Abstract

We have prepared a hydrophilic molecularly imprinted polymer (MIP) for the hydrophobic compound bisphenol A (BPA) in aqueous solution using 3-acrylamido-N,N,N-trimethylpropan-1-aminium chloride (AMTC) as the functional monomer. Under redox-polymerization conditions, BPA forms an ion-pair with AMTC, which was confirmed by 1H-NMR titration. The imprinting effect in aqueous solution was evaluated by comparison of this material with the corresponding non-imprinted polymer (NIP) and with a control polymer (CP) bearing no AMTC. The MIP showed the highest activity among the three polymers, and the imprinting factors as calculated from the amount of BPA bound to the MIP divided by the amounts bound to NIP and CP, respectively, are 1.8 and 6.0. The MIP was selective for BPA in aqueous solution, while structurally related compounds are not recognized. Such a selectivity for a hydrophobic compound is rarely observed in aqueous medium because non-specific binding of BPA inevitably leads to hydrophobic interaction.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Bisphenol A (BPA) has been used in large amounts for the production of polycarbonates and epoxy resin [1,2], and has become suspected as an endocrine-disrupting compound that is concerned as an environmental pollutant. Currently, a research group reported elevated serum level of BPA (1–1.5 ng · mL−1) in women in polycystic ovary syndrome that is the most common endocrinopathy of women of reproductive age [3]. López-Darias et al. reported that an in-situ ionic liquid-dispersive liquid-liquid microextraction procedure in conjunction with HPLC analysis succeeded the detection of BPA from seawater with the limit of detection of 4.8 ng · mL−1 [4]. Accordingly, BPA has attracted considerable attentions to measure BPA concentration at nano-gram order level by various analytical methods such as ELISA [3], LC-MS [5–8] and surface plasmon resonance analysis [9]. However, the extraction of BPA from water samples requires time-consuming and large volumes of organic solvents. Furthermore, materials used for the BPA extraction or pre-treatments do not perform sufficient selectivity for the various analytical methods [7]. Thus, highly selective materials for BPA detection are required.

Molecular imprinting has been recognized as a promising technique to construct highly selective binding cavity for target molecules in synthetic polymer matrices in a tailor-made manner [10–16]. Molecularly imprinted polymers (MIPs) are prepared by the following three steps; 1) preparation of template molecules, where the target molecules were conjugated with functional monomers by covalent or non-covalent bonds, 2) polymerization with the template molecule, a crosslinker and an initiator, and 3) removal of the template moiety from the obtained polymers to generate target-selective binding cavity [13,14]. MIPs prepared by non-covalent bonds do not need the chemical derivatization of target molecules, which leads to simple removal of target molecules under gentle conditions [13].

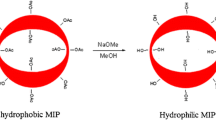

Molecular imprinting has been extensively studied for BPA recognition mainly in organic solvents by using either hydrogen bonding or covalent bond to prepare BPA-based template molecules [14–16]. Owing to the use of organic solvents, crosslinkers that can be soluble in those organic solvents should be selected, leading to the formation of hydrophobic MIPs. If such MIPs were used in aqueous solution and hydrophobic compounds including BPA are subjected for binding, those compounds bind possibly on MIPs by non-specific interaction. To achieve BPA recognition in aqueous solution, hydrophilic MIPs are necessary to design and propose for selective binding of BPA without non-specific binding. Preparative conditions are desirable to be the same as re-binding conditions because the same condition can minimize morphology changes: the same compositions of both preparative and re-binding buffers can diminish changes of the size of binding cavities. Concerning this matter, preparation of MIPs in aqueous solution is better than in organic solution, if BPA recognition is conducted in aqueous solution including river water, food products and so on. Recently, surface molecular imprinting for BPA in conjunction with sol–gel process is performed on the surface of silica nanoparticles in aqueous conditions, resulting in specific binding of BPA in water phase with the maximum binding capacity of ca. 30 μmol · g−1 [17].

In this study, we developed BPA-imprinted polymers (BPA-MIPs) capable of BPA recognition in aqueous solution. Since BPA-MIPs prepared in aqueous solution is desirable as described above, BPA needs to be solubilized in aqueous solution. BPA is known to be dissolved in water under basic conditions, where the phenolic hydroxyl groups were de-protonated and negatively charged. In order to construct specific binding sites toward BPA, a functional monomer that is positively charged under basic conditions was selected to interact with BPA. In detail, we adopted a quaternary ammonium monomer, 3-acrylamido-N,N,N-trimethylpropan-1-aminium chloride (AMTC, Fig. 1) as a positively charged functional monomer, and prepared hydrophilic BPA-MIPs under basic conditions by co-polymerization with N,N’-methylenebisacrylamide (MBAA) as a hydrophilic crosslinker. The binding characteristics and BPA recognition ability of BPA-MIPs were evaluated by batch binding tests for BPA and structurally related compounds, to demonstrate the method.

Experimental

Materials

Bisphenol A (BPA), N,N’-methylenebisacrylamide (MBAA) and ammonium peroxodisulfate (APS) were purchased from Nacalai Tesque Co. Ltd. (Kyoto, Japan http://www.nacalai.co.jp/global/). Sodium dodecyl sulfate (SDS), methanol (MeOH), hydrochloric acid (HCl), sodium hydroxide (NaOH), N,N,N’,N’-tetramethylethylenediamine (TMEDA), 4,4′-diaminodiphenylmethane (DADPM) and 17α-estradiol (EST) were purchased from Wako Pure Chemical Industries, Ltd. (Osaka, Japan http://www.wako-chem.co.jp/english/). Bisphenol B (BPB), hexestrol (HEX) and 4,4′-dimethoxybenzophenone were purchased from Tokyo Chemical Industry Co. Ltd. (Tokyo, Japan http://www.tcichemicals.com/). 3-Acrylamido-N,N,N-trimethylpropan-1-aminium chloride (AMTC) and N-(3-dimethylaminopropyl)acrylamide (DPA) were kindly provided as 75 % water solution with hydroquinone monomethylether by Kohjin Co. Ltd. (Tokyo, Japan http://www.kohjin.co.jp/english/index.html). Water was purified with a Milli-Q system (Millipore, Bedford, MA, USA http://www.millipore.com/). Sodium deuterium oxide (NaOD) was obtained from Merck Ltd (http://www.merck.co.jp/en/index.html;jsessionid=73C5BD393909E2A50971D09467A3F333). Deuterium oxide (D2O) was purchased from Cambridge Isotope Laboratories, Inc. Tween 20 was obtained from Sigma Chemical Co (http://www.sigmaaldrich.com/japan.html).

Preparation of BPA disodium salt

BPA disodium salt (Fig. 2) was prepared by mixing with NaOH in methanol. Briefly, 800 mg (20 mmol) NaOH dissolved in distilled water (6 mL) was added to 1.14 g (5.0 mmol) of BPA in methanol (2 mL). The mixture was stirred at room temperature for 1.5 h. This reaction mixture was then added to a large excess of acetone, followed by stirred vigorously. The obtained precipitate was collected by filtration, washed twice with acetone, and dried under vacuum on heating.

1H-NMR δH (300 MHz, Acetone-d 6/D2O): 1.41 (6H, s, CH3), 6.37–6.42 (4H, benzene), 6.75–6.80 (4H, benzene), MALDI-TOF MS m/z: calcd. for C15H14NaO2 −[M-Na]−: 249.09, found: 249.42. (Note: the m/z of BPA disodium salt was observed as monovalent ion: in the case of BPA molecules, m/z was found as 227.09) (calcd. for C15H15O2 − [M-H]− that is monovalent ion of BPA).

1H-NMR titration of interaction between BPA disodium salt and acrylamido-N,N,N-trimethylpropan-1-aminium chloride (AMTC)

Interaction between BPA disodium salt and AMTC was investigated by 1H-NMR spectroscopy using a 300 MHz NMR apparatus (JNM-LA300 FT NMR system, JEOL Ltd., Tokyo, Japan). 4,4-Dimethyl-4-silapentane-1-sulfonic acid was used as an internal standard. Molar ratio between BPA disodium salt and AMTC were varied to be 0:1, 1:1 and 2:1. Chemical shift change (Δδ) of the N-trimethyl group (δ = 3.12) was used as an index of the interaction. The same experiment was performed using DPA instead of AMTC, where Δδ of the N-dimethyl group was used as the index.

Job plots for the interaction between BPA disodium salt and AMTC were carried out according to the literature with minor modification [18,19], to examine stoichiometry of the complexation. BPA disodium salt and AMTC were dissolved in D2O containing 50 mM NaOD. The total molar concentration of BPA and AMTC were held at 10 mM, and the mole fraction of BPA was varied from 0 to 1, where Δδ of the N-trimethyl group of AMTC was used as an index of the complex formation.

Preparation of BPA-imprinted polymer (BPA-MIP)

BPA disodium salt and AMTC were dissolved in 50 mM NaOH (Final concentration of BPA disodium salt and AMTC was 25 mM and 50 mM, respectively), and then the mixture was incubated for 30 min at 25 °C (Solution A). MBAA dissolved in 50 mM NaOH was mixed with Solution A to yield a pre-polymerization mixture containing 5 mM BPA, 10 mM AMTC, and 100 mM MBAA. After that, TMEDA and APS was added to the mixture to be 15 mM TMEDA and 5 mM APS. After purged with nitrogen gas, the mixture (4 mL) was incubated at 25 °C for 3 h in dark. The obtained polymer was washed by repeated centrifugations, followed by ultrasonication in MeOH/H2O (1:1, v/v, 4 mL) containing 50 mM HCl. The residue was then suspended in MeOH (4 mL), and centrifuged (40,740 g, 30 min, 5 °C). The resultant polymer was dried in a vacuum oven at 40 °C for 6 h. A non-imprinted polymer (NIP) was prepared without the addition of BPA disodium salt, and a control polymer (CP) was prepared without the addition of both BPA disodium salt and AMTC. The obtained polymers were ground in a mortar before binding experiments. To examine the reproducibility of the polymerization process, a series of polymer preparations were performed (n = 6) for BPA-MIP, NIP and CP. Conversion of the obtained polymers were calculated by the following equation:

Binding experiments of the obtained polymers

Each polymer (3 mg) was suspended in various concentrations of BPA (1 mL) dissolved in 50 mM NaOH. After the incubation at 25 °C for 24 h in the dark, the suspensions were filtrated by ADVANTEC DISMIC®-13HP (PTFE 0.20 μm, Toyo Roshi Kaisha, Ltd.), and BPA disodium salt in the filtrates were quantified by using a HPLC system equipped with a sample injector (231XL, Gilson inc., USA, injection volume: 5 μL), a degasser (M&S Instruments Trading Inc., Japan), two pumps (306, Gilson inc., USA), an alkaline-resistant separation column Asahipak ODP-50 6D (150 mm × 6.0 mm I.D., Showa Denko K.K., Japan) with a guard column Asahipak ODP-50G 6A (10 mm × 6 mm I.D.), and a photodiode array detector (1100 series, Agilent Technologies, Inc., USA). MeOH:H2O (90:10, v/v) was used as an eluent, and a flow rate was 0.65 mL · min−1. Typical chromatograms were listed in the supporting information (See: Supporting Information; Fig. SI-1). Similarly, the same experiments were performed in 50 mM NaOH with 0.01 % (w/v) SDS, 50 mM NaOH with 0.00037 % (w/v) Tween 20, concentration of which was adjusted by adding 0.0037 % Tween 20 solution that was prepared by stepwise dilution of a stock solution of 0.37 % (w/v) Tween 20, and 50 % (v/v) methanolic 50 mM NaOH.

In the similar manner, binding experiments using 0.25 mM of bisphenol B (BPB), hexestrol (HEX), 17α-estradiol (EST), 4,4′-diaminodiphenylmethane (DADPM), and 4,4′-dimethoxybenzophenone (DMB) were performed in 50 %(v/v) methanolic 50 mM NaOH.

Results and discussion

Interaction between BPA disodium salt and AMTC was estimated by 1H-NMR measurements in 50 mM NaOD. Chemical shift (δ) of the N-trimethyl group of AMTC was changed, which is represented as Δδ, when the concentrations of BPA disodium salt increased (See supporting information; Fig. SI-2). This result suggests that AMTC interacted with BPA disodium salt, resulting in the complex formation. Stoichiometry of the complex formation was evaluated by Job plot (Fig. 3). A maximum was obtained at a mole function of around 0.5, however, the plot did not produce a clear line-symmetric shape. Owing to incomplete de-protonation of the phenolic hydroxyl groups (pKa: 9 to 11) [20] under the condition of 50 mM NaOD showing approximately pH 13, one to one and one to two complexes might be co-existent, resulting in giving such the irregular shape.

Interaction between BPA disodium salt and DPA was also examined in the same way. Few 1H NMR chemical shift was observed upon the addition of BPA disodium salt. This may be due to decreased positive charge of the tertiary amino group of DPA, pKa of which is reported to be 10.35 by the provided company, under the condition of 50 mM NaOD. Comparing the results for AMTC, it appeared that AMTC is suitable as a functional monomer for BPA imprinting in aqueous solution.

Using AMTC as the functional monomer, BPA-MIP and NIP were prepared in 50 mM NaOH. On the preparation, molar ratio of BPA to AMTC was selected to be 1:2, since BPA and AMTC could form 1:2 complex according to the result of Fig. 3. In addition, a molar ratio of BPA to MBAA was 1:20, which is often used for the preparation of MIPs. The average conversion (%) and coefficients of variations (CV; %) of BPA-MIP, CP, and NIP were calculated to be 88.9 (CV; 2.1), 89.0 (CV: 1.7) and 92.6 (CV: 5.4), respectively (n = 6), indicating that the polymerization process proceeded quantitatively with high reproducibility. After the washing step, the leached BPA was not detectable by the HPLC analysis (data not shown).

BPA binding on BPA-MIP was evaluated by imprinting factor (IFNIP) that was calculated by amounts of BPA bound to BPA-MIP divided by those to NIP. IFNIP was calculated to be 1.8, suggesting that BPA-imprinted cavity was formed by the polymerization under aqueous condition. It is noted that almost the same amount of bisphenol B (BPB) was bound to BPA-MIP and NIP (Fig. 4), suggesting that BPB was nonspecifically bound onto both MIP and NIP. From these results, the imprinting effect was clearly revealed, which was derived by the polymerization co-existent with BPA.

In order to suppress the nonspecific bindings on BPA-MIP caused by hydrophobic interaction, sodium dodecyl sulfate (SDS) and Tween 20 were added to the solvent for the binding experiments (Fig. 5). The binding experiments were performed for BPA-MIP and CP that was prepared in the absence of AMTC. When the surfactants were not added to the solvent, IFCP that was ratio of the amounts of BPA on BPA-MIP divided by those on CP, was 6.0. After the addition of SDS and Tween 20, IFCP values were 6.4 and 6.7, indicating that the addition of the surfactants was not effective to decrease nonspecific bindings. This result suggests that wettability of the polymer surface may not be an important factor for the nonspecific binding. SDS decreased the binding activity comparing with the original one, which is likely to be due to adsorption of SDS to hydrophobic regions of BPA-MIP, as well as neutralizing the positively charged AMTC residues in the binding cavity, resulting in decreasing BPA binding.

Effect of surfactants added to the solvent on the binding activity of BPA to BPA-MIP and CP. BPA-MIP (black) and CP (white) were incubated with BPA (0.25 mM) at 25 °C for 24 h in 50 mM NaOH (original), 50 mM NaOH with 0.01 % (w/v) SDS, 50 mM NaOH with 0.00037 %(w/v) Tween 20, and 50 mM NaOH containing 50 %(v/v) MeOH, respectively

When MeOH was used instead of the surfactants added, IFCP value increased to be 9.5. The addition of MeOH lowered dielectric constant of the solvent, yielding the decline of the distribution ratio of BPA to the polymer matrices, which might reduce the amount of BPA bound nonspecifically, while electrostatic interaction between BPA and the AMTC residues in the binding cavity could be enhanced in the medium having a lower dielectric constant. Thus, the addition of MeOH to the solvent could facilitate enhancement of IFCP, and thus, following the binding experiments were carried out by using the solvent containing MeOH.

A binding isotherm of BPA for BPA-MIP was drawn, and BPA binding was found to be saturated (Fig. 6). Dissociation constant was estimated to be approximately 0.5 mM from the obtained isotherm. Unfortunately, the isotherm was not fit to Schatchard plot [14,21], suggesting that the interaction is not based on simple ion pair formation with one to one stoichiometry. This is consistent with the irregular shape of the Job plot.

Selectivity of BPA-MIP was examined by the binding experiments towards structurally related compounds, BPA (1), BPB (2), hexestrol (3: HEX), 17α-estradiol (4: EST), 4,4′-diaminodiphenylmethane (5: DADPM), 4,4′-dimethoxybenzophenone (6: DMB) (Fig. 7). BPB is a similar compound to BPA having bisphenol group and the difference is only one carbon number at the linker part. HEX has a bulky linker between the two phenols and the distance of the two hydroxyl groups is shorter than BPA. DADPM has two amino groups and DMB has two methoxy groups instead of the hydroxyl groups. EST was added as samples to be tested, since it is a naturally occurring ligand for estrogen receptors.

Selectivity of BPA-MIP towards structurally related compounds. 1: bisphenol A (BPA), 2: bisphenol B (BPA), 3: hexestrol (HEX), 4: 17α-estradiol (EST), 5: 4,4′-diaminodiphenylmethane (DADPM), 6: 4,4′-dimethoxybenzophenone (DMB). BPA-MIP was incubated with each tested compound (0. 25 mM) at 25 °C for 24 h in 50 mM NaOH containing 50 %(v/v) MeOH

As can be seen in Fig. 7, the amount of BPA bound on BPA-MIP was much larger than that of the other compounds. For the evaluation of the selectivity, relative binding activity, given by dividing the bound amounts of tested compounds by that of BPA, were employed. The relative binding activity of BPB and HEX was found to be 0.59 and 0.12, respectively, indicating that BPA-MIP bears specific binding cavity for BPA, which can recognize only one methyl group difference. The other three compounds, EST (4), DADPM (5) and DMB (6) showed low binding activity, where relative binding activities were 0.05, 0.01 and 0.01, respectively, confirming that the AMTC residues were located at suitable positions for BPA in the imprinted cavity, and BPA binding events occurred with principal binding force of ion-pair formation. Thus, binding cavities for BPA was formed by the BPA-templated polymerization with AMTC in the aqueous condition.

Conclusion

We performed preparation method for the hydrophilic MIP capable of BPA recognition in aqueous solution. The polymerization was carried out in 50 mM NaOH, in which BPA was solubilized and formed ion-pair complexes with AMTC, which was confirmed by 1H-NMR titration. The conversion of the redox polymerization was around 90 %, and the process was highly reproducible. BPA-MIP showed highly specific binding behavior toward BPA, as compared with the structure-resembled compounds. Reduction of non-specific binding caused by hydrophobic interaction was achieved by the addition of MeOH in the solvent for BPA binding. This technique can provide a reliable way to prepare molecular recognition materials for hydrophobic compounds solubilized in aqueous media, which are directly adopted for aqueous samples without any pretreatment steps, such as solvent extraction with organic solvents.

References

Hengstler JG, Foth H, Gebel T, Kramer PJ, Lilienblum W, Schweinfurth H, Völkel W, Wollin KM, Gundert-Remy U (2011) Critical evaluation of key evidence on the human health hazard s of exposure to bisphenol A. Crit Rev Toxicol 41:263

Schecter A, Malik N, Haffner D, Smith S, Harris TR, Paepke O, Birnbaum L (2010) Bisphenol A (BPA) in U.S. Food. Environ Sci Technol 44:9425

Kandaraki E, Chatzigeorgiou A, Livadas S, Palioura E, Economou F, Koutsilieris M, Palimeri S, Panidis D, Diamanti-Kandarakis E (2011) Endocrine disruptors and polycystic ovary syndrome (PCOS): elevated serum levels of Bisphenol A in women with PCOS. J Clin Endocrinol Metab 96(3):E480–E484. doi:10.1210/jc.2010-1658

López-Darias J, Pino V, Ayala JH, Afonso AM (2011) In-situ ionic liquid-dispersive liquid-liquid microextraction method to determine endocrine disrupting phenols in seawaters and industrial effluents. Microchimica Acta 174:213

Ferrer E, Santoni E, Vittori S, Font G, Mañes J, Sagratini G (2011) Simultaneous determination of bisphenol A, octylphenol, and nonylphenol by pressurised liquid extraction and liquid chromatography-tandem mass spectrometry in powdered milk and infant formulas. Food Chem 126:360

Fontana AR, Muñoz de Toro MN, Altamirano JC (2011) One-step derivatization and preconcentration microextraction technique for determination of Bisphenol A in beverage samples by gas chromatography–mass spectrometry. J Agric Food Chem 59:3559

Ballesteros-Gómez A, Rubio S, Pérez-Bendito D (2009) Analytical methods for the determination of bisphenol A in food. J Chromatogr A 1216:449

Kavlock RJ (1999) Overview of endocrine disruptor research activity in the United States. Chemosphere 39(8):1227

Marchesini GR, Meulenberg E, Haasnoot W, Irth H (2005) Biosensor immunoassays for the detection of bisphenol A. Anal Chim Acta 528:37–45

Sellergren B (2000) Molecularly imprinted polymers: man-made mimics of antibodies and their aplications in analytical chemistry. Elsevier, Amsterdam

Komiyama M, Takeuchi T, Mukawa T, Asanuma H (2004) Molecular imprinting. Wiley-VCH Verlag GmbH & Co. KGaA, Weinheim

Takeuchi T, Hishiya T (2008) Molecular imprinting of proteins emerging as a tool for protein recognition. Org Biomol Chem 6:2459

Araki K, Goto M, Furusaki S (2002) Enantioselective polymer prepared by surface imprinting technique using a bifunctional molecule. Anal Chim Acta 469:173

Ikegami T, Mukawa T, Nariai H, Takeuchi T (2004) Bisphenol A-recognition polymers prepared by covalent molecular imprinting. Anal Chim Acta 504:131

Sanbe H, Haginaka J (2003) Uniformly sized molecularly imprinted polymers for bisphenol A and beta-estradiol: retention and molecular recognition properties in hydro-organic mobile phases. J Pharm Biomed Anal 30:1835

Sasaki S, Ooya T, Takeuchi T (2010) Highly selective bisphenol A-imprinted polymers prepared by atom transfer radical polymerization. Polym Chem 1:1684

Ren Y, Ma W, Ma J, Wen Q, Wang J, Zhao F (2012) Synthesis and properties of bisphenol A molecular imprinted particle for selective recognition of BPA from water. J Colloid Interface Sci 367:355

Hirose K (2001) A practical guide for the determination of binding constants. J Incl Phenom Macrocycl Chem 39:193

Ito K, Nagase K, Morohashi N, Ohba Y (2005) Interaction between quaternary ammonium ions and dipeptides: positive anion allosteric effect. Chem Pharm Bull 53:90

Staples CA, Dome PB, Klecka GM, Oblock ST, Harris LR (1998) A review of the environmental fate, effects, and exposures of bisphenol A. Chemosphere 36(10):2149–2173

Umpleby RJ, Baxter SC, Chen Y, Shah RN, Shimizu KD (2001) Characterization of molecularly imprinted polymers with the Langmuir-Freundlich Isotherm. Anal Chem 73(19):4584–4591

Acknowledgments

N-[3-(Dimethylamino)propyl]acrylamide methyl chloride quaternary salt and N-(3-dimethylamino-propyl)-acrylamide were kindly provided by Kohjin Co. Ltd. (Tokyo, Japan).

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

ESM 1

(DOCX 84 kb)

Rights and permissions

About this article

Cite this article

Inoue, N., Ooya, T. & Toshifumi, T. Hydrophilic molecularly imprinted polymers for bisphenol A prepared in aqueous solution. Microchim Acta 180, 1387–1392 (2013). https://doi.org/10.1007/s00604-013-0996-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00604-013-0996-5