Abstract

To study the effect of freeze–thaw weathering damage deterioration on the strength of Huashan granite, this paper conducted a freeze–thaw (FT) cycle test on Huashan granite at − 20 to 20 °C and 0–100 cycles. Thus, the basic physical parameters change law of Huashan granite after freeze–thaw weathering are obtained. The SHPB (Split Hopkinson Pressure Bar) device was used to perform uniaxial and confining impact compression of granite, analyze the macro-mechanical test phenomena, and reveal the influence of freeze–thaw damage on rock strength. The results show that frost heave failure is the principal mechanism that causes the strength to decrease after freeze–thaw weathering. The static uniaxial compressive strength and maximum tensile strength of Huashan granite decreased by 38.4 and 21.5% after 100 FT cycles, respectively. The rate of reduction of peak stress does not necessarily grow with the increase of the number of cycles, and the average reduction rate in each phase ranges from 0.1 to 2.4%. It means that the damage accumulation of freeze–thaw weathering on rocks is not a uniformly increasing damage process. The radial restraint of confining pressure can effectively increase the peak stress of the material. When the strain rate is low, no failure occurs in the specimens due to the hoop restraint of confining pressure.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Huashan Mountain is a northern branch of the Qinling Mountains, which is a complete and large granite mountain on the north side of the Qinling branch. Huashan scenic area received a total of 218.85 million tourists between 2010 and 2015 (Lv 2016). It has become an important tourist destination and the most representative geological landscape in Shaanxi Province, China, and plays an important role in the development of Shaanxi’s tourism economy. The spatial structure formed between the main peak of Huashan Mountain and the surrounding peaks and deep ravines interprets the magnificent beauty of Huashan Mountain. It is a unique style of Huashan Mountain and is rare in the world. These geological and geomorphological landscapes are typical granite geological heritage landscapes formed by magmatic movement, tectonic uplift, weathering and erosion, and human activities during the long geological period. From the foothills to the top of the Huashan area, as the altitude increases, the air pressure and average temperature also decrease, while clouds, fog, and precipitation gradually increase, and the wind force also continues to increase. It can be roughly divided into two climatic zones, the lower part is warm temperate zone-semi-humid climatic zone, and the upper mountain zone is middle temperate zone-humid climatic zone. The large temperature difference between day and night, distinct seasons, and obvious freezing and thawing seasons in mountain areas provide conditions for the deterioration of the weathering damage of the rock mass.

The pore water and fissure water in natural granite will freeze, thaw, re-freeze, and reciprocate under alternating temperature changes, which will inevitably cause a series of deteriorations such as microscopic damage, frost heave cracking, and destabilization. This is the main weathering and destruction process of the rock mass (Ruedrich et al. 2011; Sousa et al. 2005; Ghobadi and Babazadeh 2015; Takarli et al. 2008). Freeze–thaw weathering is one of the important factors that cause geological disasters. The deterioration of rocks caused by freeze–thaw weathering in Huashan area is widespread (Fig. 1). Weathered rocks can easily cause landslides or collapses under external loads (rain and snow, earthquakes, engineering construction, etc.), posing huge hidden dangers to the lives and property safety of tourists.

Deterioration of Huashan granite (Lv 2016)

It is of theoretical and engineering significance to analyze and study the mechanical properties of Huashan granite that has undergone freeze–thaw weathering. However, granite is a heterogeneous material with natural pores inside. It has many types and complex properties. There are various internal factors that affect its mechanical properties, such as mineral composition, particle size, microcrack characteristics, water content, etc. (Chen et al. 2004; Lu 2013; Setzer 1997). The complex and variable external factors make it difficult to study the dynamic mechanical properties of Huashan granite under complex stress conditions. It can be seen that the systematic experimental research and theoretical analysis of high strain rate dynamic mechanical properties in rock materials after freeze–thaw weathering have significant academic value.

Studying the mechanical properties of rock masses under freeze–thaw weathering is of great significance to rock mass strength, resource development and utilization. Scholars have conducted a large number of experiments and theoretical studies. The earliest research in this area dates back to the late 1960s. Winkler (1968) experimentally found that if there is more pore water, water undergoes a phase change at 1 atmosphere and 0 °C. The formation of pore ice will generate expansive force and cause volume expansion (Connell and Tombs 1971; Liu et al. 2011; Young and McLean 1992). The expansive force increases with the decrease of temperature and far exceeds the strength of the rock mass. Inada and YokoTa (1984) divided granite and andesite into dry group and saturated group and performed freeze–thaw cycle experiments in different temperature ranges, and analyzed the change law of freeze–thaw cycles on the compressive strength of rocks. Shen et al. (2016) discussed three indicators of freeze–thaw temperature, freeze–thaw time, and freeze–thaw cycle. According to the actual temperature in the cold area, a freeze–thaw cycle test of poorly cemented medium or hard rock with a porosity greater than 10% is recommended at a cycle temperature of − 20 ± 2 °C to 20 ± 2 °C. For hard rock with slight porosity, the freeze–thaw duration can be 1 h. The number of freeze–thaw cycles can be selected according to the non-destructive testing method of sonic wave velocity.

In terms of physical properties research, Xu and Liu (2005) systematically studied the damage process, failure mechanism and influencing factors of rocks during freeze–thaw cycles. Among them, the porosity, water content, saturation, number of freeze–thaw cycles, and cycle time of rocks have a decisive influence on freeze–thaw degradation. Javier et al. (2013) studied the rock's resistance to freezing and thawing and the petro physical evolution during weathering. The specimens were divided into five groups, and each group was tested after 0, 12, 24, 48 and 96 freeze–thaw cycles. At the end of the cycle, volume loss, changes in open porosity, visual impairment, evolution of mechanical properties, and ultrasonic propagation were measured. These rocks appear in a non-linear decay pattern, first a long-term appearance of stability, followed by rapid and catastrophic decay. During the stabilization period, new microcracks will appear in the old microcracks as the test progresses. When the critical threshold is exceeded, microcracks can become cracks and grow rapidly, causing the rock to break after a small number of cycles. Shi (1997) studied the effect of freeze–thaw cycles on the mechanical properties of concrete. The test specimens experienced temperature changes of − 30 to 10 °C and 0, 30, 60, and 90 freeze–thaw cycles. Its compressive strength, splitting tensile and shear strength, elastic modulus, Poisson’s ratio and other properties all change with the number of freeze–thaw cycles. Through microscopic inspection, the number of freeze–thaw cycles increased, and cracks on the cement slurry and cracks on the aggregate-cement slurry contact surface gradually increased and expanded. Park et al. (2004) tested the physical parameters and temperature changes of granite and sandstone in the construction area due to the needs of underground gas pipeline projects. The experimental results show that the thermal conductivity does not change much with decreasing temperature, but the specific heat capacity and thermal expansion coefficient decrease with decreasing temperature. The specific heat at − 160 °C is about 40% of the specific heat value at 20 °C.

In terms of mechanical damage research, Liu et al. (2005) conducted a freeze–thaw cycle test on granite at a minimum temperature of − 36.5. The results show that the uniaxial compressive strength of the granite after repeated freeze–thaw cycles decrease by 5–15%, the elastic modulus decrease by 32–46%, and the Poisson’s ratio increase by 10–19%. This is because the rock mass damage and cracks increase under the action of freeze–thaw cycles. Khanlari et al. (2015) selected 5 different types of sandstone for 30 freeze–thaw cycles, and measured the P-wave velocity, porosity, and uniaxial compressive strength of the specimens after each five cycles. The results show that rock strength and petrographic properties such as grain size and contact between individual grains do not provide sufficient information about the durability of the material to freeze–thaw cycles, while the pore size distribution of the compressive strength of sandstone during freeze–thaw cycles is a main factor. Al-Omari et al. (2015) studied the limestone used in the restoration of the UNESCO World Heritage Site of the Castle of Chambord, France. The castle’s rocks undergo a freeze–thaw cycle every year. Limestone samples under laboratory conditions undergo up to 50 freeze–thaw cycles at 8 different saturations. The results show that when the water content reaches 80–85%, it will cause damage to the rocks after a few freeze–thaw cycles. If the rocks are 100% saturated, the damage will be more rapid. Li et al. (2019) performed triaxial compression and three-point bending tests on granite specimens after freeze–thaw cycles at different temperatures (− 20, − 30, − 40, and − 50 °C). The X-ray diffraction (XRD) method was utilized to analyze that the rock mineral composition did not change before and after freezing and thawing. However, its microstructure becomes relatively loose and rough, the number of damaged torus is increased, and the peak intensity is reduced in macroscopically. Yamabe and Neaupane (2001) used sandstone to perform one or more freeze–thaw cycles at different temperatures, and subjected uniaxial and triaxial dynamic shock to freeze–thaw damaged samples. The results show that the axial deformation of a single freeze–thaw saturated rock mass is mainly plastic deformation, and the dry rock mass is mainly elastic deformation. The lower the freezing temperature, the more cycles and the smaller the compressive strength of the rock. The compressive strength increases with increasing confining pressure.

At present, most of the researches in this area are static tests on rock materials after freeze–thaw weathering, and there are few studies on uniaxial or triaxial dynamic mechanical tests. At the same time, there are relatively few studies on the freeze–thaw damage mechanisms that lead to a reduction in compressive strength. Therefore, in this paper, a split Hopkinson pressure bar (SHPB) device is used to analyze and study the dynamic impact mechanical properties and dynamic failure laws of Huashan granite after freezing and thawing.

2 Materials and Methods

2.1 Preparation of Freeze–Thaw Weathering Huashan Granite Specimens

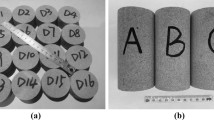

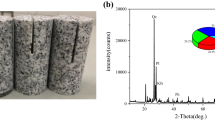

The granite material used in this research was taken from the Huashan area in Shaanxi Province, China. The granite specimen is off-white and belongs to medium-fine-grained biotite granite. According to polarization microscope visual evaluation, the main mineral components are potash feldspar (40%), plagioclase (25%), quartz (20%) and biotite (8%).

According to the requirements of the Engineering Rock Mass Test Method Standard (GB/T 50266-2013) (2013), all specimens are processed into cylindrical specimens with a diameter of 48 mm and a thickness of 25 mm during the dynamic load test. In the static load test, the specimens are processed into cylindrical specimens with a diameter of 48 mm and a thickness of 100 mm. The double-side sander is used for fine processing to ensure that the parallelism error is less than 0.05 mm, the error along the specimen height and diameter is not more than 0.3 mm, and the maximum deviation of the end surface perpendicular to the specimen axis is not more than 0.25°, as shown in Fig. 2.

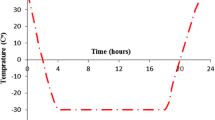

This experiment combines the experience of various scholars and the local climate change in four seasons and the temperature difference between day and night. The freezing temperature is set to − 20 °C, and the melting temperature is 20 °C. The number of freeze–thaw cycles is mainly combined with the damage and weathering of the rocks used in the freeze–thaw process. The maximum number of cycles is set to 100 times.

The freeze–thaw cycle equipment uses a TRX-80 freeze–thaw environment box, as shown in Fig. 3. The device consists of a refrigeration system, a control system, a circulation system, and a protection system. The circulatory system is divided into two kinds of internal and external circulation. During external circulation, the constant temperature liquid in the tank can be drawn out to establish a second constant temperature field. It can also be used as a cold source to direct the refrigerated liquid in the tank to the experimental container outside the machine to cool down. During the internal circulation, the liquid temperature in the tank can be uniform and stable. The temperature correction function can make the temperature accurate to 0.01 °C. The temperature range of this test is − 20 to 20 °C. The liquid medium added in the freezing and thawing environment tank is propylene glycol. The temperature–time change of the specimen in a cycle of freeze–thaw cycle is shown in Fig. 4.

2.2 SHPB Equipment

SHPB system and schematic diagram are shown in Fig. 5. The system mainly includes a launch device, an impact bar, an incident bar, a transmission bar and a damping device. When SHPB system works, the strain gauge affixed to the incident bar and transmission bar, referred to as a strain gauge A and B. The high-pressure gas drives the impact bar at a certain initial velocity, and the impact bar hits the incident bar, and a stress pulse signal \({\varepsilon }_{i}\) is generated on the incident bar, that is, the incident wave. The incident wave propagates along the bar and is recorded at the strain gauge A. When it propagates to the specimen, it causes the specimen to deform. At this time, a part of the wave generates an reverse pulse signal, that is, the reflected wave \({\varepsilon }_{r}\). A reflected wave through the strain gauge A is recorded again. The other part of the pulse penetrates the specimen and passes to the transmission bar, which is the transmitted wave \({\varepsilon }_{t}\), and is recorded when passing through the strain gauge B. According to the one-dimensional stress wave theory, the key parameters such as dynamic stress, strain and strain rate of the specimen can be deduced and obtained using the incident, reflected and transmitted pulses, and the stress–strain curve can also be obtained. The displacements \({u}_{1}\) and \({u}_{2}\) of the front and rear end faces of the specimen during the test are expressed as:

where, \({c}_{0}\) represents the elastic wave velocity of the bar; \({\varepsilon }_{1}\) and \({\varepsilon }_{2}\) are the strains of the front and rear end faces. \({\varepsilon }_{1}\) on the strain gauge A includes an incident strain pulse \({\varepsilon }_{i}\) propagating to the right and a reflected strain pulse \({\varepsilon }_{r}\) propagating to the left. \({\varepsilon }_{2}\) on the strain gauge B is the transmission strain pulse \({\varepsilon }_{t}\) propagating to the right, so the displacement of the two strain gauges can be expressed as:

The theoretical basis of Hopkinson pressure bar technology is the one-dimensional stress wave theory. Assuming that the stress pulse in the compression bar is a one-dimensional elastic wave, the axial strain measured by the strain gauge on the surface of the compression bar under the one-dimensional stress condition can replace the strain on the end face of the specimen. Therefore, by collecting the strain signals through the strain gauges on the incident bar and the transmission bar, the stress and strain of the specimen can be calculated using the one-dimensional elastic wave theory. It is also assumed that the force is uniform throughout the axial direction of the specimen, so that the force at the end face of the specimen can be considered to replace the force of the entire specimen. Ignoring the effect of stress wave dispersion, the specimen is deformed uniformly under impact load. The calculation method is simplified to the two-wave method, that is,

It can be known that the loads of the front and rear end faces are:

Therefore, the average strain of the specimen can be expressed as:

with the continuous development of loading time, the specimen deforms and the length L becomes shorter. The deformation rate of the specimen, that is, the strain rate:

The average stress of the specimen is expressed as:

where, \({A}_{s}\) is the cross-sectional area of the specimen; L is the length of the specimen; E is the elastic modulus of the pressure bar; and A is the cross-sectional area of the pressure bar.

In actual engineering, most rocks are in a triaxial complex stress state. The peak intensity and post-peak intensity of rocks are all related to the influence of confining pressure. Therefore, the triaxial confining pressure test can more comprehensively reflect the actual mechanical problems of the rock, which is of great significance for the stability prediction of the surrounding rock (Li et al. 2020). The active confining pressure equipment used in this study is shown in Fig. 6. The device is a metal sleeve that can be used on SHPB equipment, which includes a pressure vessel composed of a cylinder and two end caps, and a rubber sleeve at the center. The hydraulic oil is injected into the container during use. As the pressure increases, the specimen in the rubber sleeve receives radial pressure, which is active confining pressure.

3 Results

3.1 Static Parameters

After different freezing and thawing cycles, the static parameters such as density, elastic modulus, shear modulus, uniaxial compressive strength and maximum tensile strength of Huashan granite are shown in Table 1. It can be seen from the table that as the number of freeze–thaw cycles increases, the pores and microcracks in the rock gradually increase, resulting in a decrease in rock density. Due to freeze–thaw damage, both the static uniaxial compressive strength and the maximum tensile strength of the rock are significantly reduced, and the law is more obvious. Compared with the static compressive strength under normal conditions, after 100 freeze–thaw cycles, the compressive strength of Huashan granite decreased by 38.4%. Compared with the quasi-static maximum tensile strength under normal conditions, the compressive strength of Huashan granite after 100 freeze–thaw cycles was reduced by 21.5%.

To test the resistance of rocks to freezing and thawing weathering, the freezing resistance coefficient is used for quantitative analysis, and the calculation equation is:

where, \({c}_{f}\) is the frost resistance coefficient, \({\sigma }_{c}\) is the original uniaxial static compressive strength, and \({\sigma }_{cf}\) is the uniaxial static compressive strength of the rock after freeze–thaw cycles.

To evaluate the weathering degree of the rock after the freeze–thaw cycle, the weathering degree coefficient of the rock is introduced, the calculation equation is:

where, \({K}_{y}\) is the weathering degree coefficient; \({K}_{n}=\frac{{n}_{1}}{{n}_{2}}\) is the porosity coefficient; \({K}_{R}=\frac{{R}_{1}}{{R}_{2}}\) is the uniaxial static compressive strength coefficient; \({K}_{w}=\frac{{\omega }_{1}}{{\omega }_{2}}\) is the water absorption coefficient. \({n}_{1}\), \({R}_{1}\), \({\omega }_{1}\) are the original porosity, uniaxial static compressive strength, and water absorption of the rock, respectively. \({n}_{2}\), \({R}_{2}\), \({\omega }_{2}\) are the weathered porosity, uniaxial static compressive strength and water absorption, respectively.

It can be seen from Table 2 that the frost resistance coefficient of Huashan granite increases with the number of freeze–thaw cycles. By dividing the weathering degree coefficient into the weathering degree, Huashan granite is not weathered when it is within 60 freeze–thaw cycles. When the cycle is greater than 60 times, it enters a mild weathering stage.

3.2 Crushing Huashan Granite Specimens

From the state of the Huashan granite fragments after uniaxial impact compression, it can be found that with the increase of the average strain rate, the size of the fragments destroyed by the specimen decreases significantly, and the number of fragments increases, showing a clear rate dependence (Fig. 7). In the case of the same number of freeze–thaw cycles, when the strain rate is small, the rock specimens show the fracture characteristics of axial splitting, and most of them are tensile fracture sections. When the strain rate increases, the crushing form of the specimen is mostly crushing failure. With the increase of the number of cycles, the initial freeze–thaw damage increases, and the degree of fragmentation of the specimen increases at the same strain rate, indicating that the freeze–thaw cycle has a significant effect on the initial damage of the sample structure, and finally determines the degree of macroscopic impact compression and fragmentation. In particular, the specimens with a large number of freeze–thaw cycles showed crushing failure at various strain rates.

In the study of mechanical properties of rock materials, uniaxial impact compression is often the most basic analysis. In nature, rock masses are usually under complex stress environments and are subject to stress in three directions. Therefore, considering the existence of confining pressure is very necessary for the study of dynamic mechanical properties of rocks. The load combination of active confining pressure and axial impact compression is used to study the dynamic mechanical response law of rocks with confining pressure and axial dynamic impact.

In the triaxial impact compression test, the circumferential confining pressure has a strong restraining effect on the radial deformation of the specimen, effectively inhibits the expansion of internal cracks, and thereby improves the integrity of the specimen after impact loading. Due to the existence of confining pressure, it constraints make the specimens more complete at various strain rates, with only a few discontinuous cracks and no obvious fracture. Figure 8 is an example of a fragmentation diagram of Huashan granite with confining pressure when the average strain rate is 268 s−1. When the confining pressure is 5 MPa, there are a lot of obvious cracks in Huashan granite, but the specimen is still relatively intact; when the confining pressure is 10 MPa, only a few cracks exist on the surface of the specimen, and the whole is intact.

3.3 Impact Compression Stress–Strain Curves

The stress–strain trend of Huashan granite under uniaxial impact compression under different strain rates and freeze–thaw cycles is shown in Fig. 9. It can be observed from the figure that the dynamic impact compression failure process of Huashan granite has obvious stages. The stress–strain curve can be roughly divided into four parts: compaction stage, linear stage, yield stage and failure stage. The general law is consistent with the crushing state of the specimen. The larger the strain rate, the larger the corresponding peak stress. At the same time, the peak stress decreases with the number of freeze–thaw cycles.

The change law of peak stress after Huashan granite freeze–thaw damage is shown in Table 3. The equation for calculating the total reduction of peak stress in the table is:

where, \({\sigma }_{0}\) is the peak rock stress under normal conditions, and \({\sigma }_{0}\) is the peak stress of the rock after i cycles of freeze–thaw.

The average reduction in a phase is the difference between peak stresses of the two phases divided by the number of freeze–thaw cycles in that phase. It can be seen that the total reduction in peak strength increases with the number of cycles. When the strain rate is 182 s−1, the final total reduction of peak stress of Huashan granite is the largest, which is 70.1%. It can be found from the average reduction in the phases that the rate of peak stress reduction does not necessarily increase with the number of cycles, and the average reduction rate in each phase ranges from 0.1 to 2.4%. This shows that the damage accumulation of freeze–thaw cycles on rocks is not a damage process with a uniform increase in speed.

Ground stress is a stress that exists in the earth's crust. It is generally divided into two parts, the first part is caused by the weight of the overlying rock mass, and the second part is the tectonic stress transmitted from the adjacent part. Ground stress is the effect of internal stress on the crust due to geological tectonic movements during a long geological age. Generally, the deeper the rock is buried, the greater the vertical ground stress it is subjected to. The active confining pressure in the test effectively simulated the three-dimensional stress state of the rock.

The peak stress changes of Huashan granite at the strain rate of 268 s−1 in the presence of confining pressure are shown in Table 4. It can be seen from the table that when the confining pressure is 5 MPa or 10 MPa, the total increase in peak intensity will increase compared to that at 0 confining pressure. At 5 MPa, the increase range is from 7 to 26%, and at 10Mpa, the increase range is from 15 to 34%.

It can be seen from the stress–strain curves of different confining pressures that the peak stress changes significantly with the number of freeze–thaw cycles (Figs. 10 and 11). The triaxial stress–strain curve is very similar to the curve trend obtained from uniaxial impact compression. Generally, it has gone through the compaction stage, elastic stage, yield stage and plastic stage. When the strain rate is small, the granite is not damaged due to the hoop constraint of the confining pressure. Therefore, the peak at this time is only the nominal peak, not the ultimate peak strength under this condition.

4 Discussion

Huashan granite has been subjected to various external loads for a long time in nature, and a large number of micro-cracks and pores have formed inside. The existence of these damages deteriorates the mechanical properties of the rock mass. In the Huashan area, the temperature difference between day and night is large, and the four seasons are distinct. The long-term freeze–thaw weathering leads to the continuous generation and expansion of internal natural damage.Weathered rocks are prone to cause numerous geological disasters under the action of external loads, potentially threatening the safety of human activities in the area, and causing huge hidden dangers to lives and property.

4.1 Factors Affecting the Deterioration of Rock Freeze–Thaw Damage

Rock freeze–thaw damage degradation is a complex process coupled with multiple factors. In summary, the main influencing factors include four categories: lithology, water saturation, number of freeze–thaw cycles, and freeze–thaw cycles and cycle temperature ranges.

Lithology is one of the factors that has the greatest influence on the damage degradation of rocks during the freeze–thaw cycle. The composition of the minerals in the rock, the content of each mineral component, the size of the mineral particles, the strength of the cement, the distribution and development of joints, the porosity, and the strength of the rock will all affect the degree of damage and deterioration. It is known from experiments and relevant literature conclusions that the mineral particles are not dense, the strength of the cement is smaller, the joints are more developed, the porosity is greater, and the strength of the rock is smaller, which is more affected by the freeze–thaw cycle damage, and vice versa.

The content of water in the rock’s void is a major factor affecting the freeze–thaw damage. According to the analysis in the previous section, the process of freeze–thaw cycle degradation is actually the repeated freezing and melting process of water in the pores. Under completely dry conditions, if the temperature variation range is not large, the freeze–thaw cycle has almost no degradation effect on the rock. If the water is saturated, the rocks are more or less damaged due to different water saturation levels.

The number of freeze–thaw cycles has a very significant effect on the deterioration of rock freeze–thaw damage. Different rocks have altered durability. In general, for the same type of rock, the more freeze–thaw cycles, the longer the cycle, and the greater the damage. The test results show that as the number of freeze–thaw cycles increases, the strength of the rocks decreases significantly.

The temperature range of freeze–thaw cycles has a greater impact on the deterioration of freeze–thaw damage. The greater the temperature range, or the lower the freezing temperature, the greater the degree of rock damage. The larger the freezing and thawing temperature range is, the more the two phases of ice and water are transformed into each other, and the more obvious the frost heave effect is, the faster the rock degradation rate is.

4.2 Stress and Strain Analysis of Huashan Granite after Freeze–Thaw Weathering

At the same strain rate, when the number of freeze–thaw cycles increases, the peak stress and elastic modulus of the specimen (the slope of the line connecting the two points with the peak stress of 40 and 60% corresponding to the rising section of the stress–strain curve) show a gradual decrease. This is because the effects of freeze–thaw cycles lead to aggravation of the internal damage of the specimen and increase of cracks, which reduces the cohesive force between particles in the rock. Therefore, the strength and elastic modulus decrease significantly as the number of freeze–thaw cycles increases.

As the number of freeze–thaw cycles increases, the dynamic peak strength of the rock decreases. Although the peak strength of different specimen has a certain degree of dispersion, this trend is still very significant, which shows that the freeze–thaw cycle will indeed cause the accumulation of rock damage, thereby reducing the mechanical properties of granite. With the increase of the number of freeze–thaw cycles, the peak strain tends to become larger, but this law is more discrete. Freezing and thawing causes the cracks inside the rock to increase, the deformation space increases during the failure process, and the deformation ability is enhanced. Both the strain rate and the confining pressure have a certain strengthening effect on the peak strength and the rate effect is more obvious. The circumferential restraint force of the confining pressure effectively restrains the specimen from crushing after being impacted, and increases the peak stress of the specimen.

Under the action of freezing and thawing, the frost heave force of water causes the formation of new micro-cracks between the particles with small initial bonding force in the rock, and causes the original weaker cracks to expand rapidly. When the number of cycles continues to increase, the cracks that could not be expanded by the frost heave force are further expanded. Due to the heterogeneity of the rock, the freeze–thaw damage is a continuous accumulation process as a whole, but the relationship between the crack expansion rate and the number of freeze–thaw cycles needs further study.

5 Conclusions

Freeze–thaw weathering damage deterioration effect is one of the main factors affecting the strength of Huashan granite. Based on the SHPB test, the fracture morphology and mechanical properties of rock specimens after impact compression are analyzed. By summarizing the macro-mechanical test phenomena, revealing the influence of freeze–thaw damage on Huashan granite strength, the following conclusions are obtained:

-

(1) Due to freezing and thawing damage, the static uniaxial compressive strength and maximum tensile strength of Huashan granite are significantly reduced, and the law is more obvious. Compared with the normal state, after 100 freeze–thaw cycles, the compressive strength of Huashan granite decreased by 38.4%, and the compressive strength decreased by 21.5%.

-

(2) It can be found from the average amount of peak reduction in the phases that the rate of peak intensity reduction does not necessarily increase with the number of cycles. The average rate of reduction in each phase ranges from 0.1 to 2.4%. This shows that the damage accumulation of freeze–thaw cycles on the rocks is not a uniformly increasing damage process.

-

(3) From the stress–strain trends in different confining pressures, it can be seen that the peak stress changes significantly with the number of freeze–thaw cycles. The stress–strain curve of confining pressure is very similar to the curve trend obtained from uniaxial impact compression. In general, they have undergone a compaction phase, an elastic phase, a yield phase, and a plastic phase. When the strain rate is low, the Huashan granite does not fail due to the hoop restraint of confining pressure. Therefore, the peak value at this time is only the nominal peak value, not the limiting peak intensity under this condition.

References

Al-Omari A, Beck K, Brunetaud X et al (2015) Critical degree of saturation: a control factor of freeze–thaw damage of porous limestones at castle of Chambord, France. Eng Geol 185:71–80

Chen TC, Yeung MR, Mori N (2004) Effect of water saturation on deterioration of welded tuff due to freeze–thaw action. Cold Reg Sci Technol 38:127–136

Connell DC, Tombs JMC (1971) The crystallization pressure of ice—a simple experiment. J Glaciol 10(59):312–315

Engineering Rock Mass Test Method Standard (GB/T 50266-2013). Ministry of Housing and Urban-Rural Development of the People’s Republic of China: Beijing, 2013

Ghobadi MH, Babazadeh R (2015) Experimental studies on the effects of cyclic freezing-thawing, salt crystallization, and thermal shock on the physical and mechanical characteristics of selected sandstones. Rock Mech Rock Eng 48(3):1001–1016

Inada Y, Yokota K (1984) Some studies of low temperature rock strength. Int J Rock Mech Min Sci Geomech Abstr 21(3):145–153

Javier MM, David B, Miguel GH et al (2013) Non-linear decay of building stones during freeze–thaw weathering processes. Constr Build Mater 38:443–454

Khanlari G, Sahamieh RZ, Abdilor Y (2015) The effect of freeze–thaw cycles on physical and mechanical properties of upper red formation sandstones, central part of Iran. Arab J Geosci 8(8):5991–6001

Li Y, Chen Y, Sun H et al (2019) An experimental study of granite’s damage caused by freeze–thaw cycles in cold region. Ind Constr 49(7):83–107

Li Y, Zhai Y, Wang C et al (2020) Mechanical properties of Beishan granite under complex dynamic loads after thermal treatment. Eng Geol 267:105481

Liu C, He M, Wang S et al (2005) Experimental investigation freeze thawing damage characteristics of granite at low temperature. J Hunan Univ Sci Technol 20(1):37–40

Liu L, Ye G, Schlangen E et al (2011) Modeling of the internal damage of saturated cement paste due to ice crystallization pressure during freezing. Cem Concr Compos 33(5):562–571

Lu Y (2013) Study on mechanics characteristic of damage due to freeze-thaw action in fractured rock masses and failure mechanism. Wuhan University of Technology

Lv Y (2016) Research on formation mechanism and vulnerability of granite geoheritage in the area of Huashan Mountains. Chang’an University

Park C, Synn JH, Shin DS (2004) Experimental study on the thermal characteristics of rock at low temperatures. Int J Rock Mech Min Sci 41(Supp. 1):81–86

Ruedrich J, Kirchner D, Siegesmund S (2011) Physical weathering of building stones induced by freeze–thaw action: a laboratory long-term study. Environ Earth Sci 63:1573–1586

Setzer MJ (1997) Action of frost and deicing chemicals: basic phenomena and testing. Freeze-thaw durability of concrete. Taylor & Francis Group, pp 3–22

Shen Y, Yang G, Rong T et al (2016) Proposed scheme for freeze-thaw cycle tests on rock. Chin J Geotech Eng 38(10):1775–1782

Shi S (1997) Effect of freezing-thawing cycles on mechanical properties of concrete. China Civil Eng J 30(4):35–42

Sousa LMO, Suarez LM, Calleja L et al (2005) Influence of micro fractures and porosity on the physicomechanical properties and weathering of ornamental granites. Eng Geol 77:153–168

Takarli M, Prince W, Siddique R (2008) Damage in granite under heating/cooling cycles and water freeze–thaw conditions. Int J Rock Mech Min Sci 45:1164–1175

Winkler EM (1968) Frost damage to stone and concrete: geo-logical considerations. Eng Geol 2(5):315–323

Xu G, Liu Q (2005) Analysis of mechanism of rock failure due to freeze-thaw cycling and mechanical testing study on frozen-thawed rocks. Chin J Rock Mech Eng 24(17):3076–3082

Yamabe T, Neaupane KM (2001) Determination of some thermo-mechanical properties of Sirahama sandstone under subzero temperature condition. Int J Rock Mech Min Sci 38(7):1029–1034

Young ME, McLean C (1992) Stone cleaning in Scotland-a literature review. Research commission investigating the effects of cleaning sandstone. Robert Gordon University, pp 38–39

Funding

This research was carried out in the School of Geological Engineering and Geomatics at Chang’an University. The authors would like to thank the Natural Science Foundation of China (No. 41772277) and the Fundamental Research Funds for the Central Universities, CHD (No. 300102261101) for financial support to carry out this study.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Li, Y., Zhai, Y., Meng, F. et al. Study on the Influence of Freeze–Thaw Weathering on the Mechanical Properties of Huashan Granite Strength. Rock Mech Rock Eng 54, 4741–4753 (2021). https://doi.org/10.1007/s00603-021-02497-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00603-021-02497-w