Abstract

This contribution summarises the results from an initial electrochemical study of anti-inflammatory drug diclofenac at carbon paste electrodes focused on the applicability to the determination of this substance in environmental samples, namely, in aqueous solutions containing diclofenac. The substance of interest could be readily oxidized at carbon paste electrodes modified in situ with cetyltrimethylammonium bromide enhancing the response of diclofenac. The respective voltammetric method has been characterised with respect to the linear range, detection capabilities, and the overall analytical performance. Applicability of the procedure developed was examined on a set of model samples polluted with diclofenac before and after treatment with charcoal and/or various lipophilic ionic liquids to define the efficiency of such purification process.

Graphical abstract

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

In the environment, there are numerous chemical substances of anthropogenic origin that can be accumulated into a degree at which they may endanger most of living organisms, including human beings [1]. This is also the case of some massively used pharmaceuticals, such as diclofenac sodium [2-(2,6-dichlorophenyl)amino]benzeneacetic acid sodium salt; see Fig. 1) known as analgesic–antiflogistic drug and effective in treating acute inflammations and painful condition [2].

This medicament belongs to the most frequently used pharmaceuticals at all, when the global market produces the amounts approaching 1000 tons [3]. In the recent years, there is also growing interest in monitoring of diclofenac in the environment [4] because of its more pronounced occurrence in natural waters, where it represents a severe pollutant with proved toxicity towards some fishes, as well as other inhabitants of the aquatic realm [5, 6].

In addition, highly poisonous can also be certain derivatives of diclofenac formed either by natural disintegration of the original molecule or synthetically, after man-induced biodegradation [7]. Diclofenac itself comes into the environment mainly from the biological and clinical waste, but may also be delivered via improper disposal of unused medicaments and other pharmaceutical products. Based on systematic analysis in waste- and drinking waters, it can be estimated that the content of diclofenac in aquatic systems varies in the order of μg/dm3 [8]. Because common purification processes in wastewater treatment plants are mostly incapable to remove diclofenac and/or its potentially present metabolites, it is inevitable to utilise special procedures that are able of doing so. Typically, these approaches include highly effective physicochemical interactions, such as adsorption onto carbonaceous materials or ion-pairing with suitable ion exchangers when their performance can first be tested on model systems in laboratory conditions [9, 10].

An integral part of such modelling must be a reliable tool by means of which one can perform the respective comparative analyses. Regarding diclofenac, one of the choices can be electroanalysis, offering a high analytical performance with inexpensive instrumentation. Usually, the main principles for electroanalytical determination of diclofenac are its anodic oxidation at graphite electrodes and related configurations. For example, Madsen et al. studied the oxidation of diclofenac at a solid graphite electrode in a 0.1 M phosphate buffer (pH 7.4) with 25% (v/v) acetonitrile [11]. These authors have proposed by two-step reaction pathway involving the formation of 5-hydroxydiclofenac and its subsequent oxidation to the quinone–imine structure; both according to the overall scheme (Fig. 2).

Two-step mechanism of the electrode oxidation of diclofenac involving the formation 5-OH derivative of diclofenac and the subsequent quinone imine as the final product (according to Ref. [11])

A decade later, Cid-Ceron et al. [12] studied the oxidation pathway of diclofenac newly, in this case, using a carbon paste electrode (CPE) and pure aqueous solution with pH ~ 7. Their reaction mechanism is different from that commented above, stating that the oxidation of the title substance yields first a radical intermediate which is, in the neutral medium used, immediately hydrolysed and the doubly charged molecules then disintegrated in the following way (Fig. 3).

Two-step mechanism of the electrode oxidation of diclofenac (1) involving the formation of a radical and the subsequent hydrolysis to the final products 2,6-dichloroaniline (2) and salt of o-hydroxybenzeneacetic acid (3) (according to Ref. [12])

Most of recent electroanalytical measurements devoted to diclofenac [12,13,14,15] have employed the so-called carbon paste electrodes (CPEs; see, e.g., [16]); either as traditional carbon paste mixtures [12, 13] or in the form of some advanced configurations based on carbon nanotubes [13] and specially modified variants [14].

In this article, the results and observations from initial studies on the electrode behaviour of diclofenac at CPEs with traditional composition (made of powdered graphite and highly viscous silicone oil as a binder) and modified with cationic surfactants are summarised, followed by other electroanalytical experiments. These measurements have included optimisation of a newly proposed voltammetric method and its testing on model water samples containing diclofenac and being analysed before and after adsorption or ion exchange selected for purification the title substance from aquatic systems.

Results and discussion

Electrochemical study of diclofenac at carbon paste electrodes

Already, the first preliminary experiments have shown that diclofenac is fairly electroactive in the linear voltammetric mode (LSV or CV, respectively) when being kept in neutral aqueous media. The respective conditions for such measurements were mostly taken from the previous literature [11,12,13,14,15]; partly, from the measurements with similar configurations [11,12,13], in part from experimentation with special and chemically modified variants [11, 14, 15].

It was confirmed that the anodic oxidation of diclofenac at the CPE gives rise to a well-developed signal with a peak potential of about +0.6 V vs. Ag/AgCl/3.5 M KCl (further denoted as “ref.”). Because the fact that our working electrode could be polarized toward more positive potentials in comparison with those reported previously [11, 12], the oxidation of diclofenac was examined in a wider potential range, revealing a second oxidation signal with a peak potential of ca. + 1.1 V vs. ref. The electrode transformation of diclofenac at the CPE over a wide potential range is illustrated in Fig. 4, depicting the overlay of cyclic voltammograms obtained by five consecutive scans from − 0.5 V to + 1.5 V vs. ref. and reversely.

This result corresponds to the reaction pathway presented in Fig. 2 (according to [11]); however, when taking into account the revised mechanism (Fig. 3; after [12]), it should be completed with an additional step explaining the occurrence of the second peak observed.

Again, when considering the oxidation depicted in Fig. 3, one hypothesis behind the rise of the second signal is a possible oxidation of 2,6-dichloroaniline (2) to 2,6-dichlorophenylhydroxylamine; see Fig. 5, pathway on the left. Or, yet another explanation can be based on some interpretations of consecutive enzymatic oxidation of diclofenac [17] when the formation of p-hydroxy derivative can be assumed, see pathway right. In contrast to these pathways, an oxidation of the second hydrolytic product, o-hydroxyphenylacetate (3), seems to be much less probable [18].

Such an ambiguous interpretation suggests one that the oxidation of diclofenac at highly positive potentials has to be studied further and in more detail; best, using preparative electrolysis in combination with a suitable identification technique like FT-IR, MS, or NMR [18, 19].

Despite the previous recommendation about the suitability of neutral media for oxidation of diclofenac, a special pH study was performed, examining in detail the interval of pH 5–10, when using the corresponding solutions of BRBs. Once again, it was confirmed that the most favourable response could be obtained in neutral media, whereas more alkaline solutions had already caused a decrease of the first peak and the total disappearance of the second one. Thus, pH 7.0 was definitely set as optimal, but the originally tested BRB was replaced with a mixture of PBS (see “Experimental”), offering better signal-to-noise characteristics. The results from LSV and CV studies have also led to the choice of the proper analytical signal—the first peak corresponding to the formation of the diclofenac radical (in Fig. 3 and [12]) or to the rise of 5-OH-diclofenac if one considers older interpretation (Fig. 2 and [11]), respectively.

Finally, almost identical responses for measurements with differential pulse and square-wave voltammetry (DPV and SWV, respectively) have indicated that the reaction of interest is not kinetically controlled and hence suitable for (electro)analytical purposes.

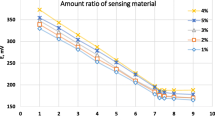

The last part of the electrochemical study with diclofenac (DCF) and CPE was devoted to the effect of a modifier on a possible enhancement of the response of interest when some commercial surfactants had been used for these assays being chosen based on the previous results [10, 15], as well as coming from own experience (see [16] and refs. therein). Such a modification is very simple, as it can be realised in situ; i.e., by adding a small amount of surfactant directly to the sample analysed. This can be exemplarily illustrated in Fig. 6, portraying the effect of cetyltrimethylammonium bromide (CTAB) that had been found the most effective for this function among all the surfactants tested.

Main oxidation peak of diclofenac and the effect of the presence of CTAB surfactant in the (sample) solution. Legend: see both insets and quartet of steps of the experiment depicted. Experimental conditions: CPE; SWV; 0.1 M PBS + 100 μM CTAB; c(diclofenac) = 5 × 10−4 mol/dm3; potential scan: + 0.2 → 1.2 V vs. ref.; SW ramp: frequency, fSW = 60 Hz, amplitude, ESW = 40 mV, potential step increment, p.i. = 5 mV

Because the respective experiments had not exhibited any accumulation tendencies at the CPE surface (and, therefore, a possibility to incorporate a pre-concentration step into the voltammetric procedure), the observed benefit of CTAB was attributed to the (pre)treatment of CPE by means of “erosion effect”. (In brief, it is a hydrophilisation of the CPE surface by repelling the lipophilic molecules of the binder by similarly lipophilic surfactant [20, 21]).

Electroanalytical determination of diclofenac in model aqueous samples before and after treatment

After a routine optimisation of important instrumental parameters, such as the potential range, scan rate, and the key parameters of differential pulse and square-wave potential ramps, the procedure with CTAB represented the method of choice for the determination of diclofenac.

Its analytical performance had been characterised with respect to the linearity range and detection abilities in both voltammetric modes with modulated ramp, resulting in an observation that the DPV offers somewhat worse performance than SWV. Typical calibration measurements for the latter in the micromolar range are shown in Fig. 7.

Dependence of the analytical signal of diclofenac on concentration in the low micromolar range. Legend: calibration voltammograms obtained by analysing the model aqueous solutions with 1, 3, 5, 7, and 10 μM diclofenac (left), the corresponding calibration plot and its evaluation by linear regression (right). Experimental conditions: CPE, SWV; model solution, 0.1 M PBS + 100 μM CTAB; potential scan, from + 0.2 to + 1.0 V vs. ref.; SW ramp: fSW = 60 Hz, ESW = 40 mV, p.i. = 5 mV, number of measurements n = 3

From the results of five replicate measurements in model solutions with sub-micromolar concentrations of diclofenac, the detection capabilities for DPV and SWV modes could be estimated. When using the criterion “3σ”, the respective LODs were about 2 × 10−7 mol/dm3 and, therefore, comparable for both voltammetric techniques with modulated potential ramp.

After the inevitable analytical characterisation, the method proposed was tested for analysis of model samples simulating the real aqueous systems (i) polluted with diclofenac and (ii) after the respective treatment chosen.

The treatment of model waste water contaminated with diclofenac itself had been examined using three different approaches: (a) sorption onto active charcoal added to the sample as small pellets; (b) ion exchange/ion-pairing with selected sparingly water-soluble ionic liquid/ion exchanger of the quaternary ammonium [R2RʹR″N+]X− type; and (c) capture onto the used charcoal/ionic liquid mixture using deactivated charcoal as possible carrier for lipophilic ionic liquids. Adsorption is effective but quite expensive method for removal of diclofenac because of the high quantity of the consumed sorbent, as published earlier [22,23,24]. Precipitation method applicable for removal of biocidal organic acids from aqueous effluents is based on the addition of sparingly water-soluble ionic liquid accompanied by the formation of insoluble ion pair by ion-exchange mechanism [25]. The main disadvantage of this method is complicated removal of produced fine precipitate in many cases. Due to this reason, application of some carrier with high affinity to the produced ion pairs R4N+Ar-COO− is crucial for their simple removal from treated water [26].

Spent charcoal serves as promising carrier due to its good affinity to the non-polar ionic liquids [27]. The effect of ionic liquid(s)/spent charcoal mixture application on removal of diclofenac is documented in Table 1 as well as Tables 3 and 4.

All the measurements of this kind had involved model solutions with the known content of diclofenac, which allowed us to define the purification efficiency via the corresponding difference (in %) between the content of diclofenac added and the residual concentration found by voltammetry with the in situ-modified CPE.

Due to the initial character of the whole study, the respective reference determinations with independent technique(s) were not performed.

The individual experiments with all the prepared and then-purified solutions, together with all three ways of purification, are summarised in Tables 1, 2, 3 and 4, offering also the full specification on the composition of the respective solutions, as well as all the efficiencies calculated from electroanalytical determinations. The data gathered in the tables document some important findings. For instance, the respective in Tables 1 and 3 indicates that hydraffin charcoal (GAC) cannot be used repeatedly for reaching of high removal of diclofenac which is in agreement with our expectation. Or, the isolation of diclofenac via the formation of ion pairs is the most effective way, allowing to purify the solutions almost completely (Table 2); however, separation of precipitated ion pair by filtration is time consuming and accompanied by clogging of filter pores in these cases. In addition, ionic liquids used in these experiments are the very expensive pure representatives of ionic liquids, which are much more expensive in comparison with charcoal. For economical reason, industrially produced mixtures arquad 2HT-75 (dialkyldimethylammonium chloride), benzalkonium chloride (alkylbenzyldimethylammonium chloride), and aliquat 336 (trialkylmethylammonium chloride) should be used for potential water treatment applications.

On the other hand, method c, adsorption using charcoal and its subsequent reuse in combination with hydrophobic ionic liquid(s) is the proper approach that enables both saving of charcoal consumption and, furthermore, simple separation of produced ion pairs resulting in higher than 90% removal of diclofenac (Table 3). Examples a-1, c-7, c-8, c-9, c-10, and c-11 illustrate repeated application of GAC in four steps using very efficient co-action of aqueous equimolar benzalkonium chloride (BAC) and aliquat 336 mixture (Table 4). This equimolar aqueous BAC + aliquat 336 mixture is very useful for simple application, because commercially available and cheap but in water insoluble aliquat 336 forms homogenous non-viscous fluid with commercially available aqueous 50 wt% BAC solution. As could be seen in Table 3, the efficiencies of 1 removal according to SWV are quite similar and above 90% in all cases (Table 4). The lower efficiencies measured by summary parameter adsorbable organic halogens (AOX) are probably caused by high concentration of chlorides in analysed samples (chlorides are produced by ion exchange and used ionic liquids are R4NCl salts, moreover). Higher values of chemical oxygen demand (COD) parameter are influenced by the excess of ionic liquids used and its negligible but measurable solubility in water.

Regarding quite high contents of diclofenac in model solutions that did not correspond to typical real samples, they were maintained to the experiments surveyed in Tables 3 and 4, studying the efficiency of the effect of used charcoal as ionic liquid carrier at limiting conditions of eventual saturation in the presence of especially high contents of the target substance.

Conclusions

In this article, we have shown that carbon paste electrodes prepared from traditional mixtures of graphite powder with paraffin oil [16] and modified in situ with cationic surfactant of the quaternary ammonium salt—in our case, cetyltrimethylammonium bromide (CTAB)—can be utilised for cheap, simple, and rapid determination of diclofenac in water samples at sub-millimolar concentration level. When coupled with voltammetric measurement, either in the DPV or SWV mode (both offering nearly comparable performance), the resultant combination represents a suitable analytical tool having some promise in analytical practice.

As shown on a series of model solutions obtained from a study on physicochemical treatment of aqueous solutions spiked with diclofenac, the respective method developed can be useful for occasional or even systematic monitoring of this worldwide used medicament. This statement corresponds to the main results from optimisation and characterisation measurements that fulfilled our anticipations that detection capabilities of the newly proposed method are sufficient for environmental samples polluted by diclofenac; typically, at the micromolar concentration level or even below.

With respect to the fact that this study was first of a kind, the samples had been prepared by treatment of aqueous solutions of diclofenac. In other words, incidental interferences from related compounds and other possible matrix constituents have not been studied here and will be the subject of interest in our further investigations.

Last but not least, this report also documents that modern electroanalysis may still offer valuable contributions in resolving actual problems, including those arising in present-day’s environmental analysis [28].

Experimental

The appropriate quantity of drug diclofenac sodium (sodium salt of [2-(2,6-dichlorophenyl)amino]benzeneacetic acid, 1; Sigma-Aldrich, USA) was dissolved in deionized water to prepare 0.025 mol/dm3 (7.96 g of 1 per dm3 of H2O), 25 mM aq. stock solution of diclofenac, and this in the individual experiments was diluted as required using demineralized water in all cases.

The first set of surfactants, serving as purification agents, was made 10% (w/w) in concentration and purchased from Sigma-Aldrich unless stated otherwise. The individual ionic liquids were as follows: (i) cetyltrimethylammonium bromide (CTAB, Alfa Aesar, USA); (ii) benzalkonium chloride (BAC, 50 wt% aq. solution); (iii) poly(dilauryldimethylammonium) bromide (20 wt% aq. solution); (iv) dilauryldimethylammonium chloride; (v) benzyldimethylstearylammonium chloride; (vi) trioctylmethylammonium chloride; (vii) aliquat 336®; (viii) arquad 2HT-75® (Brenntag, Czech republic); and (ix) luviquat FC 730®. Furthermore, two special mixtures of ionic liquids were employed: (x) “104BK” soln.: prepared by dissolving of 20.1 g aliquat 336 (50 mmol) in 30.4 g of 50 wt% aqueous solution of 50 mmol BAC and (xi) “610TW” soln.: aliquat 336 + arquad 2HT-75; prepared by dissolution of 15 mmol of lactic acid (1.78 g of 85–90 wt%) in 15 mM aqueous KOH and subsequently 75 mmol of arquad 2HT-75 and 50 mmol of aliquat 336 was homogenised in the obtained sodium lactate solution (125 mM aq. mixture of quaternary ammonium salts was obtained). Finally, an alternate purifier was the active charcoal hydraffin CC® (Donau Carbon, Austria) applied in the form of small compact pellets.

The second set of surfactants, namely: (a) CTAB; (b) sodium dodecylsulfate, SDS; (c) potassium dibutylsulfate, DBSK; and (d) nonindet® was applied as more diluted aq. solns. (1 × 10−4 mol/dm3), enabling the in situ modification of the working electrode; see below.

Britton–Robinson buffers (BRBs) were prepared from the prescribed chemicals (solution “A”: H3PO4, CH3COOH, H3BO3 and solution “B”: NaOH, respectively) and at concentrations according to the literature data; see, e.g., [29]. Their mixtures at recommended ratio then formed a set of solutions with pH 1.5–12.0. The stock solutions of other electrolytes (HCl, H2SO4, Na2HPO4, and NaCl) were made as 0.5 mol/dm3 in concentration and, for the individual experiments, diluted again as required.

Electroanalytical measurements of quantitative nature were then performed in a solution of ultimate composition—the appropriately diluted mixture of KH2PO4 + Na2HPO4 + NaCl (PBS; abbreviated from “Phosphate Buffer-Based Solution”). Finally, all the solutions were prepared from doubly deionised water obtained by passing the already distilled water through a Milli-Q water purification unit (Millipore, USA).

Instrumentation and other accessories

All electrochemical measurements were carried out using an AUTOLAB analyser (model “PGSTAT-128N; Autolab/Metrohm, The Netherlands/Switzerland), coupled with the three-electrode cell incorporating (i) the working carbon paste electrode (CPE) based on hand-homogenised carbon paste containing 0.5 g graphite powder (product “CR-5”; Maziva Týn, Czech Republic) and 0.3 cm3 paraffin oil (Uvasol® grade; Merck, USA).

This paste mixture was then manually filled into a piston-driven electrode body (of own construction described in Ref. [30]). The remaining electrodes were (ii) a Ag/AgCl/3.5 M KCl reference and (iii) a platinum auxiliary electrode (both from Metrohm). For certain comparative experiments, the glassy carbon electrode (GCE; Metrohm) when its geometric surface was the same as that of the CPE used.

The pH values were measured and/or controlled by a contact pH sensor based on ISFET principles and calibrated by the manufacturer (Hanna, Germany). If needed, the individual solutions were measured and introduced to the cell by automatic pipettes (Finpipette; Labsystems, Finland).

Samples and their processing

Adsorbable organically bound halogen (AOX) analyses were performed according to European ISO 9562 standard; chemical oxygen demand (COD) was analysed using COD sample cuvette tests LCK 514 (measurable range 100–2000 mg O2/dm3), LCK 1014 (measurable range 1000–10,000 mg O2/dm3), and LCK914 (measurable range 5–60 g O2/dm3) with spectrophotometric method using a DR 2800 device (Hach, Austria [31,32,33]).

Experiments allowing one the removal of 1 from the model aq. solutions prepared were performed in 250 and 500 cm3 volumetric flasks, respectively, placed on a special pad (model “Starfish”; Radleys Discovery Technologies, UK) devised with magnetic bar stirring. The model mixtures were then subjected by the effect of purification agent/medium, always under moderate stirring for a period of ca. 24 h at ambient temperature and under atmospheric pressure; in some tests, stirring being prolonged to 3 days. After this procedure, the individual solutions were yet filtered by passing through a ceramic filter and subjected to the voltammetric analysis. The individual types of model solutions and their exact composition are specified in “Results and discussion”, namely, in a series of Tables 1, 2, 3, 4 presented.

Specification of voltammetric measurement(s)

The experiments within the basic electrochemical study were performed either by linear voltammetry (LSV) in one direction (usually as anodic scan) or by cyclic voltammetry allowing both anodic and cathodic polarisations continuously, in one run. In electroanalytical measurements, both differential pulse (DP) and square-wave (SW) modulations were tested, the latter being chosen as the potential ramp of choice used for analyses of model solutions with 1 before and after purification. Typical experimental and instrumental conditions had included the following parameters: supporting electrolyte, 0.1 M PBS + 1 × 10−4 M CTAB; potential scan from +0.2 to 1.2 V vs. ref.; and scan rate of 50 mV s−1; the remaining parameters being specified again in “Results and discussion”, inside the respective figure captions. All three solutions analysed had to be purified by bubbling with inert gas (nitrogen with purity 99.99; Linde, Czech Rep.) to remove the dissolved oxygen.

Finally, prior to each voltammetric measurement, the CPE surface had to be renewed by wiping off a thin layer of the carbon paste with a wet filter paper, which was, with the piston-based CPE, quite simple and achievable in a few seconds.

References

Küster A, Adler N (2014) Philos Trans R Soc Lond 369:1656

Sallmann AR (1986) Am J Med 80:31

Kummerer K (2001) Pharmaceuticals in the environment: sources, fate, effects and risks. Springer, Berlin

Lonappan L, Brar SK, Das RK, Verma M, Surampalli RY (2016) Environ Intern 96:127

Schwaiger J, Ferling H, Mallow U, Wintermayr H, Negele RD (2004) Aquat Toxicol 68:141

Triebskorn R, Casper H, Heyd A, Eikemper R, Köhler HR, Schwaiger J (2004) Aquat Toxicol 68:151

Cherik D, Louhab K (2015) Res J Chem Environ 19:40

Zhang Y, Geissen SU, Gai C (2008) Chemosphere 73:1157

Coimbra RN, Escapa C, Paniagua S, Otero M (2016) Desal Wat Treat 57:27914

Lin KYA, Yang HT, Lee WD (2015) RSC Adv 99:81330

Madsen KG, Skonberg C, Jurva U, Cornett C, Hansen SH, Johansen TN, Olsen J (2008) J Chem Res Toxicol 21:1107

Cid-Cerón MM, Guzmán-Hernández DS, Ramírez-Silva MT, Galano A, Romero-Romo M, Palomar-Pardavé M (2016) Electrochim Acta 199:92

Guzmán-Hernández DS, Martínez-Cruz MA, Ramírez-Silva MT, Romero-Romo M, Corona-Avendaño S, Mendoza-Huizard LH, Palomar-Pardavé M (2016) Anal Methods 8:7868

Daneshgar P, Norouzi P, Ganjali MR, Dinarvand R, Moosavi-Movahedi AA (2009) Sensors 9:7903

Guzmán-Hernández DS, Cid-Cerón MM, Romero-Romo M, Ramírez-Silva MT, Páez-Hernández ME, Corona-Avendaño S, Palomar-Pardavé M (2017) RSC Adv 9:7909

Švancara I, Kalcher K, Walcarius A, Vytřas K (2012) Electroanalysis with carbon paste electrodes. CRC Press, Boca Raton

Tang W (2003) Curr Drug Metab 4:319

Jörissen J, Speiser B (2015) Preparative electrolysis on the laboratory scale. In: Hammerich O, Speiser B (eds) Organic electrochemistry, vol 5. CRC Press, Boca Raton, p 263

Wolter KD, Stock JT (1978) J Electrochem Soc 125:531

Digua K, Kauffmann JM, Delplancke JL (1994) Electroanalysis 6:451

Digua K, Kauffmann J-M, Khodari M (1994) Electroanalysis 6:459

Larous S, Meniai A-H (2016) Int J Hydrogen Energy 41:10380

Plakas KV, Karabelas AJ (2016) Global NEST J 18:259

Altmann J, Ruhl AS, Zietzschmann F, Jekel M (2014) Water Res 55:185

Kamenická B, Weidlich T (2018) Fibres Text 3:37

Shabtai IA, Mishael YG (2016) Environ Sci Technol 50:8246

Šimek M, Mikulášek P, Kalenda P, Weidlich T (2016) Chem Pap 70:470

Moretto LM, Kalcher K (eds) (2014) Environmental analysis by electrochemical sensors and biosensors, vol I and II. Springer, Berlin

Vohlídal J, Julák A, Štulík K (1999) Chemical and analytical tables. Grada Publishing, Prague, p 544

Švancara I, Metelka R, Vytřas K (2005) Piston-driven carbon paste electrode holders for electrochemical measurements. In: Kalcher K, Vytras K (eds) Sensing in electroanalysis. Press Centre, University of Pardubice, Pardubice, p 7

Hach (2018) COD quide preparation. https://www.hach.com/codguide-preparation. Accessed 26 Oct 2018

Hach (2018) AOX photometric determination. https://uk.hach.com/aox-cuvette-test-0-05-3-0-mg-l/product?id=26370291471. Accessed 30 Oct 2018

ISO 9562:2004 Water quality—determination of adsorbable organically bound halogens (AOX). https://www.iso.org/standard/36918.html. Accessed 30 Oct 2018

Acknowledgements

We are grateful to thank for support by Technology Agency of the Czech Republic, Project No. TH02030200. In addition, authors would like to thank Dr. Tomáš Mikysek, their colleague from the Department of Analytical Chemistry, for some valuable comments concerning the interpretation of the electrode oxidation of diclofenac.

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Kamenická, B., Bartášková, A., Švancara, I. et al. Applicability of voltammetric determination of diclofenac at carbon paste electrodes to the analysis of aqueous solutions purified by adsorption and/or ionic liquid-based ion exchange. Monatsh Chem 150, 429–437 (2019). https://doi.org/10.1007/s00706-019-2354-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00706-019-2354-8