Abstract

Although small- and medium-sized enterprises (SMEs) shape the cornerstone of the economy, they encounter various challenges in managing the transition to Industry 4.0. This condition represents an ill-structured problem under uncertainty, which requires a set of specific tools to be solved. This study relies on an integrated approach composed of the interval type-2 fuzzy best–worst method (IT2F-BWM) and the interval type-2 fuzzy decision-making trial and evaluation laboratory (IT2F-DEMATEL) method, to handle the complexities that SMEs experience in the transition to Industry 4.0. The results of the IT2F-BWM revealed the priority of the “organizational” dimension over the “technological” and “strategic” dimensions. Furthermore, the IT2F-DEMATEL results showed that the “organizational” dimension exerted the highest degree of impact. The most effective criteria (sub-dimensions) were “the lack of a skillful management team,” “the need for advanced skills,” and “having insufficient knowledge of and little interest in Industry 4.0 and its outcomes,” which fell under the “organizational,” “technological,” and “strategic” dimensions, respectively. The findings could help firms and enterprises to gain adequate knowledge of Industry 4.0 before implementing it, while clarifying how such entities can enhance their organizations and overcome obstacles by training their human resources.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

In today’s competitive business environment, many organizations seek to implement smart technologies in their production systems to improve their productivity, reduce risks, protect the environment, and offer quality products. As a response to these concerns, the notion of Industry 4.0 has received prominence because of its advantages in production/manufacturing processes and environmental protection (Abdul Moktadir et al. 2018). Industry 4.0 was first proposed in 2011 by the Federal Republic of Germany in a cooperative project undertaken by universities and private firms, as a way to sustain German industries in international competition. This notion points to a new industrial production stage in which systems combine emerging and converging technologies to increase value added and improve the product life cycle (Frank et al. 2019).

In other words, the term Industry 4.0 refers to the Fourth Industrial Revolution, representing a new organizational level and control over the whole value chain and the product life cycle. This industrial advancement specifically focuses on customer needs (Mohamed 2018). Small- and medium-sized enterprises (SMEs) are among the active players in digital transformation and Industry 4.0, although they may be positively or negatively affected by the Fourth Industrial Revolution. Meanwhile, an important condition for sustainable success in today’s economy is to promote small businesses that can leave considerable impacts on society’s income stabilization, economic growth, and employment. Today, the economy of advanced countries rests on SMEs (Omidi et al. 2018).

Due to the effective functions of SMEs, they shape the “backbone” of the economy, and that is why policy-makers and scholars tend to focus on SMEs (Safar et al. 2018). Meanwhile, many SMEs have incorporated technologies and must gain awareness of such concepts as knowledge, strategy, and planning. A good planning structure could help to properly integrate digital processes into commercial activities. Many SMEs encounter key problems, such as continuous technology development and progressive innovation, which make it difficult to supervise enterprises and complicate the implementation of different processes (Sevinç et al. 2018). Formulating the features of SMEs is an important task that helps to understand how they work and how effective they are. Such features include the following items: proximity to the market and customers, flexibility in production, small-patch production, informal structures, joint research and development, information technology, and limited financial resources (Kleindienst and Ramsauer 2018).

Industry 4.0 allows SMEs to gain significant information about the practices they should employ in their internal processes, thus increasing SMEs’ value added. However, compared with large enterprises, SMEs are more likely to experience difficulties in implementing new technologies and in upgrading their business models (Safar et al. 2018: 626). In fact, Industry 4.0 represents a major challenge for SMEs to overcome, because they are only partially prepared to adapt themselves to Industry 4.0 practices. More specifically, the smaller an enterprise is, the less likely it is to benefit from the Fourth Industrial Revolution. Most SMEs, then, are not yet ready to practice Industry 4.0 technologies (Rauch 2018: 65).

The purpose of this study is to identify the challenges that SMEs face in implementing Industry 4.0. The study proposes a framework of the challenges and then evaluates and rank them, while offering suggestions that can help SMEs to overcome the challenges they encounter. Given the advantages of implementing Industry 4.0 (e.g., increased organizational agility, increased quality, improved productivity, an improved business status, a reduced failure rate, and increased profitability), Industry 4.0 practiced in SMEs could considerably contribute to such enterprises and ultimately lead to national economic growth. Yet, implementing Industry 4.0 would require research planning and performance evaluations that can detect the weaknesses and identify the challenges that complicate Industry 4.0 implementation.

The study involves several sections. Section 2 addresses the theoretical framework of the study and a review of the literature. Following an introduction to Industry 4.0, Sect. 2 focuses on the studies concerned with this issue and identifies the existing research gaps. Section 3 presents the research method. The same section primarily explains the concept of type-2 fuzzy, and then explores the research method, which combines BWM and DEMATEL. Section 4 reports the research results. This section presents the research findings in a step-by-step fashion in line with the research steps. Finally, Sect. 5 offers a discussion of the results, and Sect. 6 mentions the concluding remarks.

2 Theoretical foundations and literature review

The eighteenth century witnessed the Industrial Revolution when the steam engine was used as a source of power and generated remarkable transformations in the industries. The Second Industrial Revolution relied on electricity and assembly lines. Integrating information technology and computers in the production process led to the emergence of the Third Industrial Revolution. In recent years, too, the Fourth Industrial Revolution, usually called Industry 4.0, has been occurring. Industry 4.0 has brought about major transformations through smart engineering and digital integration (Muhuri et al. 2019). This situation reflects a new industrial stage of production in which systems are integrated through emerging and converging technologies and contribute to value added and the product life cycle. This new industrial stage rests on the evolution of human social and technical dimensions in production systems. As such, all business activities in a value chain are conducted through smart mechanisms based on information and communications technology. Industry 4.0 stems from advanced modes of production through smart processes. Systems flexibly and automatically adapt production processes to various types of products or conditions. This process could increase quality, productivity, and flexibility, while building customized products on a large scale and contributing to sustainability and optimal consumption (Frank et al. 2019).

The core elements of cyber-physical systems involve virtual reality, augmented reality, cloud calculations and computing, big data, and the Internet of things (Abdul Moktadir, et al. 2018; Frank et al. 2019; Khan and Turowski 2016; Sevinç et al. 2018). Cyber-physical systems, for instance, represent physical objects in a factory by their virtual objects, while using data integrity, artificial intelligence, and simulation (Frank et al. 2019). Virtual reality and augmented reality are technologies that add digital information to be used by all groups of potential users. They can also supply information to operators or line managers about a product and its production progress. Such modes of reality provide platforms for developing digital environments or shaping other manufacturing processes (e.g., role play, design, control, supervision, training) (Damiani et al. 2018). Cloud computing is not an entirely new idea, although there is no universal or standard definition of it. This process rests on recent advancements in hardware, digitalization technologies, calculations, and Internet-based services (Ghobakhloo 2018).

Cloud computing makes it easy to integrate various devices because it does not require physical closeness. It can even share information and coordinate activities (Frank et al. 2019). Big data technology refers to a new generation of architectures that enable an organization to generate economic value through detecting, capturing, and analyzing a large diversity of data (Ghobakhloo 2018). Big data, contrary to traditional tools, makes it possible to conduct more advanced data analysis. This technology processes and integrates data extracted from different systems, databases, and incompatible websites, providing a clear image of a firm’s status (Witkowski 2017).

The Internet of things describes the connectivity of smart components, in which different objects are linked to a network via software programs, electronic sensors, and digital drivers/devices. In this procedure, it would be possible to collect and exchange information as well. Smart components could be remotely controlled, while the physical world and computerized systems can be integrated (Stancioiu 2017). The Internet of things integrates sensors and calculations in an Internet-based environment through wireless connections (Frank et al. 2019).

Investigating the outlook of Industry 4.0, Khan and Turowski (2016) focused on the challenges and opportunities that production companies would face in implementing Industry 4.0. They introduced five challenges including data challenge, data exchange with partners, training and skill development, process flexibility, and security. In this categorization, “data exchange” was a key challenge. Kiel et al. (2017) explored the generation of sustainable industrial value, highlighting the advantages and challenges of the industrial Internet of things in 46 German manufacturing companies. The challenges observed in their study were technical integration, organizational transformation, data security, competition, participation, future sustainability, financial resources and profitability, human resources, customer-centeredness, and the public context. Among these elements, technical integration was the most serious challenge. Schroder (2017) probed into Industry 4.0 challenges in SMEs. The challenges found in this study were a lack of unified standards, a lack of data security, a lack of a digital strategy, and a shortage of resources. The SMEs’ major shortcomings were their inadequate information and limited bandwidth for high-speed transmission without any quality loss.

Abdul Moktadir et al. (2018) evaluated the challenges in Industry 4.0 implementation by exploring process safety and environmental protection in the Bangladeshi leather industry, through the best–worst method (BWM) as a multiple-criteria decision-making (MCDM) technique. Investigating four leather production companies, they managed to find ten challenges: data insecurity, high investment, limited technological infrastructure, instable connections between companies, reduced job opportunities, a lack of Industry 4.0 strategies, environmental side effects, the complex configuration of the production model, a lack of skilled management tools, and complexities in integrating information technology and operational technologies. Among these challenges, limited technological infrastructure was the most pressing challenge in implementing Industry 4.0. Luthra and Kumar Mangla (2018) evaluated the challenges to Industry 4.0 initiatives in relation to supply chain sustainability in emerging economies in India. They identified 18 challenges and ranked them through AHP; some of the challenges were: a lack of clear understanding of Industry 4.0 outcomes, limited research and development about accepting Industry 4.0, legal issues, a poor digital operation strategy, and limited support from the management. Organizational challenges revealed the highest degree of importance, followed by technological challenges, strategy, and legal ethics.

Mohamed (2018) provided an overall review of the challenges and advantages of Industry 4.0. Following an investigation of numerous publications, Mohamed observed the following challenges: uncertainty about financial benefits, no strategy to coordinate actions across different organizational units, a lack of courage to realize radical transformation, cyber-security issues, horizontal integration, vertical integration, life cycle management, a decline in the number of workers, increased organizational complexity, smart decision-making and negotiation mechanisms, investment problems, a reduction of development and innovation phases, and a lack of concentration. Sisinni et al. (2018) explored the challenges, opportunities, and trends in the industrial Internet of things. The challenges they observed in this area were the need for efficient energy resources, security and privacy, real-time performance, coexistence, and interoperability. Sevinç et al. (2018) analyzed SMEs’ problems in Industry 4.0, using AHP and ANP. They divided the challenges into four types: innovation, cost, environmental factors, and organizational factors. The research findings revealed organizational factors were more important than the other challenges, followed by cost, environmental factors, and innovation. Exploring documents within a 10-year period, Manda and Ben Dhauo (2019) used content analysis to identify the challenges associated with the Fourth Industrial Revolution in terms of losing jobs, infrastructure, and privacy. In the case of Europe, they also observed that Industry 4.0 challenges included investment, a change in business models, data-related concerns, legal issues, standards, and incompatible skills. In the case of Germany, there were such social challenges as losing one’s job, disqualification, new types of stress, and social insecurity. Ulewicz et al. (2019) investigated Industry 4.0 challenges in SMEs in Poland and Slovakia. They introduced such Industry 4.0 challenges as a shortage of specialists, an educational system incompatible with the new needs in the labor market, limited capital, a lack of knowledge of Industry 4.0, and data security. The most important challenges were limited capital and a shortage of specialists.

As the review of the above studies suggests, research in this field, especially in the case of SMEs, remains underdeveloped, and there is no consensus on the challenges. Methodologically speaking, employing type-2 fuzzy (IT2F) sets could help to better model uncertainty in this area. Given this idea, the present study seeks to identify and rank the challenges and categorize them in the light of the dimensions related to SMEs. The reason SMEs are highly important is that they considerably contribute to employment and serve as drivers of large- and medium-sized industries. To further enhance the results, the study relies on an integrated technique composed of the interval type-2 fuzzy BWM (IT2F-BWM) and interval type-2 fuzzy DEMATEL (IT2F-DEMATEL).

3 Research method

This study was an applied survey that followed descriptive purposes. The population included small- and medium-sized food industry companies in Fars province, Iran. Five experts who were specialized in food industries or in Industry 4.0 completed copies of a questionnaire. The IT2F-BWM helped to determine the weights. Furthermore, to decide the relationships between the challenges, the IT2F-DEMATEL method was employed.

3.1 Type-2 fuzzy

In 1975, Zadeh proposed the type-2 fuzzy set as an extended version of fuzzy sets. Following that, to distinguish ordinary fuzzy sets from type-2 fuzzy sets, the former ones were called type-1 fuzzy sets. Type-2 fuzzy logic, then, is an extended form of type-1 fuzzy logic and includes two fuzzy degrees of membership. For this reason, they are also called “fuzzy–fuzzy sets” as well. Such sets are capable of dealing with and reducing the effect of uncertainty while modeling it (Coupland and John 2008). A type-2 fuzzy set, such as \(\tilde{A}\), may be characterized by the membership function \(\mu_{{\tilde{A}}} \left( {x,u} \right)\), where x ∈ X and u ∈ [0, 1]. As such, we have:

where x is a primary variable in the universe of discourse X. The type-2 membership function is represented as \(\mu_{{\tilde{A}}} \left( {x,u} \right)\). The secondary variable is u for each \(x \in X\), and \(j_{x}\) represents the primary membership degree of x as follows (Shukla et al. 2020):

Let X be the universe of discourse. If all \({\upmu }_{{{\tilde{\text{A}}}}} \left( {{\text{x}},{\text{u}}} \right)\) = 1, then \(\tilde{A}\) is called an interval type-2 fuzzy set (IT2FS) and can be formulated as:

Let X be the universe of discourse. The FOU of the IT2FS \(\tilde{A}\), denoted by FOU (\(\tilde{A}\)), can be expressed as:

where \(\underline {\mu }_{{\tilde{A}}} \left( x \right)\) and \(\overline{\mu }_{{\tilde{A}}} \left( x \right)\) are defined as:

and

For the IT2FS \(\tilde{A}\), \(\mu_{{\tilde{A}}} \left( x \right)\) and \(\overline{\mu }_{{\tilde{A}}} \left( x \right)\) are the lower MF (LMF) and the upper MF (UMF), respectively. IT2FSs are usually visualized in a simplified form, such as a trapezoidal fuzzy set for the UMF and a triangular fuzzy set for the LMF (Fig. 1):

where \(a_{1}^{U} ,a_{2}^{U} ,{ }a_{3}^{U} ,{ }a_{4}^{U} ,{ }a_{{\tilde{A}}}^{U} ,{ }a_{1}^{L} ,{ }a_{2}^{L} ,{ }a_{3}^{L} { }\;{\text{and}}\;{ }a_{{\tilde{A}}}^{L}\) are all real values, \({a}_{1}^{U}\le {a}_{2}^{U}\le {a}_{3}^{U}\le {a}_{4}^{U},{a}_{1}^{L}\le {a}_{2}^{L}\le {a}_{3}^{L}\) and \(0\le {h}_{\widetilde{A}}^{L}\le {h}_{\widetilde{A}}^{U}\le 1.\) In the case of \({h}_{\widetilde{A}}^{U}={h}_{\widetilde{A}}^{L}=1,\) IT2FSs degenerate to normal IT2FSs, and the canonical form of a normal IT2FS can be further formulated via:

The corresponding UMF \(\overline{\mu }_{{\tilde{A}}} \left( x \right)\) and LMF \(\underline {\mu }_{{\tilde{A}}} \left( x \right)\) are:

Let \(\tilde{A} = [(a_{1}^{U} ,{ }a_{2}^{U} ,{ }a_{3}^{U} ,{ }a_{4}^{U} ),{ }\left( {a_{1}^{L} ,{ }a_{2}^{L} ,{ }a_{3}^{L} } \right){ }\;{\text{and }}\;\tilde{B} = [\left( {a_{1}^{U} ,a_{2}^{U} ,a_{3}^{U} ,a_{4}^{U} } \right){ },{ }\left( {a_{1}^{L} ,{ }a_{2}^{L} ,{ }a_{3}^{L} } \right)\), as two normal IT2FSs; their numerical operations would be as follows:

-

(1)

Subtraction:

$$\widetilde{A}-\widetilde{B}=\left[\left({a}_{1}^{U}-{b}_{1}^{U}, {a}_{2}^{U}-{b}_{2}^{U}, {a}_{3}^{U}-{b}_{3}^{U}, {a}_{4}^{U}-{b}_{4}^{U}\right), \left({a}_{1}^{L}-{b}_{1}^{L}, {a}_{2}^{L}-{b}_{2}^{L}, {a}_{3}^{L}-{b}_{3}^{L}\right)\right].$$(11) -

(2)

Addition:

$$\widetilde{A}+\widetilde{B}=\left[\left({a}_{1}^{U}+{b}_{1}^{U}, {a}_{2}^{U}+{b}_{2}^{U}, {a}_{3}^{U}+{b}_{3}^{U}, {a}_{4}^{U}+{b}_{4}^{U}\right), \left({a}_{1}^{L}+{b}_{1}^{L}, {a}_{2}^{L}+{b}_{2}^{L}, {a}_{3}^{L}+{b}_{3}^{L}\right)\right].$$(12) -

(3)

Multiplication:

$$\widetilde{A}\times \widetilde{B}=\left[\left({a}_{1}^{U}{b}_{1}^{U}, {a}_{2}^{U}{b}_{2}^{U}, {a}_{3}^{U}{b}_{3}^{U}, {a}_{4}^{U}{b}_{4}^{U}\right), \left({a}_{1}^{L}{b}_{1}^{L}, {a}_{2}^{L}{b}_{2}^{L}, {a}_{3}^{L}{b}_{3}^{L}\right)\right]$$(13) -

(4)

Scalar multiplication:

$$\widetilde{kA}=\left[\left(k{a}_{1}^{U},k{a}_{2}^{U}, {ka}_{3}^{U}, {ka}_{4}^{U}\right), \left({ka}_{1}^{L}, {ka}_{2}^{L}, {ka}_{3}^{L}\right)\right]$$(14) -

(5)

Exponential operation:

$${\widetilde{A}}^{k}=[(({{a}_{1}^{U})}^{k}, ({{a}_{2}^{U})}^{k}, ({{a}_{3}^{U})}^{k}, \left({{a}_{4}^{U})}^{k}\right),(({{a}_{1}^{L})}^{k}, \left({{a}_{2}^{L})}^{k}, \left({{a}_{3}^{L})}^{k}\right)\right].$$(15) -

(6)

Division:

$$\widetilde{A}/\widetilde{B}=\left[\left({a}_{1}^{U}/{b}_{1}^{U}, {a}_{2}^{U}/{b}_{2}^{U}, {a}_{3}^{U}/{b}_{3}^{U}, {a}_{4}^{U}/{b}_{4}^{U}\right), \left({a}_{1}^{L}/{b}_{1}^{L}, {a}_{2}^{L}/{b}_{2}^{L}, {a}_{3}^{L}/{b}_{3}^{L}\right)\right].$$(16) -

(7)

Let \(\tilde{A} = [(a_{1}^{U} ,{ }a_{2}^{U} ,{ }a_{3}^{U} ,{ }a_{4}^{U} ),{ }\left( {a_{1}^{L} ,{ }a_{2}^{L} ,{ }a_{3}^{L} } \right){ }\;{\text{and}}\;{ }\tilde{B} = [\left( {a_{1}^{U} ,a_{2}^{U},a_{3}^{U},a_{4}^{U} } \right){ },{ }\left( {a_{1}^{L} ,{ }a_{2}^{L} ,{ }a_{3}^{L} } \right),\) as two normal IT2FSs; then, the approximated absolute deviation degree (AADD) between them is

$$ {\text{AADD}}\left( {\tilde{A},\tilde{B}} \right) = \frac{1}{7}\left( {\mathop \sum \limits_{i = 1}^{4} |a_{i}^{U} - b_{i}^{U} \left| { + \mathop \sum \limits_{i = 1}^{3} |a_{i}^{L} - b_{i}^{L} } \right|} \right) $$(17)(Wu et al 2019).

3.2 The best–worst method

Over the past decades, several MCDM models have been introduced. Such models have helped decision-makers (DM) to calculate the values of criteria and alternatives based on their preferences. One of the recently proposed MCDM models is called the BWM, which is regulated by comparisons. However, the BWM requires fewer and more consistent comparisons (Rezaei 2015). This method helps to weight criteria and alternatives through various elements, based on paired comparisons and a less volume of data (Alimohammadlou and Khoshsepehr 2022a). Meanwhile, the BWM can effectively correct inconsistencies in paired comparisons (Alimohammadlou and Khoshsepehr 2022b). The BWM determines the preference of the best criteria over the others, while showing the preference of all criteria over the worst one by a number falling between 1 and 9. This simple procedure is precise because it does not conduct secondary comparisons (Guo and Zhao 2017). Guo and Zhao (2017) proposed the fuzzy BWM, and Wu et al. (2019) introduced the type-2 fuzzy BWM.

3.3 DEMATEL

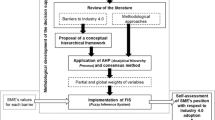

The DEMATEL technique was first proposed by the Geneva Research Centre of the Battelle Memorial. DEMATEL visualizes complex, causal relationships through matrices and charts. As a mode of structural modeling, the technique is particularly effective in analyzing causal relationships between the components of a system, and it can confirm interdependencies among the factors to reflect the relative relationships they have. DEMATEL, then, is used to investigate and solve complex and interwoven problems. The technique not only converts mutual relationships into cause–effect groups through matrices, but also it schematically depicts the relationships between the vital elements in a complex system (Sheng et al. 2018). Results obtained through this technique demonstrate (in)direct relationships between systems (Permadi et al. 2019). Ping Lin et al. (2018) first suggested fuzzy DEMATEL, and Abdullah and Zulkifli (2016) proposed IT2F-DEMATEL. In this study, the research stages were governed by combining the IT2F-based BWM and DEMATEL (see Fig. 2).

4 Review the literature

Phase 1: Review the literature and identify the challenges

Step 1: Review the literature and identify the challenges to Industry 4.0 implementation in SMEs

Exploring the studies concerned with Industry 4.0 implementation helped to identify the challenges that SMEs would encounter in implementing Industry 4.0.

Phase 2: Determine the weights of the challenges through the IT2F-BWM

Step 2: Determine the most important and worst challenges

Consider an evaluation problem with n criteria. A general way to calculate the weights of the criteria is to construct preference relations (PR) for the n criteria through:

where \({a}_{ij}\) represents the preference degree of criterion i over criterion j.

The PR of A is perfectly consistent if it satisfies \({a}_{ij}={a}_{ik}\times {a}_{kj}, \forall i, j, k\in N\). However, PRs usually involve inconsistencies, and expressing the degree of preference is the leading cause of inconsistency. As Rezaei (2015) explains, when there is a set of criteria, it would be convenient and practical to determine the most important criterion and the least important one. Once the best and worst criteria are detected, linguistic preferences can be viewed in two ways:

-

Best–worst linguistic reference vectors (BWLRVs);

-

Secondary linguistic preference (SLP) elements.

(\({a}_{i1}, {a}_{i2}, \dots {a}_{in})\,\,\mathrm{ and}\,\,({a}_{1j},{a}_{2j}, \dots , {a}_{nj})\) are defined as BWLRVs in which i is the best criterion and j is the worst one. The linguistic preference element \({a}_{ij}\) is defined as a SLP if neither i nor j is the best or worst criterion.

Step 3: Compare the most important challenge with the other ones and compare all challenges with the worst challenge

In a PR with n alternatives, the total number of comparisons is \({n}^{2}.\) After removing the diagonal elements, n (n − 1) comparisons remain. Considering the reciprocity of a PR, at least n (n − 1) / 2 comparisons are needed. In the case of the BWM, only 2n − 3 comparisons are needed, and the rest are SLPs. It is possible to obtain the SLPs using the BWLRVs. Each SLP \({a}_{ij}\) appears in two relation chains: \(a_{{{\text{Best}},i}} \times a_{ij} = a_{{{\text{Best}},{ }j}} ,{ }a_{ij} \times a_{{j,{\text{ Wirst}}}} = a_{{i,{\text{Worst}}}}\)\(.\) The SLPs function like intermediaries in the comparison chain. Next, the weights should be extracted based only on the BWLRVs. After the BWLRVs are obtained, they are transformed into IT2FSs based on Table 1.

The obtained IT2F best-to-others (IT2FBO) and IT2F others-to-worst (IT2FOW) vectors are:

Clearly, \({\widetilde{A}}_{BB}={\widetilde{A}}_{WW}=\left[\left(\mathrm{1,1},\mathrm{1,1}\right),\left(\mathrm{1,1},1\right)\right].\)

The definition of a consistent IT2F preference (IT2FP) is as follows:

The IT2FP \(\widetilde{{A}_{jk}}\) is consistent if

Step 4: Compute IT2Foptimal weights

In MCDM problems, it is crucial to determine the weights of the criteria. Assume the optimal IT2F weighting vector is \(\widetilde{W}={({\widetilde{w}}_{1}, {\widetilde{w}}_{2},\dots , {\widetilde{w}}_{n})}^{T}\). For the weights of all criteria, the IT2F weight of the best criterion is \({\widetilde{w}}_{B}\), and that of the worst criteria is \({\widetilde{w}}_{W}\). Consider the elements in the IT2FBO and IT2FOW vectors. If the IT2FP is perfectly consistent, then \({\widetilde{w}}_{B}/ {\widetilde{w}}_{W}={\overline{A} }_{Bj}\) and \({\overline{w} }_{j}/{\overline{w} }_{W}={\overline{A} }_{jw}.\) In general, perfectly consistent IT2FPs are difficult to obtain. To achieve the highest consistency rate, one creative solution is to minimize the maximum absolute gaps between \(|\frac{{\overline{w} }_{B}}{{\overline{w} }_{j}}-{\overline{A} }_{Bj}|\) and \(|\frac{{\overline{w} }_{j}}{{\overline{w} }_{w}}-{\overline{A} }_{jw}|.\) After achieving the IT2F weights of the criteria, a normalization process is needed. At this stage, the centroid of the IT2FSs should be taken into account. Based on the above analysis, the following constrained optimization model should be constructed to obtain the optimal IT2F weights \({\overline{\mathrm{W}} }^{*}={({\overline{\mathrm{w}} }_{1}^{*},{\overline{\mathrm{w}} }_{2}^{*}, \dots , {\overline{\mathrm{w}} }_{n}^{*})}^{T}\):

where \({\overline{w} }_{B}=\left[\left({\overline{w} }_{B1}^{U},{\overline{w} }_{B2}^{U},{\overline{w} }_{B3}^{U},{\overline{w} }_{B4}^{U}\right),\left({\overline{w} }_{B1}^{L},{\overline{w} }_{B2}^{L},{\overline{w} }_{B3}^{L}\right)\right],\) \({\overline{w} }_{j}=[\left({\overline{w} }_{J1}^{U},{\overline{w} }_{J2}^{U},{\overline{w} }_{J3}^{U},{\overline{w} }_{J4}^{U}\right), ({\overline{w} }_{J1}^{L},{\overline{w} }_{J2}^{L},{\overline{w} }_{J3}^{L})\), \({\overline{w} }_{w}\left[\left({\overline{w} }_{W1}^{U},{\overline{w} }_{W2}^{U},{\overline{w} }_{W3}^{U},{\overline{w} }_{W4}^{U}\right),\left({\overline{w} }_{W1}^{L},{\overline{w} }_{W2}^{L},{\overline{w} }_{W3}^{L}\right)\right],\) \({\overline{A} }_{B.J}=\left[\left({\overline{w} }_{B.J1}^{U},{\overline{w} }_{B.J2}^{U},{\overline{w} }_{B.J3}^{U},{\overline{w} }_{B.J4}^{U}\right),\left({\overline{w} }_{B.J1}^{L},{\overline{w} }_{B.J2}^{L},{\overline{w} }_{B.J3}^{L}\right)\right],\) \({\overline{A} }_{J.W}\left[\left({\overline{w} }_{J.W1}^{U},{\overline{w} }_{J.W2}^{U},{\overline{w} }_{J.W3}^{U},{\overline{w} }_{J.W4}^{U}\right),\left({\overline{w} }_{J.W1}^{L},{\overline{w} }_{J.W2}^{L},{\overline{w} }_{J.W3}^{L}\right)\right]\)

To avoid obtaining multiple optimal solutions from the model, one can minimize the maximum absolute gaps between \(|\frac{{\overline{w} }_{B}}{{\overline{w} }_{j}}\times {\overline{A} }_{Bj}|\) and \(|\frac{{\overline{w} }_{j}}{{\overline{w} }_{w}}\times {\overline{A} }_{jw}|.\) To solve the model under the assumption that the maximum absolute gap is \({\overline{\delta }}^{*}=[\left({\delta }^{*},{\delta }^{*},{\delta }^{*},{\delta }^{*}\right),({\delta }^{*},{\delta }^{*},{\delta }^{*})\), the model can be transformed through the following programming model:

The solution space of the model is an intersection of several linear constraints. One of them applies to the sum of the weights and some apply to the IT2FSs. To achieve a sufficiently large \({\delta }^{*}\) value, the solution space is non-empty. Therefore, a feasible region must exist. After solving the model, the optimal weights are obtained as \(({\overline{w} }_{1}, {\overline{w} }_{2},\dots ,{\overline{w} }_{n}{)}^{T}\mathrm{and }\,{\delta }^{*}\).

Step 5: Determine the consistency ratio

The consistency ratio (CR) is an effective index that reflects the degree of consistency in PRs (Table 2).

The CR inspects the degree of consistency and the reliability of the obtained weights through:

where CR ∈ [0, 1], CR → 0 indicates greater consistency, and CR → 1 indicates less consistency (Wu et al 2019).

Phase 3: Determine the relationships between the challenges through IT2F-DEMATEL

Step 6: Create the initial direct relation matrix

The experts’ judgments about the relationships between the challenges are measured on a scale ranging from “No influence” to “Very high influence,” and are transformed into IT2F numbers (see Table 3). Next, the initial direct relation matrix is created by aggregating the opinions of the DMs.

The IT2F score \({x}_{ij}^{k}\) is given by the DM k and indicates the influence level that the criterion i has on the criterion j. The m × n matrix is computed through Eq. (24) by calculating the average score of each of the DMs.

where H is the total number of the DMs and \(x_{ij}^{k} = \left( {a_{1}^{U} ,a_{2}^{U} ,{ }a_{3}^{U} ,{ }a_{4}^{U} } \right),{ }\left( {a_{1}^{L} ,{ }a_{2}^{L} ,{ }a_{3}^{L} { }} \right)\), where \(a_{1}^{U} ,a_{2}^{U} ,{ }a_{3}^{U} ,\,\,{\text{and}}\,\, a_{4}^{U}\) are the UMF, and \({a}_{1}^{L}, {a}_{2}^{L}, \,\,\text{and}\,\, {a}_{3}^{L}\) are the LMF (the heights of the UMF; the LMF is 1). The matrix \({A}_{ij}\) shows the initial direct relations that a criterion exerts on and receives from other criteria.

Step 7: Normalize the direct relations

Based on the initial direct relation matrix \({A}_{ij}\), the initial normalized direct relation matrix D could be computed through the following equations:

where \(\underset{1\le i\le n}{\mathrm{max}}\sum_{j=1}^{n}{A}_{ij}\) is the total direct effects of the criterion i with the most direct effects on others, and \(\underset{1\le i\le n}{\mathrm{max}}\sum_{i=1}^{n}{A}_{ij}\) is the total direct effects that the criterion j receives the most from other criteria. In other words, Eq. (26) helps to find the sum of each row of the matrix A, which represents the total direct effects the criterion i gives to the other criteria, as well as the sum of each column of the matrix A, which represents the total direct effects the criterion i receives from other criteria.

Step 8: Create the Z matrix

The matrix Z is constructed by arranging the matrix N according to the membership functions:

where \({\text{x}} = \left( {{\text{UMF}},{\text{LMF}}} \right) \, = \left( {a_{1}^{U} ,a_{2}^{U} ,{ }a_{3}^{U} ,{ }a_{4}^{U} } \right)\), \(\left( {a_{1}^{L} ,{ }a_{2}^{L} ,{ }a_{3}^{L} { }} \right).\) As a result, there are seven n × n matrices. The construction of the n × n matrix is needed for the calculations in the next step because it involves the multiplication of matrices between the matrix Z and the identity matrix. The row of the matrix Z must be matched with the column of the identity matrix.

Step 9: Create the total influence matrix

The total influence matrix T is created using Eq. (28), in which \(I\) denotes the identity matrix.

Step 10: Analyze structural correlations

Equations (29)–(31) help to calculate the sum of the rows and the sum of the columns as represented by the R vector and the C vector, respectively. As such, \(R+C\) and \(R-C\) are computed.

where \(x = \left( {{\text{UMF}},{\text{LMF}}} \right) = \left( {\left( {a,b,c,d} \right),\left( {g,h,I,j} \right)} \right)\).

Step 11: Determine the expected value E(W)

The expected values are computed through Eq. (32):

Where \(W=\left({W}_{1}^{U},{W}_{i}^{L}\right)=\left(\left({w}_{1}^{U},{w}_{2}^{U},{w}_{3}^{U},{w}_{4}^{U};\right), \left({w}_{1}^{L},{w}_{2}^{L},{w}_{3}^{L}\right)\right)\)

Step 12: Integrate the fuzzy weights and the expected value E(W)

The fuzzy weights from Eq. (22) in phase 3 are combined with the E(W). The new expected value is obtained through the multiplication operation as defined in Eq. (33).

Step 13: Create the causal diagram

The horizontal axis vector \({R}_{i}+{C}_{i}\), called “Prominence,” shows the degree of importance that the criterion i has in the system. The vertical axis \({R}_{i}-{C}_{i}\), called “Relation,” shows the net effect the criterion i exerts on the system. When the \({R}_{i}-{C}_{i}\) value is positive, the criterion i is a net causer, while when the \({R}_{i}-{C}_{i}\) value is negative, the criterion i is a net receiver.

5 Results

Phase 1: Review the literature and identify the challenges

Step 1: Review the literature and identify the challenges to Industry 4.0 implementation in SMEs

To find the studies addressing Industry 4.0 implementation in SMEs, publications indexed on the Scopus database and the Web of Science database after 2011 were searched using such keywords as “Fourth Industrial Revolution,” “challenges to Industry 4.0 implementation,” “challenges of Industry 4.0 in SMEs.” The search procedure found 95 publications. Next, after the titles of the publications were further inspected, 36 publications were removed. After that, through an investigation of the abstracts, 30 publications were further omitted. Finally, after full-text readings of the publications, 18 papers were also eliminated from the process, and ultimately 11 publications were selected for analysis. After analyzing the content of the publications, the challenges to the implementation of Industry 4.0 in SMEs were categorized into four groups (see Table 4).

Phase 2: Determine the weights of the challenges through the IT2F-BWM

Step 2: Determine the most important and worst challenges

Primarily, the most important and worst challenges were identified by the experts, who expressed their opinions by completing copies of a questionnaire. The items in the questionnaire were measured based on a 1–9 scale.

Step 3: Compare the most important challenge with the other ones and compare all challenges with the worst challenge

Tables 5 and 6 show the preferences decided by one of the experts.

Based on the content in Table 1, the importance levels of the experts’ linguistic expressions were converted into fuzzy numbers. The following vectors are IT2FBO and IT2FOW.

The IT2FBO vector:

The IT2FOW vector:

Step 4: Compute IT2F optimal weights

To calculate the IT2F optimal weights, the following optimization model was used based on the IT2F-BWM.

After the models were processed in MATLAB version 2020, the IT2F optimal weights for the three criteria were obtained:

The final weights of the three criteria were computed by averaging each weight:

Step 5: Determine the consistency ratio

The desired value of \({\updelta }^{*}\) was calculated via Eq. (23). Because \({\updelta }^{*}=0.21\), CR = 0.101176 was very close to 0, which showed the high degree of consistency of the IT2F-BWM. Table 7 shows the weights computed through the IT2F-BWM for all experts. The final weights were obtained by averaging the values of the experts’ opinions.

The same procedure was conducted for the sub-dimensions as well; Table 8 shows the final weight.

Phase 3: Determine the relationships between the challenges through IT2F-DEMATEL

Step 6: Create the initial direct relation matrix

In this step, the expert opinions from the questionnaires were converted into IT2F numbers, and then the matrix of direct relations was created by aggregating the DMs’ opinions in line with Eq. (24). For instance, the matrix A included the initial direct relation matrix of the dimensions.

where

Step 7: Normalize the direct relation matrix

The normalized direct relation matrix of the challenges, called the matrix D, was created through Eqs. (25)–(26):

where \(\left( {\frac{{A_{i, j}^{U} }}{1.82}, \frac{{A_{i, j}^{L} }}{1.67}} \right)\)

Step 8: Create the Z matrix

Given the membership functions in Eq. (27), the matrix D was sorted. There were seven n × n matrices: \({ }Z_{a} { }Z_{b} { }Z_{c} { }Z_{d} { }Z_{e} { }Z_{f} { }Z_{g}\). For instance, \(Z_{a}\) was constructed as follows:

Step 9: Create the total influence matrix T

The total influence matrix T was created based on Eq. (28):

The same procedure was used to create \({ }T_{b} { }T_{c} { }T_{d} { }T_{e} { }T_{f} { }T_{g}\).

Step 10: Analyze structural correlations

The sum of the rows and the sum of the columns were analyzed structural correlations. \(D+C\) and \(D-C\) were computed through Eqs. (29)–(31). For instance, the first upper IT2FS elements in D1 were:

In this part, due to the large number of calculations made, Tables 9 and 10 only mention the main data of the IT2FS.

Step 11: Determine the expected value E(W)

The estimated values were computed via Eq. (32). Through IT2F and trapezoidal values, Di − Ci and Di + Ci were converted into normalized values (see Table 11).

The same calculative procedure was pursued for the sub-dimensions as well; the final results are listed in columns D + C and D−C in Table 13.

Step 12: Integrate the fuzzy weights and the expected value E(W)

Equation (33) calculated the new values of D + C and D − C, as reported in Tables 12 and 13.

Step 13: Create the causal diagram

The causal diagrams were created using the values of Di − Ci (the horizontal axis) and of Di + Ci (the vertical axis). Figures 3 and 4 show the causal diagrams of the dimensions and their sub-dimensions, respectively.

The horizontal axis depicts the importance of each criterion, whereas the vertical axis could divide the criteria into cause–effect groups. Causal diagrams visualize the complex causal relationships in a structural model, providing valuable insight into the problem under investigation. Causal diagrams could also make it possible for DMs to select better choices by gaining a clear understanding of causes and effects. As an instance, the criterion “a lack of research and development activities compatible with Industry 4.0” (C32), which appears at the top of the diagram in Fig. 4, was a factor that affected the other factors and was recognized as a “cause.” In contrast, “problems in data collection and data sharing” (C13), at the bottom of the diagram in Fig. 4, was identified as an “effect.” That is, C13 was caused by the other criteria.

6 Discussion

The integrated framework composed of the IT2F-BWM and IT2F-DEMATEL revealed some interesting findings. First, the weights of the dimensions in Table 7 show that the “organizational” dimension (0.5) was the most important factor. This dimension included 9 criteria (challenges), among which “having no competence in applying new business models” (0.18) was the most significant challenge. Meanwhile, “stimulating job opportunities” (0.06) was the least important challenge. As far as the “technological” dimension is concerned, “the need for advanced skills” (0.2612) was the most effective challenge, whereas “the need for a high degree of investment” (0.0803) was the least impactful challenge. Among the factors of the “strategic” dimension, “having insufficient knowledge of and little interest in Industry 4.0 and its outcomes” (0. 2731) was the most important challenge, although “governmental laws and support” (0. 0774) was the least important element.

The results arising from the integrated model revealed other interesting issues as well. Tables 12 and 13 could help organizations to make in-depth decisions. For instance, among the three dimensions, the “organizational” dimension (D2) involved the most significant criterion with the highest D + C value. The “organizational” dimension also included the most influential (influence-giving) criterion (D − R). Yet, the criterion with the least degree of priority, with a R − D value of − 0.37, fell under the “strategic” dimension (D3). This criterion received a considerable degree of influence from the other criteria. Given the importance rates (R + D), the dimensions could be prioritized in the following order: \(D2>D3>D1\).

Among the factors of the “technological” dimension, “the need for advanced skills” (C11) showed the highest D + R value (1.94), whereas “the complexity of constructing production models” (C17) displayed the least value. In the case of the “organizational” dimension, “the lack of a skillful management team” (C22) had the highest D + R value (1.831), while “stimulating job opportunities” (C21) revealed the least value. At the “strategic” level, “having insufficient knowledge of and little interest in Industry 4.0 and its outcomes” (C36) exhibited the highest D + R value, while “governmental laws and support” (C33) showed the least value.

These observations can help organizations to make better decisions about overcoming the challenges they encounter. The findings suggested that “organizational” challenges had the highest degree of importance, which was a finding compatible with the observations of Sevinç et al. (2018) and Luthra and Kumar Mangla (2018). As such, to develop Industry 4.0, organizations must improve their capacities in terms of skilled workforce, strategic organizational policies, and leadership tools. High-ranking management must actively pursue such transformations.

The most effective challenge in the “technological” dimension was “the need for advanced skills.” This issue was also pointed out in the studies conducted by Hamedi and Zamani-Babgohari (2019) and by Manda and Ben Dhauo (2019). Managers can contribute to Industry 4.0 implementation by recruiting and developing creative and efficient human resources and by holding advanced training courses. In the case of “organizational” challenges, “the lack of a skillful management team” was the most effective challenge. This problem was also reported by Hamedi and Zamani-Babgohari (2019), Abdul Moktadir et al. (2018), Sevinç et al. (2018), Luthra and Kumar Mangla (2018), and Ulewicz et al. (2019). Therefore, by training competent employees, managers can further expand their businesses.

In the case of the “strategic” dimension, “having insufficient knowledge of and little interest in Industry 4.0 and its outcomes” was the most effective challenge. This element was recognized as an impactful challenge in the studies conducted by Luthra and Kumar Mangla (2018), Sevinç et al. (2018), Mohamed (2018), and Ulewicz et al. (2019). Arranging training courses and seminars, SME managers can deepen their employees’ understanding of Industry 4.0 and its advantages. Another strategy is to highlight the benefits gained by SMEs that employ Industry 4.0, as a way of encouraging decision-makers to expand this industry.

7 Conclusion

Industry 4.0 has brought about a revolution that can transform manufacturing plants and production systems. It provides a totally novel approach to production and the ways production methods can be integrated to achieve maximum output while using a minimum amount of resources. In implementing the principles of Industry 4.0, SMEs face numerous challenges that should be addressed before employing smart systems in their operations. This study sought to identify and evaluate Industry 4.0 implementation challenges in SMEs.

The challenges identified were first extracted by reviewing the literature and the studies concerned with smart production and the Fourth Industrial Revolution. Finally, 24 challenges were selected and were divided into three dimensions: “organizational” (9 challenges), “technological” (8 challenges), and “strategic” (6 challenges). Next, the weights of the challenges were computed through the IT2F-BWM, and the relationships between the challenges were clarified via the IT2F-DEMATEL method. Chou et al. (2012) proposed an integration of IT2F-DEMATEL and AHP. Likewise, Wu et al. (2019) incorporated the IT2F-BWM into VIKOR.

The present study, however, provided a new integrated method composed of the IT2F-BWM and IT2F-DEMATEL, to handle the topic under investigation. This integrated methodology involved three phases: In phase 1, the literature was reviewed to identify Industry 4.0 implementation challenges SMEs encountered. The IT2F-BWM was employed in phase 2, when the relative weights of the criteria were computed. In phase 3, the IT2F-DEMATEL method used fuzzy and IT2F trapezoidal numbers to avoid the reflection of ambiguity in the MCDM problems.

The proposed IT2F-BWM would require fewer paired comparisons, while providing more reliable weights than the fuzzy BWM and the original BWM. One practical advantage of this method lies in its use of IT2FSs instead of type-1 fuzzy sets, paving the way for a novel approach to linguistic decision-making. Additionally, the IT2F-based DEMATEL method divided the criteria into cause and effect groups. This methodology was more flexible thanks to the introduction of fuzzy trapezoidal numbers to the IT2F-BWM and to IT2F-DEMATEL. The procedure would make it possible to configure a model of real-life problems that are usually characterized by incorrect, ambiguous, and indeterminate information. Furthermore, the method used the weights obtained through the IT2F-BWM in phase 2 to calculate the predicted values in phase 3, incorporating the IT2F-BWM and the IT2F-DEMATEL method. This integrated method could provide a more plausible approach to the solution of MCDM problems, as it employs IT2FSs.

Data availability

Enquiries about data availability should be directed to the authors.

References

Abdul Moktadir Md, Mithun Ali S, Sarpong S, Aftab Ali Shaikh Md (2018) Assessing challenges for implementing Industry 4.0: Implications forprocess safety and environmental protection. Process Saf Environ Prot. https://doi.org/10.1016/j.psep.2018.04.020

Abdullah L, Zulkifli N (2016) Integration of fuzzy AHP and interval type-2 fuzzy DEMATEL: an application to human resource management. Expert Syst APpl 42:4397–4409. https://doi.org/10.1016/j.eswa.2015.01.021

Alimohammadlou M, Khoshsepehr Z (2022a) Green-resilient supplier selection: a hesitant fuzzy multi-criteria decision-making model. Environ Dev Sustain 24(12):1–37. https://doi.org/10.1007/s10668-022-02454-9

Alimohammadlou M, Khoshsepehr Z (2022b) Investigating organizational sustainable development through an integrated method of interval-valued intuitionistic fuzzy AHP and WASPAS. Environ Dev Sustain 24(2):2193–2224

Chou Y, Sun C, Yen H (2012) Evaluating the criteria for human resource for science and technology (HRST) based on an integrated fuzzy AHP and fuzzy DEMATEL approach. Appl Soft Comput 12(1):64–71. https://doi.org/10.1016/j.asoc.2011.08.058

Coupland S, John R (2008) Type-2 fuzzy logic and the modelling of uncertainty. In: Fuzzy sets and their extensions: representation aggregation and models, vol 220. Springer-Verlag, Germany, Berlin, pp 3–22

Damiani L, Demaratini M, Guizzi G, Revetria R, Tonelli F (2018) Augmented and virtual reality applications in industrial systems: a qualitive review towards the industrt 4.0 Era. IFAC PapersOnline 51(11):624–630. https://doi.org/10.1016/j.ifacol.2018.08.388

Frank AG, Dalenogare LS, Ayala NF (2019) Industry 4.0 technologies: implementation patterns in manufacturing companies. Int J Prod Econ 210:15–26. https://doi.org/10.1016/j.ijpe.2019.01.004

Ghobakhloo M (2018) The future of manufacturing industry: a strategic roadmap toward Industry 4.0. J Manuf Technol Manag 29(6):910–936. https://doi.org/10.1108/JMTM-02-2018-0057

Guo S, Zhao H (2017) Fuzzy best-worst multi-criteria decision-making method and its applications. Knowl-Based Syst 121:23–31. https://doi.org/10.1016/j.knosys.2017.01.010

Hamedi M, Zamani-Babgohari, A (2019) Evaluating Industry 4.0 implementation challenges in production companies through the fuzzy best-worst method. In: The 4th industrial management international conference. Yazd University

Khan, A., & Turowski, K. (2016). A perspective on industry 4.0: from challenges to opportunities in production systems. In: Proceedings of the international conference on internet of things and big data (IoTBD 2016), pp 441–448, https://doi.org/10.5220/0005929704410448

Kiel D, Muller JM, Arnold C, Voigt K (2017) Sustainable industrial value creation: benefits and challenges of industry 4.0. Int J Innov Manag. https://doi.org/10.1142/S1363919617400151

Kleindienst M, Ramsauer C (2018) SMEs and industry 4.0—introducing a KPI based procedure model to identify focus areas in manufacturing industry. Athens J Bus Econ 2(2):109–122. https://doi.org/10.30958/ajbe.2-2-1

Luthra S, Kumar Mangla S (2018) Evaluating challenges to Industry 4.0 initiatives for supply chain sustainability in emerging economies. Process Saf Environ Prot 117(2018):168–179. https://doi.org/10.1016/j.psep.2018.04.018

Manda MI, Ben Dhauo S (2019) Responding to the challenges and opportunities in the 4th Industrial revolution in developing countries. In: ICEGOV2019 proceedings of the 12th international conference on theory and practice of electronic governance, Melbourn, pp 244–253. https://doi.org/10.1145/3326365.3326398

Mohamed M (2018) Challenges and benefits of industry 4.0: an overview. Int J Supply Oper Manag 5(3):256–265

Muhuri P, Shukla A, Abraham A (2019) Industry 4.0: a bibliometric analysis and detailed overview. Eng Appl Artif Intell 78:218–235. https://doi.org/10.1016/j.engappai.2018.11.007

Omidi N, Mohammadi A, Pourashraf Y, Khaili K (2018) Analyzing the impacts of the factors affecting the establishment and development of small and medium-sized enterprises in rural areas of Ilam province, Iran. J Space Econ Rural Dev 3(25):145–164

Permadi GS, Vitadiar TZ, Kistofer T, Mujianto AH (2019) The Decision Making Trial and Evaluation Laboratory (Dematel) and Analytic Network Process (ANP) for Learning Material Evaluation System, E3S Web of Conferences 125, https://doi.org/10.1051/e3sconf/2019125ICENIS 2019 2 23011

Ping Lin K, Lang Tseng M, Feng Pai P (2018) Sustainable supply chain management using approximate fuzzy DEMATEL method. Resour Conserv Recycl 128:134–142. https://doi.org/10.1016/j.resconrec.2016.11.017

Rauch E, Matt DT, Brown CA, Towner W, Vickery A, Santiteerakul S (2018) Transfer of industry 4.0 to small and medium sized enterprises. In: Conference: transdisciplinary engineering methods for social innovation of industry 4.0, at Modena (Italy), https://doi.org/10.3233/978-1-61499-898-3-63

Rezaei J (2015) Best-worst multi-criteria decision-making method: Some properties and a linear model. Omega. https://doi.org/10.1016/j.omega.2015.12.001

Safar L, Sopko J, Bednar S, Poklemba R (2018) Concept of SME business model for industry 4.0 environment. TEM J 7(3):626–637. https://doi.org/10.18421/TEM73-20

Schroder C (2017) The challenges of industry 4.0 for small and medium-sized enterprises. Friedrich-Ebert-Stiftung, Bonn

Sevinç A, Gür S, Eren T (2018) Analysis of the Difficulties of SMEs in Industry 40 Applications by Analytical Hierarchy Process and Analytical Network Process. Processes 6, 264, 1–16. https://doi.org/10.3390/pr6120264

Sheng L, Xiao Y, Hu-Chen L, Ping Z (2018) DEMATEL technique: a systematic review of the state-of-the-art literature on methodologies and applications. Math Probl Eng. https://doi.org/10.1155/2018/3696457

Shukla AK, Nath R, Muhuri PK, Lohani QMD (2020) Energy efficient multi-objective scheduling of tasks with interval type-2 fuzzy timing constraints in an Industry 4.0 ecosystem. Eng Appl Artif Intell. https://doi.org/10.1016/j.engappai.2019.103257

Sisinni E, Saifullah A, Han S, Jennehag U, Gidlund M (2018) Industrial internet of things: challenges, opportunities, and directions. IEEE Trans Ind Inform 14(11):4724–4734. https://doi.org/10.1109/TII.2018.2852491

Stancioiu A (2017) The fourth industrial revolution “Industry 4.0.” Rev Fiabil Durabilitate 1(19):74–78

Ulewicz R, Novy F, Sethanan K (2019) The challenges of industry 4.0 for small and medium enterprises in Poland and Slovaki. Qual Prod Improv 1(1):147–154. https://doi.org/10.2478/cqpi-2019-0020

Witkowski K (2017) Internet of things, big data, industry 4.0– innovative solutions in logistics and supply chains management. Procedia Eng 182:763–769. https://doi.org/10.1016/j.proeng.2017.03.197

Wu Q, Zhou L, Chen Y, Chen H (2019) An integrated approach to green supplier selection based on the interval type-2 fuzzy best-worst and extended VIKOR methods. Inf Sci 502:394–417. https://doi.org/10.1016/j.ins.2019.06.049

Funding

The authors declare that no funds, grants, or other support were received during the preparation of this manuscript.

Author information

Authors and Affiliations

Contributions

All authors contributed to the study conception and design. Material preparation, data collection, and analysis were performed by MA and SS. The first draft of the manuscript was written by SS, and MA commented on previous versions of the manuscript. MA read and approved the final manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare that there is no conflict of interests regarding the publication of this paper.

Ethical approval

This article does not contain any studies with human participants or animals performed by any of the authors.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Alimohammadlou, M., Sharifian, S. Industry 4.0 implementation challenges in small- and medium-sized enterprises: an approach integrating interval type-2 fuzzy BWM and DEMATEL. Soft Comput 27, 169–186 (2023). https://doi.org/10.1007/s00500-022-07569-9

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00500-022-07569-9