Abstract

Anodic oxidation of silver–zinc alloys with a concentration of zinc of up to 30 at.% (alpha phase) in a deaerated aqueous solution of 0.1 M KOH was studied by voltammetry and chronoamperometry with synchronous registration of the photocurrent. A preliminary modification of the alloy surface due to the selective zinc dissolution, with monitoring of the potential and charge, was carried out in a deaerated aqueous solution of 0.01 M HNO3 + 0.09 M KNO3. As a result of the modification, the surface layer of the alloy was enriched with an electropositive component and vacancies, whose concentration exceeded the equilibrium concentration. The anodically formed Ag(I) oxide was characterized by an n-type conductivity and the predominance of donor defects in the crystal lattice. Their concentration increased and the width of the space charge region of the semiconductor oxide decreased with an increase in the concentration of non-equilibrium vacancies in the surface layer of the alloy.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The anodic oxidation of metals and alloys in an alkaline medium is usually accompanied by the formation of oxide layers on their surfaces. The kinetics of the oxide formation and the composition and properties of oxide layers depend on the potential of the electrode, its chemical composition, and the structural state of its surface. The structural state of the alloy surface can be changed within the specified limits by a preliminary anodic modification due to selective dissolution (SD) of the electronegative component. In this case, an electronegative component of the alloy goes into solution in the form of ions, and the surface layer of the alloy is enriched with an electropositive component and vacancies [1,2,3], whose concentration exceeds the equilibrium concentration [4,5,6]. It is important to ensure the morphological stability of the alloy surface and to avoid the formation of a porous structure during the selective dissolution, which is possible only if some critical potential is exceeded [7]. Therefore, it is necessary to dissolve an alloy in the subcritical potential region. In this case the surface layer of the alloy remains morphologically stable, while removal of the electronegative component atoms from the crystal lattice leads to creation of a high vacancy concentration in the surface layer, changing its structural state. The formation of vacancies during the selective dissolution is confirmed by positron annihilation spectroscopy [8] during a sufficiently deep and long selective dissolution in the overcritical region. Thus, one can assume vacancy formation as a result of less noble metal leaching in the subcritical potential region as well, but in a relatively smaller amount than in the overcritical potential region.

The influence of the structural state of an alloy surface on the kinetics of the oxide growth and its properties is most likely manifested during the initial stage of the oxide formation while the thickness of the oxide film is in the nanometer range.

This research is important due to the need to find new ways to obtain materials with the desired properties. In this paper, we consider the possibility of controlling the properties of oxide nanofilms which were formed anodically on alloys of the Ag–Zn system by changing the concentration of zinc in the bulk of the alloy and non-equilibrium vacancies in its surface layer. The scope of practical application of semiconductor oxides of silver and zinc in the processes of catalysis and electrocatalysis [9,10,11,12] and in the manufacture of electronic [13,14,15] and sensor devices [16] is determined by a set of their structure-dependent parameters. A possible way to improve the functional characteristics of semiconductor structures is by combining silver and zinc oxides [17]. Other combinations based on these metals and their oxides are also possible. For example, Ag–ZnO nanorods are considered in [18] to be effective catalysts and photocatalysts; Ag–ZnO nanowires can be used as photodetectors [19], and ZnO/Ag nanolayers can serve as Schottky diodes [20]. In this regard, the anodic oxidation of silver–zinc alloys is a promising way to create oxide structures.

To expand the range of in situ methods used to define the properties of semiconductor oxide phases, we considered the photoelectrochemical measurements. The photocurrent generated in semiconductor films whose thickness is less than the width of the space charge region is a size-dependent parameter [21,22,23]. Numerical processing of the dependence of the photocurrent on the thickness of the oxide film [23,24,25] allows one to obtain its optical and structural parameters.

The purpose of this work is to determine the effect of the alloy composition and the concentration of vacancies in its surface layer (which are predetermined by the conditions of the preliminary selective dissolution) on the regularities of the Ag(I) oxide anodic formation and its properties.

Experimental

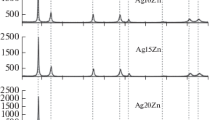

Alloys of the Ag–Zn system with concentrations of zinc NZn = 5, 10, 15, 20, and 30 at.% were obtained by their exposure in vacuumed ampoules for 2 h at a temperature of 1000 °C followed by cooling to room temperature. The phase (α-phase) and chemical composition of the alloys were confirmed by X-ray diffraction and energy-dispersive microanalysis [26]. The obtained alloys were used to make working electrodes with a horizontally oriented working surface. Surface preparation included mechanical grinding and cathodic polarization with a potential of E = − 1.1 V relative to the standard hydrogen electrode scale (SHE) for 5 min.

Solutions of 0.1 M KOH (pH 12.89) and 0.01 M HNO3 + 0.09 M KNO3 (pH 2.16) were prepared in bidistilled water from chemically pure reagents and deaerated by sparging with chemically pure argon for 2 h.

Electrochemical studies in acidic solutions were carried out in a three-electrode glass cell with undivided anode and cathode spaces. The auxiliary electrode was platinum. A silver oxide reference electrode with a potential of E = 0.350 V (SHE) was made by the electrochemical oxidation of silver in the aerated 0.1 M KOH solution at I = 5 mA for 20 min.

Photoelectrochemical studies in alkaline solutions were carried out in a three-electrode Plexiglas cell with undivided anode and cathode spaces and a quartz window for pulsed irradiation of the electrode surface. The pulse duration was 5 ms and the frequency was 5 Hz. The irradiation source was an ultra-bright NSPB300A quasi-monochromatic light-emitting diode (LED) with a wavelength of λ = 470 nm. The lighting power was maintained at a constant level providing the density of the luminous flux on the electrode surface, Φ0 = 1.64 × 1014 photons s−1 cm−2.

The preliminary anodic modification of the alloy surface due to the selective dissolution of zinc was carried out in an acidic solution for 60 s at various potentials E1, E2, and E3 (Table 1), which had been determined in [27] and provided the conditions for the thermodynamic stability of silver. After the anodic modification, the alloys were transferred into an alkaline solution and the potentiostatic oxidation was carried out at the potentials of EAg(I) determined in [26] and corresponding to the range of potentials for the formation of the Ag(I) oxide.

A Compact-2015 Photo Edition potentiostat (manufactured at the Laboratory of Renewable Energy Sources of Saint Petersburg Academic University of the Russian Academy of Sciences) combined with a personal computer (PC) was used to provide a pulsed lighting mode with a specified power and frequency of synchronous measurement of the polarization current and photocurrent. The densities of the polarization current and photocurrent were calculated per unit of the geometric area of the electrode, which was 0.4–0.5 cm2.

Results and discussion

Preliminary anodic modification of alloy surface in acidic solution

Chronoamperograms obtained on silver–zinc alloys in an acidic solution of 0.01 M HNO3 + 0.09 M KNO3 at different potentials of the preliminary anodic modification, E1, E2, and E3, were characterized by a drop in current to rather low, almost stationary values (Fig. 1a). This was due to a significant decrease in the surface concentration of zinc in comparison with its bulk concentration. The electronegative component (zinc) continued to dissolve, but the rate of the process decreased noticeably over time due to diffusion limitations [1, 4, 6].

The mixed electrochemical-diffusion mechanism of the dissolution of electronegative component A from homogeneous A–B alloys was proposed in [1, 28, 29], in particular for Zn–Ag alloys with a predominance of silver [4, 30]. In this case the chronoamperograms can be linearized in coordinates i-t−1/2 according to the following equation:

and the slope of the linear dependence allowed us to determine the diffusion coefficient of component A in the surface layer of the alloy and the concentration of vacancies [4, 29, 30]. In Eq. (1), I is the current, zA is the number of electrons involved in the process of oxidation of the electronegative component, F = 96,485 C mol−1 is the Faraday constant, NA is the bulk concentration of atoms of component A in the alloy (Table 1), S is the geometric surface of the electrode (Table 1), Vm is the molar volume calculated from the lattice parameter of alloys [26] (Table 1), R = 8.31 J mol−1 K−1 is the universal gas constant, T = 298 K is temperature, η is overvoltage, t is time, and DA is the diffusion coefficient of component A, which is determined by the following relation:

Here, Dvac is the diffusion coefficient of vacancies, and Nvac is the concentration of vacancies. Surely the vacancies forming during the selective dissolution are different in their energy and transport properties; therefore, these parameters are considered in this paper as effective ones.

The diffusion coefficient of vacancies in a binary alloy is estimated within the linear approximation [4, 29, 30]:

where NB is a bulk concentration of component B, and Dvac(A) and Dvac(B) are coefficients of diffusion of vacancies in metals A and B, respectively, which can be estimated using the thermodynamic characteristics of their formation:

Here, D*A(A) and D*B(B) are the self-diffusion coefficients, N0vac(A) and N0vac(B) are the equilibrium concentrations of vacancies, and ΔfG0vac(A) and ΔfG0vac(B) are the standard Gibbs energies of equilibrium vacancies formed in metals A and B, respectively.

The results of calculations according to (3)–(5) for alloys of the Zn–Ag system, taking into account the values D*Zn(Zn) = 1.15 × 10−18 cm2 s−1, D*Ag(Ag) = 3.3 × 10−32 cm2 s−1 [31], ΔfG0vac(Zn) = 41,900 J mol−1, and ΔfG0vac(Ag) = 102,400 J mol−1 [32] are shown in Table 2.

On the chronoamperograms obtained in 0.01 M HNO3 + 0.09 M KNO3 on Zn–Ag alloys at potentials E1, E2, and E3, one can distinguish linear sections in i-t−1/2 coordinates. An example of linearization is shown for chronoamperograms obtained on the Ag10Zn alloy at different potentials, and hence the overvoltage (Fig. 1b). This experimentally observed linearization confirms that a possible effect of equilibrium potential and overvoltage variation in the course of dissolution can be neglected within a certain time interval. The anodic dissolution potentials are high enough to provide the overvoltages, at which Eq. (1) can be simplified as \(I\left(t\right)=\frac{{z}_{\text{A}}F{N}_{\text{A}}{D}_{\text{A}}{}^{1/2}S}{{V}_{\text{m}}{\pi }^{1/2}{t}^{1/2}}\), because equality \(\left[1-{e}^{-\frac{{z}_{\text{A}}F}{RT}\eta }\right]\approx 1\) holds at rather large positive η.

From the slope of the linear section on the chronoamperograms of Zn–Ag alloys, one can determine the diffusion coefficient DA of component A, and then calculate the concentration of vacancies Nvac using Eq. (2). The calculation results (Table 2) showed that with an increase in the potential of the selective dissolution, the diffusion coefficient of zinc and the concentration of non-equilibrium vacancies increased (Table 2). Thus, by varying the dissolution potential, the surface layer of the alloy with different degrees of structural disorder can be formed. However, with an increase in the concentration of zinc in the alloy, these parameters decreased. It should be noted that the concentration of equilibrium vacancies calculated from the thermodynamic parameters of the process of their formation also decreased with an increase in the concentration of zinc in the alloy.

The results of estimating the diffusion-kinetic parameters of vacancies are further used in the analysis of the influence of the structural disorder of the alloy surface layer on its photoelectrochemical behavior.

Potentiostatic oxide formation on alloys in alkaline solution

Given the significant enrichment of the surface of Ag–Zn alloys with silver as a result of the preliminary selective dissolution of zinc, it can be assumed that the product of their further oxidation in 0.1 M KOH was mainly represented by silver oxide.

During potentiostatic polarization of anodically modified alloys of the Ag–Zn system in 0.1 M KOH, the chronoamperograms showed a decrease in the anodic current over time in the range of potentials for the formation of Ag(I) oxide: at first it was sharp, then later it slowed (Fig. 2a). The current densities were low.

The chronoamperograms of the Ag5Zn alloy after SD showed a maximum with a small amplitude, which most likely characterized the nucleation processes. With an increase in the SD potential, this maximum decreased in amplitude and shifted to occur with higher values of t. For the rest of the alloys, a maximum was not observed; however, an increase in the anodic current was recorded with an increase in the potential of the preliminary SD over the entire duration of the chronoamperograms.

Photocurrent in the Ag2O oxide

Almost immediately after switching on the potentiostatic polarization of silver and its alloys with zinc in 0.1 M KOH, a positive photocurrent was recorded (Fig. 2b), which indicated the appearance of an oxide film with an n-type conductivity on the surface, which was caused by the predominance of donor defects.

As the charge accumulated and the anode film thickened, the positive photocurrent increased and reached a certain stationary value. This form of dependence is characteristic of thin oxide films whose thickness is less than the width of the space charge region of the semiconductor [21,22,23,24]. As the initial bulk concentration of zinc in the alloy increased, there was a decrease in the stationary value of the photocurrent at all potentials of the preliminary SD.

According to [23, 24], it is possible to obtain a number of structure-sensitive parameters of oxide films formed on alloys with different concentrations of zinc and non-equilibrium vacancies by rearranging the dependence of the photocurrent on time in the photocurrent-thickness coordinates:

Here, iph is the photocurrent density, e is the electron charge (1.6 10−19 C), η is the internal quantum yield, f is the coefficient accounting the difference of the rate constant for generation and consumption of charge carriers, Ф0 is the density of the incident luminous flux, R is the reflection coefficient of the luminous flux from the oxide/solution interface, α is the light absorption index, L is the thickness of the oxide film, and \(i_{{{\text{ph}}}}^{{{\text{max}}}}\) is the density of the maximum photocurrent. Equation (6) is valid for semiconductor films with a small thickness (αL < 1).

An example of the corresponding rearrangement for alloys after anodic modification in 0.01 M HNO3 + 0.09 M KNO3 at E1 showed that the experimental values (markers in Fig. 3) satisfy the theoretical dependence calculated from (3) (lines in Fig. 3). With an increase in thickness, the photocurrent increased, approaching the theoretically expected maximum photocurrent \({i}_{ph}^{max}\) Numerical processing of the experimental data using Eq. (6) in the TableCurve 2D program for regression analysis allowed us to obtain the value of \(i_{{{\text{ph}}}}^{{{\text{max}}}}\) and light absorption index α. Their optimal values were determined on the basis of the maximum agreement between the experimental and theoretical dependences. The thickness that corresponded to the achieved ratio of iph(L)/\({i}_{ph}^{max}\) = 0.99 characterized the width of the space charge region (SCR) W [23, 24]. Based on this, it was possible to calculate the concentration of donor defects ND:

and the Debye screening length in the semiconductor LD:

where ε0 = 8.854 10−12 F m−1 is the dielectric constant, ε(Ag2O) = 8.8 [33] is the dielectric permittivity, E is the electrode potential, Efb = 0.33 V [34] is the flat-band potential of the Ag(I) oxide, k = 1.38 10−23 J K−1 is the Boltzmann constant, and T = 298 K is temperature.

The structure-sensitive parameters calculated for the Ag(I) oxide which was formed anodically on polycrystalline and structure-vacancy silver, which had been obtained as a result of the preliminary anodic modification of alloys due to SD, are presented in Table 3.

For the Ag(I) oxide formed on all of the studied alloys, the value of maximum photocurrent \({i}_{ph}^{max}\) was lower than for the Ag(I) oxide on pure polycrystalline silver. A similar situation was observed for the Ag(I) oxide on alloys of a Ag–Au system [23, 24]. The light absorption index was about 105 cm−1, which is typical for photoactive semiconductor electrodes [35].

On the whole, there was a decrease in \({i}_{ph}^{max}\) and an increase in α with an increase in the initial bulk concentration of zinc in the alloy (from 5 to 20 at.%) and the concentration of non-equilibrium vacancies in the surface layer of each alloy. There was a slight secondary rise in these parameters on the Ag30Zn alloy despite a continuing decrease in the concentration of non-equilibrium vacancies.

For each alloy, the width of the SCR and the Debye region decreased with an increase in the vacancy defectiveness of the surface layer (Table 3). An increase in the initial concentration of zinc in the alloy to 20 at.% had the same effect, which was especially clear in the Ag(I) oxides formed on alloys without preliminary anodic modification [26].

The concentration of donor defects in the Ag(I) oxide increased significantly during the transition from silver to alloys and increased with an increase in the potential of the preliminary anodic modification and, consequently, with an increase in Nvac.

As a whole, values of ND remained much smaller than, for example, those calculated in [36] from the results of impedancometry for the electrodeposited zinc oxide (~ 1020 cm−3); however, they were consistent with the results obtained in [37] for lead oxide (~ 1015 cm−3). Thus, photoelectrochemical measurements can be considered as a method for diagnosing the properties of semiconductor oxide phases.

Therefore, it is possible to trace a certain influence of the chemical composition of the alloy of the Ag–Zn system with NZn ≤ 30 at.% and the energy state of its surface determined by the number of non-equilibrium vacancies on the structure-sensitive parameters of anodically formed oxides. The dependence of the maximum photocurrent, the light absorption index, the concentration of donor defects, the width of the space charge region, and the Debye screening length on the structural state of the substrate surface suggest that the formation of the Ag(I) oxide proceeds predominantly by the direct oxidation of silver rather than through the stages of dissolution/redeposition, at least at the initial stages, until the film thickness does not exceed the width of the SCR.

Conclusions

-

1.

The preliminary anodic modification of Ag–Zn alloys in a deaerated solution of 0.01 M HNO3 + 0.09 M KNO3 leads to the appearance of a surface layer enriched with silver and non-equilibrium vacancies whose concentrations increase with an increase in the anodic modification potential; however, they decrease with an increase in the concentration of zinc in the alloy.

-

2.

The potentiostatic anodic oxidation in deaerated 0.1 M KOH of alloys of the Ag–Zn system with a bulk concentration of zinc of up to 30 at.% and various concentrations of non-equilibrium vacancies in the surface layer results in the formation of the Ag(I) oxide with an n-type conductivity and a predominance of donor defects.

-

3.

With an increase in the concentration of non-equilibrium vacancies in the surface layer of the alloy, and with an increase in the bulk concentration of zinc in the alloy to 20 at.%, there is a decrease in the maximum photocurrent, the width of the space charge region, and the Debye screening length in the oxide film, as well as an increase in the concentration of donor defects in the Ag(I) oxide structure.

-

4.

The dependence of the structure-sensitive parameters of the Ag(I) oxide on the initial concentration of zinc in the alloy and the concentration of vacancies in the surface layer indicates the predominance of the direct mechanism of silver oxidation, at least during the initial stages of the oxide formation.

References

Pickering HW (1967) Electrolytic dissolution of binary alloys containing a noble metal. J Electrochem Soc 114:698–706

Hoshi Y, Ozawa R, Tada E, Nishikata A, Tsuru T (2012) Selective dissolution of binary Pt–Co alloys of different compositions in sulphuric acid solution. Corros Sci 65:512–519

Nikitina EV, Karfidov EA, Kazakovtseva NA (2020) Anodic selective dissolution of copper alloys in chloride and carbonate melts. J Alloys Compd 845:156238

Vvedenskii AV, Kozaderov OA (2013) Linear voltammetry of anodic selective dissolution of homogeneous metallic alloys. In: Saito Y, Kikuchi T (eds) Voltammetry: theory, types and applications. Nova Science Publishers, New York, pp 269–292

Spassov T, Lyubenova L, Liu Y, Bliznakov S, Spassova M, Dimitrov N (2009) Mechanochemical synthesis, thermal stability and selective electrochemical dissolution of Cu–Ag solid solutions. J Alloys Compd 478:232–236

Kutyrev AE, Andreev YY (2007) Thermodynamic calculation of the critical potentials of the selective dissolution of Ag-Au and Cu-Au alloys. Prot Met 43:141–148

Landolt D (2007) Corrosion and surface chemistry of metals. EPFL Press, Lausanne, p 622

Gao P, Zhu Z, Ye X, Wu Y, Jin H, Volinsky AA, Qiao L, Su Y (2015) Defects evolution in nanoporous Au(Pt) during dealloying. Scripta Mater 113:68–70

Kim M-J, Chou Y-S, Park S-H, Huh Y-D (2012) Facile synthesis and fine morphological tuning of Ag2O. Cryst Growth Des 12:4180–4185

Wang W, Zhao Q, Dong J, Li J (2011) A novel silver oxides oxygen evolving catalyst for water splitting. Int J Hydrogen Energy 36:7374–7380

Shinde SS, Patil PS, Gaikwad RS, Mane RS (2010) Influence of high quality zinc oxide film and their photoelectrochemical performance. J Alloys Compd 503:416–421

Gupta M, Sharma V, Shrivastava J, Solanki A (2009) Preparation and characterization of nanostructured ZnO thin film for photoelectrochemical splitting for water. Bull Mater Sci 32:23–30

Wei J, Lei Y, Jia H, Cheng J, Hou H, Zheng Z (2014) Controlled in situ fabrication of Ag2O/AgO thin films by a dry chemical route at room temperature for hybrid solar cells. Dalton Trans 43:11333–11338

Sarkar D, Ghosh CK, Mukherjee S, Chattopadhyay KK (2013) Three dimensional Ag2O/TiO2 Type-II (p–n) nanoheterojunctions for superior photocatalytic activity. ACS Appl Mater Interfaces 5:331–337

Mirzaeian M, Ogwu AA, Jirandehi HF, Aidarova S, Ospanova Z, Tsendzughul N (2017) Surface characteristics of silver oxide thin film electrodes for supercapacitor applications. Colloids Surf A 519:223–230

Shahriary L, Athawale AA (2015) Electrochemical deposition of silver/silver oxide on reduced graphene oxide for glucose sensing. J Solid State Electrochem 19:2255–2263

Ma S, Xue J, Zhou Y, Zhang Z (2014) Photochemical synthesis of ZnO/Ag2O heterostructures with enhanced ultraviolet and visible photocatalytic activity. J Mater Chem A 2:7272–7280

Mahanti M, Basak D (2012) Ag-ZnO nanorods having enhanced emission and photocurrent properties. AIP Conf Proc 713–714

Li Y, Zhao X, Fan W (2011) Structural, electronic, and optical properties of Ag-doped ZnO nanowires: first principles study. J Phys Chem C 115:3552–3557

Krajewski TA, Luka G, Gierltowska S, Zakrzewski AJ, Smertenko PS, Kruszewski P, Wachnicki L, Witkowski BS, Lusakowska E, Jakiela R, Godlewski M, Guziewicz E (2011) Hafnium dioxide as a passivating layer and diffusive barrier in ZnO/Ag Schottky junctions obtained by atomic layer deposition. Appl Phys Lett 98:263502

McAleer JF, Peter LM (1980) Photocurrent spectroscopy of anodic oxide films on titanium. Faraday Discuss Chem Soc 70:67–75

Collisi U, Strehblow H-H (1990) The formation of Cu2O layers on Cu and their electrochemical and photoelectrochemical properties. J Electroanal Chem 284:385–401

Kudryashov DA, Grushevskaya SN, Ganzha SV, Vvedenskii AV (2009) Effect of the crystal face orientation and alloying with gold on the properties of thin anodic films of Ag(I) oxide: I. Photocurrent Prot Met Phys Chem Surf 45:501–511

Vvedenskii A, Grushevskaya S, Kudryashov D, Ganzha S (2010) The influence of the conditions of the anodic formation and the thickness of Ag(I) oxide nanofilm on its semiconductor properties. J Solid State Electrochem 14:1401–1413

Ganzha SV, Maksimova SN, Grushevskaya SN, Vvedenskii AV (2011) Formation of oxides on copper in alkaline solution and their photoelectrochemical properties. Prot Met Phys Chem Surf 47:191–202

Murtazin MM, Nesterova MYu, Grushevskaya SN, Vvedenskii AV (2019) Silver(I) Oxide on silver–zinc alloys: anodic formation and properties. Russ J Electrochem 55:680–689

Grushevskaya SN, Vvedenskii AV, Zaitseva VO (2020) Parameters of oxide films anodically formed on Ag-Zn alloys with different concentrations of vacancy defects in the surface layer. Kondens Sredy Mezhfaznye Granitsy = Condensed Matter and Interphases 22:48–57

Pickering HW (1968) Volume diffusion during anodic dissolution of a binary alloy. J Electrochem Soc 115:143–147

Kozaderov OA, Sazhneva OV, Koroleva OV, Vvedenskii AV (2005) Solid-Phase Diffusion at a Potentiostatic Dissolution of Silver Alloyed with Gold. Prot Met 41:329–340

Kozaderov OA, Bobrinskaya EV, Kartashova TV, Vvedenskii AV (2005) Solid-Phase Diffusion at a Galvanostatic Anodic Dissolution of Zn-Ag and Cu-Au Alloy. Prot Met 41:449–459

Larikov LN, Isaichev VI (1987) Diffuziya v metallakh i splavakh (Diffusion in Metals and Alloys). Naukova Dumka, Kiev, p 510

Orlov AN, Trushin YuV (1983) Energii tochechnykh defektov v metallakh (Energies of Point Defects in Metals). Energoizdat, Moscow, p 80

Novyi spravochnik khimika i tekhnologa [New handbook for a chemist and technologist] / Ed. By A. V. Moskvin. SPb.: Professional, 2006. P. 1464. (In Russ.)

Jiang ZY, Huang SY, Qian B (1994) Semiconductor properties of Ag2O film formed on the silver electrode in 1 M NaOH solution. Electrochim Acta 39:2465–2470

Peter LM, Walker AB, Bein T, Hufnagel AG, Kondofersky I (2020) Interpretation of photocurrent transients at semiconductor electrodes: Effects of band-edge unpinning. J Electroanal Chem 872:114234

Singh N, Choudhary S, Upadhyay S, Satsangi VR, Dass S, Shrivastav R (2014) Nanocrystalline Zn1−xAgxOy thin films evolved through electrodeposition for photoelectrochemical splitting of water. J Solid State Electrochem 18:523–533

Sharon M, Mukhopadhyay I, Ghosh S (1999) Photoelectrochemical laser imaging on anodically prepared a-PbO thin films. J Solid State Electrochem 3:141–147

Acknowledgments

The study was supported by the Ministry of Science and Higher Education of the Russian Federation under Agreement N 075–15-2021–1351.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Bocharnikova, M.Y., Murtazin, M.M., Grushevskaya, S.N. et al. Anodic formation and properties of nanoscale oxide layers on silver–zinc alloys with different concentrations of non-equilibrium vacancies. J Solid State Electrochem 26, 1637–1644 (2022). https://doi.org/10.1007/s10008-022-05204-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10008-022-05204-z