Abstract

Organic compounds become promising candidates for cathodes of rechargeable lithium battery (RLB) due to the high theoretical capacity and improved safety. However, they exhibit low conductivity and easy dissolution in electrolyte, which leads to the low utilization of active materials and poor cycling stability of RLBs. Here, we synthesize a novel composite of activated hierarchical porous carbon supporting poly(1,5-diamino-anthraquinone) (aHPC@PDAA), using Ce(SO4)2 as oxidant and naphthalenesulfonic acid (NSA) as soft template for PDAA. The as-synthesized composite exhibits uniformly nanoporous structure with nano-sized PDAA particles distributed homogenously inside and outside of pores. The aHPC@PDAA cathode for RLBs achieves high electrochemical performance with a discharge capacity as much as 250 mAh g−1 at the current density of 100 mA g−1, which still maintains 176 mAh g−1 after 2000 charging-discharging cycles.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Nowadays, rechargeable lithium batteries (RLBs) have been widely used and considered as compelling energy storage devices for the portable electronic products and green transportations due to the high energy density [1–3]. Inorganic materials containing transition metals such as Ni, Co, and Mn are often used for the active materials of positive electrodes in RLBs, but they induce environmental problems and are costly. Moreover, they also have limited capacities and safety issues, which hinder their large-scale applications for upcoming portable electronic devices [4, 5]. In comparison, organic compounds have attracted more and more attention as the cathode materials for RLBs, due to their high theoretical specific capacity, tunable redox potential, safety, and environmental friendliness [6–9]. To date, several organic materials have been reported, such as conducting polymers [7, 10], organosulfur compounds [11, 12], free radical compounds [13, 14], and conjugated carbonyl compounds [9, 15–19].

Due to the incorporation of quinone groups, conjugated carbonyl compounds are emerging as one of the most promising organic electrode materials with their fast reaction kinetics and large theoretical capacity. Among these, π-conjugated amino-anthraquinone polymers have attracted our attention, which hybridize quinone groups with a couple of polyaniline backbones and exhibit great electrochemical performance [20–23]. However, there are still some obvious demerits of these polymers, such as severe dissolution and sluggish charge transport speed, which decrease the utilization of active materials and affect cycling performance of RLBs [8, 17, 24, 25]. To address these problems, designing nanostructured polymer particles should be considered, which has made a great breakthrough for different materials [26–29]. Besides, introducing carbon-based materials as scaffolds is also an effective way, which could enhance the conductivity of polymers and contribute to their nanostructure at the same time [30–37].

Activated hierarchical porous carbon (aHPC) is one of the most attractive scaffolds and has been studied intensively due to the large surface area, high conductivity, inner-connective porous structure, and great adsorption to active materials [38–42]. More importantly, the confinement effect of pores for aHPC is an effective strategy to suppress the dissolution of active materials and improve the cycling stability [43–46]. Therefore, we bring the idea of introducing aHPC as scaffold to fabricate the activated hierarchical porous carbon supporting poly(1,5-diamino-anthraquinone) (aHPC@PDAA) composite and suppress the dissolution of poly(1,5-diamino-anthraquinone) (PDAA) both by generating nanostructured PDAA particles and by the confinement effect of pores, which is a new strategy for these polymers and has not been reported before.

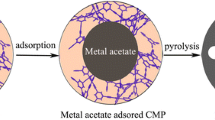

Herein, aHPC with abundant nanopores is obtained by the carbonization of polyformaldehyde resin (PF) and the activation with KOH. The obtained aHPC functions as the scaffold for PDAA with the vacuum impregnation-assisted in situ polymerization method, getting aHPC@PDAA composite as a result. In the meantime, β-naphthalene sulfonic acid (β-NSA) is used during the polymerization process, which functions both as a dopant for PDAA and a soft template for its polymerization to form the porous structure. The procedure schematic diagram is shown in Fig. 1. The introduction of aHPC is also beneficial to the formation of nano-sized PDAA and could improve the electron and ion transport speed of the active materials. As a result, the as-prepared aHPC@PDAA composite exhibits improved specific capacity, rate capability, and good cycle life.

Experimental section

Preparation of aHPC

HPC was prepared using the modified method as reported in our previous work [43], and the detailed process was shown in Electronic Supporting Information.

Then, HPC was activated by KOH. Typical procedure was as follows: 0.6 g of HPC was immerged with KOH solution (1.2 g KOH in 10 mL ethanol), followed by magnetic stirring for 3 h and evaporation of ethanol at 70 °C for 3 h. Then, the HPC/KOH mixture was grinded and heated to 800 °C at the heating rate of 5 °C min−1 for 90 min in the tube furnace. The activated sample was boiled in 1 M HCl for 1 h and then washed with deionized water to neutral. aHPC was obtained after filtration and drying at 120 °C for 24 h.

Synthesis of aHPC@PDAA, HPC@PDAA, and PDAA

The aHPC@PDAA composite was synthesized by a chemically oxidative polymerization method. Typical procedure was as follows: (1) 0.1 g aHPC was vacuumed for 1 h; (2) 0.6 g DAA (Aladdin Industrial Corporation) (2.5 mmol) and 0.56 g NSA (Aladdin Industrial Corporation) (2.5 mmol) were dissolved in 40-mL 1 M H2SO4 DMAc solution, then the mixed solution was added to aHPC under vacuum and stirred for 2 h; (3) 2.04 g Ce(SO4)2 (5 mmol) was dissolved in 90 mL 1 M H2SO4 DMAc solution, and half of the solution was added into the above suspension dropwise, followed by 24 h continuous stirring at 20 °C, after which the second half was added and continuously stirred for another 24 h at the same condition. (4) The resulting product was washed with DMAc, ethanol, and deionized water and afterwards freeze dried for use. For comparison, the aHPC@PDAA-o composite was prepared in the similar procedure above except for the absence of NSA, and the HPC@PDAA composite was also prepared in the similar procedure except that aHPC was replaced by HPC. Pure PDAA doped with NSA was synthesized through the similar procedure above without the presence of aHPC.

Material characterization

The morphologies of the samples were investigated through field emission scanning electron microscopy (FE-SEM, HitachiS-4800) and transmission electron microscopy (TEM, JEOL JEM-2100, 200 kV). Nitrogen adsorption-desorption isotherms were recorded using a Micromeritics ASAP 2020 analyzer at 77 K. Before measurements, the samples were degassed in vacuum at 353 K for 12 h. The specific surface area and pore volume of samples were calculated by Brunauer-Emmett-Teller (BET) and t-plot method. The nonlocal density functional theory (NLDFT) model was used to obtain the pore size distribution. Fourier transform infrared spectra (FT-IR) were obtained through a Nicolet 5700 spectrometer by KBr pellets. X-ray photoelectron spectroscopy (XPS) analysis was performed in a Thermo Scientific ESCALAB 250Xi X-ray photoelectron spectrometer equipped with a monochromatic Al Kα X-ray source (1486.6 eV). The electrical conductivity of the samples was measured using a SX 1934 four-probe instrument using the compressed pallets. Digital photos were taken by Pentax K-50. The UV-Vis spectra were obtained using a Shimadzu UV-2102PC spectrophotometer.

Battery assembled and electrochemical measurements

The composite positive electrodes were prepared by mixing 80 wt.% composites, 10 wt.% acetylene black, and 10 wt.% LA132 (2 wt.% solution dissolved in water) to form slurries. The slurries were uniformly coated onto the aluminum foil, followed by the drying process performed in a vacuum oven at 80 °C for 48 h. After then, the positive electrodes were obtained by cutting into 12-mm-diameter disks. The PDAA positive electrode was composed of 48 wt.% PDAA, 42 wt.% acetylene black, and 10 wt.% LA132, and the fabrication process was similar with the above. The loading mass of PDAA on Al foil was approximately 1 mg cm−2.

Lithium metal foil was used as anode, and 1 M bis-(trifluoromethane)sulfonimide lithium (LiTFSI) in dimethoxyethane (DME) and dioxolane (DOL) (1/1, by volume) was used as electrolyte. Coin-type (CR 2016) cells were assembled in an argon atmosphere glove-box.

The galvanostatic charge/discharge tests and rate performance were carried out on a LAND CT2001A battery tester at a different current density between 1.5 and 3.5 V vs. Li/Li+. The cyclic voltammetry (CV) (scan rate 0.1 mV s−1; cutoff voltage 1.5–3.5 V) and electrochemical impedance measurements (frequency range 105–10−2 Hz; amplitude 5 mV) were conducted on a CHI 660D electrochemical workstation.

Results and discussions

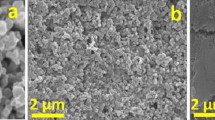

As shown in Fig. 2a, b, both HPC and aHPC exhibit similar honeycomb-like hierarchical porous structure, indicating that the KOH activation process of aHPC brings little destruction to its three dimensional structure. To explore the effect of KOH activation on HPC, the nitrogen adsorption and desorption isotherms of HPC and aHPC were obtained (Fig. 2c). Both of them are type IV with H1 hysteresis, revealing the hierarchical porous structure with open cylindrical pores, which come from the removal of hard template, the generation of CO2 in the carbonization process, or the corrosion of KOH in the activation process. Table 1 shows the specific porosity properties for HPC and aHPC. After activation, the total pore volume and BET surface area increase from 1.04 to 1.32 m3 g−1 and 898.4 to 1252 m2 g−1, respectively. And most of the increment for surface area is brought by micropores, which rise from 492.8 to 704.9 m2 g−1. The above suggests that large amount of micropores are generated during the KOH activation process. The corresponding pore size distribution is shown in Fig. 2d. Both HPC and aHPC possess abundant mesopores and macropores in the range of 20–80 nm, similar to the size of hard template (Fig. S1). And aHPC shows another narrow peak centered around 12 nm in the pore size distribution, indicating that KOH activation also brings some mesopores [42, 47, 48]. It is worth mentioning that the increase of the amount of micropores and mesopores would contribute a lot to the inner-connective pore structure [42, 49, 50], and it is very favorable for the diffusion of solution and ion transportation. Furthermore, after KOH activation, aHPC still maintains a relatively high electrical conductivity of 2.3 S cm−1 (Table 1).

Apart from improving the porosity properties, KOH activation also changes the surface functionality of HPC, which is confirmed by XPS analysis. The survey scan of HPC and aHPC is shown in Fig. 2e, which suggests the presentence of C and O elements in both of them. However, the O content in aHPC is 1.9 % higher than that of HPC (Table 2), indicating that oxygen functional groups have been generated during the activation process. To further verify the detailed information about those functional groups, deconvolution analysis of C1s spectra for HPC and aHPC are performed in Fig. 2f, where four peaks are fitted at 284.6, 285.7, 286.8, and 289.3 eV, corresponding to C=C (C1), C−O (C2 phenolic, alcohol, ether), C=O (C3 carbonyl or quinine groups), and O−C=O (C4 carboxyl groups), respectively [51, 52]. It is also noted that the relative content of graphitized carbon (C1) decreases after the activation, while the content of the carbon bonded to oxygen-containing functions (C2, C3, C4) has an increase, and most of the increase is brought by quinine groups (C3). The O1s deconvolution results in Fig. S2 also exhibit consistent results, suggesting that the interface affinity of the scaffold has been enhanced after KOH activation and DAA monomers are more likely to be anchored on its porous walls and turned into polymerization sites in the following process [47]. Therefore, aHPC would be a very competitive candidate as the scaffold for polymer materials in RLBs.

To verify the effect of scaffolds on the polymerization of polymers, the morphologies of pure PDAA, HPC@PDAA, and aHPC@PDAA composite are illustrated by FE-SEM and TEM images. For pure PDAA, the FE-SEM image presents severe aggregation of polymers (Fig. S3), and its TEM image also shows a consistent phenomenon (Fig. S4). For HPC@PDAA composite, a certain amount of pores appear in it and some of the PDAA particles are also nanostructured (Fig. 3a), suggesting that the existence of the HPC scaffold restricts the aggregation of PDAA to some extent. Meanwhile, its TEM image (Fig. 3c) is still similar with pure PDAA (Fig. S4) and no porous structure can be observed, indicating the fact that most PDAA still aggregate on the external surface of pores in the HPC@PDAA composite. On the contrary, the aHPC@PDAA composite displays more loose and porous morphology (Fig. 3b), and its TEM image (Fig. 3d) exhibits relatively distinct porous structure with uniformly distributed active materials, suggesting the fact that much more amount of PDAA particles are nanostructured and most of them are generated homogenously inside and outside of aHPC pores. The above difference may be attributed to the improved properties of aHPC, which can be specified as follows. Firstly, the developed interconnected pore structure of aHPC enhances the diffusion of DAA monomers inside of all pores. Secondly, the oxygen functional groups on the porous walls of aHPC could anchor the active material and provide polymerization sites uniformly. Thirdly, the larger pore volume and higher surface area provide much more inside-pore space for PDAA and prevent the aggregation of polymers. Additionally, to verify the effect of NSA, aHPC@PDAA-o is fabricated without NSA, and the SEM image of it is shown in Fig. S5. PDAA nanoparticles are accumulated together with merely no porosity in the aHPC@PDAA-o composite, suggesting that the NSA soft-template contributes a lot to the porous structure of the composites.

The porosity properties for aHPC@PDAA and HPC@PDAA are obtained by nitrogen adsorption and desorption isotherms (Fig. 3e). Similar with aHPC and HPC, the nitrogen adsorption and desorption isotherms for aHPC@PDAA and HPC@PDAA are also type IV with H1 hysteresis, and they have less adsorption amount of nitrogen in the whole range, suggesting the fact that polymer particles have filled the pores of scaffolds for both two composites. Additionally, compared with HPC@PDAA, aHPC@PDAA presents higher micropore volume and larger micropore BET surface area (Table 1), indicating that the number of micropores in aHPC@PDAA is superior to HPC@PDAA. The pore size distribution in Fig. 3f also presents a consistent result, in which HPC@PDAA exhibits more diameters in the range of 10–60 nm and aHPC@PDAA possesses more diameters of 1–10 nm. This feature of pore size distribution provides strong evidence for the fact that a large amount of PDAA nanoparticles distribute uniformly inside of pores for aHPC@PDAA, but most DAA only polymerize and aggregate outside of pores in HPC@PDAA, thus abundant micropores are left in aHPC@PDAA but vast mesopores and macropores still exist in HPC@PDAA. Moreover, the structure with PDAA nanoparticles inside of pores is very favorable for the cycling stability, since the confinement effect of pores could effectively restrict the dissolution of polymers during the cycling [43, 53]. Furthermore, high surface area and medium pore volume in aHPC@PDAA (Table 1) are also beneficial to shorten the path of lithium transportation and enhance the rate performance.

To evaluate the effect of aHPC on the chemical structure of PDAA, the FTIR analysis is performed (Fig. 4). Both aHPC@PDAA and HPC@PDAA display the FTIR spectra similar to pure PDAA, which have the main bands at 1601, 1492, and 1259 cm−1, corresponding to C=C stretching vibrations of N=Q=N and N−Q−N rings and the C−N stretching vibration, respectively (Fig. S6) [22, 36]. It is also notably observed that the C=C stretching vibrations of N=Q=N in composites have been strengthened by the introduction of carbon scaffolds, especially for aHPC@PDAA. These may suggest that the quinonoid structure of PDAA in composites has been stabilized by the π-π electron interaction between the π-bonded surface of aHPC (HPC) and the quinoid rings of PDAA. Moreover, the fact that a large amount of PDAA nanoparticles distribute evenly inside and outside of aHPC pores has strongly promoted this π-π interaction in the aHPC@PDAA composite.

To evaluate the electrochemical performance of samples, the typical CV curves for aHPC@PDAA, HPC@PDAA, and pure PDAA at a scan rate of 0.1 mV s−1 are shown in Fig. 5a. Two pairs of redox peaks around 2.2/2.1 and 2.6/2.5 V can be observed in the CV curve of the PDAA cathode, corresponding to the redox reaction of quinone groups and the doping/redoping process of polyaniline skeletons, respectively (Fig. S6) [32, 54]. In more specific terms, quinine (Q) turns into quinone radical anion (Q•–) or quinone dianion (Q2−) for generating Li2Q around 2.2/2.1 V and amine (−NH–)/imine converts into cation (=N+–) around 2.6/2.5 V. However, there is only one redox peak around 2.2/2.1 V observed in the CV curves for both aHPC@PDAA and HPC@PDAA. The absence of redox peak around 2.6/2.5 V in composite cathodes may be ascribed to the fact that the enhanced π-π electron interaction between PDAA and aHPC (HPC) causes the gradual transition of amine reacting position. Figure 5b–d presents the corresponding charge/discharge plots at different current densities. All the three cathodes display consistent results with the corresponding CV curves at a low current density of 50 mA g−1, where two plateaus around 2.5 and 2.1 V are observed for PDAA while only one plateau around 2.1 V is obtained for both aHPC@PDAA and HPC@PDAA. In addition, with the increase of current density, the charge and discharge profiles of aHPC@PDAA barely show any change compared with those of PDAA and HPC@PDAA, indicating that the aHPC@PDAA cathode displays less polarization and better rate performance.

The corresponding rate performance is shown in Fig. 6. It is noted that aHPC@PDAA presents much higher capacity compared to PDAA and HPC@PDAA, especially at a large current density, which delivers a capacity of 261 mAh g−1 at 50 mA g−1 and still maintains 165 mAh g−1 (63.2 %) at 600 mA g−1 (capacity was calculated based on the mass of PDAA). By contrast, HPC@PDAA and PDAA exhibit a capacity of 246 and 232 mAh g−1 at 50 mA g−1 and only maintain 102 mAh g−1 (41.5 %) and 73 mAh g−1 (31.5 %) at 600 mA g−1, respectively. Moreover, the capacity of aHPC@PDAA recovers to 232 mAh g−1 (88 %) when it is charged and discharged at 50 mA g−1 again, indicating its stability at different rates. The improved capacity and stabilized rate performance of aHPC@PDAA can be ascribed to its unique porous structure with large surface area, high conductivity, and uniformly distributed PDAA nanoparticles. All the above advantages are beneficial for the high transportation speed of both electronics and ions and significantly promote the utilization of active materials. Therefore, the enhanced electrochemical properties are obtained for aHPC@PDAA.

The cycling performance of samples at a current density of 100 mA g−1 is shown in Fig. 7a. The capacity of HPC@PDAA and PDAA decreases quickly during cycles, especially in the first 100 cycles (from 238 to 151 mAh g−1 and from 217 to 136 mAh g−1, respectively), and their capacity retentions are only 45 and 38.2 % after 2000 cycles. By contrast, aHPC@PDAA loses 20 % of its initial capacity after 100 cycles (from 250 to 200 mAh g−1). Then, only a little fading can be observed and the capacitance retention is still 70.4 % after 2000 cycles. These indicate that the cycling stability of aHPC@PDAA is significantly improved due to the introduction of aHPC.

To further explore the cycling stability, the electrochemical impedance for PDAA and aHPC@PDAA cathodes are measured before and after cycling (Fig. 7b). Initially, the aHPC@PDAA cathode possesses much smaller charge transfer resistance (R CT) compared to the pure PDAA cathode, which are 194.7 and 692 Ω, respectively. After 2000 times cycling, the R CT of aHPC@PDAA only increases to 239 Ω while that of pure PDAA is as much as 992 Ω. The EIS analysis also proves that the aHPC@PDAA cathode exhibits significantly improved cycling stability, which could be ascribed to the following factors. Firstly, the introduction of aHPC effectively restricts the aggregation of polymers, and nanostructured PDAA particles deposit firmly and evenly on the porous walls of aHPC through the π-π interaction and the hydrogen bonds. Secondly, the confinement effect of pores strongly inhibits the dissolution of active materials, and the structure destruction of the electrode can also be reduced during charge-discharge cycling. The speculations can be further supported by pictures of diaphragms and FE-SEM images of electrodes obtained from the batteries that have been cycled (Fig. S7). For pure PDAA and HPC@PDAA cathodes, they present severe swelling phenomenon, and diaphragms for them have turned red, while the aHPC@PDAA cathode shows no swelling phenomenon and its diaphragm turns only a little yellow.

All above has proved that depositing PDAA nanoparticles inside of nanopores is an effective way to enhance the stability of RLBs. However, compared with some materials fabricated by electrochemical polymerization method [27], the initial discharge capacity decrease of aHPC@PDAA is still unsatisfactory. To explore the reason, all the original electrodes were soaked in 3-mL LiTFSI electrolyte at 70 °C for 7 days. As shown in Fig. S8, the obtained soak solution for PDAA and HPC@PDAA obviously turn red, and the one for aHPC@PDAA also changes into a little pink, suggesting that some oligomers may exist in the active materials. The UV-Vis spectra of the soak solutions further confirm the above deduction (Fig. S9), where all of them exhibit a similar peak with the spectrum of the DAA monomer. These oligomers can dissolve in the organic electrolyte solution during the initial charge/discharge cycles, which causes the initial rapid decrease of capacity. Therefore, removing the involved oligomer of aHPC@PDAA is an effective way to further enhance the cycling stability, and our next job would focus on it.

Conclusions

Three-dimensional porous aHPC@PDAA composite has been fabricated successfully by the vacuum impregnation-assisted in situ polymerization method with aHPC as scaffold and NSA as soft template. The prepared aHPC@PDAA composite exhibits uniform distribution of PDAA nanoparticles both inside and outside of pores and possesses large effective surface area (264.8 m2 g−1) and high conductivity (2.2 S cm−1). Beyond that, benefiting from the enhanced quinonoid structure of PDAA and the confinement effect of pores, the aHPC@PDAA cathode achieves significantly improved electrochemical performance. As a consequence, it exhibits high discharge capacity (250 mAh g−1 at 100 mA g−1), good cycling ability (retaining 176 mAh g−1 after 2000 times cycles), and compelling rate performance (165 mAh g−1 at 600 mA g−1). Therefore, the aHPC@PDAA composite would be an alternative promising candidate of high-performance electrode materials for Li-organic batteries.

References

Yang H, Yu X, Meng H, Dou P, Ma D, Xu X (2015) J Mater Sci 16:5504–5513

Wang C, Ma X, Cheng J, Sun J, Zhou Y (2006) J Solid State Electrochem 3:361–364

Ramesh-Kumar P, Venkateswarlu M, Satyanarayana N (2012) J Appl Electrochem 3:163–167

Chen M, Xia X, Yuan J, Yin J, Chen Q (2015) J Power Sources 288:145–149

Ramar V, Balaya P (2016) J Power Sources 306:552–558

Xu F, Chen X, Tang Z, Wu D, Fu R, Jiang D (2014) Chem Commun 37:4788–4790

Tsutsumi H, Yamashita S, Oishi T (1997) J Appl Electrochem 4:477–481

Liang Y, Tao Z, Chen J (2012) Adv Energy Mater 7:742–769

Luo C, Huang R, Kevorkyants R, Pavanello M, He H, Wang C (2014) Nano Lett 3:1596–1602

Qiu H, Wan M, Matthews B, Dai L (2001) Macromolecules 4:675–677

Kato M, Senoo KI, Yao M, Misaki Y (2014) J Mater Chem A 2:6747–6754

Zhang K, Hu Z, Tao Z, Chen J (2014) Sci China Mater 1:42–58

Gottis S, Barres AL, Dolhem F, Poizot P (2014) ACS Appl Mater Interfaces 14:10870–10876

Su C, Yang F, Ji L, Xu L, Zhang C (2014) J Mater Chem A 2:20083–20088

Zeng RH, Li XP, Qiu YC, Li WS, Yi J, Lu DS, Tan CL, Xu MQ (2010) Electrochem Commun 9:1253–1256

Chen J, Zhang Q, Zeng M, Ding N, Li Z, Zhong S, Zhang T, Wang S, Yang G (2016) J Solid State Electrochem. Doi:10.1007/s10008–016–3126-6

Xie J, Wang Z, Gu P, Zhao Y, Xu ZJ, Zhang Q (2016) Sci China Mater 1:6–11

Iordache A, Maurel V, Mouesca JM, Pécaut J, Dubois L, Gutel T (2014) J Power Sources 267:553–559

Yokoji T, Matsubara H, Satoh M (2014) J Mater Chem A 2:19347–19354

Naoi K, Suematsu S, Hanada M, Takenouchi H (2002) J Electrochem Soc 4:A472–A477

Wan W, Lee H, Yu X, Wang C, Nam KW, Yang XQ, Zhou H (2014) RSC Adv 38:19878–19882

Suematsu S, Naoi K (2001) J Power Sources 97-98:816–818

Song Z, Zhou H (2013) Energy Environ Sci 6:2280–2301

Gao M, Yang F, Wang X, Zhang G, Liu L (2007) J Phys Chem C 46:17268–17274

Li J, Zhan H, Zhou L, Deng S, Li Z, Zhou Y (2004) Electrochem Commun 6:515–519

Liu H, Zhang G, Zhou Y, Gao M, Yang F (2013) J Mater Chem A 44:13902–13913

Sun M, Li H, Wang J, Wang G (2015) Carbon 94:864–871

Yang C, Sun M, Wang X, Wang G (2015) ACS Sustain Chem Eng 3:2067–2076

Pirnat K, Dominko R, Cerc-Korosec R, Mali G, Genorio B, Gaberscek M (2012) J Power Sources 199:308–314

Song Z, Xu T, Gordin ML, Jiang YB, Bae IT, Xiao Q, Zhan H, Liu J, Wang D (2012) Nano Lett 5:2205–2211

Nikoofard H, Omrani A, Niaki M (2014) Monatsh Chem 2:267–273

Shen YF, Yuan DD, Ai XP, Yang HX, Zhou M (2015) J Polym Sci Part B: Polym Phys 53:235–238

Zhao L, Wang W, Wang A, Yuan K, Chen S, Yang Y (2013) J Power Sources 233:23–27

Song Z, Zhan H, Zhou Y (2009) Chem Commun 4:448–450

Liu M, Miao YE, Zhang C, Tjiu WW, Yang Z, Peng H, Liu T (2013) Nanoscale 16:7312–7320

Sun M, Wang G, Yang C, Jiang H, Li C (2015) J Mater Chem A 3:3880–3890

Zhou Y, Wang B, Liu C, Han N, Xu X, Zhao F, Fan J, Li Y (2015) Nano Energy 15:654–661

Tian M, Wang W, Liu Y, Jungjohann KL, Thomas Harris C, Lee YC, Yang R (2015) Nano Energy 11:500–509

Zhao Q, Wang X, Liu J, Wang H, Zhang Y, Gao J, Lu Q, Zhou H (2015) Electrochim Acta 154:110–118

Zhou Z, Xie W, Li S, Jiang X, He D, Peng S, Ma F (2015) J Solid State Electrochem 4:1211–1215

Wang T, Shi P, Chen J, Cheng S, Xiang H (2016) J Nanoparticle Res 18:1–9

Chang J, Gao Z, Wang X, Wu D, Xu F, Wang X, Guo Y, Jiang K (2015) Electrochim Acta 157:290–298

Chi TY, Li H, Li XW, Bao H, Wang GC (2013) Electrochim Acta 96:206–213

Yang J, Wang S, Ma Z, Du Z, Li C, Song J, Wang G, Shao G (2015) Electrochim Acta 159:8–15

Wang M, Zhang H, Zhang Y, Li J, Zhang F, Hu W (2013) J Solid State Electrochem 8:2243–2250

Li X, Rao M, Li W (2015) J Solid State Electrochem 1:153–161

Tian X, Zhao N, Wang K, Xu D, Song Y, Guo Q, Liu L (2015) RSC Adv 5:40884–40891

Ma F, Wan J, Wu G, Zhao H (2015) RSC Adv 5:44416–44422

Zhao Q, Wang X, Xia H, Liu J, Wang H, Gao J, Zhang Y, Liu J, Zhou H, Li X, Zhang S, Wang X (2015) Electrochim Acta 173:566–574

Cheng P, Gao S, Zang P, Yang X, Bai Y, Xu H, Liu Z, Lei Z (2015) Carbon 93:315–324

Bichat MP, Raymundo-Piñero E, Béguin F (2010) Carbon 48:4351–4361

Senthilkumar B, Khan Z, Park S, Kim K, Ko H, Kim Y (2015) J Mater Chem A 3:21553–21561

Zhao L, Wang WK, Wang AB, Yu ZB, Chen S, Yang YS (2011) J Electrochem Soc 9:A991–A996

Naoi K, Suematsu S, Manago A (2000) J Electrochem Soc 147:420–426

Acknowledgments

We greatly appreciate the financial support of the National Natural Science Foundation of China (51173042) and Shanghai Municipality Research Project (15520720500).

Author information

Authors and Affiliations

Corresponding author

Electronic Supplementary Material

ESM 1

(DOC 4055 kb)

Rights and permissions

About this article

Cite this article

Zhang, T., Li, H., Tang, Q. et al. Activated hierarchical porous carbon@π-conjugated polymer composite as cathode for high-performance lithium storage. J Solid State Electrochem 20, 2169–2177 (2016). https://doi.org/10.1007/s10008-016-3215-6

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10008-016-3215-6