Abstract

The flexible TiC/carbon nanofiber (TiC/C NF) film was prepared by electrospinning, stabilization, and carbonization. All the obtained TiC/CNFs had rough surface and random orientation, and the TiC nanoparticles (NPs) were uniformly dispersed on the CNFs. With the increase of TiC NPs, the flexural property of TiC/CNF film increased. While, the electrical conductivity increased, reaching a largest value before decreasing as the amount of TiC NPs increases. These highly flexible films showed promising electrical conductivity and electrocatalytic activity. Hence, they were employed as counter electrodes (CEs) for flexible dye-sensitized solar cells (FDSSCs). After the optimization of the amount of TiC NPs in CNFs (when the Tip content in precursor was 12 wt%), a high conversion efficiency of 3.80% was obtained. This is due to its optimum electrical conductivity and catalytic active sites. Based on the optimum amount of TiC NPs, the mesopores TiC/CNF composite films were fabricated by the introduction of various amount of polymethyl methacrylate (PMMA) in an electrospun solution. With the ratio of PMMA/(PAN/PVP) increasing, the specific surface area and the electrical conductivity increased, reached the largest values corresponding to 1:1, and then decreased. The increased surface area and conductivity facilitated the diffusion of electrolyte and reduction of triiodide, resulting in the improvement of the properties of CEs. When the FDSSCs were assembled with mesoporous TiC/CNF films as CEs, the conversion efficiency can be further enhanced up to 4.47%, which can be even comparable to the Pt/FTO CE.

ᅟ

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

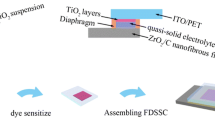

As a promising photovoltaic device, flexible dye-sensitized solar cells (FDSSCs) have attracted much attention due to their advantages such as flexibility, environment friendliness, relatively low cost, colorfulness, portable, and the possibility of roll-to-roll fabrication process [1]. As is well known, counter electrode (CE) plays an important role in collecting external circuit electronics and catalyzing triiodide (I3 −) reduction. Therefore, the excellent conductivity and catalytic ability towards I3 −/I− species become the key issues for the enhancement of conversion efficiency (η) for FDSSCs. So far, platinum (Pt) is an ideal material as the electrocatalyst of CE. However, Pt is expensive and rare, and hence, it is not suitable for the mass production and commercialization of FDSSCs.

For the past two decades, several Pt-free or low Pt loading materials have been developed to reduce the fabrication cost of FDSSCs: carbon material (carbon spheres [2], graphene [3], carbon aerogel [4], and carbon nanotubes [5], e.g.), conducting polymers [6, 7], and inorganic compounds including transition metal oxide [8], sulfides [9], selenides [10], and carbides [11]. Among carbonaceous materials, electrospun carbon nanofibers (CNFs) and their composites have been employed as efficient catalyst owing to the prominent properties such as high conductivity, large surface area, uniform diameter, and intrinsically corrosion resistance against the redox couple [12]. Nevertheless, the electrocatalytic activity of CNFs remains to be desired, and transition metal compounds exhibit excellent electrocatalytic activity but poor conductivity. Accordingly, transition metal compounds/CNF composite CEs have attracted extensive attention such as TiC/CNFs [13], WC/CNFs [14], CoS/CNFs [15], and Co3O4/CNFs [16]. These CEs were achieved by doctor blading or screen printing the paste containing organic binder onto the substrate and used in rigid glass dye-sensitized solar cells (DSSCs). Although the binder is used to facilitate the preparation of CE and improve the adhesion between the materials and the substrates, the binder can bring the possible side reaction [17]. Besides, the conductive oxide coating plastic films (ITO-PEN or ITO-PET) are always used as the flexible substrate of CE for FDSSCs [18,19,20]. However, the ITO is very expensive and fragile. The flexible substrates such as metal foil [21,22,23], metal mesh [24, 25], carbon cloth [26, 27], fabric [28], graphene papers [29], carbon fiber paper[30], and flexible graphite sheet [31] have been explored to replace the ITO or ITO/PEN for FDSSCs.

It would be of interest to ask if a highly flexible transition metal compounds/CNF film could be prepared, it would serve as a binder-free CE as well as a substrate for FDSSCs. In this study, the highly flexible TiC/CNF films are prepared by electrospinning, stabilization, and carbonization and used in FDSSCs as CEs. And the effects of the amount of TiC on the morphologies, structures, and properties are investigated. On the basis of optimum TiC amount, the mesoporous TiC/CNF CEs are prepared and the effects of mesoporous structures on the properties of CE for FDSSCs are studied.

Experimental section

Materials

Polyacrylonitrile (PAN, M w = 140,000) was purchased from Hangzhou Acrylon Co. Polyvinylpyrrolidone (PVP, M w = 1,300,000), titanium isopropoxide (Tip), P25 (TiO2 nanoparticles), lithium iodide (LiI, 99%), iodine (I2, 99.8%), and lithium perchlorate (LiClO4, 99.9%) were obtained from Aladdin. N, N-Dimethylformamide (DMF) and acetic acid were supplied from Hangzhou Gaojing Fine Chemical Industry Co. Polymethyl methacrylate (PMMA) was purchased from Shanghai Macklin Biochemical Technology Co. The acetonitrile was bought from Tianjin Kermel Chemical Reagent Co. The tert-butyl alcohol was received from Tianjin Yongda Chemical Reagent Company. The dye (N719), quasi solid state electrolyte (OPV-MPV-I), Pt/FTO, and flexible ITO/PEN substrate (the transmittance > 90%, 60 Ω/□) were supplied from OPV Tech Co.

Fabrication of the CEs

Flexible TiC/CNF composite films with various amounts of TiC were prepared by electrospinning and thermal treatment. First, 0.4 g PAN, 0.4 g PVP, and 6 mL DMF were mixed in a sealed glass bottle and magnetically stirred 4 h at 25 °C. Then, 5, 9, 12, and 15 wt% Tip were respectively added to the solution containing a little acetic acid and stirred overnight to form precursor solutions. Subsequently, the precursor solution was transferred to a 10-mL glass syringe connected with a stainless needle. During electrospinning, the flow rate was 0.8 mL h−1, the collecting distance was 14 cm, and the applied voltage was 15 kV. These electrospun PAN/PVP/Tip membranes were peeled off from the aluminum foil and placed into a tube furnace for thermal treatment. After that, they were stabilized at 250 °C for 1 h in air with a heating rate of 5 °C min−1 and carbonizedat1000 °C for 0.5 h in argon. The membranes from different amounts of Tip in precursor solution were marked as Tip-5, Tip-9, Tip-12, and Tip-15, respectively. The mesoporousTiC/CNF films were fabricated by the same process. First, the PAN/PVP/Tip/DMF solution was prepared by a similar method with Tip-12. Second, the 12 wt% Tip was dispersed in a 22 wt% PMMA solution in DMF. Third, the two prepared solutions were mixed together with different mass ratios. The calculated blend ratios of PMMA/(PAN/PVP) were 0.25:1, 1:1, and 2:1 (by weight). Through electrospinning and thermal treatment with the same parameters, the mesoporous TiC/CNF films were obtained. The three samples were denoted as TiC/C-0.25, TiC/C-1, and TiC/C-2, respectively.

FDSSC fabrication

For the flexible photoanode, the P25 was firstly sintered under air condition at 450 °C for 2 h. Then, 9.5 wt% sintered P25 was dispersed in anhydrous ethanol and magnetically stirred 6 h. The stabilized P25 dispersion was electrosprayed onto a cleaned ITO/PEN substrate (1 × 2 cm) and dried in air. Thereafter, the substrate was immersed in a solution of 0.5 mM N719 dye in acetonitrile and tert-butanol (volume ratio 1:1) for 24 h. Finally, the dye-absorbed photoanode and CE (TiC/CNF film or mesoporous TiC/CNF film) were sealed together. The interface between the photoanode and the CE was filled with the quasi solid state electrolyte. The active area of FDSSCs was 0.25 cm2. Additional, the DSSCs with Pt/FTO CE and flexible photoanode were fabricated with the same process as contrast.

Measurements

A field-emission scanning electron microscope (FESEM, Ultra55, ZEISS, Germany) was employed to examine morphology of the nanofibrous film. The elemental compositions of the fiber surface were estimated by energy-dispersive spectroscopy (EDS) which was attached with FESEM. The microstructures of the samples were investigated by transmission electron microscope (TEM, JEM 2100, Japan). The X-ray diffractomer (XRD, Thermo ARL-X’TRA, America) with Cu Kα (λ = 1.5418 Å) was utilized to identify the crystalline structure of the sampleand the scan range was from 20°to 80° (2θ). The specific surface area and pore size distribution were conducted using N2 adsorption/desorption isotherms by means of the Brunauer-Emmett-Teller (BET). The flexural properties of the samples were measured by computer controlled stiffness tester (model LLY-01, Laizhou Electron Instrument Co., Ltd.). The electrical properties of the samples were characterized by a four-point probe tester (SZT-2). The electrochemical properties of the samples were obtained with electrochemical working station (CHI660C, Shanghai Chen Hua instrument Co.). Cyclic voltammetry (CV) measurements of TiC/CNF-, mesoporous TiC/CNF-based CEs were carried out in a three-electrode system in acetonitrile solution, which containing 0.5 mM I2, 5 mM LiI, and 0.1 M LiClO4 with a scan rate 20 mV s−1. Thereinto, a Pt wire is worked as a CE, versus the Ag/AgCl reference electrode. The electrochemical impedance spectroscopy (EIS) and Tafel polarization measurements were performed using the symmetrical cells (CE//electrolyte//CE). Photocurrent density-voltage (J-V) curves were measured using Keithley Model 2400-SCS Source meter under AM 1.5 illumination. A xenon arc light was used as a light source (CHF-XM 35-500W, Beijing Chang Tuo Technology Co.), and the intensity of light was 100 mW cm−2.

Results and discussion

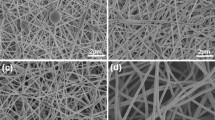

Figure 1 shows the FESEM images of TiC/CNFs with different amounts of Tip in the precursor. As can be seen, these continuous NFs are involved in numerous macropores, which is conducive to the diffusion of electrolyte. Note that the long NFs are randomly oriented in all directions, and the doped nanoparticles (NPs) are attributed to the decomposition of Tip. Furthermore, the amounts of NPs increase with Tip. As shown in Fig. 1, the average diameters of the composite NFs are 307 ± 32 nm for Tip-5, 339 ± 80 nm for Tip-9, 394 ± 32 nm for Tip-12, and 447 ± 32 nm for Tip-15, respectively. Fig. S1 shows the EDS result of TiC/CNFs. The EDS spectrum of TiC/CNFs shows peaks of C and Ti, which indicates that the composite nanofibrous film was prepared successfully.

The typical X-ray diffraction (XRD) pattern of the composite NFs is presented in Fig. 2. A broad peak at 25° can be attributed to carbon (002). Other distinct diffraction peaks centered at 36, 42, 62, 74, and 78°, which are assigned to the crystallographic planes of (111), (200), (220), (311), and (222) for the cubic structures of TiC (JCPDS no. 32-1383). These peaks further confirm that the NPs are TiC. The formation of TiC involves three stages [32]: firstly, the decomposition of the Tip (C12H28O4Ti) to TiO2 in Eq. (1); Subsequently, PAN [C3H3N)n] and PVP [(C6H9NO)n] are converted into C gradually after stabilization and carbonization as shown in Eqs. (2) and (3); after that, the transformation of TiO2 and C to TiC in Eq. (4).

TEM and HRTEM were used to observe the detailed microstructures of the sample. The TEM image of TiC/CNFs in Fig. 3a confirms that TiC crystallites are relative small and randomly distributed in the matrix of carbon. As evidenced from the HRTEM image (Fig. 3b), the interplanar spacing of TiC crystallites is 2.5 Å, corresponding well to the reported value of the (111) crystal plane of TiC [33].

The flexural properties of TiC/CNF composite films with different amounts of TiC were tested using computer controlled stiffness tester. All the parameters are summarized in Table 1. The slip length (L) could be obtained directly from the tester. The bending stiffness (B) and modulus of elasticity (q) were obtained according to Eqs. (5) and (6).

Where G and t represent the area density and thickness of the film. The details of G, L, B, and t values are listed in Table S1. The flexural properties of the nanofibrous film are evaluated mainly by modulus of elasticity. In general, a high modulus of elasticity means a low flexibility. It is observed that the flexibility of composite nanofibrous film is gradually increased with TiC NPs. The possible toughing mechanism is conceived. Similar to the nanoceramics [34], the fracture toughness of CNFs can be strengthened by the introduction of TiCNPs. It is well known that CNFs is a kind of brittle material and brittle fracture occurs when the force is applied on it. The enhancement on the toughness of the nanofibrous film could be attributed to two reasons. On the one hand, the doped TiCNPs increase the fracture energy [35]. There is only one kind of interface on the CNFs. By contrast, a secondary interface between CNFs and TiC emerges after the introduction of NPs. When the nanofibrous film is subjected to external force, the secondary interface becomes stronger, while the main interface becomes weaker. Both strong and weak interfaces exist reinforce the toughness of TiC/CNF composite film. On the other hand, due to the existence of residual stress, microcracks near the phase boundary of CNFs-TiC absorb a large amount of energy, and the resistance to crack propagation can be significantly enhanced, leading to increased toughness. The digital photographs of TiC/CNF film are shown in Fig. 4, the film can be bent into a circle (Fig. 4a) or folded into a roll (Fig. 4b), even can be twisted into a rope (Fig. 4c).

The electrical properties of TiC/CNF composite films with various amounts of TiC are given in Table 2. With the increase in the content of Tip from 5 to 12 wt%, the conductivity increases as expected due to the increase in the amount of conductive TiC. With further increase of Tip from 12 to 15 wt%, the conductivity decreases slightly. This can be attributed to the excesses in the amount of TiC in the CNFs, which can deteriorate the continuity and one-dimensional conductive pathway of CNFs. Among the TiC/CNF composite films, Tip-12 possesses the maximum average conductivity (33.33 Sm−1) and the minimum square resistance (22.50 Ω-□).

The electrocatalytic activity of CEs was measured by CV with a three-electrode system. Figure 5a depicts CV curves of Tip-5, Tip-9, Tip-12, and Tip-15. There are two pairs of redox peaks for the all CEs, corresponding to oxidation and reduction of I3 −/I− and I3 −/I2. The more negative pair (Aox/ARe) is assigned to Eq. (7), which directly affects the performance of FDSSCs, and the more positive one (Box/BRe) is assigned to Eq. (8), which has little effect on the performance of FDSSCs. We focus on the negative pair (I3 −/I−).

a Cyclic voltammograms obtained at a scan rate of 20 mVs−1 for the oxidation and reduction of I3 −/I− redox couple using TiC/CNF working electrode, Pt wire as the counter electrode and Ag/AgCl as the reference electrode. The electrolyte is 0.5 mM I2, 5 mM LiI, and 0.1 M LiClO4 in acetonitrile. b The Nyquist plots of the symmetrical dummy cells using TiC/CNF CEs. The inset shows the equivalent circuit. c The Tafel polarization curves of the dummy cells fabricated with TiC/CNF CEs. d The current density-voltage curves for FDSSCs with TiC/CNF CEs

In this type of CV, a higher reduction current density (I pc) indicates a higher electrocatalytic activity. It can be seen that the values of I pc (ARe) for Tip-5, Tip-9, Tip-12, and Tip-15 are 4.55, 6.60, 7.45, and 5.85 mA cm−2, respectively. The Tip-12 CE shows a higher I pc than other CEs, implying the best electrocatalytic activity, which originates from the optimum amount of TiC as catalytic active sites.

To further study the electrocatalytic activity of the CEs, the symmetrical dummy cells (CE//electrolyte//CE) were used for the EIS characterization. The inset in Fig. 5b is the equivalent circuit used to analyze the EIS. The internal series resistance (R s) is the onset point of the first semicircle in the high frequency region, which represents the contact resistance of the CE. The charge-transfer resistance (R ct) can be calculated by the diameter of the semicircle illuminated in the spectra, which represents the resistance at the electrocatalytic film/electrolyte interface. A low R ct value implies rapid passage of a large amount of charge.

As shown in Fig. 5b and Table 3, the values of both R ct and R s for Tip-12 is the lowest among these CEs, which indicates the best electrocatalytic activity of Tip-12 due to a balance of active sites and electrical conductivity.

To further explore the interfacial charge-transfer property of the couple I3 −/I− on the electrode surface, Tafel polarization curves were carried out in dummy cells. Generally, a Tafel curve can be divided into three zones: (1) the polarization zone (|V| < 120 mV), (2) the Tafel zone (120 mV < |V| < 400 mV), and (3) the diffusion zone (|V| > 400 mV). The exchange current density (J 0) is evaluated from the intercept of the extrapolated linear of anodic and cathodic branches in Tafel zone when the overpotential is zero. In theory, a higher J 0 suggests a better catalytic activity. Additionally, J 0 is inversely related to R ct according to the Eq. (9).

Where R ct is extracted from the EIS, T is the absolute temperature, R is the gas constant, and n is the number of electrons transferred for the I3 − reduction.

Figure 5c displays the Tafel plots of TiC/CNFs with different amount of TiC, and the values of J 0 are also summarized in Table 3. It is clear seen that the highest value of J 0 can be achieved using the Tip-12 CE, implying the better electrocatalytic activity of Tip-12 than that of other TiC/CNF CEs.

Figure 5d shows the representative current density-voltage curves (J-V) of FDSSCs with different TiC/CNF CEs, and the corresponding photovoltaic parameters are summarized in Table 3. The FDSSCs that employed Tip-12 flexible CE show the highest η of 3.80%, which results from the superior J sc and FF. The higher J sc and FF for Tip-12 CE attribute to the lower internal resistance and suitable active sites. Based on previous results, it is reasonable that the Tip-12 is selected as the basis for the preparation of mesoporous TiC/CNF flexible CEs.

To further improve the electrocatalytic activity of CE, the mesoporous TiC/CNF films were prepared. Figure 6b shows the typical FESEM image of mesoporous TiC/C-1. In the precursor solution, the PMMA served as the sacrificial component. Due to the immiscibility and thermal stability between PMMA and PAN/PVP during electrospinning and thermal treatment [36], the continuous NFs could be obtained. During the carbonization process, the PMMA decomposed, behaving as a self-sacrificed material and resulting in the formation of the mesoporous TiC/CNF composite with a large pore volume and high specific surface area. By contrast, for all the mesopore TiC/CNF films, the FESEM images reveal no difference in the surface morphology with and without the addition of PMMA in the precursor solution and no obvious pores are observed on the surface of CNFs (the FESEM images of other mesoporous TiC/CNFs are shown in Fig. S2). When the mass ratio of PMMA/(PAN/PVP) increased to 2:1, the NFs exhibit a non-uniform distribution of fibers (Fig. S2c). It is known that the spinability of PMMA is lower than that of PAN/PVP [37], and hence, the diameters of NFs are less homogeneous with large amount of PMMA.

To further confirm the difference between the TiC/CNFs and the mesoporous TiC/CNFs, TEM examinations were carried out as shown in Fig. 7. In contrast with TiC/CNFs (Fig. 7a), abundant pores are observed throughout the mesoporous TiC/CNFs (Fig. 7b). At the same time, the HRTEM image inset in Fig. 7b shows clear lattice fringes separated by 2.5 Å, which corresponds to the (111) lattice plane of TiC.

To investigate the effect of PMMA content on the pore structures of TiC/CNFs, nitrogen adsorption-desorption isotherms for Tip-12 and mesoporous TiC/CNFs are shown in Fig. 8a. All isotherms are type IV pattern characteristic for mesoporous materials. The hysteresis loop is associated with capillary condensation in the mesoporous [38]. A summary of calculated BET-specific surface area, total pore volume, and average pore size from isotherms is listed in Table 4. Obviously, the BET surface area increases with the PMMA/(PAN/PVP) ratio from 0.25:1 to 1:1 and then it almost remains constant with the ratio of PMMA/(PAN/PVP) further increasing. Figure 8b reflects the respective pore size distribution. The pore sizes locate at 1–60 nm. For mesoporous TiC/CNF films, the amounts of pores with sizes of 6 to 15 nm obviously increase. However, the pore sizes of three mesoporous TiC/CNF composites are similar. The total pore volume increases with the introduction of PMMA. The abundant micropores (< 2 nm) and a few mesopores are the reason why the pore sizes of three mesoporous TiC/CNF composites are relative small. An initial increase in BET surface area for the samples is due to more mesoporous. However, with a further increase of the content of PMMA, the decomposition of excessive PMMA leads to drastic decrease of carbon content, which has a greater contribution to more micropores. Hence, excessive PMMA has no longer contributed to the enhancement of a specific surface area. Typically, the TiC/C-1 shows the excellent pore characteristics with a BET-specific surface area of 280 m2 g−1, total pore volume of 0.165 cm2 g−1, and average pore size of 2.36 nm than any other samples. In consideration of the size of I3 − ions is over 1 nm, the intrinsically macropores and the increase of mesoporous structures of electrospun nanofibrous film, leading to enhanced reaction rate of I3 −/I− redox. Because, the enriched porous provides more chance of electrolyte to contact with TiC/CNF CE [36]. It is worth believing that it is extremely beneficial in FDSSC application.

The flexural properties of mesoporous TiC/CNF composite films with various amounts of PMMA content are analyzed. As shown in Table 5, the modulus of elasticity of mesoporous TiC/CNF films increases compared to the Tip-12. The results manifest that the increase of mesoporous would damage the flexibility of TiC/CNF film. Nevertheless, the mesoporous TiC/CNF film still can be twisted as shown in Fig. S3.

For mesoporous TiC/CNF composite films with different PMMA content, the addition of a suitable amount of PMMA could improve the electrical conductivity as shown in Table 6. Kim reported that the electrical conductivity of CNF film was increased by the addition of PMHS, which acted as a catalyst for creating pores [39]. Our results are consistent with their works. As the mass ratio of PMMA increases from 1/5 to 1/2, an increase in conductivity is observed, from 33.33 Sm−1 for Tip-12 to 80.00 Sm−1 for TiC/C-1, while a decrease in the square resistance from 22.50 Ω-□ for Tip-12 to 9.20 Ω-□ for TiC/C-1. With further increasing the mass ratio of PMMA to 2/3, the intensive PMMA pyrolysis result in the decrease of carbon content; thus, the conductivity decreases to 34.13 Sm−1 (square resistance 23.03 Ω-□). Additionally, the Pt/FTO exhibits exceptional electrical property (square resistance, 8.60 Ω-□; average conductivity, 90.91 Sm−1).

Figure 9a shows the CV curves of mesoporous TiC/CNF films. The values of I pc are 19.55, 21.63, and 15.34 mA cm−2 for TiC/C-0.25, TiC/C-1, and TiC/C-2. The values of I pc of all mesoporous TiC/CNF CEs are over Tip-12 and Pt/FTO (2.00 mA cm−2). Obviously, the TiC/C-1 shows the highest I pc than other samples. For the mesoporous TiC/CNF CEs, the macropores are helpful to the absorption of electrolyte, while the mesoporous have appropriate adsorption energy, which facilitates the diffusion and adsorption of I3 −. Based on these results, the TiC/C-1 is expected to be excellent and flexible substitute for rigid Pt/FTO CE.

The EIS spectra of the various mesoporous TiC/CNF CEs and reference Pt/FTO CE are shown in Fig. 9b. The simulated data are summarized in Table 7. Since the mesopores in the TiC/CNFs facilitate the diffusion of electrolyte, it can be inferred that the more mesoporous are, the easier the diffusion of electrolyte. Notably, the values of R ct for mesoporous TiC/CNF CEs are smaller than Tip-12 initiated from more mesoporous. The TiC/C-1 shows the smallest R ct, which shows its better electrocatalytic activity among various mesoporous TiC/CNF CEs.

Figure 9c displays the Tafel polarization curves for the electrodes of TiC/C-0.25, TiC/C-1, TiC/C-2, and the reference Pt/FTO. With the increase of PMMA in the precursor solution, the J 0 of these CEs shows an increasing tendency from TiC/C-0.25 to TiC/C-1 and then a decreasing tendency from TiC/C-1 to TiC/C-2. It is noted that the TiC/C-1 exhibits the largest J 0 among mesoporous TiC/CNF CEs and even over Pt/FTO glass CE. The J 0 for TiC/C-1 is larger than Tip-12, the intrinsic electrocatalytic activity of TiC and large surface area of the nanofibrous film are apparently the reasons for its favorable role in enhancing the J 0 of the composite film. The order of J 0 is well accordance with calculated J 0 from Eq. (7).

Figure 9d shows the current density-voltage curves (J-V) of FDSSCs with different mesoporous TiC/CNF CEs and Pt/FTO-based DSSCs. And the corresponding photovoltaic parameters are also summarized in Table 7. Among the cells based on TiC/C-x CEs, the one of TiC/C-0.25 displays the η of 4.16% due to the relatively larger J sc and V oc than that of Tip-12 CE. With the largest J sc, V oc, and FF among mesoporousTiC/CNF CEs, the cell based on the TiC/C-1 CE achieves the highest η of 4.47% and even comparable to that of the one using Pt/FTO CE (4.60%), suggesting its excellent electrocatalytic activity. The larger V oc offers an easier reduction process for the I3 − to I−. In comparison to TiC/CNF CE-based FDSSCs, the values of V oc of mesoporous TiC/CNF CEs are markedly enhanced, suggesting their excellent catalytic activities closely associated with the well-developed macropores and mesoporous structures. Noticeably, the TiC/C-2 shows relatively low V oc of 0.60 V, J sc of 12.09 mA cm−2, and FF of 50.52%, implying its poorer electrocatalytic activity of TiC/C-2 CE, thanks to its poorer electrical property.

The improvement of photovoltaic performance for mesoporous TiC/CNF CEs arises from the following reasons. First, the flexibility, conductivity, and electroactivity of CNF film are improved arises from the doping of TiC NPs. By optimizing the amount of TiC NPs, the TiC/CNF composite film achieves an optimal efficiency used as CE for FDCSSCs. Second, the regulation of pore structures increases the BET surface area of the nanofibrous film. The higher surface area and enriched mesoporous contribute to the fast diffusion of electrolyte and effective catalysis of I3 −. In summary, the synergistic effect promotes higher photovoltaic performance by providing the smaller internal series resistance and higher value of J sc, V oc, and FF. Optimizing flexible photoanode and developing more efficient CE materials would further in favor of the enhancement of efficiency of FDSSCs.

Conclusions

The flexible TiC/CNF films with various amounts of TiCNPs have successfully been prepared through electrospinning and thermal treatment process. Doped Ti CNPs increased the fracture toughness, and the possible mechanism was proposed. The TiC/CNF films with favorable electrical conductivity and appropriate catalytic active sites are employed as CEs. After optimizing the amount of TiC NPs, the Tip-12 film makes itself acquire a conversion efficiency of 3.80%. On the basis of Tip-12, flexible mesoporous TiC/CNF films with different PMMA content are prepared. When the ratio of PMMA/(PAN/PVP) is 1:1, the TiC/C-1 film with macropores and mesoporous structures possesses a specific surface area of 280 m2 g−1, average pore diameter of 2.36 nm and total pore volume of 0.165 cm2 g−1, and electrical conductivity of 80.00 Sm−1. By combining the easier electrolyte diffusion and the faster reduction of I3 −, the TiC/C-1 exhibited superior electrocatalytic activity when used as CE. As a consequence, the mesoporous TiC/C-1 CE-based FDSSCs achieved the maximum photovoltaic conversion efficiency of 4.47%, which is very close to 4.60% of the Pt-based DSSCs under the same experimental condition. Hence, mesoporous TiC/CNF film possesses great potential in the application in the flexible CE of the FDSSCs due to their facile preparation, excellent flexibility, low cost, and high electrocatalytic efficiency.

References

Liang J, Zhang G, Sun W, Dong P (2015) High efficiency flexible fiber-type dye-sensitized solar cells with multi-working electrodes. Nano Energy 12:501–509

Zhu Y, Gao C, Han Q, Wang Z, Wang Y, Zheng H, Wu M (2017) Large-scale high-efficiency dye-sensitized solar cells based on a Pt/carbon spheres composite catalyst as a flexible counter electrode. J Catal 346:62–69

Xu X, Yang W, Chen B, Chen Z, Zhou C, Ma X, Hou L, Tang Y, Yang F, Ning G, Zhang L, Li Y (2017) Phosphorus-doped porous graphene nanosheet as metal-free electrocatalyst for triiodide reduction reaction in dye-sensitized solar cell. Appl Surf Sci 405:308–315

Zhao B, Huang H, Jiang P, Zhao H, Huang X, Shen P, Wu D, Fu R, Tan S (2011) Flexible counter electrodes based on mesoporous carbon aerogel for high-performance dye-sensitized solar cells. J Phys Chem C 115:22615–22621

Peng S, Wu Y, Zhu P, Thavasi V, Mhaisalkar SG, Ramakrishna S (2011) Facile fabrication of polypyrrole/functionalized multiwalled carbon nanotubes composite as counter electrodes in low-cost dye-sensitized solar cells. J Photochem Photobiol A 223:97–102

Sun H, Luo Y, Zhang Y, Li D, Yu Z, Li K, Meng Q (2010) In situ preparation of a flexible polyaniline/carbon composite counter electrode and its application in dye-sensitized solar cells. J Phys Chem C 114:11673–11679

Anothumakkool B, Agrawal I, Bhange SN, Soni R, Game O, Ogale SB, Kurungot S (2016) Pt- and TCO-free flexible cathode for DSSC from highly conducting and flexible PEDOT Paper Prepared via in situ interfacial polymerization. ACS Appl Mater Interfaces 8:553–562

Zhang L, Que L, Wu W, Wu J (2016) High-performance Pt-NiO nanosheet-based counter electrodes for dye-sensitized solar cells. J Solid State Electrochem 20:759–766

Antonelou A, Syrrokostas G, Sygellou L, Leftheriotis G, Dracopoulos V, Yannopoulos SN (2016) Facile, substrate-scale growth of mono- and few-layer homogeneous MoS2 films on Mo foils with enhanced catalytic activity as counter electrodes in DSSCs. Nanotechnology 27:045404

Dong J, Wu J, Jia J, Ge J, Bao Q, Wang C, Fan L (2017) A transparent nickel selenide counter electrode for high efficient dye-sensitized solar cells. Appl Surf Sci 401:1–6

Li L, Sui H, Zhang W, Li X, Yang K, Hagfeldt A, Wu M (2016) Mesoporous carbon-imbedded W2C composites as flexible counter electrodes for dye-sensitized solar cells. J Mater Chem C 4:6778–6783

Joshi P, Zhang L, Chen Q, Galipeau D, Fong H, Qiao Q (2010) Electrospun carbon nanofibers as low-cost counter electrode for dye-sensitized solar cells. ACS Appl Mater Interfaces 2:3572–3577

Saranya K, Subramania A, Sivasankar N, Mallick S (2016) ElectrospunTiC embedded CNFs as a low cost platinum-free counter electrode for dye-sensitized solar cell. Mater Res Bull 75:83–90

Jeong I, Lee J, Joseph KLV, Lee HI, Kim JK, YoonS LJ (2014) Low-cost electrospun WC/C composite nanofiber as a powerful platinum-free counter electrode for dye sensitized solar cell. Nano Energy 9:392–400

Saranya K, Subramania A, Sivasankar N, Bhargava P (2017) In-situ growth of CoS nanoparticles onto electrospun graphitized carbon nanofibers as an efficient counter electrode for dye-sensitized solar cells. J Nanosci Nanotechnol 17:398–404

Li L, Xiao J, Sui H, Yang X, Zhang W, Li X, Hagfeldt A, Wu M (2016) Highly effective Co3S4/electrospun-carbon-nanofibers composite counter electrode synthesized with electrospun technique for cobalt redox electrolyte based on dye-sensitized solar cells. J Power Sources 326:6–13

Huang J, Zhang B, Xie YY, Lye WWK, Xu ZL, Abouali S, Garakani MA, Huang JQ, Zhang TY, Huang B, Kim JK (2016) Electrospun graphitic carbon nanofibers with in-situ encapsulated Co–Ni nanoparticles as freestanding electrodes for Li–O2batteries. Carbon 100:329–336

Luo QP, Wang B, Cao Y (2017) Single-crystalline porous ZnO nanosheet frameworks for efficient fully flexible dye-sensitized solar cells. J Alloys Compd 695:3324–3330

Qin Q, He F, Zhang W (2016) One-step electrochemical polymerization of polyaniline flexible counter electrode doped by graphene. J Nanomater 2016:1–7

He XL, Shen RX, Yang GJ, Li CJ, Fang B (2015) Behavioral study of flexible platinum counter electrodes under alternative bending conditions. RSC Adv 5:73155–73161

Li CT, Lee CT, Li SR, Lee CP, Chiu IT, Vittal R, Wu NL, Sun SS, Ho KC (2016) Composite films of carbon black nanoparticles and sulfonated-polythiophene as flexible counter electrodes for dye-sensitized solar cells. J Power Sources 302:155–163

Ma T, Fang X, Akiyama M, Inoue K, Noma H, Abe E (2004) Properties of several types of novel counter electrodes for dye-sensitized solar cells. J Electroanal Chem 574:77–83

Toivola M, Ahlskog F, Lund P (2006) Industrial sheet metals for nanocrystalline dye-sensitized solar cell structures. Sol Energy Mater Sol Cells 90:2881–2893

Yang Y, Zhao B, Tang P, Cao Z, Huang M, Tan S (2014) Flexible counter electrodes based on nitrogen-doped carbon aerogels with tunable pore structure for high-performance dye-sensitized solar cells. Carbon 77:113–121

Xiao Y, Wu J, Yue G, Lin J, Huang M, Lan Z, Fan L (2012) Electrodeposition of high performance PEDOT/Ti counter electrodes on Ti meshes for large-area flexible dye-sensitized solar cells. Electrochim Acta 85:432–437

Chen TY, Huang YJ, Li CT, Kung CW, Vittal R, Ho KC (2017) Metal-organic framework/sulfonated polythiophene on carbon cloth as a flexible counter electrode for dye-sensitized solar cells. Nano Energy 32:19–27

Chen SL, Tao J, Tao HJ, Shen YZ, Wang T, Pan L (2016) High-performance and low-cost dye-sensitized solar cells based on kesterite Cu2ZnSnS4 nanoplate arrays on a flexible carbon cloth cathode. J Power Sources 330:28–36

Sahito IA, Sun KC, Arbab AA, Qadir MB, Choi YS, Jeong SH (2016) Flexible and conductive cotton fabric counter electrode coated with graphene nanosheets for high efficiency dye sensitized solar cell. J Power Sources 319:90–98

Bi H, Chen J, Zhao W, Sun S, Tang Y, Lin T, Huang F, Zhou X, Xie X, Jiang M (2013) Highly conductive, free-standing and flexible graphene papers for energy conversion and storage devices. RSC Adv 3:8454

Lan JL, Feng HP, Wei TC, Peng C, Cheng HP, Chen WH, Chang YH, Hsu WC, Wan CC (2010) Platinum nanoparticles on flexible carbon fiber paper without transparent conducting oxide glass as counter electrode for dye-sensitized solar cells. J Chin ChemSoc 57:1217–1220

Chen J, Li K, Luo Y, Guo X, Li D, Deng M, Huang S, Meng Q (2009) A flexible carbon counter electrode for dye-sensitized solar cells. Carbon 47:2704–2708

Zhu P, Hong Y, Liu B, Zou G (2009) The synthesis of titanium carbide-reinforced carbon nanofibers. Nanotechnology 20:255603

Zhao Y, Thapa A, Feng Q, Xi M, Qiao Q, Fong H (2013) Electrospun TiC/C nano-felt surface-decorated with Pt nanoparticles as highly efficient and cost-effective counter electrode for dye-sensitized solar cells. Nano 5:11742–11747

Xu C, Huang C, Ai X (2006) Toughening and strengthening of advanced ceramics with rare earth additives. Ceram Int 32:423–429

Zhang Y, Guo L, Zhao X, Wang C, Ye F (2015) Toughening effect of Yb2O3 stabilized ZrO2 doped in Gd2Zr2O7 ceramic for thermal barrier coatings. Mater Sci Eng A 648:385–391

Park SH, Kim BK, Lee WJ (2013) Electrospun activated carbon nanofibers with hollow core/highly mesoporous shell structure as counter electrodes for dye-sensitized solar cells. J Power Sources 239:122–127

Kim C, Jeong YI, Ngoc BT, Yang KS, Kojima M, Kim YA, Endo M, Lee JW (2007) Synthesis and characterization of porous carbon nanofibers with hollow cores through the thermal treatment of electrospun copolymeric nanofiber webs. Small 3:91–95

Park SH, Jung HR, Kim BK, Lee WJ (2012) MWCNT/mesoporous carbon nanofibers composites prepared by electrospinning and silica template as counter electrodes for dye-sensitized solar cells. J Photochem Photobiol A246:45–49

Kim BH, Yang KS, Woo HG, Oshida K (2011) Supercapacitor performance of porous carbon nanofiber composites prepared by electrospinning polymethylhydrosiloxane (PMHS)/polyacrylonitrile (PAN) blend solutions. Synth Met 161:1211–1216

Funding

The financial support of this work was provided by the Program for Zhejiang Provincial natural Science Foundation of China (LZ16E020002), Innovative Research Team of Zhejiang Sci-Tech University (15010039-Y), Foundation of Key Laboratory of Textile Fiber & Product (Wuhan Textile University), Ministry of Education (FZXW2017004), and National Natural Science Foundation of China (51402260).

Author information

Authors and Affiliations

Corresponding authors

Electronic supplementary material

ESM 1

(DOCX 670kb)

Rights and permissions

About this article

Cite this article

Xie, X., Yin, X., Zhai, J. et al. The preparation of highly flexible mesoporous TiC/CNF film for flexible dye-sensitized solar cells. J Solid State Electrochem 22, 1185–1195 (2018). https://doi.org/10.1007/s10008-017-3852-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10008-017-3852-4