Abstract

Valley closure movements have been observed for decades in Australia and overseas when underground mining occurred beneath or in close proximity to valleys and other forms of irregular topographies. Valley closure is defined as the inward movements of the valley sides towards the valley centreline. Due to the complexity of the local geology and the interplay between several geological, topographical and mining factors, the underlying mechanisms that actually cause this behaviour are not completely understood. A comprehensive programme of numerical modelling investigations has been carried out to further evaluate and quantify the influence of a number of these mining and geological factors and their inter-relationships. The factors investigated in this paper include longwall positional factors, horizontal stress, panel width, depth of cover and geological structures around the valley. It is found that mining in a series passing beneath the valley dramatically increases valley closure, and mining parallel to valley induces much more closure than other mining orientations. The redistribution of horizontal stress and influence of mining activity have also been recognised as important factors promoting valley closure, and the effect of geological structure around the valley is found to be relatively small. This paper provides further insight into both the valley closure mechanisms and how these mechanisms should be considered in valley closure prediction models.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

In the coalfields of New South Wales (NSW), Australia, particularly in the Southern Coalfield, numerous underground longwall panels have been, or are proposed to be, extracted near to and beneath natural features such as river valleys, water catchments and cliffs. This is the nature of the region’s geomorphology. Figure 1 illustrates the geographic conditions, major water catchments and mining leases in the Southern Coalfield.

Major water bodies, mining leases and upland swamps in the Southern Coalfield (NSW Department of Planning 2008)

When underground mining occurs beneath or in the vicinity of valleys and other irregular surface topographies such as water catchments and cliffs, the valley sides are observed to move inwards towards the valley centreline and the observed vertical subsidence at the base of the valley is less than the subsidence that would be expected in flat terrain. The convergence of two sides of the valley is referred to as valley closure, and the reduction in subsidence or relative upward movement at the bottom of the valley is termed upsidence.

Valley closure subsidence effects have been observed for many years in Australia. Both the past and potential future impacts of mining-induced ground movements on significant natural features in the Southern Coalfield, NSW, have been recognised to be issues of significant community interest and government concerns. The mining-induced subsidence effects on the natural features are often associated with the valley closure subsidence impacts, resulting in risks to water flows and ecosystems, including loss of surface flow to the subsurface, river bed failure (cracking of river beds and underlying strata), loss of standing pools, methane emission, cliff falls and rock falls.

To date, valley closure subsidence has mainly been studied using the state-of-the-art empirical methods based on an extensive database of field measurements. The first major prediction method was originally developed at the beginning of the 2000s (Waddington and Kay 2001, 2002), and recently this method has been upgraded using a more extensive raw survey database (MSEC 2014). However, it can be noted that the empirical methods have difficulties in addressing the possible influence of various factors, such as sub-surface geological features or horizontal in situ stress, especially when there are insufficient monitoring data to review a hypothesis. There are also a range of numerical modelling techniques that can be used to study the valley closure subsidence behaviour, and their essential differences and capabilities have been discussed by the authors (Zhang et al. 2012). It should be noted that there is still scope for improving the numerical models such as accurately representing the near-surface geology and surface topography and systematically examining the numerous factors that could affect the valley-related movements.

Valley closure movements have been recognised to be a result of the interplay between several governing factors. The failure mechanisms contributing to these phenomena are still not completely understood, due to the complexity of the local geology and further research is still required. Previous two-dimensional numerical modelling study conducted by the authors (Zhang et al. 2014) has identified some preliminary potential parameters that may be affecting valley closure movement. This paper aims to extend the range of potential influencing factors, including longwall positional factors (the offset distance from longwall to the valley and the orientation of the longwall to the valley); the orientation of in situ horizontal stress; mining factors including panel width and depth of cover and geological structures around the valley. Parametric analyses will be conducted to quantify the effects of these governing factors as well as their inter-relationships.

2 Description of Geological Conditions

The Southern Coalfield is one of the major coalfields within the Sydney Basin, which is a part of the much larger Sydney-Gunnedah-Bowen Basin that extends from coastal southern NSW to central Queensland. It is filled mainly with sedimentary rocks. Figure 2 depicts a generalised stratigraphic column of the strata in the Southern Coalfield. The numerical models described in this paper are developed based on typical mining and geological information from the Southern Coalfield, primarily that at Metropolitan Colliery, which is located in the Southern Coalfield, approximately 30 km north of Wollongong in New South Wales. Stratigraphic thickness from the lithology log at Metropolitan Colliery is listed in Table 1.

Generalised stratigraphy column of the Southern Coalfield (Geosensing Solutions 2008)

The Hawkesbury Sandstone tends to dominate the uppermost unit of the stratigraphy, which ranges in thickness of about 240 to 330 m. It is common that river valleys cut down the underlying Hawkesbury Sandstone to form the irregular topography. The principal coal-bearing sequence in the Southern Coalfield is the Illawarra Coal Measures, and the Bulli seam represents the majority of the coal reserves in the Southern Coalfield. Bulli seam is the major formation where hard coking coal is mostly found, and generally requires underground mining at depths of more than 400 m. Thickness varies from 30 cm in the far south to approximately 4 m in the northern part of the field. As an example, the Bulli seam thickness and depth of cover along a monitoring line at Metropolitan Colliery are shown in Fig. 3.

Monitoring data at Metropolitan Mine (DeBono and Tarrant 2011)

The high ratio of horizontal to vertical in situ stress has been a feature of the geological environment in the Sydney Basin, resulting from extensive stress measurements in the sedimentary basin. The horizontal to vertical stress ratios are typically in the range of 1.5–2.0 across the Sydney Basin. A higher horizontal to vertical stress ratio in excess of 3.0 has been measured in a number of locations at Tower Colliery in the Southern Coalfield (Hebblewhite et al. 2000).

In general, it can be suggested that the horizontal and sub-horizontal bedding planes have been recognised as the most important form of discontinuity in the Sydney area from a large amount of field investigations. Vertical joints are typically in an orthogonal pattern, thus large-scale brick-shaped blocks can form in the sedimentary rocks, especially in Hawkesbury Sandstone. Based on numerous studies on the geometry of cross beddings and joints in Sydney rocks by several methods such as field mapping and aerial photo interpretation (Holla and Barclay 2000; Waddington and Kay 2001, 2002), the pattern of beddings and joints in the major stratigraphic units within the Southern Coalfield is listed in Table 2.

3 Numerical Model Setup

Valley closure movements are analysed using the Universal Distinct Element Code (UDEC) (Itasca 2011) and the Three-dimensional Distinct Element Code (3DEC) (Itasca 2013). UDEC and 3DEC are numerical analysis programs based on the distinct element method for discontinuous modelling. Calculation of stresses and deformations is based on the explicit finite difference method.

The models are developed based on the mining and geological conditions in the Southern Coalfield, primarily that at Metropolitan Colliery. The estimation of strength and deformation parameters of the overburden was determined by: taking into account the laboratory test results of standard specimens; the relative scale effects and experiences in assessment of the engineering geologic features of rocks from the literature; and calibration using available monitoring data, which was discussed in detail in the previous modelling study (Zhang et al. 2014). Mohr–Coulomb constitutive model was used in the modelling. The adopted material properties of the stratigraphic units for the model are listed in Table 3. Based on the information on the rock discontinuities from numerous site investigations for specific projects in the Sydney region (Bertuzzi and Pells 2002; Keilich 2009; Waddington and Kay 2001, 2002), the adopted discontinuity properties for the numerical modelling in this study have been decided as: joint normal stiffness is 26 GPa/m, joint shear stiffness is 2.6 GPa/m, joint friction angle is 25°, joint cohesion is zero and joint tensile strength is zero.

Calibration of the numerical models against monitored/empirical data is essential to ensure that computer simulation produces realistic results. Field monitoring results and empirical databases are used for the validation of the numerical model, as described in the previous study (Zhang et al. 2014), and it provides confidence that the modelled subsidence and horizontal displacement are consistent with the field monitored database as well as the empirical prediction profiles.

A typical river valley in the Southern Coalfield (Fig. 4) with valley depth of 60 m and valley side slope of 45° has been used for the benchmark model. Bulli seam with an extraction height of 3 m was modelled, and the depth of cover above the longwalls was 472 m. The benchmark model ranged up to 2200 m wide and 550 m deep, placing boundaries sufficiently far from the valley and longwall panels to avoid adverse horizontal and vertical boundary effects, and a horizontal/vertical stress ratio of 2 was used. The block sizes were determined based on the pattern of beddings and joints as described in the previous chapter. It should be noted that due to the limitations of computational processing time, it was unrealistic to generate the 3D grid system with high density for each stratigraphic formation as used in the 2D models. In the 3DEC model, therefore, the blocks were subdivided to increase the density of blocking over the regions of particular interest around the valley and above the panel to allow subsidence, valley deformation and cave propagation above the goaf to be developed sufficiently.

Vertical section of a river valley in the Southern Coalfield (MSEC 2012)

The applicability of 3DEC for modelling valley closure subsidence has been evaluated by comparing modelled horizontal and vertical displacements with the previous UDEC results (Zhang et al. 2015). A 3DEC slice model is also established to examine the influence of grid densities, utilising high-densified grids over each formation. The thickness of the 3DEC slice model (Y value) is limited to 100 m with the dimensions being 1632 m × 100 m × 550 m. Figure 5 shows the model layouts for the three scenarios. Figures 6 and 7 summarise the horizontal movements and subsidence derived from the UDEC model, the 3DEC slice model and the 3DEC full model, respectively.

Model grid system for: a UDEC model, b 3DEC slice model and c 3DEC full model (Zhang et al. 2015)

Comparison of horizontal movements for the three scenarios at ground level (Zhang et al. 2015)

Comparison of subsidence profiles for the three scenarios (Zhang et al. 2015). a UDEC model and b 3DEC model

As for the 3DEC full model and the 3DEC slice model, the horizontal movements and subsidence profiles are close enough to be considered similar. In interpreting the curves from the three-dimensional and two-dimensional modelling results, the 3DEC modelling results are in overall agreement with that of UDEC although it appears that simulations based on 3DEC tend to have more horizontal movements in the valley area. In summing up, the three-dimensional models provide reasonable correlations with the outcomes from the two-dimensional analyses in terms of the horizontal displacements and subsidence.

Figure 8 shows the general model setup for UDEC and 3DEC (1632 m × 1000 m × 550 m), respectively. Variations in model setup for different mining, geological and topographical scenarios are presented in the following chapter.

4 Analysis of Modelling Results

4.1 Effect of Longwall Position Relative to Valley

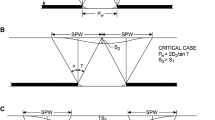

Previous numerical modelling conducted by the authors (Zhang et al. 2014) has recognised that the longwall position relative to the valley is a principal factor influencing mining-induced valley closure. A critical zone is then identified for valley closure, where the offset is less than 310 m (angle of draw being 33°), i.e. the longwall panel is located less than two longwall widths away from the valley. It is recognised that the most obvious changes of the valley closure movement occur within the critical zone, with the value decreasing by 80 %. It should be noted that in the previous modelling work, carried out in two directions with mining longwalls sequentially towards the valley and mining away from the valley, the mining did not go directly beneath the valley (it either stopped at or started at the valley bottom, as shown in Fig. 9), and thus could not completely analyse the interaction between the valley location and mining activities. Further numerical simulations have been carried out on the modelling of seven longwall panels to further examine the effect of mining in a series passing beneath the valley, as illustrated in Fig. 10.

Figure 11 presents the trend of modelled valley closure, plotted against the offset distance from the valley centreline to the panel edge on the valley side. It is apparent that a steep increase of valley closure value is observed when mining through the valley, where the longwall is located within the critical zone. The modelled closure only increases slightly for the first two longwalls mined beyond the valley, which are not located in the critical zone, and tends to become stable as the longwall panels are located further away from the valley. Based on the results of this study, valley closure is predicted to increase by in excess of approximately seven times when mining beneath the valley, and the sequential excavation through the valley is critical to the valley closure movements.

The results are in good agreement with the observed valley closure movements from Metropolitan Colliery, due to the similar geological and mining conditions. The numerical modelling closely matches the observed results. It should be noted that the field observed valley closure decreases when longwall 14 (i.e. second last in the series) is extracted (Fig. 11), resulting in a difference in the valley closure from the modelled values. This could be explained as that this longwall at Metropolitan Colliery was extracted beneath another valley structure and the presence of this valley reduces the transfer of horizontal stresses from the goaf above to the major valley (Fig. 12); therefore, less valley closure is observed. Measurable closure is predicted to occur beyond a 35° angle of draw which is consistent with field observations. The furthest distance that valley closure movements have been measured from longwall mining at Metropolitan Colliery is around 960 m (angle of draw being 64°), and the modelling shows that closure occurring at distances greater than 940 m (around six panel widths) was less than 5 mm (typical survey tolerance), which is negligible.

4.2 Effect of Angle Between Valley Alignment And Mining Direction

Another longwall positional factor is examined in this section—orientation of mining relative to the valley. Effect of the angle between the alignment of the valley and the longwall is investigated by changing the angle as 0°, 45° and 90°. The top view of the horizontal movement contours induced by the extraction of these panels is presented in Fig. 13. In all cases, it is clearly observed that the valley wall that is closest to the longwall moves towards the valley centreline rather than the goaf area, indicating obvious closure movements of the valley walls.

The magnitudes of valley closure for the three mining orientations are listed in Table 4. It is apparent from the table that the orientation of mining has a pronounced influence on the magnitude of valley closure. The valley closure is much larger when mining is parallel to the valley direction, 76 mm; the valley closure has an intermediate value of 54 mm where the angle between the valley alignment and mining direction is 45°; and the lowest value of 48 mm occurs when the mining is orientated perpendicular to the valley.

Figure 14 presents the top view of the major horizontal stress around the valley in the Hawkesbury Sandstone and the shear displacement at the valley base. As can be seen from the figure, mining parallel to valley concentrates more horizontal stress on the valley side which is close to the goaf (left valley side) which is greater than the other two mining orientations. It is found that the redistribution of horizontal stress dominates in the orientation perpendicular to the valley, and this could be a reason for the difference of the valley closure under different mining orientations. In cases where the orientation of the longwall is parallel to the valley, this increase of horizontal stress acting underneath the valley side closest to the longwall develops a pronounced shearing plane for the valley side to move towards the valley centreline. However, if the mining orientation is perpendicular to the valley, the redistribution of horizontal stress mainly occurs along the valley axis, rather than across the valley. Therefore, the valley wall on the goaf side seems not to be appreciably affected by the mining-induced stress arching effect, and the horizontal stress is distributed in a more symmetrical pattern. The other reason may be that mining parallel to the valley creates a larger void to redistribute the stresses which are perpendicular to both the valley and longwall (i.e. the full length of longwall, rather than just the end). Apart from this, valley closure could also be affected by the conventional mining-induced horizontal movements. When mining occurs parallel to the valley, the conventional horizontal movements are in the direction of valley closure, and this may be additive with the valley closure values. On the other hand, in the case where the angle between longwall and valley is 45° or 90°, the valley closure could be influenced less by the conventional horizontal movements.

The results of the 3DEC analyses are consistent with field observed data provided by MSEC (2014), which reviewed the influence of the angle between the alignment of the valley and longwall on the observed valley closure movements based on extensive measurements. The observed valley closure movements for those cases where the angles between the valley and longwall alignment were less than 30° were generally higher than those cases when the angles were greater than 60°. Figure 15 illustrates the observed and predicted valley closure for cases where the angles between the valley and longwall alignment were larger than 60° and less than 30°, and it was clear that “the mean values for the red cases (0°–30°) are almost double the mean values of the blue cases (30°–60°)” (MSEC 2014). The 3DEC results regarding the relationships of the orientation of mining relative to the valley and the valley closure movements are consistent with the field observations.

Field observed and predicted valley closure for different alignment angles between valley and longwall (MSEC 2014)

4.3 Effect of Horizontal Compressive Stresses

In the previous study (Zhang et al. 2014), the influence of the magnitude of horizontal stress on valley-related movements had been discussed for given geological conditions, and it was found that for longwall with an offset distance of 112 m (within the critical zone), the valley closure values increased steeply as the horizontal/vertical stress ratio increased from 1 to 3, as shown in Fig. 16. After understanding the influence of the magnitude of horizontal stress, a further assessment was carried out to study how the orientation of the major horizontal stress affects valley closure development. A series of 3DEC models were developed with varying directions of the major horizontal compressive stress (parallel to the valley and perpendicular to the valley) for difference longwall locations relative to the valley. It should be noted that due to the limitation of computation for the 3DEC modelling, only four single longwall extractions were simulated with varying offset distances to the valley centreline.

Valley closure for varying horizontal stresses (Zhang et al. 2014)

In the first scenario, a series of models are built with varying longwall panel proximities to the valley, and the major horizontal stress is assigned in the direction perpendicular to the valley centreline. The major horizontal stress is then changed to be parallel to the valley centreline for the other scenario. Figure 17 compares the trend of valley closure for the two stress directions. It shows that the high valley closure is observed when the longwall is located within the critical zone (where the offset is less than 310 m, i.e. the longwall panel is located less than two longwall widths away from the valley), and then the closure movements decrease to lower values for the increasing offset distance over the extracted panels, exhibiting realistic valley closure changes.

For the longwall which is located directly beneath the valley, the valley closure is not significantly affected by the change of major horizontal stress direction. It can be explained that when the longwall lies directly underneath the valley, the mining-induced valley closure movements are much greater than the values derived from other longwall extractions. Due to the unfavourable and critical location of the panel relative to the valley, the intermediate principal stress is high enough to cause high level valley closure movements. Moreover, the conventional mining-induced horizontal movement above the panel is in the same alignment as the valley closure, which can be an additive to the closure values. Therefore, in this case the specific location of longwall is the dominant factor contributing to valley closure, rather than the orientation of the major horizontal stress. For other panel extractions, a notable difference in the valley closure values is observed, indicating that when the major horizontal stress is in the same alignment as the valley, less valley closure movements are expected, and vice versa.

From the previous discussion, it can be seen that the redistribution of horizontal stress plays an important role in the development of valley closure movements. The change of horizontal stress at the base of the valley as panels are extracted is also studied. As can be seen in Fig. 18, in the critical case where the direction of mining is parallel to the valley, the major horizontal compressive stress at the valley bottom starts to increase when the longwall face is 300 m in advance of the monitoring point. When the longwall passes under the monitoring point, the horizontal stress continues to increase in compression. When the longwall face is around 300 m past the monitoring point, the horizontal stress slightly increases, and seems to remain relatively constant until the end of the panel.

Recent studies in the measurement of the horizontal stress in valleys confirmed that the horizontal stress in the base of the valley increased as mining occurred nearby. Shen et al. (2010) conducted near-surface stress monitoring in a river valley in a study of subsidence control at West Cliff Colliery. It was found that the compressive stress in the river bed increased as mining approached the river.

Walsh et al. (2014) measured stress changes when studying the valley closure movements at Sandy Creek Waterfall. The location of one of the monitoring points and the longwalls is presented in Fig. 19a. Monitoring results showed that the stress change in the valley floor at the top of the waterfall exhibited an increase pattern during the passage of the adjacent longwall panels (particularly longwall 6 which was parallel to the alignment of the valley at the monitoring point), as presented in Fig. 19b.

Summary of horizontal compressive stress changes at the valley floor (Walsh et al. 2014)

4.4 Effect of Panel Width

The influence of panel width on valley closure was studied, by modelling a series of different panel widths ranging from 100 to 600 m. It is difficult to directly demonstrate the effects of panel width on valley closure using empirical or field monitoring data, as it is difficult to separate the panel width from other geological parameters, since there are limited case studies where there are varying panel widths with the similar surface topographies and overburden geologies. However, the modelled vertical subsidence can be compared with the empirical prediction curve (Waddington and Kay 1998), to provide verification of the numerical models in predicting the valley closure with various panel widths. It should be noted that the longwall width/depth ratios in the Southern Coalfield are usually limited to 0.9, and even the widest longwall is still sub-critical, with a panel width/depth ratio less than 1.4 (Holla and Barclay 2000; Whittaker and Reddish 1989). Figure 20 represents maximum vertical subsidence as a ratio of the extracted coal seam thickness, and good correlations between modelled and empirical predicted maximum subsidence (Waddington and Kay 1998) are found in the figure. It is clear that the value of modelled maximum subsidence increases as the panel width to depth ratio increases from 0.2 to 1.3 and thus follows the trend of the empirical prediction profile.

Figure 21 clearly shows that the extraction with varying panel width has induced a significant change in the magnitude of valley closure. The valley closure increases with a panel width up to a maximum value of around 350 m (panel width/depth of cover being 0.75), and then the value drops off for super-critical widths. The observed change in valley closure could be attributed to the mining-induced stress redistribution around the valley (Fig. 22). Stress arching occurs due to the extraction of the longwall panel, and as the panel width increases from 100 to 350 m, intensive horizontal stress concentration develops upwards between the caved zone and the valley wall that is close to the goaf. It generates a strong pushing effect on the valley side and thus inducing larger closure values. However, where the panel width continues to increase above 350 m, the stress arching reaches its limit vertically (i.e. the caving and fractured zones approach the surface), and due to the super-critical widths, the stress redistribution develops in a much wider pattern, and the peak of the stress arc moves horizontally away from the left valley wall, following the panel centreline. This could lead to the decrease of horizontal compressive stress beneath the valley wall, and thus less closure movements.

4.5 Effect of Depth of Cover

Apart from the panel width, depth of cover itself is a potential factor that could affect valley closure. The effect of cover depth was studied by modelling various depths of cover values. The longwall panel width is fixed at 163 m, and the depth of cover above the coal seam was varied as 472, 408, 326 and 272 m, respectively. The benchmark models in this study used a panel width/depth ratio of 0.35, i.e. a longwall width of 472 m, and a further three scenarios are built with the ratios being 0.4, 0.5 and 0.6, thereby representing the typical mining conditions in the Southern Coalfield. The critical longwall was extracted for these scenarios. The values of valley closure are plotted in Fig. 23. It is clear from the figure that the amount of valley closure increases as the panel width/depth ratio increases, indicating that mining at shallower cover depth induces more valley closure than deeper extractions.

Figure 24 compares the horizontal stresses around the valley for the different depth of cover scenarios. The graph shows that the stress arching effect is more pronounced beneath the valley wall that is closest to the goaf. As the depth of the cover becomes shallower, redistribution of in situ stresses increases. To quantify the stress change in each scenario, the stresses were interrogated at the level of the valley base in the models. Figure 25 presents the magnitudes of the modelled horizontal stresses. As can be seen from the figure, the horizontal stress beneath the left valley side increases by around 2 MPa as the panel depth changes from 472 to 272 m, which is positively correlated with the stress redistribution pattern illustrated in Fig. 24.

The depth of cover has also been examined as a potential factor influencing valley closure movements based on the available field data (MSEC 2014). Figure 26 shows the observed incremental valley closure plotted against the depth of cover over the longwall panel from a range of sites. It should be noted that the incremental valley closure is the additional valley closure resulting solely from the extraction of one panel. Hence it can be used to validate the valley closure movements induced by single longwall panel extraction in the UDEC models. The numerical modelling results are then added in the figure and compared with the empirical data set, and it is apparent that the models predict the valley closure within the range of measured movements, which has a large scatter due to the measurements being taken from sites with varying valley heights and locations relative to the mining. It should be noted that few panels have been extracted beneath larger river valleys since 2005, resulting in the reduction of the measured valley closure data in these sites. Therefore, the empirical database is limited by the limited information on these ongoing valley closure results. Although inclusion of the depth of cover as a potential factor influencing valley closure, according to the empirical analyses (MSEC 2014), is not recommended, the modelling results in this study show that valley closure does exhibit reasonable increase as depth of cover becomes shallower.

Modelled results in comparison with filed observations (based on MSEC 2014)

4.6 Effect of Angle Between Valley and Joint Sets

Variation of natural joint strike angle relative to the valley is usually observed in the field. Assessment is conducted to evaluate the influence joint strike angle from a series of models in which the joint strike angle is varied in 15° increments from 0° to 90°. Typical model setups are illustrated in Fig. 27, and it should be noted that the major horizontal compressive stress is assigned perpendicular to the valley, as the worst case scenario. Comparison of the valley closure for different joint strike angle with respect to valley alignment is presented in Fig. 28. It can be seen from the figure that the magnitude of valley closure gradually decreases as the degree of joint angle increases from 0° to 45°, and then increases as the angle rises to 90°. The variation of the angle between the joint and the valley alignment has a small effect on the valley closure movements, compared to other potential factors that have been evaluated in this paper.

Figure 29 shows the available field observed valley closure values in the function of the angles between the natural joint strike and valley alignment (MSEC 2014), plotted against the modelled results. Given that the geological and mining conditions used in the models could be different from the sites inspected, the predicted valley closure movements from numerical modelling sit in the reasonable range. However, it does not seem to be possible to establish a relationship between the angle between joint strike and valley alignment using the empirical data, due to the limited information available and the scatter in the results.

Comparison of modelled valley closure with filed observations for difference joint strike angles (based on MSEC 2014)

5 Conclusions

Valley closure movements have been identified as a significant part of non-conventional subsidence effects. The numerical modelling developed in this paper provides a quantitative approach to looking in detail at the valley closure movements. The contributing mining, geological and geotechnical factors influencing the magnitude of valley closure movements have been isolated and assessed individually.

The major influences on valley closure movements are the longwall positional factors, which include the offset distance from longwall to the valley, and the orientation of the longwall relative to the valley. A critical zone with an angle of draw being smaller than 33° had been identified from the previous study (Zhang et al. 2014), and this paper further examined the effect of sequential longwall panel extractions passing beneath the valley. It is found that valley closure increases by in excess of approximately seven times when mining through the valley while the change out of the critical zone is minimal. When considering the orientation of the longwall with respect to the valley, mining parallel to valley induces much more valley closure than mining perpendicular to the valley or mining at 45° with regard to the valley.

Another major factor promoting valley closure is the redistribution of horizontal stress. It is found that the mining-induced horizontal stress is predominantly redistributed perpendicular to the mining advance (across the panel). When the major horizontal stress is directed across the valley, the valley sides will have greater lateral movements towards the valley centreline which are driven by the horizontal compressive stress.

Influence of the mining activity has been examined by analysing factors including panel width and depth of cover. The valley closure increases with panel width up to a maximum value around 350 m, i.e. width-to-depth ratios up to 0.75, where the stress arching reaches the maximum height, followed by a decrease for super-critical widths. The redistribution of horizontal stress increases as the depth of cover becomes shallower leading to greater magnitude of valley closure movements, based on the geological conditions used in the modelling. Effect of geological structure around the valley has also been studied by modelling varying joint strike angle relative to the valley. However, the influence is small when compared to other potential factors, and it is also unclear what the joint strike angle will have on valley closure based on the empirical database.

The numerical predictive technique of valley closure subsidence in this research will be a useful source of reference for investigating valley-related movements as well as underground mine planning.

References

Bertuzzi R, Pells PJN (2002) Geotechnical parameters of Sydney sandstone and shale. J AGS 37(5):41–54

DeBono P, Tarrant G (2011) An analysis of long term subsidence at Metropolitan Colliery. In: 8th triennial conference on management of subsidence: state of the art, mine subsidence technological society, Newcastle, pp 81–88

Geosensing Solutions (2008) A compilation of surface geological features in the western portion of Metropolitan Colliery, 43 p

Hebblewhite BK, Waddington A, Wood J (2000) Regional horizontal surface displacements due to mining beneath severe surface topography. In: 19th international conference on ground control in mining, Morgantown, 8–10 August, pp 149–157

Holla L, Barclay E (2000) Mine subsidence in the southern coalfield. New South Wales Dept. of Mineral Resources, NSW

Itasca U (2011) UDEC—Universal Distinct Element Code. Itasca Consulting Group Inc., Minneapolis

Itasca U (2013) 3DEC—3 Dimensional Distinct Element Code. Itasca Consulting Group Inc., Minneapolis

Keilich W (2009) Numerical modeling of mining subsidence, upsidence and valley closure using UDEC. Dissertation, University of Wollongong

MSEC (2012) Subsidence predictions and impact assessments for natural features and surface infrastructure in support of the extraction plan, Revision B, MSEC448, 186 p

MSEC (2014) Effects of geology on observed valley closure movements with updated valley closure prediction method. ACARP Project No. C18015

NSW Department of Planning (2008) Southern Coalfield—colliery holdings, mine workings and upland swamps, Map 6

Shen B, Alehossein H, Pousen B, Waddington AA (2010) Subsidence control using coal washery waste. ACARP Research Project No. C16023

Waddington AA, Kay DR (1998) Development of the incremental profile method of predicting subsidence and its application in the Newcastle Coalfield. In: 4th triennial conference on buildings and structures subject to ground movement, Newcastle

Waddington AA, Kay DR (2001) Research into the impacts of mine subsidence on the strata and hydrology of river valleys and development of management guidelines for undermining cliffs, gorges and river systems. ACARP Research Project No. C8005

Waddington AA, Kay DR (2002) Research into the impacts of mine subsidence on the strata and hydrology of river valleys and development of management guidelines for undermining cliffs, gorges and river systems. ACARP Research Project No. C9067

Walsh RV, Hebblewhite B, Nicholson, MA, Barbato J, Mills K, Li G, Brannon PJ (2014) Monitoring of ground movements at Sandy Creek Waterfall and implications for understanding the mechanics of valley closure movements. In: 9th triennial conference on mine subsidence: risk management in action, Newcastle, 11–13 May, pp 227–244

Whittaker BN, Reddish DJ (1989) Subsidence: occurrence, prediction and control. Elsevier, Amsterdam

Zhang C, Mitra R, Hebblewhite B (2012) Review of numerical modelling evaluation of mechanisms for valley closure subsidence under irregular topographic condition. In: Eurock 2012-ISRM international symposium, Stockholm, 28–30 May 2012

Zhang C, Mitra R, Oh J, Hebblewhite B (2014) Investigation of geological and geotechnical effects on valley closure subsidence behaviour. In: 9th triennial conference on mine subsidence: risk management in action, Newcastle, 11–13 May, pp 207–220

Zhang C, Mitra R, Oh J, Hebblewhite B (2015) Investigation of geomechanical mechanisms contributing to valley closure subsidence effects—a 3D numerical modelling approach. In: 13th international ISRM congress 2015—international symposium on rock mechanics, Montreal, 10–13 May 2015

Acknowledgments

The authors would like to acknowledge Mine Subsidence Engineering Consultants for their valuable comments and suggestions on this paper.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhang, C., Mitra, R., Oh, J. et al. Analysis of Mining-induced Valley Closure Movements. Rock Mech Rock Eng 49, 1923–1941 (2016). https://doi.org/10.1007/s00603-015-0880-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00603-015-0880-1