bed morphodynamics. Water Resources Res. (2020).

Peng, Z., Bai, B., Jiang, S.: Coupling effects of pore structure and hydrodynamics on particle migration and deposition characteristics in saturated porous media. Chin. J. Rock Soil Mech. 37(05), 1307–1316 (2016)

Quan, L., Xian, C., Cheng, Z., Ting, Z.: Effect of particle size on the migration-deposition characteristics of suspended particles in porous media. Chin. J. Geotech. Eng. 36(10), 1777–1783 (2014)

Bai, B., Jiang, S., Liu, L., Li, X., Wu, H.: The transport of silica powders and lead ions under unsteady flow and variable injection concentrations. Powder Technol. 2021;387.

Bai, B., Xu, T., Nie, Q., et al.: Temperature-driven migration of heavy metal Pb2+ along with moisture movement in unsaturated soils. Int. J. Heat Mass Transf. 153, 119573 (2020)

Bing, B., Jiaxi, Z., Lulu, L., Yanjie, J.: The deposition characteristics of coupled lead ions and suspended silicon powders along the migration distance in water seepage. Transport Porous Med. 134(3), 707–727 (2020)

Xianze, C., Yong, F., Hongxing, W., Shibing, H.: Experimental investigation of suspended particles transport in porous medium under variable temperatures. Hydrol Process. 33(7) (2019)

Bai, B., Long, F., Rao, D., Xu, T.: The effect of temperature on the seepage transport of suspended particles in a porous medium. Hydrol Process 31(2), 382–393 (2017)

Chuancheng, X., Yan, W., Ganbing, L., Hang, C., Keke, L.: Effect of temperature and pH on the osmotic migration of suspended particles in porous media. Chin. J. Geotech. Eng. 41(11), 2112–2119 (2019)

Benamar, A., Ahfir, N., Wang, H., Alem, A.: Particle transport in a saturated porous medium: pore structure effects. CR GEOSCI. 339(10), 674–681 (2007)

You, Z., Bedrikovetsky, P., Badalyan, A., Hand, M.: Particle mobilization in porous media: temperature effects on competing electrostatic and drag forces. Geophys. Res. Lett. 42(8), 2852–2860 (2015)

Rosenbrand, E., Kjøller, C., Riis, J.F., Kets, F., Fabricius, I.L.: Different effects of temperature and salinity on permeability reduction by fines migration in Berea sandstone. Geothermics 53, 225–235 (2015)

García-García, S., Jonsson, M., Wold, S.: Temperature effect on the stability of bentonite colloids in water. J. Colloid Interfaces Sci. 298(2), 694–705 (2006)

Sasidharan, S., Torkzaban, S., Bradford, S.A., Dillon, P.J., Cook, P.G.: Coupled effects of hydrodynamic and solution chemistry on long-term nanoparticle transport and deposition in saturated porous media. Colloids Surf. A 457, 169–179 (2014)

Bennacer, L., Ahfir, N.D., Bouanani, A., et al.: Suspended particles transport and deposition in saturated granular porous medium: particle size effects. J. Transp. Porous Media 100(3), 377–392 (2013)

Alem, A., Elkawafi, A., Ahfir, N.D., et al.: Filtration of kaolinite particles in a saturated porous medium: Hydrodynamic effects. J. Hydrogeol. J. 21(3), 573–586 (2013)

Wang, H.Q., Lacroix, M., Massei, N., et al.: Particle transport in porous medium: Determination of hydrodispersive characteristics and deposition rates. J. Géosciences de Surface/Surf. Geosci. 331(2), 97–104 (2000)

Cui, X., Liu, Q., Zhang, C.: Detachment characteristics of deposited particles in porous medium: experimentation and modeling. Transp. Porous Media. 119, 633–647 (2017)

Schittich, A.R., Wünsch, U.J., Kulkarni, H.V., et al.: Investigating fluorescent organic-matter composition as a key predictor for arsenic mobility in groundwater aquifers. J. Environ. Sci. Technol. 52(22), 13027–13036 (2018)

Quan, L., Xian, C., Cheng, Z., et al.: Research advances in the characterization of transportation and deposition of suspended particles in porous media. Chin. J. Rock Mech. Eng. 34(12), 2410–2427 (2015)

Wang, C., Bobba, A.D., Attinti, R., Shen, C., Lazouskaya, V., Wang, L., Jin, Y.: Retention and transport of silica nanoparticles in saturated porous media: efect of concentration and particle size. Environ. Sci. Technol. 46, 7151–7158 (2012)

Acknowledgements

This research was supported by the National Natural Science Foundation of China (Grant No. 41702254), Open Research Program of MOE Key Laboratory of Groundwater Circulation and Environmental Evolution, China University of Geosciences (Beijing) (Grant No. 2021-001), Educational Commission of Hubei Province of China (T2020005), and the Young Top-notch Talent Cultivation Program of Hubei Province. The data used in this paper are available upon request from the corresponding author.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

We declare that we do not have any commercial or associative interest that represents a conflict of interest in connection with the work submitted.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Cui, X., Li, J., Fei, W. et al. Migration and deposition behavior of silica powder in saturated sand: coupled effects of temperature and flow rate. Granular Matter 24, 95 (2022). https://doi.org/10.1007/s10035-022-01254-2

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10035-022-01254-2