Abstract

An inexpensive and effective preparative protocol for the highly efficient synthesis of structurally diverse 3,5-diaryl-1,2,4-thiadiazoles at ambient temperature with 2,4,6-trichloro-1,3,5-triazine (CC) and DMSO in polyethylene glycol 400 (PEG-400) as solvent is described.

Graphical abstract

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The 1,2,4-thiadiazole scaffold represents an important class of core structures in pharmaceutical molecules and products possessing a variety of biological activities [1, 2]. Also, the properties of 1,2,4-thiadiazoles as thiol trapping agents have been recently reviewed [3]. Although currently the only commercial 1,2,4-thiadiazole drug is the antibiotic cefozopram [4], there are a number of synthetic products related to this system with a broad range of biological activities, e.g., anti-inflammatory [5], cardiovascular [6, 7], or antibiotic activity [8, 9].

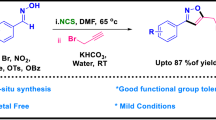

Despite their wide range of pharmacological activity and synthetic applications, only a few methodologies have been reported in the literature for the synthesis of 3,5-diaryl-1,2,4-thiadiazoles. The synthesis of these compounds is limited to the oxidative dimerization reaction of thioamides with 1-methylpyridinium chloride, benzoyl chloride, or acetyl chloride in chlorinated organic solvents [10]; or by using a stoichiometric amount of PhI(OAc)2 at 70 °C [11]. Nonetheless, the preparation of these substituted 1,2,4-thiadiazoles remains a challenge. All of the reported procedures require drastic reaction conditions due to low yields, expensive or not readily available reagents, or tedious workup. Some of these reactions also require high temperatures.

In our opinion, it is still possible and desirable to devise new preparative procedures which would be easy, inexpensive, safe, and effective for this transformation. We hope that the new method reported in this paper may fulfill, at least in part, these expectations.

Results and discussion

As a part of our interest in finding synthetic applications of 2,4,6-trichloro-1,3,5-triazine (CC) [12] and designing new eco-friendly transformations in organic synthesis [13–16], we envisaged the use of CC–DMSO in polyethylene glycol 400 (PEG-400) for the transformation of arylthioamides into the corresponding 3,5-diaryl-1,2,4-thiadiazoles (Scheme 1).

In preliminary investigations, thiobenzamide (1 mmol) was used as a model substrate for optimization of reaction conditions. The influence of solvents on the reaction yields was examined first. The reaction was carried out at 25 °C for 10 min with CC (30 mol%) and DMSO (1 mmol) in 2 cm3 of various solvents and we found that PEG-400 was the best solvent in terms of yield and reaction time (Fig. 1).

Further studies showed that the optimal ratio of thioamide/CC/DMSO is about 1:0.3:1; reducing the loading of CC or DMSO led to a dramatic decline in yields. Moreover, in the absence of CC or DMSO no oxidative reaction was observed. Having determined the optimum reaction conditions, in order to demonstrate the generality and applicability of the present process, we performed the reaction on a variety of arylthioamides with CC–DMSO at 25 °C in PEG-400. The results are summarized in Table 1.

In all cases, the use of 0.3 equivalent of CC and 1 equivalent of DMSO was sufficient to achieve high to excellent yields of the desired products. Electron-donating and electron-withdrawing substituents on the aromatic ring did not profoundly affect the efficiency of the reactions. Acid-sensitive groups such as methoxy or furyl were retained, showing the mildness of the present reaction conditions.

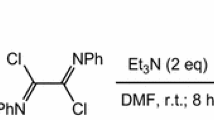

Although the mechanism is not clear, this reaction presumably proceeds via the formation of N-chlorothioamide and subsequent dimerization to give intermediate A which undergoes intramolecular cyclization to the corresponding thiadiazole (Scheme 2).

The recycling performance of PEG-400 was also investigated in the synthesis of 3,5-diphenyl-1,2,4-thiadiazole as a model. The data showed that PEG-400 could be reused at least five times.

In conclusion, we have found that combination of CC and DMSO in PEG-400 as a green medium makes an inexpensive and highly efficient promoter system for the elaboration of substituted 3,5-diaryl-1,2,4-thiadiazoles with high to excellent yields in very short reaction times. In addition to its efficiency and simplicity, this study provides an alternative procedure for the synthesis of biologically active 3,5-diaryl-1,2,4-thiadiazoles.

Experimental

PEG-400, 2,4,6-trichloro-1,3,5-triazine (CC), DMSO, and other chemicals were purchased from Merck Chemical Co. and used without further purification. Arylthioamides were prepared as described in [16]. Melting points were measured on a Stuart Scientific SMP2 apparatus. Elemental analyses for C, H, N, and S were performed by using a Leco CHNS-932 analyzer, and the results agreed favorably with the calculated values. 1H and 13C NMR spectra were measured in CDCl3 solution with a Bruker DRX-500 Avance spectrometer at 500.1 and 125.7 MHz.

General experimental procedure for the synthesis of 3,5-diaryl-1,2,4-thiadiazoles

To 1.0 mmol thioamide dissolved in 2 cm3 PEG-400, 0.055 g 2,4,6-trichloro-1,3,5-triazine (0.3 mmol) and 0.078 g DMSO (1 mmol) were added at 25 °C. The reaction mixture was vigorously stirred at room temperature until thioamide had completely disappeared (the progress of the reaction was followed by TLC). When the reaction was completed, it was quenched with 10 cm3 ice water and stirred at room temperature for 10 min. The stirring was stopped and the mixture was filtered. The filtrate was extracted with ethyl acetate (3 × 5 cm3) and dried over anhydrous MgSO4. After the removal of the solvent the residue was purified by flash column chromatography on silica gel (30% ethyl acetate in n-heptane as eluent) to afford the pure product.

Procedure for determining the recyclability of PEG-400

Recyclability of the solvent was studied by using the reaction of 0.137 g thiobenzamide (1.0 mmol) as a model. We found that after the reaction was over and washed with ice water, the aqueous layer can be dried at 80 °C for 12 h and reused in at least five runs with insignificant changes in yields.

References

Castro A, Castaño T, Encinas A, Porcal W, Gil C (2006) Bioorg Med Chem 14:1644

Leung-Toung R, Wodzinska J, Li W, Lowrie J, Kukreja R, Desilets D, Karimian K, Tam TF (2003) Bioorg Med Chem 11:5529

Tam TF, Leung-Toung R, Li W, Spino M, Karimian K (2005) Mini Rev Med Chem 5:367

Iizawa Y, Okonogi K, Hayashi R, Iwahi T, Yamazaki T, Imada A (1993) Antimicrob Agents Chemother 37:100

Song YT, Connor DT, Sercel AD, Sorenson RJ, Doubleday R, Unangst PC, Roth BD, Beylin VG, Gilbertsen RB, Chan K, Schrier DJ, Guglietta A, Bornemeier DA, Dyer RD (1999) J Med Chem 42:1161

Kohara Y, Kubo K, Imamiya E, Wada T, Inada Y, Naka T (1996) J Med Chem 39:5228

Shen L, Zhang Y, Wang A, Sieber-McMaster E, Chen X, Pelton P, Xu JZ, Yang M, Zhu P, Zhou L, Reuman M, Hu Z, Russell R, Gibbs AC, Ross H, Demarest K, Murray WV, Kuo G-H (2007) J Med Chem 50:3954

Ishikawa T, Iizawa Y, Okonogi K, Miyake A (2000) J Antibiot 53:1053

Marcinkeviciene J, Rogers MJ, Kopcho L, Jiang W, Wang K, Murphy DJ, Lippy J, Link S, Chung TDY, Hobbs F, Haque T, Trainor GL, Slee A, Stern AM, Copeland RA (2000) Biochem Pharmacol 60:339

Forlani L, Boga C (2002) J Chem Soc Perkin Trans 2: 768 (references therein)

Yan M, Chen Z-C, Zheng Q-G (2003) J Chem Res 618

Khosropour AR, Mohammadpoor-Baltork I, Khodaei MM, Jowkar M (2006) Heterocycles 68:1551

Khosropour AR, Khodaei MM, Beygzadeh M (2007) Heteroatom Chem 18:684

Khosropour AR, Khodaei MM, Hoseini Jomor S (2008) J Heterocycl Chem 45:683

Khosropour AR (2008) Ultrason Sonochem 15:659

Noei J, Khosropour AR (2008) Tetrahedron Lett 49:6969 and references therein

Patil PC, Bhalerao DS, Dangate PS, Akamanchi KG (2009) Tetrahedron Lett 50:5820

Acknowledgments

The authors are grateful to the Center of Excellence of Chemistry of University of Isfahan (CECUI) and also the Research Council of the University of Isfahan for financial support.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Khosropour, A.R., Noei, J. A convenient strategy for the synthesis of 3,5-diaryl-1,2,4-thiadiazoles: oxidative dimerization of arylthioamides using CC–DMSO in PEG-400. Monatsh Chem 141, 649–651 (2010). https://doi.org/10.1007/s00706-010-0295-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00706-010-0295-3