Abstract

Enterprise hard disk drives (HDDs) are widely used in high-end storage systems for data center. One of key performance requirements for enterprise HDDs is data access rate, which demands very high rotational speed (e.g. 15 k rpm or more) to permit fast access time. To reach such high speed, the disk spindle motor draws more power to spin and hence the temperature of HDD enclosure increases due to large windage loss. It has been known, temperature rise is one of the most fundamental factors that affect the reliability of the disk drive. In order to develop high reliable enterprise HDDs, thermal management of enterprise HDDs needs to be optimized to improve heat dissipation. One possible approach is to fill disk drive with helium because of its lower density and higher thermal conductivity. This paper investigates thermal performances of helium-filled enterprise disk drives through FEM simulations with experimental validations. Windage loss and heat convection of the HDD filled with helium and air are analysed. The simulated and measured temperature distributions of one commercial enterprise HDD with helium-filled and helium-air mixture are compared with those of an air-filled one. The results show 41% reduction of temperature rise of HDD enclosure can be achieved by filling with helium in comparison with that of air-filled HDD. It is also projected that in terms of equivalent cooling capability like air-filled HDD at 15 k rpm, helium-filled HDD spindle can spin up to 19 k rpm, which will greatly increase data access rate by 25% for future enterprise applications.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Enterprise hard disk drives (HDDs) have been widely used in high-end storage systems such as in data center. One of the key performance requirements for enterprise HDDs is data access rate, which demands higher rotational speed (15 k rpm) to permit fast access time. To reach such high speed, the disk spindle motor draws more power to spin and hence the temperature of HDD enclosure increases due to large windage loss (Wood 2009). It has been known, temperature rise is one of the most fundamental factors that affect the reliability of the disk drive. Higher temperatures can cause off-track errors due to thermal tilt of the disk stack and actuator, or even result in head crash due to outgassing of spindle and voice-coil motor (VCM) lubricants at 60 ~80°C depending on the type of materials being used (Prater and Tzeng 1994; Eibeck and Cohen 1988). In order to develop high reliable enterprise HDDs, thermal management of enterprise HDDs needs to be re-designed to improve heat dissipation (Wood 2009). One possible approach is to fill disk drive with helium because of its lower density and higher thermal conductivity.

In the 1980s, Eibeck and Cohen (1988) employed the finite difference method to develop a general HDD thermal model and also studied sensitivity of the steady-state temperature results to heat transfer coefficient variations and heat sources. In 1990, Sato et al. (1990) experimentally studied the thermal characteristics of 14-inch helium-filled HDD running at 3600 rpm. Their results showed that windage loss in the helium-filled HDD is 1/5 of air-filled one. Such reduction in windage loss can lower the temperature of the helium-filled HDD enclosure by ~30%. However, the disk drives studied in the references are out-of-date format factor HDDs with lower rotational speeds. There is a demand for HDD designers to study modern high-speed HDDs filled with helium for enterprise applications. Recently, Aruga et al. (2007) measured and analysed the disturbances attribute to flow induced vibration using helium-filled enterprise HDD. Their results reveal that helium-filled HDD is also able to reduce windage disturbances from airflow and hence suppress positioning error signals. This paper investigates thermal performances of helium-filled enterprise disk drives through FEM simulations with experimental validation. Windage loss and heat convection of the drive filled with both helium and air are analysed. The simulated and measured temperature distributions of one commercial enterprise helium-filled HDD are compared those in air-filled one.

2 HDD thermal characterization

Helium is inert and monatomic in all standard conditions. Due to relatively low molecular mass and size, in the gas phase, helium’s thermal conductivity and specific heat are bigger than those of any other gases except hydrogen. Moreover, its diffusion rate through solids is three times that of air. Table 1 shows the thermophysical properties of air and helium gases. These inherent inertness and high thermal conductivity enable helium to be a more efficient heat transfer medium. Comparing with air, helium can reduce the aerodynamic drag which experienced by spinning disks within HDDs, thereby reducing power requirements for the spindle motor. A helium-filled HDD thus consumes less power than a comparable disk drive that operates in air environment. With lower density, helium results in better motor efficiencies and hence lower power consumption for a given performance level. Therefore, as an alternative to air-filled HDDs, high efficient heat dissipation may be achieved by filling the disk drives with helium.

In order to perform thermal analysis of helium-filled disk drives, major heat sources or losses of the HDD are first being identified by empirical formulations and experiments. Different operating losses generated in HDD enclosure are calculated and measured accordingly to form heat sources in the thermal analysis. In this study, one 3.5-inch commercial enterprise HDD with 15 k rpm is selected. Its major heat generation components such as spindle motor, VCM, R/W sensor, flying control thermal heater and windage loss are characterized in Table 2. It should be noted that windage losses between helium-filled and air-filled HDD enclosures have larger differences due to the change of windage shear torque at the spinning disk and is described by the following empirical equation (Ecert 1959; Sato et al. 1990):

where ω is the rotational angular velocity, R is disk radius, ν is the kinematic viscosity, ρ is gas density, β is coefficient related to disk surface areas, which is equal to 0.036 (Ecert 1959).

As a comparison, the windage losses of a 70 mm-diameter thin disk spinning in both air and helium at various spindle speeds have been plotted in Fig. 1. The graph shows that the windage loss can be reduced by ~80% at 15 k rpm for a helium-filled drive, compared with an air-filled drive. More reduction of windage loss can be projected at 20 k rpm.

In addition to heat sources, the convection heat transfer coefficients within HDD enclosure need to be characterized. Since the HDD enclosure is filled with gas such as air or helium, the convection heat transfer between the surfaces of the HDD components and gas is considered using the convection heat transfer coefficients. Generally, the coefficients can be applied to the surface of the HDD components with the surrounding gas temperatures. In the current HDD study, forced convection heat transfer must be incorporated due to the spinning disks within the HDD enclosure. However, these coefficients are not easily determined as they vary with the temperature distributions, fluid properties and surrounding flow characteristics within HDD enclosure. Therefore, for the sake of simplicity, the mean convection heat transfer coefficient over the surface of rotating disk is estimated by (Daily and Nece 1960).

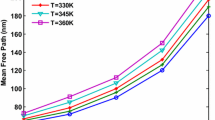

where G is dimensionless spacing d/R, d is gap between the wall surface (top cover) and disk surface. Figure 2 shows the calculated mean heat transfer coefficients over the surface of rotating disk at different rotating speeds for both air-filled and helium-filled HDDs. It has been observed that the mean heat transfer coefficient in helium is almost twice as much than the one in air, which agrees with the experimental results (Sato et al. 1990).

3 FEM modeling and validations

Thermal analysis was performed using ANSYS (2007) package. The basic mathematical structure in ANSYS is a system of partial differential equations (PDEs). ANSYS applies the finite element method (FEM) when solving the PDEs. The PDE formulation for steady state heat conduction is governed by the Fourier’s law of heat conduction equation:

where T is temperature, H heat generation or heat dissipation per unit volume and λ xx , λ yy , λ zz conductivity in the element x, y, and z directions, respectively.

A FEM model of the 3.5-inch commercial enterprise HDD was constructed by ANSYS. The model consists of ~220 thousands of elements to represent the whole HDD including disks, VCM, suspensions, sliders, spindle motor, base plate and top cover as well as internal gas. Since the gas (air/helium) inside the HDD enclosure is well mixed by the high speed rotating disks, the gas temperature variation throughout the whole HDD is neglected (Sato et al. 1990). Thus, the gas inside the HDD has been assumed to be highly conductive (Tan et al. 2009). In addition, isotropic thermal conductivities of HDD components are used. Furthermore, the thermophysical properties in Table 1 are kept constant throughout all the simulations as the gas temperature changes are found to be in a narrow range of 35–55°C. The properties of mixture gas are estimated by linear interpolating between gases contents. Each heat source has been assumed to be evenly distributed throughout the related heat generation component’s volume. The external boundary conditions of the top cover and external side surfaces of HDD include ambient temperature of 23°C and the convection heat transfer coefficient of 9.5 W/m2 K, which is a slightly high-end value as the experiment was not conducted in a draught-free environment.

The FEM model was validated by comparing the simulation results with the experimental measurements using the thermocouples. Figure 3 shows the experimental setup for HDD temperature measurements. Type T thermocouples were affixed to the top cover surface at the six measured locations to measure the HDD temperatures at steady state heat transfer condition.

Figure 4 shows the experimentally measured (values in bracket) and FEM simulated steady-state temperatures of the top cover surface for air-filled HDD and 50%helium-50%air mixed gas filled HDD. The predicted temperatures agree well with the experimentally measured values.

Figure 5 summaries the simulated and measured steady-state temperatures of HDD top cover surface at the six locations as shown in Fig. 3 for air-filled and 30%helium-70%air mixed gas filled HDDs. The errors of the FEM model have been found to be less than 2%.

4 Results and discussion

Figure 6 shows the simulated steady-state temperature distributions of the major components within helium-filled and air-filled HDDs, respectively. Using helium-filled disk drive, the maximum temperature of the spindle motor was reduced by 12–13°C. This prediction is in good agreement with the experimental results (Sato et al. 1990).

Figure 7 displays the enlarged temperature profiles of voice coil motor (VCM) and disk-spindle for helium-filled and air-filled HDDs. It can be seen that, through using helium filled HDD, the variations of components’ temperatures have been reduced tremendously (~52%). Such reduction could decrease off-track thermal-induced deformations and hence improve R/W head performance. The effects of the different helium-air mixture contents on HDD temperature rise have been shown in Fig. 8. The results suggest that the maximum reduction of HDD top cover surface temperature rise can be as high as 41% for pure helium-filled HDD.

Furthermore, in order to investigate the capability of cooling down by forced convection of an enterprise helium-filled HDD, the surface forced convection heat transfer coefficients at various airflow speeds were evaluated by using isothermal flat plate theory (Incropera and DeWitt 2002) to both helium-filled and air-filled HDD models. It simulated both helium and air HDDs would be exposed to the same air forced convection condition such as using fan cooling system in disk array, at the steady-state heat transfer condition. The term “cooling capability” is used to quantify the capability of the HDD being cooled down by force convection. Figure 9 shows that one air-filled HDD with 15 k rpm could spin up 19 k rpm when air is replaced with helium, in meanwhile, it still maintains equivalent cooling capability like air-filled HDD. This finding suggests that one air-filled HDD, when filled with helium, it could spin at a higher speed (with 25% increment) so that faster data access time and retrieval rates can be achievable in enterprise applications.

5 Conclusions

In this paper, thermal performance of helium-filled enterprise HDDs was investigated by FEM simulation with experimentally validated. The results indicate that 41% reductions of temperature rise of helium-filled HDD enclosure are achievable in comparison with that of air-filled HDD. Such reduction will decrease off-track thermal deformations and hence improve R/W head performance, lifetime and reliability of enterprise HDDs. The studies also predict that in terms of equivalent cooling capability like air-filled HDD at 15 k rpm, helium-filled HDD spindle speed can reach up to 19 k rpm, which will greatly increase data access rate in enterprise applications.

References

ANSYS Inc. (2007) ANSYS v10.0, ANSYS, Inc., Canonsburg

Aruga K, Suwa M, Shimizu K, Watanabe T (2007) A study on positioning error caused by flow induced vibration using helium-filled hard disk drives. IEEE Trans Magn 43(2):3750–3755

Daily JW, Nece RE (1960) Chamber dimension effects on induced flow and frictional resistance of enclosed disks. J Basic Eng 82:217–232

Ecert ERG (1959) Heat and mass transfer. McGraw-Hill, New York

Eibeck PA, Cohen DJ (1988) Modelling thermal characteristics of a fixed disk drive. IEEE Trans Compon Hybrids Manuf Technol 11(4):566–570

Incropera FP, DeWitt DP (2002) Fundamentals of heat and mass transfer, 5th edn. Wiley, New York

Prater W, Tzeng HM (1994) Thermal and heat-flow aspects of actuators for hard disk drives. In: Proceedings of IEEE inter-society conference on thermal phenomena, pp 261–268

Sato I, Otani K, Mizukami M, Oguchi S, Hoshiya K (1990) Characteristics of heat transfer in small disk enclosures at high rotation speeds. In: Proceedings of IEEE inter-society conference on thermal phenomena, pp 130–135

Tan CPH, Yang JP, Mou JQ, Ong EH (2009) Three dimensional finite element model for transient temperature prediction in hard disk drive. In: Proceedings of IEEE Asia-Pacific magnetic recording conference, Singapore, pp DP-09 and DP-08

Wood R (2009) Future hard disk drive systems. J Magn Magn Mater 321(6):555–561

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yang, J., Tan, C.P.H. & Ong, E.H. Thermal analysis of helium-filled enterprise disk drive. Microsyst Technol 16, 1699–1704 (2010). https://doi.org/10.1007/s00542-010-1121-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00542-010-1121-x