Abstract

Surfactin biosurfactant produced by Bacillus sp. has been studied, because it has enormous potential in several applications in the oil and cosmetics industry. The cultivation conditions for obtaining this bioproduct, however, still require attention, as, for example, parameters related to oxygen supply and consumption. In this study, different volumetric oxygen transfer coefficient (KLa) levels (0–11.56 h−1) were tested in bench-scale bioreactor for surfactin biosurfactant production by Bacillus velezensis H2O-1, using induced surface aeration. While conditions close to anaerobiosis showed insignificant production of surfactin, an intermediated KLa condition (4.24 h−1) generated the best surfactin concentration (579.6 mg L−1), with a volumetric productivity of 11.9 mg L−1 h−1. These results showed that the oxygen demand to produce surfactin is not high, being possible to use induced surface aeration strategy in bioreactors, minimizing foam formation. In addition, in all KLa conditions tested, surfactin homologues C14 and C15 had higher relative abundance. Nevertheless, the KLa parameter seems to have had minimal influence on affecting the relative abundances of surfactin homologues produced. Particularly noteworthy in this study is the possibility of producing surfactin using a low-cost and scale-up feasible aeration strategy, unlike the foam collection strategies developed in other studies to obtain this bioproduct.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Biosurfactants are amphiphilic molecules with surface-active properties produced by biological systems, mainly microorganisms. When compared to synthetic surfactants, biosurfactants have several advantages, such as low toxicity, biodegradability and the possibility of being synthesized from renewable raw material [1]. On the other hand, the main disadvantages of biosurfactants in comparison with synthetic surfactants is the high production costs and scale-up difficulties [2].

Among the different types of biosurfactants, cyclic lipopetides (CLPs) have interesting characteristics, such as the fact that they present incredibly low values of critical micellar concentration (CMC) and the fact that they are generally produced by Bacillus sp., non-pathogenic microorganisms [3]. Structurally, CLPs molecules have a fatty acid in combination with a peptide moiety. Several CLPs families and homologues are normally produced by the same strain [4]. These CLPs differ by the amino acid composition of the peptide moiety, the length of the fatty acid chain, and the link between the two parts [5]. Among others, surfactin, iturin, fengicin, kurstakin and polymixin can be mentioned among Biosurfactant LPs families [5]–[7], with the surfactin family being the most studied [8].

Despite the great interfacial properties and potential applications of surfactin that have been recognized in the literature for some time—this molecule was discovered in 1969 [9], this bioproduct production in industrial scale is not yet a reality. This is mainly due to the difficulty of supplying oxygen to the surfactin production bioprocess, avoiding excessive foam formation. Several studies report the use of foam collection systems on bioreactors [10]–14]. Some authors suggest the use of aeration through membranes [15]–17]. These technologies, despite being indeed successful in controlling excessive foaming, have high costs and scale-up complexity.

In addition, the difficulty in supplying oxygen to the bioprocess to obtain surfactin has led the scientific community to a lack of information regarding the real oxygen demand for the formation of this bioproduct. Several works about culture medium optimization have already been published [5, 18, 19], but few have studied the role of oxygenation in the production of CLPs. Jokari et al. (2012) [20] studied the effect of aeration rate on surfactin production in shaken flasks with specific designs, reporting a surfactin volumetric productivity of 49 mg L−1 h−1 using a KLa of 259.56 h−1. Yeh et al. (2006) [10] reported a foam collection and cell recycling system, capable of producing 106 mg L−1 h−1 of surfactin at an optimized KLa of 47.52 h−1 reaching a maximum bioproduct concentration of 6.45 g L−1 on the collected foam. Nazareth et al. (2021) [12] reported a volumetric productivity of 9.98 mg L−1 h−1 for an optimized KLa of 45.41 h−1, tested in a benchtop bioreactor coupled to a foam trap, reaching a surfactin concentration of 239.74 mg L−1 considering the total volume of the test (2159.84 mg L−1 of surfactin in the collected foam). Interestingly, due to the operational difficulty of supplying oxygen without foam excessive generation, Hoffmann et al. (2020) [21] studied the anaerobic production of surfactin in bioreactors by nitrate respiration, reaching 190 mg L−1 of surfactin. However, under anaerobic culture conditions, a higher production of acetate has been reported, impairing cell growth. Hoffmann et al. (2020) [21] conducted a specific experiment to evaluate Bacillus subtilis cellular growth with different initial concentrations of acetate added artificially. While in the control condition (no acetate added) the µmax was 0.123 h−1, with an initial concentration of 0.5 g L−1 acetate the µmax dropped to 0.095 h−1. Thus, the search for alternative strategies to reduce foam formation allows the reduction of expenses with defoamer and with the foam separation step, in addition to enabling the use of conventional bioreactors to produce this biomolecule.

Another issue to be considered is whether the supply of oxygen to the bioprocess may be altering the relative quantity of surfactin homologues or other CLPs produced. Many published works report the variety of CLPs produced by new Bacillus sp. strains discovered [22]–[24]. Some authors also describe changes in the relative quantities of CLP families produced according to culture media composition variation [18, 19]. More deeply, the peptide biodiversity of the surfactin biomolecules may be related to the peptide’s synthesis by multienzymatic proteins called nonribosomal peptide synthetases. This biodiversity also depends on the fatty acid moiety, which length can vary from 12 to 17 carbons atoms, with fifteen different isoforms, enlarging the surfactin structures possibility [9]. However, no studies were found correlating different bioprocess oxygenation levels with changes in the production of different surfactin homologues or other CLPs.

It is interesting to note that, if hypothetically the oxygen demand to produce surfactin is not high, it is possible to use induced surface aeration [25] strategies in bioreactors, injecting air into the bioreactor headspace instead of using the spargers and also adjusting an impeller near the liquid surface to increase oxygenation. Naturally, it is not possible to obtain a high KLa value with this aeration method, but it is a simple, inexpensive and easily scalable technique.

The aim of this study, therefore, was to evaluate the surfactin production by Bacillus velezensis H2O-1 in bench-scale bioreactors using induced surface aeration, at different oxygenation levels, making it possible to correlate different KLa with overall surfactin productivity and with the relative abundance of different surfactin and other CLPs homologues.

Materials and methods

Microorganism and culture medium

The surfactin producer strain Bacillus velezensis H2O-1, originally isolated from an oil reservoir in Brazil and previously described by Korenblum et al. [26, 27] was used in bioreactor experiments. The microorganism was kept in a freezer at – 80 ° C in Luria–Bertani Miller (LB) broth, added with 20% glycerol.

The culture medium previously optimized for surfactin production in shake flasks by Bacillus velezensis H2O-1 was used in this work [28, 29], having the following composition (% w/v): glucose 1.0; Na2HPO4 0.5; KH2PO4 0.2; (NH4)2SO4 0.1. In addition, the biomass propagation medium was supplemented with yeast extract (0.05% w/v).

Bioreactor design and culture conditions

As represented in Fig. 1, an induced surface aeration system was used in the surfactin production experiments. A 2 L New Brunswick Bioflo 310 benchtop bioreactor was used. The vessel had a height-to-diameter ratio H/D = 2, allowing a large headspace surface area. The agitation system had two flat blade impellers, with a diameter one-half of the vessel diameter. One of the impellers was set near the liquid surface to increase oxygenation from induced surface aeration [25]. The vessel also had four equally spaced baffles to improve mixing and reduce vortex formation. A controlled air flow was fed directly into the bioreactor headspace, passing through a control valve (CV) and a 0.22 µm membrane filtration (MF). Exhausted air was removed by passing through a condenser (C) and a manually controlled globe valve (GV). Headspace pressure was measured by a pressure indicator (PI). The fact that no air bubbles into the liquid prevents most of the excessive foaming. The agitation rate was controlled by a motor driven from the top of the vessel. The vessel was equipped with probes for temperature control and dissolved oxygen (DO) measurement (not represented in Fig. 1). Samples were taken via a sample valve (not shown in Fig. 1) for offline analysis of substrate and product concentrations.

The medium culture volume inside the vessel was 0.9 L and the bioreactor was inoculated with 100 mL of a preinoculum previously grown at 30 °C and 170 rpm for 16 h. The temperature was maintained at 30 °C for every condition tested. Each condition was performed in duplicate and ended with 48 cultivation hours. The volumetric mass transfer coefficient KLa, that describes the efficiency with which oxygen can be delivered to a bioreactor for a given set of operating conditions, tested in each condition ranged between 0.97 h−1 and 11.56 h−1 by varying aeration rate (into the bioreactor headspace) and stirring speed (Table 1). A condition close to anaerobiosis was also tested (condition A), where there was no air supply throughout the process and the culture medium dissolved oxygen was set to zero by bubbling N2 prior to the grown pre-inoculum addition. No antifoaming agent was added in any experiment.

KLa determination was performed by a static gassing out technique [30], prior to the surfactin production experiments. In a cell-free culture medium, DO concentration is lowered by gassing the liquid out with nitrogen gas. Aeration is then initiated at a constant stirring speed and air flow rate (according to Table 1) and the DO concentration increase is monitored using dissolved O2 electrode. The plot of ln (CL*–C) versus time will produce a straight line, where the slope is equal to KLa. (C is the concentration of DO in the culture medium, CL* is the saturated DO concentration).

The oxygen transfer rate (OTR) was calculated as OTR = KLa (CL*–C). Oxygen uptake rate (OUR) was calculated using Eq. (1):

The specific oxygen uptake rate (SOUR) was calculated by dividing the OUR by the biomass concentration as shown in Eq. (2). Both OUR and SOUR were calculated in the first hours of the stationary phase of microbial growth, where surfactin production is most pronounced:

Surfactin, glucose, and biomass quantification

Surfactin production was quantified as previously described by Guimarães et al. (2019) [28]. Bioreactor samples were centrifuged at 12,500 × g at 4 °C for 20 min. The supernatant was diluted (2 ×) in acetonitrile, filtered through a 0.22 μm membrane and injected into a C18 column (150 × 4.6 mm, 5 μm particle size; ZORBAX) in an Agilent 1200 high-performance liquid chromatography system (HPLC) to separate the surfactin homologues according to Sousa et al. (2012) [31]. The mobile phase used was 20% trifluoroacetic acid (3.8 mM) and 80% acetonitrile, the flow rate was set at 1.0 mL min−1, and the system temperature was 30 °C. Detection was performed at 210 nm and injection volume was 20 µL. The relative peaks of the different surfactin isoforms were integrated and quantified according to the calibration curve obtained with standard surfactin (Sigma-Aldrich, Ref: S3523).

Glucose consumption was analyzed directly by HPLC (HPLC Agilent Technologies) equipped with HPX-87H column (BioRad—300 mm × 7.8 mm) and refractive index detector. H2SO4 5 mM was used as mobile phase at a flow rate of 0.6 mL min−1. Column temperature was set at 40 °C. Quantification was based on a calibration curve obtained with standard glucose (Sigma-Aldrich, Ref: G6918).

Cell growth was assessed by measuring absorbance at 600 nm. The absorbance value was converted to dry cell weight (DCW) concentration using a standard curve [DCW (g L−1) = 0.715 × ABS; R2 = 0.988].

Surface tension and critical micellar concentration measurement

Surface tension (ST) and critical micellar concentration (CMC) were analyzed using the pendant drop method (Krüss DSA100 goniometer, Model OF 3210) according to Song and Springer (1996) [32]. Pendant drops ST measurements were performed at 23 °C, with the relative humidity maintained at 55%. The same method was used to determine the CMC by serial dilutions of the biosurfactant according to Sheppard and Mulligan (1987) [33].

Surfactin relative abundance

The detection of CLPs in the supernatant samples was performed according to a methodology similar to that presented by Liu et. al (2007) [34]. Aliquots of the cell-free supernatant were diluted 3 × in a 1:1 (v/v) methanol/acetonitrile solution containing 0.05% formic acid (v/v) and subjected to direct injection (3 µL/min flow) in the Bruker Maxis Impact spectrometer with ESI-Q-TOF–MS (electrospray ionization quadruple-time-of-flight mass spectrometry) configuration. As electrospray ionization source a capillary voltage of 4500 V, 180 °C, was used and an acquisition rate of 1 Hz and a scanning range of 100 to 2000 m/z. Detection occurred using the positive ion mode. Data-dependent acquisition (DDA/AutoMS) was used as the data acquisition mode, with collision energy from 30 to 100 eV.

For CLP biosurfactant identification and relative abundance determination, the peak quantification was performed using the mMass software [35] from a CLP biosurfactant mass library adapted from Price et. al (2007), Sarwar et al. (2017), Liu et al. (2007), Gu. et Al. (2017) and Kaisermann (2017) [23, 34, 36]–38 and presented in Table 2.

Data analysis

A spreadsheet software (Microsoft® Excel®) was used to analyze the obtained data. Means, standard deviations (SD) and variance values were calculated. Single factor analysis of variance (ANOVA) was used to determine significant differences between treatments at p < 0.05.

Results and discussion

K LA effect on surfactin production

Figure 2A, B and C illustrates the obtained results of surfactin final concentration, biomass and glucose final concentration, and YP/S, respectively, for each KLa value tested. All results presented in Fig. 2 were obtained with a cultivation time of 48 h. Summary of each process parameters obtained are shown in Table 3. ST and CMC results obtained for each KLa tested are presented in Table 4. The highest surfactin concentration (579.6 mg L−1) and volumetric productivity (11.90 mg L−1 h−1) were obtained in the KLa of 4.24 h−1. Interestingly, at the highest tested KLa level of 11.56 h−1, a lower production of surfactin was observed: 290.96 mg L−1final surfactin concentration, and a volumetric productivity of 5.88 mg L−1 h−1. On the other hand, obtained values for the yield factor YP/S showed that there was no statistically significant difference (p < 0.05) for the conditions of KLa 2.07 to 11.56 h−1, indicating similarity in the glucose uptake for surfactin formation.

A Final surfactin concentration for each KLa condition tested in a bioreactor, with 48 h of cultivation time. B Final biomass and glucose concentration for each KLa condition tested in a bioreactor, with 48 h of cultivation time.; C Final YP/S for each KLa condition tested in a bioreactor, with 48 h of cultivation time

Except for the condition close to anaerobiosis (KLa = 0 h−1), no significant differences (p < 0.05) were observed in the measured physicochemical parameter CMC (Table 4), being the reported CMC values of 15–19 mg.L−1 consistent with those commonly described in the literature [28, 39]. As for the TS measured values, KLa conditions 2.07–11.56 h−1 were statistically equal (p < 0.05), and lower than the TS values obtained for the other KLa conditions. Interestingly, even at the lowest surfactin concentration (9.31 mg L−1), the surface tension lowering was considerably effective (47.7 mN m−1) compared with others biosurfactants, as rhamnolipids, for example, that needs higher concentrations to promote this effect. The literature reports that the uniqueness of the peptide loop present in surfactin provides to it an excellent molecular action at the interfaces [9].

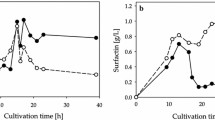

Figures 3, 4 and 5 show the kinetics of surfactin (P) production, glucose (S) consumption and biomass (X) generation for KLa condition of 2.07, 4.24 and 11.56 h−1, respectively. In the kinetics presented, it is remarkable to notice that the oxygen consumption is in fact low in the bioprocess. Only in the kinetics of the KLa 2.07 h−1 condition did the DO value reach zero during the exponential phase of cell growth, remaining around 40% in the stationary phase of cell growth. For the conditions of KLa 4.24 and 11.56 h−1, the DO did not even reach zero in the exponential phase of cell growth, and remained around 64% in the stationary phase of growth for the condition of KLa 4.24 h−1 and 75% in the KLa condition 11.56 h−1. These results are strong indications that, in fact, the oxygen demand for conducting this type of bioprocess is relatively low, making an induced surface aeration strategy viable.

Although the calculated SOUR values were similar for KLa's of 2.07, 4.24 and 5.89 h−1, there was a significant increase for the condition of KLa 11.56 h−1 (Table 3), which in fact was accompanied by a decrease in surfactin production. SOUR is routinely used to indicate metabolic shifts in cells [37]. These results may be related to the Leucine metabolism, the main amino acid present in the surfactin peptide moiety (4 of 7 residues). Coutte et. al (2015) [38] reported significant surfactin yield improvement by leucine supplementation. Leucine is known to be an amino acid synthesized via pyruvate, α-acetolactate and α-ketoisovalerate. When the oxygen consumption is high, the amount of pyruvate oxidized in the TCA cycle may increase, resulting in low leucine formation [39] and consequent low surfactin formation. On the other hand, if the oxygen supply is extremely low or non-existent, pyruvate will be directed into lactate fermentation [39], also resulting in low surfactin formation.

In many surfactin production studies in benchtop bioreactors available in the literature, the surfactin concentration is measured in the collected foam, which means a bioproduct concentration up to 10x [10]. Interestingly, studies that related KLa to surfactin production described much higher KLa values as optimal, around 45–48 h−1, using foam collection [8, 10]. Yeh et al. (2006) [8] reported optimal surfactin production at a KLa value of 47.52 h−1, reaching surfactin concentrations of 6.45 g L−1 in the foam. Nazareth et al. (2021) [10] reported a volumetric productivity of 9.98 mg L−1 h−1 for an optimized KLa of 45.41 h−1, reaching a surfactin concentration of 239.74 mg L−1 in the main bioreactor and 2159.84 mg L−1 of surfactin in the collected foam. Possibly, in aeration system using bubbling and foam collection, it is necessary to work with higher KLa values to compensate for the loss of bacterial cells entrapped in the foam and carried out into the foam collector. In other words, for the cell density within the bulk liquid to remain at adequate levels for surfactin production, considering the biomass loss carried out in the collected foam, it is likely that higher KLa values must be used, due to the oxygen consumption required for cell multiplication.

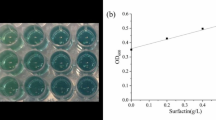

In this study, in none of the aeration conditions tested, excessive foam formation was observed, as depicted in Fig. 6. At the highest KLa tested of 11.56 h−1, in fact, a slightly thicker layer of foam was observed (roughly 2–4 cm of foam thickness), probably caused by the higher stirring speed with an impeller close to the liquid surface (characteristic of the induced surface aeration strategy). However, even in this condition, the foam remained stable and far from reaching the top of the bioreactor, which would cause filters fouling and other operational difficulties. This result indicates that induced surface aeration is a promising technology for surfactin production, reducing the expenses and operational complexity with the foam collection step. In addition, because there was no irregular loss of culture volume or cells through the foam in the tests performed, it was possible, in an unprecedented way in the literature, to make a comparison of different KLa´s in the bioprocess for surfactin production.

Bioreactor photos under different KLa conditions tested, near the end of the bioprocess with 48 h. A 2.07 h−1; B 4.24 h−1; C 11.56 h−1. There was no excessive foaming under any tested aeration conditions. In the condition of KLa 11.56 h−1, in fact, a slightly thicker layer of foam was observed, probably caused by the higher agitation speed with an impeller close to the surface

K La effect on surfactin homologues relative abundance

Figure 7 shows the final supernatant sample mass spectrum of KLa = 4.24 h−1 condition, more productive in terms of surfactin concentration. The highest peak in spectra at m/z = 1044.65 refers to molecular ion surfactin Leu/Ile-7 C14 [M + Na]+. Naturally, mass spectrometry results do not provide the differentiation of compounds having the same mass (such as Leu and Ile, for example), nor the type of fatty acid chain (linear, iso or anteiso), but provides the global mass and the peptide moiety primary sequence. Figure 8 depicts the relative abundance of the identified surfactin homologues for each aeration condition. All supernatant samples showed that the surfactin homologue present in the highest relative abundance was Surfactin Leu/Ile-7 C14, followed by Surfactin Leu/Ile-7 C15, Surfactin Leu/Ile-7 C13, Surfactin Leu/Ile-7 C12 and by Surfactin Leu/Ile-7 C16. This result is in agreement with what Kaisermann (2017) [38] reported for the analysis of Sigma's surfactin standard by mass spectrometry, where it was observed that the main homologue present is indeed Surfactin Leu/Ile-7 C14. In addition, Iturin Asn-1 C14, Iturin Asn-1 C15, Bacillomycin D C14 and Bacillomycin D C15 peaks were identified in all samples, but in very low relative amounts, approximately 1–2% of the relative intensity of Surfactin Leu/Ile-7 C14 (major homologue). Species of fengycin, kurstakin or polymyxin families were not detected in any of the samples.

ESI-Q-TOF–MS mass spectra of KLa 4.04 h−1 sample. Main surfactin homologues molecular ions are marked at m/z = 1044.65 (surfactin Leu/Ile-7 C14 [M + Na]+), m/z = 1058.67 (surfactin Leu/Ile-7 C15 [M + Na]+), m/z = 1030.64 (surfactin Leu/Ile C13 [M + Na]+), m/z = 1016.64 (surfactin Leu/Ile-7 C12 [M + Na]+), m/z = 1074.64 (surfactin Leu/Ile-7 C15 [M + K]+)

The increase in KLa was accompanied by a small tendency to decrease the relative abundance of the surfactin leu/Ile-7 C15 homologue, from KLa 2.07–5.89 h−1 (Fig. 8). Likewise, there was a slight tendency to increase in the relative abundance of the Leu/Ile-7 C14 surfactin homologue with increasing KLa. Intracellular fatty acids metabolism is divided into straight chain fatty acid synthesis and branched‐chain fatty acid synthesis. Acetyl-CoA is the precursor of straight‐chain fatty acids, while the precursors of branched‐chain fatty acids are catabolic products of Val, Leu, and Ile [40]. More specifically, branched-chain fatty acid synthesis from Leu and Ile generates uneven chains of fatty acids [40]. In fact, Liu et al. (2012) [41] experimentally demonstrated that, in a culture for surfactin production using B. subtilis TD7, Leu and Ile supplementation significantly enhanced the proportion of surfactins with odd β-hydroxy fatty acid. It is to be expected, therefore, that the generation of C15 fatty acids is to some extent a competitive metabolic pathway for the total surfactin production, which has Leu in large amounts in its peptide portion. This would mean a decreasing trend, therefore, for the relative abundance of C15 surfactin homologues under conditions, where the total surfactin concentration was higher. Observing the results of the present study, this trend was observed to a certain extent, comparing the results of KLa 5.89–11.56 h−1, where in KLa 11.56 h−1 a lower total concentration of surfactin was obtained and an increase in the C15 homologue was observed (Fig. 8). However, this same behavior was not observed when comparing the results of KLa 4.24–5.89 h−1, since in KLa 4.24 h−1 a higher total concentration of surfactin and a higher concentration of the C15 homologue were observed at the same time.

In addition, in all KLa conditions tested, surfactin homologues C14 and C15 had higher relative abundance. Interestingly, these are the surfactin homologues reported in the literature with the greatest disease-suppression capacity [4], antiviral activity [42], insecticidal activity [43] and as activators of several plant-defense mechanisms [44]. This relationship is a strong indication that the surfactin production profile of the strain tested in this study Bacillus velezensis H2O-1 has great application potential in plant disease biocontrol.

Conclusions

The studies in this work indicate that the oxygen consumption for surfactin production is relatively low (SOUR values of approx. 7.3 mgO2 gX−1 h−1), allowing the use of induced surface aeration and evidencing that complex operational strategies such as foam collection or culture medium composition strategies to induce nitrate respiration are not necessary. It must be considered that the induced surface aeration system described in this study is considerably simpler operationally and scalable when compared to foam collection strategies. Due to the tendency of cells to be entrained in the generated foam, problems such as loss of cells from the main bioreactor and clogging of the foam collection system are widely reported in the literature of foam collection strategies [8, 12]. The operation of a bioprocess where the bioreactor volume is erratically lost and that requires the collected cells separation and recycling will be more difficult to scale-up and operate, in addition to entailing higher fixed and operational costs.

Concerning the different surfactin homologues produced at the tested KLa levels, C14 and C15 homologues were the most abundant in all conditions tested. Surfactin C14 and C15 homologues are often described as more efficient for many applications [4, 39, 40]. Nevertheless, the KLa parameter seems to have had minimal influence on affecting the relative abundances of surfactin homologues produced.

In addition, this study highlights the indication that high KLa values can be deleterious to the total surfactin production (above 11.56 h−1), which makes sense when considering the biosynthesis of the main amino acid present in the peptide portion of the surfactin molecule, leucine. As pyruvate is one of its main precursors, it can be expected that high oxygen availability will increase the amount of pyruvate being oxidized in the TCA cycle, resulting in insufficient leucine formation and consequent low surfactin production. On the other hand, conditions close to anaerobiosis (KLa values close to zero), in fact, showed almost zero production of surfactin and little cell growth.

Finally, because there was no irregular loss of culture volume or cells through the foam in the tests performed with this study, it was possible to carry out, in an unprecedented way in the literature, a benchtop bioreactor system study comparing different KLa´s in the bioprocess for surfactin production, obtaining surfactin volumetric productivity values close to 11.9 mg L−1 h−1 in KLa of 4.24 h−1.

Data Availability

The data that support the findings of this study are available from the corresponding author, upon reasonable request.

References

de Araujo LV et al (2016) Rhamnolipid and surfactin: Anti-adhesion/antibiofilm and antimicrobial effects. Food Control 63:171–178. https://doi.org/10.1016/j.foodcont.2015.11.036

Irorere VU, Tripathi L, Marchant R, McClean S, Banat IM (2017) Microbial rhamnolipid production: a critical re-evaluation of published data and suggested future publication criteria. Appl Microbiol Biotechnol 101(10):3941–3951. https://doi.org/10.1007/s00253-017-8262-0

Ongena M et al (2007) Surfactin and fengycin lipopeptides of Bacillus subtilis as elicitors of induced systemic resistance in plants. Environ Microbiol 9(4):1084–1090

Malfanova N, Franzil L, Lugtenberg B, Chebotar V, Ongena M (2012) Cyclic lipopeptide profile of the plant-beneficial endophytic bacterium Bacillus subtilis HC8. Arch Microbiol 194(11):893–899. https://doi.org/10.1007/s00203-012-0823-0

Mnif I, Ghribi D (2015) Review lipopeptides biosurfactants: mean classes and new insights for industrial, biomedical, and environmental applications. PeptideScience 104:3. https://doi.org/10.1002/bip.22630

Hathout Y, Ho Y, Ryzhov V, Demirev P, Fenselau C (2000) Kurstakins : a new class of lipopeptides isolated from bacillus thuringiensis. J Nat Prod 63:1492–1496. https://doi.org/10.1021/np000169q

Velkov T, Roberts KD, Nation RL, Thompson PE, Li J (2014) Pharmacology of polymyxins: new insights into an ‘old’ class of antibiotics. Future Microbiol 8(6):1–20. https://doi.org/10.2217/fmb.13.39.Pharmacology

Coutte F et al (2017) Microbial lipopeptide production and purification bioprocesses, current progress and future challenges. Biotechnol J 12(7):1–10. https://doi.org/10.1002/biot.201600566

Théatre A et al (2021) The surfactin-like lipopeptides from bacillus spp.: natural biodiversity and synthetic biology for a broader application range. Bioeng. Biotechnol, Front. https://doi.org/10.3389/fbioe.2021.623701

Yeh M, Wei Y, Chang J (2006) Bioreactor design for enhanced carrier-assisted surfactin production with Bacillus subtilis. Process Biochem 41:1799–1805. https://doi.org/10.1016/j.procbio.2006.03.027

Chen C-Y, Baker SC, Darton RC (2006) Batch production of biosurfactant with foam fractionation. J Chem Technol Biotechnol 81:1923–1931

Nazareth TC, Zanutto CP, Maass D, Ulson De Souza AA, Ulson De Souza SMDAG (2021) Impact of oxygen supply on surfactin biosynthesis using brewery waste as substrate. J Environ Chem Eng 9:4. https://doi.org/10.1016/j.jece.2021.105372

Guez JS, Vassaux A, Larroche C, Jacques P, Coutte F (2021) New continuous process for the production of lipopeptide biosurfactants in foam overflowing bioreactor. Bioeng Biotechnol, Front. https://doi.org/10.3389/fbioe.2021.678469

Biniarz P, Henkel M, Hausmann R, Łukaszewicz M (2020) Development of a bioprocess for the production of cyclic lipopeptides pseudofactins with efficient purification from collected foam. Front Bioeng Biotechnol. https://doi.org/10.3389/fbioe.2020.565619

dos Santos LFM, Coutte F, Ravallec R, Dhulster P, Tournier-Couturier L, Jacques P (2016) An improvement of surfactin production by B. subtilis BBG131 using design of experiments in microbioreactors and continuous process in bubbleless membrane bioreactor. Bioresour Technol 218:944–952. https://doi.org/10.1016/j.biortech.2016.07.053

Coutte F, Lecouturier D, Leclère V, Béchet M, Jacques P, Dhulster P (2013) New integrated bioprocess for the continuous production, extraction and purification of lipopeptides produced by Bacillus subtilis in membrane bioreactor. Process Biochem 48(1):25–32

Berth A, Lecouturier D, Loubiere K, Dhulster P, Delaplace G (2019) Modelling and optimisation of gas-liquid mass transfer in a microporous hollow fiber membrane aerated bioreactor used to produce surfactin. Biochem Eng J 145:109–119. https://doi.org/10.1016/j.bej.2018.10.029

Sun D et al (2019) Effect of media and fermentation conditions on surfactin and iturin homologues produced by Bacillus natto NT-6: LC–MS analysis. AMB Express 9:1. https://doi.org/10.1186/s13568-019-0845-y

Bartal A et al (2018) Effects of different cultivation parameters on the production of surfactin variants by a Bacillus subtilis strain. Molecules 23:2–14

Jokari S, Rashedi H, Amoabediny GH, Yazdian F, Rezvani M, Hatamian Zarmi AS (2012) Effect of aeration rate on biosurfactin production in a miniaturized bioreactor. Int J Environ Res 6(3):627–634

Hoffmann M et al (2020) Towards the anaerobic production of surfactin using Bacillus subtilis. Front Bioeng Biotechnol. https://doi.org/10.3389/fbioe.2020.554903

Vigneshwaran C, Vasantharaj K, Krishnanand N, Sivasubramanian V (2021) “Production optimization, purification and characterization of lipopeptide biosurfactant obtained from Brevibacillus sp. AVN13. J Environ Chem Eng. https://doi.org/10.1016/j.jece.2020.104867

Price NPJ, Rooney AP, Swezey JL, Perry E, Cohan FM (2007) Mass spectrometric analysis of lipopeptides from Bacillus strains isolated from diverse geographical locations. Microbiol Lett 271:83–89. https://doi.org/10.1111/j.1574-6968.2007.00702.x

Chen Y, Liu SA, Mou H, Ma Y, Li M, Hu X (2017) Characterization of lipopeptide biosurfactants produced by Bacillus licheniformis MB01 from marine sediments. Front Microbiol. https://doi.org/10.3389/fmicb.2017.00871

Shiau C (1995) Oxygen transfer in bubble and bubbleless aeration sistems. Doctor of philosophy thesis, department of civil and mining engineering, university of wollongong. https://ro.uow.edu.au/theses/1255

Korenblum E et al (2005) Production of antimicrobial substances by Bacillus subtilis LFE-1, B. firmus H2O–1 and B. licheniformis T6–5 isolated from an oil reservoir in Brazil. J Appl Microbiol 98(3):667–675. https://doi.org/10.1111/j.1365-2672.2004.02518.x

Korenblum E et al (2012) Purification and characterization of a surfactin-like molecule produced by Bacillus sp. H2O–1 and its antagonistic effect against sulfate reducing bacteria. BMC Microbiol. https://doi.org/10.1090/tran/7225

Guimarães CR et al (2019) Surfactin from Bacillus velezensis H2O–1: production and physicochemical characterization for postsalt applications. J Surfactants Deterg 22(3):451–462. https://doi.org/10.1002/jsde.12250

Guimarães CR (2015) Avaliação da produção de surfactina- like por Bacillus sp. H2O–1. Master of science thesis, Universidade Federal do Rio de Janeiro

Dunn IJ, Einsele A (1975) Oxygen transfer coefficients by the dynamic method. J Appl Chem Biotechnol 25(9):707–720

Sousa M, Melo VMM, Rodrigues S, Sant’ana HB, Goncalves LRB (2012) Screening of biosurfactant-producing Bacillus strains using glycerol from the biodiesel synthesis as main carbon source. Bioprocess Biosyst Eng 35(6):897–906. https://doi.org/10.1007/s00449-011-0674-0

Song B, Springer J (1996) Determination of interfacial tension from the profile of a pendant drop using computer-aided image processing: 2. Exp J Coll Inter Sci 184(1):77–91. https://doi.org/10.1006/jcis.1996.0598

Sheppard JD, Mulligan CN (1987) The production of surfactin by Bacillus subtilis grown on peat hydrolysate. Appl Microbiol Biotechnol 27(2):110–116. https://doi.org/10.1007/BF00251931

Liu X, Haddad NIA, Yang S, Mu B (2007) Structural characterization of eight cyclic lipopeptides produced by Ba- cillus subtilis HSO121. Protein Pept Lett 14:766–773

Strohalm M, Kavan D, Novák P, Volný M, Havlíček V (2010) mMass 3: a cross-platform software environment for precise analysis of mass spectrometric data. Anal Chem 82:4648–4651

Sarwar A, Corretto E, Aleti G, Abaidullah M, Sessitsch A, Hafeez FY (2017) Qualitative analysis of biosurfactants from Bacillus species exhibiting antifungal activity. PLoS ONE 13(6):1–15

Gu Q et al (2017) Bacillomycin D produced by bacillus amyloliquefaciens is involved in the antagonistic Interaction with the Plant-Pathogenic Fungus Fusarium graminearum. Appl Enviromental Microbiol 83(19):1–17

Kaisermann C (2017) Bioprocess intensification of surfactin production. Doctor of philosophy thesis. School of chemical engineering and analytical science university of manchester. https://www.research.manchester.ac.uk/portal/files/60829897/FULL_TEXT.PDF

Freire DA, Simonelli G, de Assis DJ, Druzian JI, Kluhpiuho A, Lobato DCL (2020) Surfactin production using papaya peel aqueous extract as substrate and its application for iron adsorption. Res Soc Dev 9(7):1–26

Kaneda T (1991) Iso- and anteiso-fatty acids in bacteria: Biosynthesis, function, and taxonomic significance. Microbiol Rev 55(2):288–302. https://doi.org/10.1128/mmbr.55.2.288-302.1991

Liu JF, Yang J, Yang SZ, Ye RQ, Mu BZ (2012) Effects of different amino acids in culture media on surfactin variants produced by Bacillus subtilis TD7. Appl Biochem Biotechnol 166(8):2091–2100. https://doi.org/10.1007/s12010-012-9636-5

Kracht M, Rokos H, Özel M, Kowall M, Pauli G, Vater J (1999) Antiviral and hemolytic activities of surfactin isoforms and their methyl ester derivatives. J Antibiot (Tokyo) 52(7):613–619. https://doi.org/10.7164/antibiotics.52.613

Assié LK et al (2002) Insecticide activity of surfactins and iturins from a biopesticide Bacillus subtilis Cohn (S499 strain). Meded Rijksuniv Gent Fak Landbouwkd Toegep Biol Wet 67(3):647–655

Jourdan E et al (2009) Insights into the defense-related events occurring in plant cells following perception of surfactin-type lipopeptide from Bacillus subtilis. Mol Plant Microbe Interact 22(4):456–468. https://doi.org/10.1094/MPMI-22-4-0456

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflicts of interest in the publication.

Ethics approval

Not applicable.

Consent to participate

All authors consent to participate.

Consent for publication

All authors consent for publication.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

de Paula Vieira de Castro, R., Alves Lima Rocha, V., Cezar Fernandes da Silva, M. et al. New insight into the role of oxygen supply for surfactin production in bench-scale bioreactors using induced surface aeration. Bioprocess Biosyst Eng 45, 2031–2041 (2022). https://doi.org/10.1007/s00449-022-02807-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00449-022-02807-8