Abstract

The paper presents some results of the research connected with the development of new approach based on the artificial neural network (ANN) of predicting the ultimate tensile strength of the API X70 steels after thermomechanical treatment. The independent variables in the model are chemical compositions (carbon equivalent), based upon the International Institute of Welding equation (CEIIW), the carbon equivalent, based upon the chemical portion of the Ito-Bessyo carbon equivalent equation (CEPcm), the sum of the niobium, vanadium and titanium concentrations (VTiNb), the sum of the niobium and vanadium concentrations (NbV), the sum of the chromium, molybdenum, nickel and copper concentrations (CrMoNiCu), Charpy impact energy at −10 °C (CVN) and yield strength at 0.005 offset (YS). For purpose of constructing these models, 104 different data were gathered from the experimental results. The data used in the ANN model is arranged in a format of seven input parameters that cover the chemical compositions, yield stress and Charpy impact energy, and output parameter which is ultimate tensile strength. In this model, the training, validation and testing results in the ANN have shown strong potential for prediction of relations between chemical compositions and mechanical properties of API X70 steels.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

1.1 Pipeline steels

Currently, there is a requirement to transport crude oil and gas by pipeline at a higher operating pressure to increase the capacity. This demands the use of high-strength steels. Increasing the strength of the pipeline steel enables a significant reduction in wall thickness with resulting reduction in weight. Thus, a major aim within the steel industry is to develop high-strength microalloyed pipeline steels (~700–800 MPa). It is, however, important that the increase in the yield strength is not accompanied by a decrease in fracture toughness and formability because a decrease in toughness will promote stress-induced cracking, and reduced formability will cause difficulties in forming (e.g., pipe-bowing). Thus, high strength in relationship with high toughness and formability are important requirements of the pipeline industry [1–3].

High strength–toughness combination is necessary for pipeline steels for transporting natural gas and crude oil over a long distance under high pressure [2]. Other characteristics that are needed include resistance to hydrogen-induced blister cracking in sour service environment [4, 5], stress corrosion cracking resistance, especially in H2S environment [6–8], and fatigue resistance [9, 10]. It is important that the microstructure of the pipeline steel provides combination of above-mentioned properties.

The evolution of microstructure depends on alloy chemistry and thermomechanical processing. Alloying additions such as Mn, Nb, V, Ti, Mo, Ni, Cr and Cu are commonly employed in pipeline steels to achieve the desired microstructure and mechanical properties [5, 6, 11–13]. However, sensible selection of alloying elements is necessary to obtain advantageous effect on mechanical properties with reduced alloy cost. For instance, the number of alloying elements is reduced to achieve lower carbon equivalent (CE) to guarantee good field weldability [2, 3]. On the other hand, alloy additions such as Cr, Cu and Ni are added to obtain strength in severe corrosive environment [2, 5]. Controlled thermomechanical processing is considered as the primary path for the development of API-grade pipeline steels because it provides the desirable and fine-grained microstructure. In addition, it allows high strength–toughness combination to be achieved with accelerated cooling [3]. The ultimate microstructure strongly depends on the processing parameters such as reheating temperature, percentage reduction, deformation temperature, cooling rate, and coiling temperature [14]. This is because fine austenite grains, substructure and dislocations in austenite effectively promote the transformation of fine ferrite. The primary grain refinement in controlled rolling is achieved through recrystallization of austenite during deformation and through the use of microalloying elements, such as Nb that precipitates as fine carbides and inhibits grain growth [15].

In steel-related research, which is also the focus of this study, ANN has been used widely to understand a wide range of problems including phase transformations [16], surface texture [17–19] and mechanical properties [20–23]. For instance, Trzaska and Dobrzanski [24] applied ANN to decide the composition of steel for achieving a particular hardness. Monajati et al. [25] used ANN to understand the effects of the processing parameters on the mechanical properties such as yield strength, work hardening and plastic strain ratio. Corrosion studies have also been made using the ANN [26, 27]. An overview of the application of neural networks to study material science problems has been demonstrated by Mukherjee and Singh [28] and Bhadeshia et al. [29].

In this research, ANN has been employed to determine the ultimate tensile strength. ANN has been used to determine the ultimate tensile strength as a function of eleven alloying elements(C, Si, Mn, Cu, Ni, Cr, Mo, Ti, V, Nb and B), yield strength (at 0.005 offset strain) and impact energy (at −10 °C). The theory behind the ANN configuration and the performance with regard to high-strength low-carbon steels is discussed in the ensuing sections. More precisely, using the experimental data of 104 microalloyed steels, the ANN has been developed to predict the ultimate tensile strength for a given set of input variables mentioned above.

1.2 Artificial neural networks

ANNs were developed to model the human brain [30]. Even an ANN fairly simple and small in size when compared to the human brain has some powerful characteristics in knowledge and information processing because of its similarity to the human brain. Therefore, an ANN can be a powerful tool for engineering applications [31]. McCulloch and Pitts [32] defined artificial neurons for the first time and developed a neuron model as in Fig. 1. McCulloch and Pitts’ network [32] formed the basis for almost all later neural network models. Afterward, Rosenblatt [33] devised a machine called the perceptron that operated much in the same way as the human mind. Rosenblatt’s perceptrons [33] consist of “sensory” units connected to a single layer of McCulloch and Pitts [32] neurons. Rumelhart et al. [34] derived a learning algorithm for perceptron networks with constituted hidden units. Their learning algorithm is called back-propagation and is now the most widely used learning algorithm. Figure 2 shows a typical architecture of a multilayer perceptron neural network with an input layer, two hidden layers and one output layer. As a result of these studies, together with the developments in computer technology, using ANN has become more efficient after 1980 [35].

Architecture of applied neural network [32]

A typical architecture of multilayer perceptron neural network [38]

As it can be seen from Fig. 1, an artificial neuron is composed of five main parts: inputs, weights, sum function, activation function and outputs. Inputs are information that enters the neuron from other neurons of from external world. Weights are values that express the outcome of an input set or another process element in the preceding layer on this process element. Sum function is a function that calculates the effect of inputs and weights completely on this process element. This function computes the net input that approaches a neuron [36]. The weighted sums of the input components (net) j are calculated using the below equation as follows:

where (net) j is the weighted sum of the jth neuron for the input received from the preceding layer with n neurons, W ij is the weight between the jth neuron in the previous layer, x i is the output of the ith neuron in the previous layer [35], b is a fix value as internal addition and R represents sum function. Activation function is a function that processes the net input obtained from sum function and determines the neuron output. In general for multilayer feed-forward models as the activation function, sigmoid activation function is used. The output of the jth neuron (out) j is computed using Eq. (2) with a sigmoid activation function as follows [37]:

where α is constant used to control the slope of the semi-linear region. The sigmoid nonlinearity activates in every layer except in the input layer [35]. The sigmoid activation function represented by Eq. (2) gives outputs in (0, 1). If desired, the outputs of this function can be adjusted to (−1, 1) interval. As the sigmoid processor represents a continuous function, it is particularly used in nonlinear descriptions, because its derivatives can be determined easily with regard to the parameters within (net) j variable [35].

LMBP is often the fastest available back-propagation algorithm and is highly recommended as a first-choice supervised algorithm, although it requires more memory than other algorithms.

2 Training and verifying

2.1 Data collection

Tensile test was performed at room temperature. Transverse sample were cut from body of the pipe according to API standard [39]. The gauge length was 50.8 mm, and a 0.5-class extensometer was used to measure the extension. The tensile samples were prepared according to ASTM E8 [40]. The impact test samples were cut, transverse to the rolling axis (according to API standard), from an area free of defects, machined and prepared according to ASTM E 23 standard [40]. The samples had the following dimensions: 10 mm × 10 mm × 55 mm. During the test, the samples were struck with a high-energy pendulum (750 J). The hardness test load was 10 kgf, and the test method was dead-weight. The transverse samples were prepared according to IPS standard [41]. The chemical analysis of elements in steels was carried out using ARL quantometer 2460 model. Sample preparation and test were done according to ASTM A751 [40]. Transverse sample extracted from body of the pipe.

In the present investigation, the artificial neural network has been trained, tested and validated for prediction of ultimate tensile strength of X70 pipeline steels. For this purpose, the experimental data of 104 pipeline steels with different chemical compositions have been used. The input variables of the ANN modeling are the weight percent of alloying elements, the yield strength and the Charpy impact energy at −10 °C. These parameters along with their ranges have been summarized in Table 1.

2.2 Neural network model structure and parameters

ANN modeled in this research has seven neurons in the input layer and one neurons in the output layer. According to the API Specification 5L/ISO 3183 [39], the values for input layers were carbon equivalent, based upon the International Institute of Welding equation (CEIIW) (Eq. 3), the carbon equivalent, based upon the chemical portion of the Ito-Bessyo carbon equivalent equation (CEPcm) (Eq. 4), the sum of the niobium, vanadium and titanium concentrations (VTiNb), the sum of the niobium and vanadium concentrations (NbV), the sum of the chromium, molybdenum, nickel and copper concentrations (CrMoNiCu), Charpy impact energy at −10 °C (CVN) and yield strength at 0.005 offset (YS). The value for output layer was ultimate tensile stress (UTS).

Two hidden layers with 10 and 8 neurons were used in the architecture of multilayer neural network because of its minimum absolute percentage error values for training and testing sets. The neurons of neighboring layers are completely interconnected by weights. Finally, the output layer neurons produce the network prediction as a result. From the total 104 gathered date, 74 were randomly selected and trained by the network, 15 data were used for validation and the other 15 data were used for testing the network.

In this study, the back-propagation training algorithm has been utilized in two feed-forward hidden layers. Back-propagation algorithm, one of the most well-known training algorithms for the multilayer perceptron, is a gradient descent technique to minimize the error for a particular training pattern in which it adjusts the weights by a small amount at a time [38]. The nonlinear sigmoid activation function was used in the hidden layer and the neuron outputs at the output layer. The trained model was only tested with the input values, and the predicted results were close to experiment results. The values of parameters used in neural network model are given in Table 1.

3 Results and discussion

3.1 The effects of chemical composition

The parameter that has been most used in practice to measure steel weldability is the carbon equivalent (CE) formula, where good weldability is in general obtained by maintaining a low CE. This method of evaluation is based upon the empirically identified tendencies in the variation of the Martensite start (Ms) temperature as a function of the alloying elements present in the steel [39].

In the 1980s, the technical specifications for pipelines indirectly addressed the issue of weldability by the chemical composition limits imposed. According to the API 5L standard, the maximum carbon level for an X-65 steel was stipulated to be 0.26 pct, whereas for the X-70 grade, this maximum was lowered to 0.23 pct [42]. More modern high-strength low-alloy (HSLA) steels have been produced with a much lower C content of around 0.1 pct, and the tendency is to exploit even lower levels.

The current tendency to reduce the C level leads to a decrease in CE and reduces hardenability. For steels with C levels of around 0.1 pct, good weldability is achieved by the addition of appropriate alloying elements. The addition of Mn inhibits the formation of high-temperature transformation products such as pearlite and polygonal ferrite as well as promoting solid solution strengthening of the ferrite. Nickel, in addition to increasing hardenability, also increases toughness. Aluminum is exploited as a deoxidizing agent and, via nitride precipitation, as a grain refiner, whereas Nb serves to guarantee the precipitation processes, which retard austenite grain growth [43].

The addition of microalloying elements also contributes to the formation of martensite/retained austenite (MA) and thereby the weldability. Carbide-forming elements such as Mo, Nb and V retard the decomposition of MA. The addition of Mn, Cr and Nb lowers the Banite start (Bs) temperature and promotes the formation of MA. In the published literature, it is mentioned that the presence of MA can be considered deleterious to toughness. It has also been observed, however [44–46], that this deleterious effect is not only associated with MA volume fraction, but also with its morphology, size and distribution in the matrix.

3.2 Artificial neural network modeling

In terms of simulating the heat treating process using ANN, one should consider that the physical simulation by experimental work not only is time consuming but also cannot overcome many errors encountered at a laboratory scale. Hence, a well-established ANN modeling can allow predicting ultimate tensile strength with the capability for replacing even mathematical modeling. The current ANN model adopts a nonlinear mapping method to set up models according to input and output data directly. In this respect, extensive research activities were made to optimize many industrial processes using ANN. The obtained results can be discussed as follows: First, the use of artificial neural network exhibits excellent accuracy in predicting the ultimate tensile strength outputs. Secondly, as already stated, there are many contributing factors in ultimate tensile strength that cannot be considered in the mathematical modeling, but they can be easily incorporated in neural network modeling. Thirdly, the present artificial neural network can predict the mechanical properties directly and in a much more rapid approach compared to the mathematical modeling such as finite element.

These characteristics of present ANN in predicting the ultimate tensile strength can be very precious from an industrial point of view. A network with four layers, seven neurons for the input layer, 10 neurons for the first hidden layer, 8 neurons for the second hidden layer and one neuron for the output layer was designed. This combination resulted in a feed-forward neural network that requires a back-propagation algorithm. As already indicated, the input variables for establishing a new ANN model were considered as chemical compositions and yield strength and Charpy impact energy results.

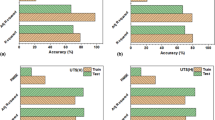

The trained network was then used to compare the predicted and measured values. These comparisons are shown in Fig. 3. In these figures, the ultimate tensile strength values results. As it is obvious, the values predicted by ANN are in very good agreement with the ones obtained by experimental work.

Figure 3 presents the comparison between measured and predicted results for ultimate tensile strength levels. The agreements between the predicted and measured values indicate that this approach can be very useful in modeling the mechanical properties of steels. That is because, in all cases, the prediction values match the measured amounts very well. Once more, this clearly indicates the accurate function of the trained ANN in predicting the ultimate tensile strength. Consequently, the developed ANN model can be used to simulate and predict the ultimate tensile strength of steels. As mentioned earlier, the complexity of thermomechanical treatment, due to interacting many parameters simultaneously (e.g., material composition, applied strain, strain rate, austenitizing time and temperature, cooling rate), can make it difficult to get accurate experimental results in this regard.

It terms of the contribution of errors, it is worth mentioning that the errors are inevitable in any approach. However, there are always shortcomings that can affect the accuracy of both the measured and predicted values. These can be, for example, nonuniform microstructure in the specimen, inhomogeneity of the mechanical properties in the samples.

In this study, the error during the training, validation and testing in ANN model can be expressed as absolute fraction of variance (R 2) which is calculated by the below equation [47]:

where t is the target value and o is the output value.

All of the results obtained from experimental studies and predicted by using the training, validation and testing results of ANN model are given in Fig. 3a–c, respectively. The linear least-square fit line, its equation and the R 2 values are shown in these figures for the training, validation and testing data. Also, inputs values and experimental results with validation and testing results obtained from ANN model are given in Tables 2 and 3, respectively. As it is visible in Fig. 3, the values obtained from the training, validation and testing in ANN model are very close to the experimental results.

The result of testing phase in Fig. 3 shows that the ANN model are capable of generalizing between input and output variables with reasonably good predictions. The performance of the ANN model is shown in Fig. 3. The best value of R 2 is 91.58 % for training set, and the minimum values of R 2 are 91.3 % for testing set in the ANN model. All of R 2 values show that the proposed ANN model are suitable and can predict UTS values for every age very close to the experimental values.

4 Conclusions

An artificial neural network model was developed to model and predict the ultimate tensile strength of X70 pipeline steels. The values predicted by present model are in very good agreement with those measured by experimental results. Therefore, the present ANN model can be used to predict accurately the ultimate tensile strength of X70 pipeline steels. ANN models will be valid within the ranges of variables.

References

Zhao M-C, Yang K, Shan Y (2002) The effects of thermo-mechanical control process on microstructures and mechanical properties of a commercial pipeline steel. Mater Sci Eng A 335:14–20

Bott IS, Souza LFG, Teixeira JCG, Rios PR (2005) High-strength steel development for pipelines: a Brazilian perspective. Metall Mater Trans A 36A:443–454

Hillenbrand IHG, Graf IM, Kalwa IC (2001) Development and production of high strength pipeline steels. In: Proceedings of the conference niobium 2001, Orlando, FL, USA

Takahashi A, Iino M (1996) Thermo-mechanical control process as a tool to grain-refine the low manganese containing steel for sour service line pipe. ISIJ Int 36(2):235–240

Takahashi A, Iino M (1996) Microstructural refinement by Cu addition and its effect on strengthening and toughening of sour service line pipe steels. ISIJ Int 36(2):241–245

Takahashi A, Ogawa H (1996) Influence of microhardness and inclusion on stress oriented hydrogen induced cracking of line pipe steels. ISIJ Int 36(2):334–340

Zhao M-C, Yang K (2005) Strengthening and improvement of sulfide stress cracking resistance in acicular ferrite pipeline steels by nano-sized carbonitrides. Scripta Mater 52:881–886

Contreras A, Albiter A, Salazar M, Perez R (2005) Slow strain rate corrosion and fracture characteristics of X-52 and X-70 pipeline steels. Mater Sci Eng A 407:45–52

Kim YM, Kim SK, Lim YJ, Kim NJ (2002) Effect of microstructure on the yield ratio and low temperature toughness of linepipe steels. ISIJ Int 42(12):1571–1577

Zhong Y, Xiao F, Zhang J, Shan Y, Wang W, Yang K (2006) In situ TEM study of the effect of M/A films at grain boundaries on crack propagation in an ultra-fine acicular ferrite pipeline steel. Acta Mater 54:435–443

Junhua K, Lin Z, Bin G, Pinghe L, Aihua W, Changsheng X (2004) Influence of Mo content on microstructure and mechanical properties of high strength pipeline steel. Mater Des 25:723–728

Lee WB, Hong SG, Park CG, Kim KH, Park SH (2000) Influence of Mo on precipitation hardening in hot rolled HSLA steels containing Nb. Scripta Mater 43:319–324

Sun W, Lu C, Tieu AK, Jiang Z, Liu X, Wang G (2002) Influence of Nb, V and Ti on peak strain of deformed austenite in Mo-based micro-alloyed steels. Mater Process Technol 125–126:72–76

Xiao FR, Liao B, Shan YY, Qiao GY, Zhang Y, Zhang C, Yang K (2006) Challenge of mechanical properties of an acicular ferrite pipeline steel. Mater Sci Eng A 431:41–52

Shanmugam S, Ramisetti NK, Misra RDK, Hartmann J, Jansto SG (2008) Microstructure and high strength–toughness combination of a new 700MPa Nb-microalloyed pipeline steel. Mater Sci Eng A 478:26–37

Khalaj G, Khoeini M, Khakian-Qomi M (2012) ANN-based prediction of ferrite fraction in continuous cooling of microalloyed steels. Neural Comput Appl. doi:10.1007/s00521-012-0992-4

Tugrul O, Yigit K (2005) Predictive modeling of surface roughness and tool wear in hard turning using regression and neural networks. Int J Mach Tools Manuf 45:467–479

Fredj NB, Amamou R (2006) Ground surface roughness prediction based upon experimental design and neural network models. Int J Adv Manuf Technol 31:24–36

Brahme A, Winning M, Raabe D (2009) Prediction of cold rolling textures of steels using an artificial neural network. Comput Mater Sci 46:800–804

Nazari A (2011) Application of artificial neural networks for analytical modeling of Charpy impact energy of functionally graded steels. Neural Comput Appl. doi:10.1007/s00521-011-0761-9

Nazari A, Milani AA, Zakeri M (2011) Modeling Ductile to brittle transition temperature of functionally graded steels by artificial neural networks. Comput Mater Sci 50:2028–2037

Nazari A, Sedghi A, Didehvar N (2011) Modeling impact resistance of aluminum-epoxy laminated composites by artificial neural networks. J Compos Mater. doi:10.1177/0021998311421222

Nazari A (2011) Microhardness profile prediction of functionally graded steels by artificial neural networks. Int J Damage Mech. doi:10.1177/1056789511432653

Trzaska J, Dobrzanski LA (2005) Application of neural networks for designing the chemical composition of steel with the assumed hardness after cooling from the austenitising temperature. J Mater Process Technol 164–165:1637–1643

Monajati H, Asefi D, Parsapour A, Abbasi S (2010) Analysis of the effects of processing parameters on mechanical properties and formability of cold rolled low carbon steel sheets using neural networks. Comput Mater Sci 49:876–881

Parthiban T, Ravi R, Parthiban GT, Srinivasan S, Ramakrishnan KR, Raghavan M (2005) Neural network analysis for corrosion of steel in concrete. Corros Sci 47:1625–1642

Rolich T, Rezic I, Curkovic L (2010) Estimation of steel guitar strings corrosion by artificial neural network. Corros Sci 52:996–1002

Mukherjee M, Singh SB (2009) Artificial neural network: some applications in physical metallurgy of steels. Mater Manuf Process 24:198–208

Bhadeshia HKDH, Dimitriu RC, Forsik S, Pak JH, Ryu JH (2009) On the performance of neural networks in materials science. Mater Sci Technol 25:504–510

Mukherjee A, Biswas SN (1997) Artificial neural networks in prediction of mechanical behavior of concrete at high temperature. Nucl Eng Des 178(1):1–11

Ince R (2004) Prediction of fracture parameters of concrete by artificial neural networks. Eng Fract Mech 71(15):2143–2159

McCulloch WS, Pitts W (1943) A logical calculus of the ideas immanent in neural nets. Bull Math Biophys 5:115–137

Rosenblatt F (1962) Principles of neuro dynamics: perceptrons and the theory of brain mechanisms. Spartan Books, Washington, DC

Rumelhart DE, Hinton GE, William RJ (1986) Learning internal representation by error propagation. In: Rumelhart DE, McClelland JL (eds) Proceeding parallel distributed processing foundation, vol 1. MIT Press, Cambridge

Liu SW, Huang JH, Sung JC, Lee CC (2002) Detection of cracks using neural networks and computational mechanics. Comput Methods Appl Mech Eng 191(25–26):2831–2845

Anderson JA (1983) Cognitive and psychological computation with neural models. IEEE Trans Syst Man Cybern V.SMC-13 5:799–814

Hopfield JJ (1982) Neural networks and physical systems with emergent collective computational abilities. Proc Nat Acad Sci 79:2554–2558

Nazari A, Riahi S (2011) Artificial neural networks to prediction total specific pore volume of geopolymers produced from waste ashes. Neural Comput Appl. doi:10.1007/s00521-011-0760-x

API Specifications 5L (2007) Specifications for line pipe, 44th edn. American Petroleum Institute, Washington DC

Annual Book of ASTM Standards (1997) Metals test methods and analytical, section 3, vol 3.01. ASTM, Easton, USA, pp A751, E8, E23-93a, E45

Iranian Petroleum Standards (IPS) (2004) Material and equipment standard for line pipe, 2nd edn. Iranian Ministry of Petroleum, Tehran, Iran

Pickering FB (1978) Physical metallurgy and the design of steels, materials science series. Applied Science Publishers, London, pp 60–88

Jones BL (1984) ASM international conference on technology and applications of HSLA steels, Philadelphia, PA, 1983. ASM, Metals Park, OH, pp 715–722

Montemarano TW, Sack BP, Gudas JP, Vassilaros MG, Vanderveldt HH (1986) High strength low alloy steels in naval construction. J Ship Prod 2:145–162

Matsuda F, Fukada Y, Okada H, Shiga C, Ikeuchi K, Horii Y, Shiwaka T, Suzuki S (1996) Review of mechanical and metallurgical investigations of martensite-austenite constituent in welded joints in Japan. Welding in the World / Le Soudage dans le Monde, vol 37, issue 4, pp 134–154

Kawabata F, Okatsu M, Amano K, Nakanom Y (1995) Metallurgical and mechanical features of X100 line pipe steel. Pipeline Technol 2:263–271

Nazari A, Riahi S (2011) Prediction split tensile strength and water permeability of high strength concrete containing TiO2 nanoparticles by artificial neural network and genetic programming. Compos B Eng 42:473–488

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Khalaj, G., Azimzadegan, T., Khoeini, M. et al. Artificial neural networks application to predict the ultimate tensile strength of X70 pipeline steels. Neural Comput & Applic 23, 2301–2308 (2013). https://doi.org/10.1007/s00521-012-1182-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00521-012-1182-0