Abstract

A de novo heterodimeric coiled-coil system formed by the association of two synthetic peptides, the Ecoil and Kcoil, has been previously designed and proven to be an excellent and versatile tool for various biotechnology applications. However, based on the challenges encountered during its chemical synthesis, the Kcoil peptide has been designated as a “difficult peptide”. In this study, we explore the expression of the Kcoil peptide by a bacterial system as well as its subsequent purification. The maximum expression level was observed when the peptide was fused to thioredoxin and the optimized purification process consisted of three chromatographic steps: immobilized-metal affinity chromatography followed by cation-exchange chromatography and, finally, a reverse-phase high-performance liquid chromatography. This entire process led to a final volumetric production yield of 1.5 mg of pure Kcoil peptide per liter of bacterial culture, which represents a significant step towards the cost-effective production and application of coiled-coil motifs. Our results thus demonstrate for the first time that bacterial production is a viable alternative to the chemical synthesis of de novo designed coil peptides.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Coiled-coils are structural protein domains composed of three to five amphipathic alpha helices found in a great variety of proteins (Burkhard et al. 2001; Cohen and Parry 1986; Lupas 1996). Based on naturally occurring structures, a de novo heterodimeric coiled-coil system has been previously designed and characterized. It is formed by the association of two synthetic peptides, the Ecoil and Kcoil, each composed of a distinct seven residue repeat (denoted [abcdefg]n) where n represents repetition number, “a” and “d” positions are occupied by hydrophobic residues, while the “e” and “g” positions are occupied by charged residues. The designed hydrophobic core and electrostatic interactions make this coiled-coil structure very stable (Fig. 1a) (De Crescenzo et al. 2003a; Grigoryan and Keating 2008; Chao et al. 1996) whereas each coil component remains monomeric on its own in solution. The creation of such new bio-inspired molecules with enhanced features can find widespread use in a number of biomedical and therapeutic applications (Bromley and Channon 2011). More specifically, the E/K coiled-coil system has proven to be an excellent and versatile tool for (1) the detection of coil-tagged proteins by Western blot (Boucher et al. 2010) or ELISA (Liberelle et al. 2010a), (2) the coiled-coil-mediated protein dimerization (De Crescenzo et al. 2004), as well as (3) the stable and oriented capture of coil-tagged proteins onto various surfaces harboring the partner coil peptide for applications in biosensing (Chao et al. 1998; De Crescenzo et al. 2003b) and regenerative medicine (Murschel et al. 2013; Liberelle et al. 2010b; Fortier et al. 2013; Murschel et al. 2015). To date, the Ecoil peptide [(EVSALEK)5 sequence] has been expressed as part of larger fusion proteins produced in mammalian cells (Murschel et al. 2013; Liberelle et al. 2010b) or bacteria (Le et al. 2009), whereas the partner Kcoil peptide [(KVSALKE)5 sequence], has been generated by solid phase peptide synthesis (SPPS) with an N-terminal cysteine residue that is included for immobilization purposes. The SPPS technique has the advantage of allowing the incorporation of unnatural amino acids as well as for the rapid production of milligram quantities of peptide (Kohn and Hodges 1998). However it presents several drawbacks including expensive processing costs and difficulties associated with mass production. SPPS is indeed a multi-stage process that requires chemical protection/deprotection steps for every introduced residue. The number of steps thus increases chances to produce mismatched peptides, which negatively impacts the final production yield. This is especially the case for the Kcoil peptide, for which challenges associated with its chemical synthesis have been recently highlighted (Winkler and Tian 2015). In the laboratory, this may translate into large amounts of final product (>50 %) containing errors in the sequence, which in turn imposes costly high-resolution chromatography steps to get pure Kcoil peptide. Moreover, chemical synthesis of peptides involves significant volumes of coupling and/or activating reagents, which can be aggressive or even toxic to the environment (Guzman et al. 2007). For these reasons, there is an unmet and critical need for the production of long coil peptides using a bacterial expression system in order to further expand the use of these peptides in emerging and promising applications requiring large quantities such as the development of coiled-coil-based scaffolds (Gerling-Driessen et al. 2015) for tissue engineering (Woolfson and Mahmoud 2010; Aronsson et al. 2015) and gene delivery (Assal et al. 2015).

a Helical-wheel representation of the heterodimeric E/K coiled-coil peptide system. The interchain electrostatic interactions between the charged residues are indicated by the arrows. b Schematic representation of Kcoil-fusion protein sequence design. Arrows indicate the restriction enzyme sites required to insert the cDNA corresponding to the fusion protein and the Kcoil sequence within the different plasmids. A three amino-acid sequence (CGG) was added upstream the Kcoil peptide cDNA in order to allow any thiol coupling procedure for Kcoil peptide grafting. A TEV site was also added for fusion protein removal and pure Kcoil peptide recovery

However, the biological production of the Kcoil peptide poses significant challenges; first of all because of its size (the 5 heptad repeats and cysteine-containing linker correspond to a 38 amino-acid-long peptide) which makes it very susceptible to intracellular proteolysis, and second, due to the presence of a high density of positively charged residues (2 lysine residues per heptad) that makes it very toxic to the bacteria and consequently leads to poor expression. Moreover, the development of a suitable purification scheme is hampered since the hydrophobic core of the coil peptide may affect its solubility and the lack of an aromatic residue in the original sequence precludes its quantification by absorbance measurements at 280 nm. In the present work, we report on the successful recombinant production of a cysteine labelled Kcoil peptide as an alternative to SPPS. Kcoil expression levels were first compared when fused to three common soluble carrier proteins: thioredoxin (TRX), maltose binding protein (MBP) and N-utilization substance A protein (NusA), then a culture protocol amenable to large scale was developed and, finally, an efficient purification strategy involving three chromatographic steps was set up.

Materials and methods

Chemicals and reagents

Orange II sodium salt (92 % purity), ethidium bromide (95 % purity), cysteine (99 % purity), bromophenol blue, imidazole and Coomassie Brilliant Blue (100 % purity) were purchased from Sigma-Aldrich Canada, Ltd. (Oakville, ON). Cysteine-tagged Kcoil peptides were chemically synthesized by the peptide facility at University of Colorado (Denver, CO, USA) to be used as control. CM5 sensor chips, HEPES-buffered saline (HBS-P), amine-coupling kit [including 2-(2-pyridinyldithio) ethaneamine, PDEA] were obtained from GE Healthcare (Baie d’Urfe, QC). Milli-Q quality water [18.2 MΩ cm; total organic compounds (TOC) = 4 ppb] was generated with a Millipore Gradient A 10 purification system. Cysteine (99 + % purity), acetic acid glacial (99.7 % purity), hydrochloric acid (HCl, 37.7 % v/v), yeast extract and peptone were obtained from VWR International, Ltd. (Mont-Royal, QC, Canada). Isopropyl β-d-1-thiogalactopyranoside (IPTG) and Dithiothreitol (DTT) were purchased from INALCO (San Luis Obispo, CA, USA). Ampicillin, sodium chloride (NaCl) and sodium dodecyl sulfate (SDS) were obtained from Fisher scientific (Ottawa, ON). BL21(DE3) competent cells (Novagen) and Tobacco Etch Virus (TEV) protease were generated in house.

Generation of the expression vectors

The EcoRI site of the pET15b vector (Novagen) was first deleted by site-directed mutagenesis using the following primers: CAAGAATTATCATGTTTGACAGCTTATC and ATGATAATTCTTGAAGACGAAAGGGC; the deletion was verified by sequencing. Then, two oligonucleotides of sequence CATGGGCAGCAGCCATCATCATCATCATCACAGCAGCGGTACCGAAAACTTGTATTTCCAGGGATCCCCGGGAATTCATCGTGACTGAA and GATCTTCAGTCACGATGAATTCCCGGGGATCCCTGGAAATACAAGTTTTCGGTACCGCTGCTGTGATGATGATGATGATGGCTGCTGCC were phosphorylated with the T4 Polynucleotide Kinase (Fermentas, CA), annealed, and ligated in between the NcoI and BamHI sites of the modified pET vector to generate a pET-TEV vector, thereby destroying the original BamHI site and adding a new multiple cloning site. This strategy allows for the production of proteins being His-tagged at their N-terminus where the His tag can be removed by treatment with the Tobacco Etch Virus (TEV) protease. Furthermore, genes can be cloned in between the His tag and the TEV site corresponding DNA sequences by taking advantage of the KpnI site. The genes coding for the thioredoxin (TRX), the N-utilization substance A protein (NusA) and the maltose binding protein (MBP) were amplified using the primers summarized in Table 1. PCR amplified products were then digested with KpnI and inserted into the KpnI site of pET-TEV to generate pET-TEV-TRX, pET-TEV-NusA and pET-TEV-MBP vectors. Positive clones were verified by sequencing.

Cloning Kcoil coding sequence

Kcoil DNA coding sequence was amplified by polymerase chain reaction (PCR) from pIDTBlue:Kcoil plasmid (integrated DNA technology, US) using the primers reported in Table 1. Subsequently, the PCR products as well as the different expression vectors already containing the gene of the protein to be fused to the Kcoil peptide (pET-TEV-TRX, pET-TEV-NusA and pET-TEV-MBP) that had been generated as described above, were double-digested by BamHI and EcoRI restriction enzymes. Kcoil DNA sequence was cloned using a 4:1 ligation ratio (insert/vector) and then transformed in E. coli DH5α competent cells. Positive clones were verified by sequencing.

Screening of expression levels

Plasmids (pET-TEV-TRX, pET-TEV-NusA and pET-TEV-MBP) encoding Kcoil peptide were used to transform BL21(DE3) E. coli cells. Single positive transformed colonies were used to inoculate 5 mL of LB medium containing ampicillin (100 µg/mL) and were grown overnight at 37 °C in a shaker at 200 rpm. Bacteria pre-cultures were then diluted in 50 mL of LB medium and fusion protein expression was induced by adding 0.7 mM of isopropyl β-d-1-thiogalactopyranoside (IPTG) at an optical density (OD) of approximately 0.6 (600 nm). Following an induction period of 5 h, cells were harvested by centrifugation (10 min at 3000 rpm) and cellular pellets were re-suspended in 10 mL of lysis buffer (20 mM NaPO4 pH 7.4, 500 mM NaCl, 1 mM DTT and 0.5 M EDTA) and then sonicated (Branson Sonifier, US) on ice for 30 s. Soluble and insoluble fractions were separated by centrifugation at 13,000 rpm (30 min) using a microcentrifuge (Thermo Fisher Scientific Inc., US) and each fraction sample was analysed by SDS-PAGE.

Optimization of TRX-tagged Kcoil peptide purification

To prepare the culture, 1 L of overnight pre-culture of BL21(DE3) cells expressing the TRX-Kcoil fusion protein was diluted in 8 L of fresh LB medium containing 100 µg/mL ampicillin. IPTG was then added at a final concentration of 0.7 mM at an OD600nm of approximately 0.6 and the culture was incubated at 37 °C for 5 h. The cellular pellet was collected by centrifugation (10 min at 8000 rpm and 4 °C) and kept frozen at −20 °C until use. Cell disruption was carried out by re-suspension of the cellular pellet in lysis buffer (20 mM PO4 pH 7.4, 500 mM NaCl and 25 mM imidazole), followed by several cycles through the French press. After an ultracentrifugation step at 105,000×g for 1 h at 4 °C, the His-tagged TRX-Kcoil fusion protein was purified by ion metal affinity chromatography (IMAC): the supernatant containing soluble proteins was loaded on a Ni2+-charged 5-mL His-trap HP column (GE Healthcare, Sweden) using an ÄKTA-purifier UPC 10 system (GE Healthcare, Sweden) and the His-tagged fusion protein was eluted by applying a 25-to-500 mM imidazole gradient (10 min, flow rate of 5 mL/min). Collected fractions were overnight dialyzed against TEV cleavage buffer (25 mM NaPO4 pH 7.4, 125 mM NaCl and 10 mM DTT) at 4 °C. The thioredoxin fusion protein was subsequently treated with TEV at an enzyme/substrate ratio of 1:80 (c/c) for 2 h at room temperature and the cleavage mixture was directly injected onto a HiLoad™ 16/10 SP Sepharose® Fast Flow column (GE Healthcare, Sweden) that had been pre-equilibrated with 10 column volumes of phosphate buffer (25 mM NaPO4 pH7.4, 125 mM NaCl) at 90 cm/h. The column was then eluted using a 125-to-500 mM NaCl gradient (20 column volumes of elution buffer at the same flow rate) subjected to buffer exchange against Milli-Q water fractions corresponding to the same peak were pooled, concentrated and then containing 5 % acetic acid at 4 °C. Finally, a reverse-phase high performance liquid chromatography (RP-HPLC) step was carried out using a C4 column (Grace Vydac, USA) connected to a Bio-Rad system (Biologic autoflow, US). A linear gradient from 20 to 35 % over 15 min of acetonitrile containing 0.05 % trifluoroacetic acid was applied at 8 mL/min to elute the Kcoil peptide. Collected fractions were concentrated and finally lyophilized for storage until needed.

SDS-PAGE analysis

Samples were analysed by SDS-PAGE (non-reducing conditions) on 15 % gels and stained by Coomassie Brilliant Blue G-250 after a heat treatment of 10 min at 100 °C. 5 µL of Precision Plus Protein™ Dual Xtra Standards (Bio-Rad, CA) was used as a pre-stained molecular weight marker for Kcoil peptide detection while PageRuler Prestained Protein Ladder (Thermo-Scientific, CA, USA) was used for protein expression monitoring during the production and purification process.

Kcoil peptide characterisation

Kcoil peptide quantification

The total amount of purified biologically produced Kcoil peptide was estimated by adapting the protocol described by Drogoz et al. for primary amine detection in solution (Drogoz et al. 2007). A volume of 900 µL of previously diluted sample were mixed with 100 µL of Orange II solution (0.8 mM) and incubated for 15 min at room temperature. Supernatant absorbance was measured at 484 nm after 30 min of centrifugation at 20,000×g. Absorbance measurements were performed using a UV-2100 spectrophotometer (Unico, Spain).

Mass spectrometry molecular weight verification

Accurate mass measurements were performed on a LC/MSD-TOF instrument (Agilent Technologies) in positive electrospray mode. Protonated molecular ions (M+H)+ and/or sodium adducts (M+Na)+ were used for empirical formula confirmation.

Surface plasmon resonance (SPR) biosensor assay

The interaction between biologically produced Kcoil and its partner Ecoil peptide was recorded in real-time using a SPR biosensor assay. Chemically synthesised Kcoil was used as positive control. The assay was performed at 25 °C as described by Murschel and colleagues (Murschel et al. 2013), using a Biacore T100 biosensor instrument with HBS-P as a running buffer. Cysteine-tagged Kcoils (chemically- and biologically-produced) were first immobilized onto distinct CM5 sensor chip surfaces using standard ligand thiol coupling procedure (Murschel et al. 2013). The Ecoil-EGF protein corresponding to an Ecoil peptide/epidermal growth factor (EGF) fusion protein (Boucher et al. 2008) was injected on both Kcoil surfaces as well as on a mock surface (activated/deactivated surface) at 100 nM for 15 s at 100 µL/min. In between Ecoil-EGF injections, surfaces were regenerated by two injections of guanidine hydrochloride (6 M, 15 s each). For a more accurate functional characterization of the biologically produced Kcoil, kinetic experiments were performed by SPR on similar Kcoil peptide surfaces. Several Ecoil solutions at concentrations ranging from 0.5 to 5 nM, were injected over 60 RU of immobilized Kcoil. Control-corrected sensorgrams were analyzed, assuming a simple 1:1 Langmuir binding interaction between Kcoil and Ecoil (De Crescenzo et al. 2003b).

Results and discussion

Expression of chimeras corresponding to Kcoil peptide fused to three different protein carriers

Since the main objective of the biological production of the Kcoil peptide is to further expand its biomedical applications, the cDNA encoding the Kcoil peptide was designed as depicted in Fig. 1b. The cDNA sequence corresponding to the three Cys-Gly-Gly residues that had been included to perform any thiol coupling procedure for Kcoil peptide grafting, were added upstream of the cDNA sequence encoding the Kcoil peptide. The bacterial production of the Kcoil peptide presents a significant challenge because of (1) the peptide size, (2) its sequence comprising a hydrophobic core combined to positively charged residues. An additional difficulty for process development also came from the impossibility to detect the peptide by absorbance at 280 nm (addition of a tyrosine residue to the original coil sequence to facilitate concentration determination of the purified product, resulted in the generation of an insoluble peptide in water, data not shown). For all these reasons, we tried to express the Kcoil peptide in inclusions bodies since we believed that its expression would be more efficient as the inclusion bodies might reduce its cytotoxicity while protecting the peptide from proteolysis (Li 2011). For this purpose, the Kcoil peptide cDNA was fused to the ketosteroid isomerase protein (KSI). After solubilisation and His trap capture, the theoretical yield we calculated was about 5 mg/L of bacterial culture. As an alternative to the expression in inclusion bodies, the soluble expression of the Kcoil peptide a as fusion protein was then tried (Terpe 2003; Li 2009).

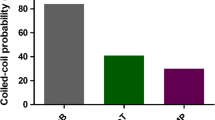

First of all, the expression level with pGEX vectors encoding Kcoil peptide fused to glutathione-S-transferase (GST) was very low (0.375 mg per liter of bacterial culture) and the peptide was still expressed in inclusion bodies (the design of a purification protocol based on inclusion bodies was unsuccessful in our hands, data not shown). In an effort to further increase Kcoil solubility and expression, other soluble fusion protein tags were assessed including TRX, NusA and MBP. These tags were chosen as they not only protect the cellular host from peptide toxicity, but they can also prevent the target peptide partner from undergoing intracellular proteolysis (Sahdev et al. 2008; Xu et al. 2007; Li 2012), typically resulting in a significant increase of the expression yield. The recombinant plasmids (pET-TEV-TRX, pET-TEV-NusA and pET-TEV-MBP) were transformed into BL21(DE3) E. coli cells. E. coli was used as a host because (1) it requires inexpensive carbon sources for growth, (2) it is a well characterized organism with a very short doubling time allowing for rapid biomass growth and product accumulation and, finally, (3) bioprocess scale-up is relatively easy (Sahdev et al. 2008; Kyle et al. 2010; Baneyx 1999). In addition, the use of a bacterial expression platform was well suited to the Kcoil peptide since no post-translational modifications (e.g., glycosylation) are required for its activity.

For expression level comparison, cultures were performed under generic conditions as described in the “Materials and methods” section. SDS-PAGE analysis (data not shown) indicated that the highest expression level of the Kcoil peptide was obtained with the TRX-fusion protein (Sahdev et al. 2008; Baneyx 1999; Terpe 2003; Davis et al. 1999; Esposito and Chatterjee 2006; Song et al. 2011). Of interest, TRX has also been reported to enhance the solubility of recombinant antimicrobial peptides sharing similar properties as our Kcoil peptide (e.g. positively charged and small size) (Li 2009, 2011; LaVallie et al. 2000; Jing et al. 2010; Yang et al. 2009). It has been previously suggested that the good production yields recorded for cationic peptides fused to TRX were due to its anionic character (pI = 4.67) that can neutralize the high positive charge of cationic peptides, hence increasing the expression levels for this class of peptides. However, other studies have also suggested that the expression level might be related to (1) the mRNA stability of the partner (Yang et al. 2009), (2) the chaperone-like activity of TRX (Xu et al. 2007; Li 2009) or (3) its relatively low molecular-weight (~11.7 kDa), making the peptide of interest a large fraction of the fusion protein (Li 2011; Shlyapnikov et al. 2008).

Optimisation of Kcoil peptide purification

As the best expression level for biological Kcoil peptide production was observed when fused to TRX, further process development efforts were conducted using this expression vector following IPTG induction (Fig. 2). Cell disruption and fraction separation were performed as described in the “Materials and methods” section. SDS-PAGE analysis of the soluble and insoluble fractions confirmed that the TRX-Kcoil complex was mostly expressed in the soluble fraction (Fig. 3). Taking advantage of the N-terminal hexahistidine (His)6 tag, a Ni2+-chelating affinity chromatography step was thus performed first to purify the fusion protein. The estimated yield of eluted protein after this step was almost 22 mg of protein per liter of bacterial culture (Table 2). TEV cleavage was then performed to remove the TRX tag from the Kcoil moiety.

After TEV cleavage, two expected bands of approximately 12 kDa and 8 kDa were detected by polyacrylamide gel electrophoresis. These bands corresponded to the TRX protein and to Kcoil homodimers resulting from the formation of intermolecular cysteine bridges, respectively, thereby confirming that the specific enzymatic cleavage reaction was nearly complete after 2 h (Fig. 3). Monitoring the TEV cleavage reaction over 24 h indicated that there was no difference with other longer incubation times (2, 4, 8 and 24 h, data not shown). These results are in good agreement with previous reports indicating that protein cleavage by the TEV protease is highly specific and efficient. Furthermore, the use of the TEV protease is advantageous since its production in large quantities is easier than for other proteases, even at the laboratory scale (Esposito and Chatterjee 2006).

Following Kcoil peptide cleavage, it was necessary to remove the TRX protein from the mixture before a final purification step by RP-HPLC (Fig. 2). For this purpose, the solution mixture resulting from cleavage was directly applied to a SP-Sepharose FF column and the flow through collected. This strategy was selected as we were unable to efficiently capture the (His)6-tagged thioredoxin alone after TEV cleavage, even after several treatments with denaturants (e.g., high concentration of urea and guanidine hydrochloride; data not shown) most likely due to either strong electrostatic interactions between the lysine residues of the Kcoil peptide and the anionic thioredoxin (Yang et al. 2009; McCoy and La Ville 2001) or the presence of a loop within the active site of thioredoxin, which may favour small peptide binding. Noteworthy, TRX protein carrying peptide of interest in this active-site loop was reported to retain its structure (LaVallie et al. 1993), which may explain the inefficacity of denaturant treatment to release the Kcoil peptide.

Collected fractions were analysed by both absorbance measurement at 280 nm (to detect thioredoxin) and SDS-PAGE (for thioredoxin and Kcoil detection) in order to verify the efficacy of this second chromatography step. In our strategy, the Kcoil was successfully eluted at approximately 40 % of the linear salt gradient (0–0.5 M NaCl) at a pH lower than its theoretical isoelectric point (pI = 9.2) (Fig. 4a) while the (His)6-thioredoxin protein was recovered in the flow through in agreement with its pI being equal to 4.67. These results were verified by SDS-PAGE (Fig. 3). While the IEX-peak1 fraction did not contain any detectable K coil peptide, for the second peak that had been eluted from the ion exchange chromatography, gel staining revealed a band corresponding to an apparent molecular weight between 5 and 10 kDa. Since non-reducing conditions were used during SDS-PAGE experiments, this band may correspond to the formation of cysteine-bound Kcoil dimers. Cation exchange chromatography enabled us to separate almost 92 % of the originally expressed (His)6-thioredoxin from Kcoil peptide (Table 2; Fig. 4a) using a very slow salt gradient (20 column volumes with 90 cm/h as a flow rate), and once again supporting the hypothesis that strong electrostatic interactions between the positively charged Kcoil and the anionic residues of TRX protein resulted in a stable complex after TEV cleavage.

a Kcoil peptide and Thioredoxin fusion protein separation by cation exchange chromatography. After enzymatic digestion, the mixture was injected on a SP-Sepharose FF column using phosphate buffer (pH 7.4) as loading buffer and a 0–100 % linear gradient of NaCl (corresponding to 125-to-500 mM, dashed line) for elution. The nomenclature (IEX-peak1 and IEX-peak2) is the same as in Fig. 3. b Reverse-phase HPLC analysis of SP-Sepharose eluted fractions. Kcoil peptide was eluted from the C4 column using a 20–35 % linear gradient (15 min) of buffer B (intermittent line) (acetonitrile with 0.05 % of TFA). Reduced Kcoil peptide was detected by absorbance at 214 nm (continuous line) at approximately 180 mL of eluted volume; the small oxidized fraction of Kcoil correspond to the shoulder (arrow) at the base of the Kcoil peak

Based on our SDS-PAGE results, fractions corresponding to the second peak of the ion-exchange chromatography were pooled, concentrated, and subjected to a RP-HPLC purification step (Fig. 2). This final purification was very efficient (97.4 %), as 1.51 mg (i.e., 363 µmol) of pure Kcoil peptide per liter of bacterial culture was obtained as quantified by the Orange II primary amine detection method (Table 2). Fractions corresponding to the Kcoil peptide were eluted from the preparative C4 column using a linear gradient of acetonitrile with 0.05 % of trifluoroacetic acid (Fig. 4b). The oxidized form of the peptide was eluted slightly before its reduced counterpart, as confirmed by mass spectrometry analysis. The absorbance profile at 215 nm is in agreement with the observation by Lee and colleagues related to the separation of the oxidized and reduced forms of a protein by RP-HPLC when using a hydrophobic column (Lee et al. 2000). Of interest, the volumetric yield reported by Le and colleagues (Le et al. 2009) for the bacterial production and purification of a Kcoil peptide fused to EGF was of 0.107 µmol/L. Their purification strategy was based on solubilization from inclusion bodies. In contrast, we here demonstrate that higher yields (3.6 µmol/L) may be obtained using a soluble carrier protein such as thioredoxin. Our yield is similar to those reported for antibacterial bioactive peptides that were produced using the same fusion protein and that displayed similar size as our Kcoil peptide (M w = 2.9–3.7 kDa, e.g. Plantaricin E, F, J and K) (Pal and Srivastava 2014). Higher yields have been obtained for other anti-microbial peptides (3.2 mg to 11 mg/L of bacterial culture) using thioredoxin as a carrier protein (Xu et al. 2007; Li 2012; Jing et al. 2010; Shlyapnikov et al. 2008) suggesting that the hydrophobic nature of the Kcoil peptide may negatively impact its expression level. Others studies have also shown that prokaryotic production of auto-assembling amphiphilic peptides could attain gram per liter quantities using an inclusion body strategy and/or using a tandem repeat strategy; which cannot be applied in our case due to the important positive charge that would result from a tandem repeat Kcoil peptide (Kyle et al. 2010; Riley et al. 2009; Hartmann et al. 2008, 2009; Prakash et al. 2012). Thus, considering all the challenges associated to the Kcoil peptide primary sequence—10 lysines out of 38 residues as well as a strong proportion of hydrophobic residues, the process we here report (Fig. 2) lead to a significant yield of highly pure Kcoil peptide.

A mass-spectrometry analysis (data not shown) of the eluted fractions from RP-HPLC was performed in order to confirm the identity of the biologically produced peptide via its molecular weight. The ESI-TOF analysis of the biological Kcoil showed an average mass of 4159.9 Da, in excellent agreement with the Kcoil theoretical mass of 4158.9 Da while the second significant RP-HPLC peak corresponded to a mass of 8316.2 Da, unambiguously indicating that this peak corresponded to the oxidized form of the Kcoil peptide (theoretical mass of 8315.8 Da). Both SDS-PAGE and mass spectrometry results confirmed that the Kcoil peptide was highly pure.

Bioactivity assay on the BIACORE

In order to confirm the activity of the Kcoil peptide produced in bacteria, an SPR-based biosensor assay was performed according to a previously developed method (Murschel et al. 2013). SPR analysis was chosen to compare the kinetics of interactions of the biologically produced Kcoil peptide with its partner Ecoil peptide to those of a chemically synthesized Kcoil peptide. The ability of biologically produced Kcoil to be covalently immobilized to the dextran-coated surface via the thiol coupling procedure was first evaluated by monitoring the net mass accumulation on the surface (data not shown). The same assay was carried out using the chemically synthesised Kcoil as a positive control and gave similar results. As observed in Fig. 5a, the control corrected sensorgrams corresponding to the injection of the Ecoil-EGF fusion protein over both Kcoil surfaces gave almost superimposable curves. A more detailed SPR study was also performed by injecting increasing concentrations of Ecoil peptides on a surface displaying a low amount of Kcoil (<60 RU, see Fig. 5b). The corresponding sensorgrams were globally fit to a simple Langmuirian model, from which a dissociation constant K D of 137 pM was calculated. This value was close to that previously reported for Ecoil peptide binding to chemically produced Kcoil peptide (K D = 63 pM) (De Crescenzo et al. 2003b), given that different peptide quantification methods (Orange II assay, as described above, vs. amino acid analysis) and instruments were used in both studies. Altogether, the biologically produced Kcoil peptide presented the same kinetic behaviour as its chemically synthesized equivalent when binding to its Ecoil partner.

a Control-corrected sensorgrams corresponding to the injection of 100 nM of E5-EGF over the same amount of either chemically-synthesized (gray) or bacteria-produced (black) Kcoil that had been immobilized at the biosensor surface. b Kinetic analysis of E/Kcoil interaction using a simple binding model. Various concentrations of Ecoil peptide, ranging from 0.5 to 5 nM, were injected over less than 60 RU of immobilized bacteria-produced Kcoil. Both experimental data and global fit corresponding to a simple Langmuirian model are shown

In conclusion, we here report a novel approach for the bacterial production and subsequent purification of a de novo designed Kcoil peptide as an attractive alternative to its chemical synthesis. Among all the fusion proteins we tested, TRX was the best carrier for the production of soluble Kcoil peptide and subsequent purification. Finally, the bioprocess we developed (Fig. 2) represents an easy and low cost approach that can expand the Ecoil/Kcoil heterodimer utilization to several applications in the biopharmaceutical and biomedical fields.

References

Aronsson C, Dånmark S, Zhou F, Öberg P, Enander K, Su H, Aili D (2015) Self-sorting heterodimeric coiled coil peptides with defined and tuneable self-assembly properties. Sci Rep 5:14063. doi:10.1038/srep14063

Assal Y, Mizuguchi Y, Mie M, Kobatake E (2015) Growth factor tethering to protein nanoparticles via coiled-coil formation for targeted drug delivery. Bioconjug Chem 26(8):1672–1677. doi:10.1021/acs.bioconjchem.5b00266

Baneyx F (1999) Recombinant protein expression in Escherichia coli. Curr Opin Biotechnol 10(5):411–421

Boucher C, St-Laurent G, Loignon M, Jolicoeur M, De Crescenzo G, Durocher Y (2008) The bioactivity and receptor affinity of recombinant tagged EGF designed for tissue engineering applications is defined by the nature and position of the tags. Tissue Eng Part A 14(12):2069–2077. doi:10.1089/ten.tea.2008.0037

Boucher C, St-Laurent G, Jolicoeur M, Crescenzo GD, Durocher Y (2010) Protein detection by Western blot via coiled-coil interactions. Anal Biochem 399(1):138–140. doi:10.1016/j.ab.2009.12.007

Bromley EH, Channon KJ (2011) Alpha-helical peptide assemblies giving new function to designed structures. Prog Mol Biol Transl Sci 103:231–275. doi:10.1016/B978-0-12-415906-8.00001-7

Burkhard P, Stetefeld J, Strelkov SV (2001) Coiled coils: a highly versatile protein folding motif. Trends Cell Biol 11(2):82–88

Chao H, Houston ME Jr, Grothe S, Kay CM, O’Connor-McCourt M, Irvin RT, Hodges RS (1996) Kinetic study on the formation of a de novo designed heterodimeric coiled-coil: use of surface plasmon resonance to monitor the association and dissociation of polypeptide chains. Biochemistry 35(37):12175–12185. doi:10.1021/bi9530604

Chao H, Bautista DL, Litowski J, Irvin RT, Hodges RS (1998) Use of a heterodimeric coiled-coil system for biosensor application and affinity purification. J Chromatogr B Biomed Sci Appl 715(1):307–329

Cohen C, Parry DAD (1986) α-Helical coiled coils—a widespread motif in proteins. Trends Biochem Sci 11(6):245–248. doi:10.1016/0968-0004(86)90186-6

Davis GD, Elisee C, Newham DM, Harrison RG (1999) New fusion protein systems designed to give soluble expression in Escherichia coli. Biotechnol Bioeng 65(4):382–388

De Crescenzo G, Litowski JR, Hodges RS, O’Connor-McCourt MD (2003a) Real-time monitoring of the interactions of two-stranded de novo designed coiled-coils: effect of chain length on the kinetic and thermodynamic constants of binding. Biochemistry 42(6):1754–1763. doi:10.1021/bi0268450

De Crescenzo G, Pham PL, Durocher Y, O’Connor-McCourt MD (2003b) Transforming growth factor-beta (TGF-beta) binding to the extracellular domain of the type II TGF-beta receptor: receptor capture on a biosensor surface using a new coiled-coil capture system demonstrates that avidity contributes significantly to high affinity binding. J Mol Biol 328(5):1173–1183

De Crescenzo G, Pham PL, Durocher Y, Chao H, O’Connor-McCourt MD (2004) Enhancement of the antagonistic potency of transforming growth factor-beta receptor extracellular domains by coiled coil-induced homo- and heterodimerization. J Biol Chem 279(25):26013–26018. doi:10.1074/jbc.M400655200

Drogoz A, David L, Rochas C, Domard A, Delair T (2007) Polyelectrolyte Complexes from Polysaccharides: formation and Stoichiometry Monitoring. Langmuir 23(22):10950–10958. doi:10.1021/la7008545

Esposito D, Chatterjee DK (2006) Enhancement of soluble protein expression through the use of fusion tags. Curr Opin Biotechnol 17(4):353–358. doi:10.1016/j.copbio.2006.06.003

Fortier C, De Crescenzo G, Durocher Y (2013) A versatile coiled-coil tethering system for the oriented display of ligands on nanocarriers for targeted gene delivery. Biomaterials 34(4):1344–1353. doi:10.1016/j.biomaterials.2012.10.047

Gerling-Driessen UIM, Mujkic-Ninnemann N, Ponader D, Schöne D, Hartmann L, Koksch B, Gerling-Driessen UIM, Schöne D, Koksch B, Ponader D, Mujkic-Ninnemann N, Hartmann L (2015) Exploiting Oligo(amido amine) backbones for the multivalent presentation of coiled-coil peptides. Biomacromolecules 16(8):2394–2402. doi:10.1021/acs.biomac.5b00634

Grigoryan G, Keating AE (2008) Structural specificity in coiled-coil interactions. Curr Opin Struct Biol 18(4):477–483. doi:10.1016/j.sbi.2008.04.008

Guzmán F, Barberis S, Illanes A (2007) Peptide synthesis: chemical or enzymatic. Electron J Biotechnol 10(2):279–300. doi:10.2225/vol10-issue2-fulltext-13

Hartmann BM, Kaar W, Falconer RJ, Zeng B, Middelberg AP (2008) Expression and purification of a nanostructure-forming peptide. J Biotechnol 135(1):85–91. doi:10.1016/j.jbiotec.2008.03.003

Hartmann BM, Kaar W, Yoo IK, Lua LH, Falconer RJ, Middelberg AP (2009) The chromatography-free release, isolation and purification of recombinant peptide for fibril self-assembly. Biotechnol Bioeng 104(5):973–985. doi:10.1002/bit.22447

Jing XL, Luo XG, Tian WJ, Lv LH, Jiang Y, Wang N, Zhang TC (2010) High-level expression of the antimicrobial peptide plectasin in Escherichia coli. Curr Microbiol 61(3):197–202. doi:10.1007/s00284-010-9596-3

Kohn WD, Hodges RS (1998) de novo design of alpha-helical coiled coils and bundles: models for the development of protein-design principles. Trends Biotechnol 16(9):379–389. doi:10.1016/S0167-7799(98)01212-8

Kyle S, Aggeli A, Ingham E, McPherson MJ (2010) Recombinant self-assembling peptides as biomaterials for tissue engineering. Biomaterials 31(36):9395–9405. doi:10.1016/j.biomaterials.2010.08.051

LaVallie ER, DiBlasio EA, Kovacic S, Grant KL, Schendel PF, McCoy JM (1993) A thioredoxin gene fusion expression system that circumvents inclusion body formation in the E. coli cytoplasm. Biotechnology (NY) 11(2):187–193

LaVallie ER, Lu Z, Diblasio-Smith EA, Collins-Racie LA, McCoy JM (2000) Thioredoxin as a fusion partner for production of soluble recombinant proteins in Escherichia coli. Methods Enzymol 326:322–340

Le PU, Lenferink AE, Pinard M, Baardsnes J, Massie B, O’Connor-McCourt MD (2009) Escherichia coli expression and refolding of E/K-coil-tagged EGF generates fully bioactive EGF for diverse applications. Protein Expr Purif 64(2):108–117. doi:10.1016/j.pep.2008.11.005

Lee JY, Yoon CS, Chung IY, Lee YS, Lee EK (2000) Scale-up process for expression and renaturation of recombinant human epidermal growth factor from Escherichia coli inclusion bodies. Biotechnol Appl Biochem 31(Pt 3):245–248

Li Y (2009) Carrier proteins for fusion expression of antimicrobial peptides in Escherichia coli. Biotechnol Appl Biochem 54(1):1–9. doi:10.1042/ba20090087

Li Y (2011) Recombinant production of antimicrobial peptides in Escherichia coli: a review. Protein Expr Purif 80(2):260–267. doi:10.1016/j.pep.2011.08.001

Li Y (2012) A novel protocol for the production of recombinant LL-37 expressed as a thioredoxin fusion protein. Protein Expr Purif 81(2):201–210. doi:10.1016/j.pep.2011.10.011

Liberelle B, Bartholin L, Boucher C, Murschel F, Jolicoeur M, Durocher Y, Merzouki A, De Crescenzo G (2010a) New ELISA approach based on coiled-coil interactions. J Immunol Methods 362(1–2):161–167. doi:10.1016/j.jim.2010.09.027

Liberelle B, Boucher C, Chen J, Jolicoeur M, Durocher Y, De Crescenzo G (2010b) Impact of epidermal growth factor tethering strategy on cellular response. Bioconjug Chem 21(12):2257–2266. doi:10.1021/bc1002604

Lupas A (1996) Coiled coils: new structures and new functions. Trends Biochem Sci 21(10):375–382

McCoy J, La Ville E (2001) Expression and purification of thioredoxin fusion proteins. In: Ploegh HL (ed) Current protocols in protein science, vol 28. Wiley, pp 16.8.11–16.8.14. doi:10.1002/0471140864.ps0607s10

Murschel F, Liberelle B, St-Laurent G, Jolicoeur M, Durocher Y, De Crescenzo G (2013) Coiled-coil-mediated grafting of bioactive vascular endothelial growth factor. Acta Biomater 9(6):6806–6813. doi:10.1016/j.actbio.2013.02.032

Murschel F, Zaimi A, Noel S, Jolicoeur M, De Crescenzo G (2015) Specific adsorption via peptide tags: oriented grafting and release of growth factors for tissue engineering. Biomacromolecules. doi:10.1021/acs.biomac.5b00955

Pal G, Srivastava S (2014) Cloning and heterologous expression of plnE, -F, -J and -K genes derived from soil metagenome and purification of active plantaricin peptides. Appl Microbiol Biotechnol 98(3):1441–1447. doi:10.1007/s00253-013-5097-1

Prakash A, Parsons SJ, Kyle S, McPherson MJ (2012) Recombinant production of self-assembling beta-structured peptides using SUMO as a fusion partner. Microb Cell Fact 11:92. doi:10.1186/1475-2859-11-92

Riley JM, Aggeli A, Koopmans RJ, McPherson MJ (2009) Bioproduction and characterization of a pH responsive self-assembling peptide. Biotechnol Bioeng 103(2):241–251. doi:10.1002/bit.22274

Sahdev S, Khattar SK, Saini KS (2008) Production of active eukaryotic proteins through bacterial expression systems: a review of the existing biotechnology strategies. Mol Cell Biochem 307(1–2):249–264. doi:10.1007/s11010-007-9603-6

Shlyapnikov YM, Andreev YA, Kozlov SA, Vassilevski AA, Grishin EV (2008) Bacterial production of latarcin 2a, a potent antimicrobial peptide from spider venom. Protein Expr Purif 60(1):89–95. doi:10.1016/j.pep.2008.03.011

Song J, Chen W, Lu Z, Hu X, Ding Y (2011) Soluble expression, purification, and characterization of recombinant human flotillin-2 (reggie-1) in Escherichia coli. Mol Biol Rep 38(3):2091–2098. doi:10.1007/s11033-010-0335-4

Terpe K (2003) Overview of tag protein fusions: from molecular and biochemical fundamentals to commercial systems. Appl Microbiol Biotechnol 60(5):523–533. doi:10.1007/s00253-002-1158-6

Winkler DF, Tian K (2015) Investigation of the automated solid-phase synthesis of a 38mer peptide with difficult sequence pattern under different synthesis strategies. Amino Acids 47(4):787–794. doi:10.1007/s00726-014-1909-6

Woolfson DN, Mahmoud ZN (2010) More than just bare scaffolds: towards multi-component and decorated fibrous biomaterials. Chem Soc Rev 39(9):3464–3479. doi:10.1039/c0cs00032a

Xu X, Jin F, Yu X, Ji S, Wang J, Cheng H, Wang C, Zhang W (2007) Expression and purification of a recombinant antibacterial peptide, cecropin, from Escherichia coli. Protein Expr Purif 53(2):293–301. doi:10.1016/j.pep.2006.12.020

Yang YL, Tian ZG, Teng D, Zhang J, Wang JR, Wang JH (2009) High-level production of a candidacidal peptide lactoferrampin in Escherichia coli by fusion expression. J Biotechnol 139(4):326–331. doi:10.1016/j.jbiotec.2009.01.003

Acknowledgments

We would like to acknowledge the regional Center for Mass Spectrometry at University of Montreal for the peptide exact mass analysis and July Dorion-Thibaudeau and Frederic Murschel for their help during SPR assay development. This work was partly supported by the Natural Sciences and Engineering Research Council of Canada (NSERC) Discovery Grant program and the Canada Research Chair on Protein-enhanced Biomaterials.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

None.

Additional information

Handling Editor: J. D. Wade.

Rights and permissions

About this article

Cite this article

Riahi, N., Cappadocia, L., Henry, O. et al. Soluble expression, purification and functional characterization of a coil peptide composed of a positively charged and hydrophobic motif. Amino Acids 48, 567–577 (2016). https://doi.org/10.1007/s00726-015-2113-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00726-015-2113-z