Abstract

Acetic acid is an important chemical raw material that can be produced directly from sugars in lignocellulosic biomass. Development of kinetic models that capture the bioconversion dynamics of multiple sugar systems will be critical to optimization and process control in future lignocellulosic biorefinery processes. In this work, a kinetic model was developed for the single- and dual-substrate conversion of xylose and glucose to acetic acid using the acetogen Moorella thermoacetica. Batch fermentations were performed experimentally at 20 g L−1 total sugar concentration using synthetic glucose, xylose, and a mixture of glucose and xylose at a 1:1 ratio. The product yield, calculated as total product formed divided by total sugars consumed, was 79.2, 69.9, and 69.7 % for conversion of glucose, xylose, and a mixture of glucose and xylose (1:1 ratio), respectively. During dual-substrate fermentation, M. thermoacetica demonstrated diauxic growth where xylose (the preferred substrate) was almost entirely consumed before consumption of glucose began. Kinetic parameters were similar for the single-substrate fermentations, and a strong linear correlation was determined between the maximum specific growth rate μ max and substrate inhibition constant, K s . Parameters estimated for the dual-substrate system demonstrated changes in the specific growth rate of both xylose and glucose consumption. In particular, the maximum growth rate related to glucose tripled compared to the single-substrate system. Kinetic growth is affected when multiple substrates are present in a fermentation system, and models should be developed to reflect these features.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Second generation biorefineries that utilize lignocellulosic biomass are expected to become a major contributor to the sustainable production of commodity fuels and chemicals. Organic acids, such as acetic acid, produced directly from microbial fermentation of lignocellulosics are of particular interest [1]. Approximately 11 million tons per year of acetic acid is produced for the manufacture of important chemical compounds, such as, vinyl acetate monomers, acetic anhydride, and ethyl esters, with only about 2 % of production coming from microbial processes. Commercial facilities are currently being demonstrated for the production of acetic acid from hybrid poplar in the Pacific Northwest [2]. However, the economical production of lignocellulosic fuels has been largely dependent on feedstock costs [3], making the complete utilization of all carbohydrates a critical attribute to the biorefinery process.

Microorganisms with the ability to convert both hexose and pentose carbohydrates are vital for the efficient and economical utilization of lignocellulosic biomass. The most commonly used microorganism in the biofuels industry is Saccharomyces cerevisiae, which can convert hexoses to ethanol, but other organisms have been used to produce xylitol, acetic acid, butyric acid, and many other products [4]. Acetogenic bacteria, or acetogens, are anaerobes that use the acetyl-CoA pathway (or more commonly called the Wood–Ljungdahl pathway) for the reduction of CO2 to acetic acid or acetate. Moorella thermoacetica (formerly known as Clostridium thermoaceticum) was one of the first acetogens to be studied [5]. Moorella thermoacetica is a rod-shaped, Gram-positive, anaerobic, thermophilic, homoacetogenic bacterium that is both autotrophic and heterotrophic, allowing it to consume a wide range of substrates including: carbohydrates, gases, alcohols, organic acids, and methoxylated aromatic compounds. It was first noticed for its ability to convert glucose to acetate at nearly 100 % theoretical mass yield. From an industrial perspective, this organism is attractive for its high carbon conversion efficiency, in addition to being both anaerobic and thermophilic, which could potentially lower fermentation cost compared to common aerobic fermentation.

Moorella thermoacetica can readily ferment a mixture of monosaccharide substrates. Some of the earliest analysis performed with this organism [6], demonstrated this for three different sugars: xylose, fructose, and glucose. Their results indicated that when synthetic glucose or fructose was mixed with xylose, a delay was observed before the hexose sugars were utilized. For all three sugars mixed together, xylose was again fermented first, followed by fructose, and then, glucose was consumed until the end of the fermentation. Conversely, Brumm [7] showed simultaneous utilization in mixtures containing fructose and glucose, and xylose and glucose. But, as shown by Andreesen et al. [6], there was a faster consumption rate for xylose. Balasubramanian et al. [8] found that in a medium containing glucose and xylose, the xylose was consumed first, however, xylose uptake was very slow. A lag phase was observed for the first 20 h, after which an exponential growth phase occurred for about 60 h. Majority of the xylose consumption and acetic acid production occurred during the exponential phase, indicating growth-associated acid production. Using a mixture of five sugars, xylose was consumed first, then glucose, followed by arabinose, mannose, and galactose [8]. Acid-hydrolyzed poplar hemicellulose has also been demonstrated as an acceptable substrate for M. thermoacetica [9]. It was estimated that 87–92 % of available sugars were consumed, with a final acetic acid concentration of 11.3–11.9 g L−1 after 72 h.

Organisms that consume multiple sugars often exhibit diauxic behavior, preferential consumption of a particular substrate prior to another [10]. This catabolic repression can change the characteristics of fermentation compared to single-substrate systems, causing increases or decreases in cellular growth rate, which ultimately lead to shorter or longer residence times. The dynamic behavior of such a process can be further complicated by the bioreactor operation mode (e.g., batch, fed-batch, or continuous), where substrate feed concentrations could potentially be varied by upstream processing and feedstock irregularities. Kinetic models can be employed to understand how upstream bioconversion processes affect fermentation, since experimental studies are time-consuming and costly. Also, these models can be utilized to develop operation and process control strategies for bioconversion [11].

Kinetic models for fermentation systems can be experimental, mechanistic, or a combination of the two. Mechanistic models, based on fundamental mass/energy balances, can be classified as segregated or unsegregated, and structured or unstructured. Unsegregated–unstructured models assume a homogeneous reactor environment where the average cell behavior can be used to predict the kinetics of the system with minimal kinetic parameters, and are most commonly found in the literature [11]. However, for fermentation systems of multiple substrates, unsegregated–structured models and, in some cases, segregated–structured models have been employed. Segregated models consider the behavior of individual cells in a heterogeneous environment, where each cell in a population will have different characteristics at any point in time during the process (e.g., age, cell mass, and viability), and structured models describe cellular growth by several mechanistic variables. These models are often computationally much more complex, which makes their implementation often cumbersome and, in some cases, impossible to solve in a manageable time frame for optimization studies [11]. Using the acetogen M. thermoacetica, Nishiro et al. [12] studied the effects of initial glucose concentrations using a Monod-type growth model with second-order substrate inhibition terms and a non-competitive product inhibition term. Similarly, Wang and Wang [13] used a simple growth model with product inhibition to study the maximum acetate concentration in batch fermentations using M. thermoacetica before growth was completely exhausted. These initial models were valuable in explaining basic characteristics of batch behavior on single substrates; however, there has been relatively minimal research in developing kinetic models for multiple-substrate systems using simple unsegregated models.

To be useful for modeling lignocellulosic hydrolyzates, kinetic models of microorganism growth will need to include multiple substrates consumption, as well as additional inhibition terms to accurately reflect the system. The aim of this research is to develop a mechanistic model for fermentation of glucose and xylose, main components of lignocellulosic hydrolyzate, to acetic acid using the acetogen M. thermoacetica. The parameters for the model were estimated using experimental data obtained from batch fermentation of single-substrate consumption of glucose and xylose, and a mixture of glucose and xylose at a 1:1 ratio. This work presents a full kinetic model for the consumption of single- and dual-substrate fermentation of synthetic sugars for the microorganism M. thermoacetica.

Model development

An unstructured–unsegregated model was developed for batch fermentation of glucose, xylose, and a mixture of glucose and xylose to acetic acid. Several assumptions were used in the model development including: the medium is well mixed and homogenous due to the small volume used in experimentation; temperature and pH are held constant during fermentation; a cell maintenance term is neglected due to the growth rate being much greater; product formation is assumed to be only growth-associated, which is shown experimentally.

Given the aforementioned assumptions, a model for batch growth of M. thermoacetica on carbohydrates can be written as,

where X, S i , and P are the biomass, substrate (i = 1 for xylose and i = 2 for glucose) and product concentration, respectively, with reaction rates of microorganisms cell growth (r x ), substrate consumption (\(r_{{s_{i} }}\)), and product formation (r p ).

For this work, growth kinetics include both substrate and product inhibition characteristics, and terms associated with catabolic repression are based off the work of [14],

where μ gi is the specific growth rate of the biomass associated with substrate i (i = 1 for xylose and i = 2 for glucose); μ d is the rate of cell death (considered constant, μ d = K d ); μ max,gi is the maximum growth rate of cells; K s,i is the substrate saturation constant; P max is the maximum acetic acid concentration before 90 % inhibition; Y xs,i and Y px,i are the cell yield and product yield constants, respectively; and K i is an inhibitory constant of the substrate causing catabolic repression (if no catabolic repression exists, then K i = 0). The growth rate expressions described in Eqs. (5, 6, 7, 8, 9, 10) include four main terms: a monod growth component with saturation kinetics, where growth is limited by low substrate concentration; a catabolic repression term where the glucose consumption is inhibited by xylose; an end-product inhibition term, where growth is reduced as product concentration increases; and a cell death term. The end-product inhibition term was chosen based on the previous work performed in [13], which demonstrated an inverse linear relationship between acetic acid concentrations and cell growth for M. thermoacetica in batch conditions.

Parameter estimation

Experimental data collected were divided into a calibration and validation data set, where 50 % of the collected data were used for calibration, and 50 % were used for validation. Parameter estimation is found by minimizing the Chi-squared error between the model predictions and experimental data from the batch system. This is determined through minimization of the following objective function,

where θ is the vector of kinetic parameters; X j , S i,j , and P j are experimental data of biomass, substrate (i = 1 for xylose, and i = 2 for glucose), and product concentrations at sampling time j; X m,j , S m,j , and P m,j are the concentrations computed by the model in each sampling time; and σ 2 is the variance between experimental replicates for total of samples n in the calibration data set. The parameters are subjected to upper and lower bounds to ensure realistic values,

where θ q is parameter q, l q is the lower bound for parameters, and u q is the set of upper bounds on the parameters. The minimization was performed using MATLAB (MathWorks, Natick, MA) nonlinear regression function lsqnonlin ().

Materials and methods

Microorganism cultivation

Moorella thermoacetica (ATCC 39073) was acquired from the American Type Culture Collection (Manassas, VA) grown in medium containing in g L−1 of yeast extract, 10; glucose/xylose/1:1 ratio 20; l-Cysteine hydrochloride monohydrate 1.0; KH2PO4 7.0; NaHCO3 16; K2HPO4 5.5; (NH4)2SO4 1.0; MgCl2-6H2O, 0.33; CaCl2 0.05; NaMoO4-2H2O 0.0025; Fe(NH4)2SO4-6H2O 0.04; Co(NO3)2-6H2O 0.03; Na2SeO3 0.0002; and NiCl2-6H2O 0.0002. The pH of the medium was adjusted to pH 7.4 using 5 M NaOH. Inoculants were grown at 58 °C in stoppered and crimp-sealed 150 mL Wheaton serum bottles sparged with filter-sterilized 100 % CO2, inoculated with 10 % by volume of a 36 h culture (total volume of inoculant 100 mL). Cells were grown in the media through three transfers before they were used for analyses of growth yields and kinetic model [6].

Experimental conditions

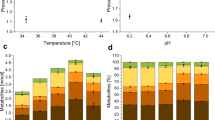

Batch fermentations were performed in quadruplicate using a 1.3-L BioFlo 115 (New Brunswick Scientific Co., Inc., Edison, NJ) bioreactor with 500 mL of working volume under anaerobic conditions. Sterilization of the fermenter vessel containing carbohydrates was performed in an autoclave at 121 °C for 30 min. Deoxygenated CO2 was filtered and sparged at a flow rate of 0.5 L min−1 into the bottom of the vessel continuously. Temperature of the bioreactor was held at 58 °C and pH 6.8. A 5 M aqueous solution of sterilized NaOH was added to maintain pH throughout fermentation. Inoculation was performed with 10 % v/v of three-stage seeded organism grown on glucose, xylose, or glucose and xylose in 1:1 ratio. Four batch fermentations were performed for approximately 20 g L−1 initial concentrations of glucose, xylose, and a mixture of glucose/xylose at a 1:1 ratio (10, 10 g L−1) each.

Growth, acetic acid, and carbohydrates analysis

A 1-mL sample was taken from the fermenter at specified time points and used for analysis. The samples were centrifuged for 5 min at 10,000 rpm, removing the supernatant for high-performance liquid chromatograph (HPLC), and then, the pellet was resuspended in 1 mL of deionized water. The supernatant was then put through a 0.2-µm filter to remove any remaining cells. The cell-free supernatant was used for off-line determination of sugars (glucose and xylose) and acetic acid in a Shimatzu Prominence LC HPLC with Phenomenex RHM monosaccharide H+ (ion exclusion) column. Bacteria concentration was determined by optical density (OD) at 600 nm. The OD was converted to cell dry mass following NREL protocol [15].

Results and discussion

Kinetic model calibration and parameter estimation

Experimental data were broken into a calibration data set and a validation data set for model prediction. The calibration data set was used to estimate kinetic model parameters. For the single-substrate models, five parameters were estimated from experimental data, and these values are shown in Table 1 along with their 95 % confidence interval. The maximum acetate concentration has been well documented in the literature to be in the range of 45–60 g L−1 [13]; for our model, P max is held constant at 48 g L−1. An important aspect of kinetic model development is determining the uniqueness of parameters estimates, which is often referred to as the identifiability of a parameter. The parameters were ranked from least identifiable (unique) to most identifiable based on an orthogonalization algorithm [16]. The results show that the value of K s is the least identifiable parameter. The correlation matrix indicates the linear dependence of parameters upon each other, and these values are shown in Table 1. A strong correlation (value close to 1.0) reveals that the value of one parameter has a strong dependency on the value of another. All parameters show high linear correlation with at least one other parameter. The root mean squared error (RMSE) was calculated as,

and demonstrates the spread between predicted and experimental data. Both single-substrate models show good agreement between model and data. In Table 1, the RMSE was calculated for a calibration set (RMSEC) for single-substrate fermentations.

The maximum growth rates estimated by the model were 0.13 and 0.15 h−1 for glucose and xylose, respectively. Product formation can be seen to be largely growth-associated, which confirms previous assumptions. The yield constants, Y px and Y xs , estimated from the nonlinear parameter estimation were also in good agreement with experimentally derived product yield constant as calculated by the effective product yield (Y ps = Y px × Y xs ), as 77 % (79 % from data) and 69 % (69 % from data) for glucose and xylose, respectively, compared to the experimental yields. Experimental studies have shown M. thermoacetica having a maximum specific growth rate ranging from 0.1 to 0.25 h−1 when grown on glucose during batch fermentation. Schwartz and Keller [17] found for different strains of M. thermoacetica a mass doubling time of 5–18 h. Wang and Wang [13] found at optimal pH a maximum specific growth rate (μ max) of 0.22 h−1, and a product yield of 0.85 g-acetate/g-glucose. Sugaya et al. [18] calculated for batch fermentation a maximum cell growth rate of 0.1 h−1, and a growth rate of 0.2 h−1 for a continuous reactor at steady state. Similarly, the work of Brownell and Nakas [9] demonstrated a specific growth rate of 0.14 h−1.

The kinetic parameters were estimated for the dual-substrate growth model with experimental data from batch culture containing a 1:1 ratio of glucose and xylose. The kinetic parameters estimated and RMSEC for the dual growth model are shown in Table 2. The major difference compared to the single-substrate model were the maximum growth rate, μ max, and substrate saturation constant, K s , which were decreased for xylose consumption and increased for glucose consumption. This demonstrates the catabolic repression that occurs with the mixed sugars as the organism is slower to consume the preferred substrate xylose, and then rapidly consumes glucose once majority of the xylose is consumed. During consumption of xylose, glucose catabolism is accounted for in the parameter K 1. Once majority of xylose was consumed, the enzyme that is repressed by xylose is fully expressed, and a second growth stage occurs as glucose is consumed. The maximum growth rate for glucose consumption was nearly six times greater than for xylose.

Kinetic model validation

The kinetic model for single sugars was validated using independent data (50 % of data) from the calibration data set. Fermentation of single sugars (glucose and xylose) was conducted under anaerobic conditions and monitored for 48 h. Sample points for the replicates were taken at the same time points. The root mean square error of prediction (RMSEP) was calculated as 0.92 for glucose and 0.93 for xylose in the single-substrate models. The RMSEP for the dual-substrate model was calculated as 1.02. This demonstrates that the model is appropriate for predicting both single- and dual-substrate fermentation for M. thermoacetica under the experimental conditions described in the Materials and Methods section above. Results from experimental validation data against model predictions are shown below in Fig. 1 for single sugars and in Fig. 2 for dual sugars.

Fermentation of single sugars

Moorella thermoacetica consumed all glucose (initial concentration of 18.4 g L−1), and xylose (initial concentration of 17.4 g L−1) in under 40 h of total fermentation time (Fig. 1). The product yield, calculated as total product formed divided by total sugars consumed, was 79 and 70 % for glucose and xylose, respectively (Fig. 1). Acetic acid was the only major metabolite found, and its production was mainly associated with cell growth for both substrates. The maximum volumetric production rate was 0.4 and 0.3 g L−1 h−1 for glucose and xylose, respectively. Maximum cell mass was approximately 16.5 g L−1 for both xylose and glucose. The characteristic growth curve of the organism was similar from batch-to-batch and for both sugars. This indicates that M. thermoacetica is a stable microorganism that can achieve predictable behavior under similar growth conditions for both glucose and xylose. Experimental data were broken into calibration and validation data sets, where 50 % of the collected data were used for calibration and 50 % were used for validation. Results from single-substrate fermentation experiments and associated prediction model are shown in Fig. 1. The figure shows the model predictions compared to the validation data set.

The growth behavior of M. thermoacetica on single substrates (glucose or xylose) was similar to that previously reported. Cell concentration increased for roughly 32–35 h, then decreased rapidly. It has been suggested that the sudden decrease is due to cell lysis, however, this was not investigated in this study. It is well known that the growth of M. thermoacetica is highly dependent on its exogenous environment including availability of nutrients and trace metals, pH, and substrate concentration [5]. Typical cell production was determined to be about 4 g-wet cells per liter for various standard media [6]. Higher ranges (7–10 g-cells per liter) were achieved with exogenous CO2 sparged into the media and starting at a more alkaline pH. Our work shows a much higher cell concentration of 16.5 g L−1; which can also be attributed to continuously sparging CO2 in the media during fermentation.

Product yields were similar to previous work, with glucose having a higher yield and volumetric productivity than xylose fermentation. Brownell et al. [9] demonstrated acetate yields on batch xylose fermentation ranging from 60 to 81 %, and for glucose 75–85 %. In their work, product inhibition was assumed to be the major factor that decreased fermentation yields with low initial sugar concentrations. Wang and Wang [13] concluded that both acetate ion (at high pH, above 6.0) and undissociated acetic acid (at low pH, below 6.0) exhibit inhibitory effects. During this work, pH was held constant at 6.8, and the acetate concentration remained well below the maximum concentration of 48 g L−1, however, it was still enough to reduce the conversion efficiency. Additionally, it has been suggested that 10 % of substrate consumption is used for cell maintenance, which puts it below the theoretical conversion limit [17].

Fermentation of dual sugars

The dynamic behavior of the dual-substrate system differed from the single-sugar fermentations. The growth characteristics are representative of catabolic repression, with xylose repressing the utilization of glucose. Figure 2 shows the growth, acetic acid production, and substrate utilization by M. thermoacetica grown on a mixture of glucose (~9.9 g L−1) and xylose (~9.0 g L−1). The initial growth rate was slower while both sugars were present compared to single-substrate fermentation. Consumption of glucose does not begin until the preferred substrate, xylose, is over 70 % (~24 h) utilized. However, once the xylose was entirely consumed, the growth on glucose was much faster increasing the maximum cell concentration to 15.4 g L−1. This is in agreement with previous studies with sequential consumption of xylose, then glucose [6, 8], and not the simultaneous utilization that was observed by Brumm [7]. The faster xylose consumption in the dual-sugar fermentation of 27 h (Fig. 1b) compared to single xylose fermentation of 40 h (Fig. 2) could be due to almost twice higher concentration of xylose at the beginning of single-sugar fermentation and the carbon source of 1:1 glucose to xylose ratio (10, 10 g L−1) during pre-growing of M. thermoacetica cells as shown by Brumm [7]. The average yield for the dual-substrate fermentation was similar to single-substrate fermentation at 70 %. It was observed that as the organism switches from consuming xylose to glucose, the growth rate rapidly increases, until all substrate is consumed and cell lysis begins. This indicates two phases of exponential growth, the initial with xylose and then with glucose once the enzyme involved in the catabolism of glucose becomes active. Maximum cell concentration was similar to that of single substrate as was that of final acetate concentration. As the xylose concentration drops below some critical value, the expression of enzymes occurs.

Conclusion

In this work, kinetic growth models for the well-known acetogen M. thermoacetica were developed. An unstructured–unsegregated mechanistic model was used to predict fermentation of both single sugars (glucose and xylose) and a mixture of sugars with diauxic growth. Although there exists high linear correlation between parameters, the simple model for mixed sugar kinetics provides adequate representation of diauxic growth. Through nonlinear parameter estimation, it was shown that growth parameters can vary greatly between single- and dual-substrate systems. This is an important fact to consider when developing models for future lignocellulosic biomass bioconversion processes, as feedstock will contain various concentrations of monosaccharides achieved by different feedstock types, as well as processing technologies. The minimally realized kinetic model has potential application for optimization of converting lignocellulosic sugars to acetic acid since it was able to describe complex fermentation relationships and provided insight into characteristic growth dynamics (i.e., diauxic growth, change in growth rate) and is suitable for future process control efforts.

Abbreviations

- S :

-

Substrate concentration (g L−1)

- X :

-

Cell mass concentration (g L−1)

- P :

-

Product concentration (g L−1)

- r x :

-

Reaction rate of cell growth (g L−1 h−1)

- r s :

-

Reaction rate of substrate consumption (g L−1 h−1)

- r p :

-

Reaction rate of product formation (g L−1 h−1)

- μ g,i :

-

Specific growth rate (h−1)

- μ max,gi :

-

Maximum specific growth rate (h−1)

- K s :

-

Substrate saturation constant (g L−1)

- K 1 :

-

Substrate inhibition constant

- P max :

-

Maximum product concentration before inhibition (g L−1)

- K d :

-

Cell death rate constant (h−1)

- Y xs :

-

Cell growth yield from substrate (\({\text{g cells g}}^{ - 1} {\text{substrate}}\))

- Y px :

-

Product yield from cells (\({\text{g product g}}^{ - 1} {\text{cells}}\))

- Y ps :

-

Product yield from substrate, or effective product yield (\({\text{g product g}}^{ - 1} {\text{substrate}}\))

References

Sauer M, Porro D, Mattanovich D, Branduardi P (2008) Microbial production of organic acids: expanding the markets. Trends Biotechnol 26:100–108. doi:10.1016/j.tibtech.2007.11.006

Bacovsky D, Ludwiczek N, Ognissanto M, Worgetter M (2013) Task 39 IEA Bioenergy. http://task39.org/2013/12/report-on-the-status-of-advanced-biofuels-demonstration-facilities-in-2012/. Accessed 01 June 2016

Juneja A, Kumar D, Murthy G (2013) Economic feasibility and environmental life cycle assessment of ethanol production from lignocellulosic feedstock in Pacific Northwest US. J Renew Sustain Energy 5:1–40

Ewanick S, Schmitt E, Gustafson R, Bura R (2014) Use of Raman spectroscopy for continuous monitoring and control of lignocellulosic biorefinery processes. Pure Appl Chem 86:1321–1432. doi:10.1515/pac-2013-1022

Drake HL, Daniel SL (2004) Physiology of the thermophilic acetogen Moorella thermoacetica. Res Microbiol 155:422–436. doi:10.1016/j.resmic.2004.03.003

Andreesen JR, Schaupp A, Neurauter C et al (1973) Fermentation of glucose, fructose, and xylose by Clostridium thermoaceticum: effect of metals on growth yield, enzymes, and the synthesis of acetate from CO2. J Bacteriol 114:743–751

Brumm PJ (1988) Fermentation of single and mixed substrates by the parent and an acid-tolerant, mutant strain of Clostridium thermoaceticum. Biotechnol Bioeng 32:444–450

Balasubramanian N, Kim JS, Lee YY (2001) Fermentation of xylose into acetic acid by Clostridium thermoaceticum. Appl Biochem Biotechnol 91–93:367–376

Brownell JE, Nakas JP (1991) Bioconversion of acid-hydrolyzed poplar hemicellulose to acetic acid by Clostridium thermoaceticum. J Ind Microbiol 7:1–6. doi:10.1007/BF01575595

Harder W (1982) Strategies of mixed substrate utilization in microorganisms. Phi Trans R Soc Lond B 297:459–480. doi:10.1098/rstb.1982.0055

Gernaey KV, Lantz AE, Tufvesson P et al (2010) Application of mechanistic models to fermentation and biocatalysis for next-generation processes. Trends Biotechnol 28:346–354. doi:10.1016/j.tibtech.2010.03.006

Nishio N, Kuroda K, Nagai S et al (1990) Methanogenesis of glucose by defined thermophilic coculture of Clostridium thermoaceticum and Methanosarcina sp. J Ferment Bioeng 70:398–403

Wang G, Wang D (1984) Elucidation of growth inhibition and acetic acid production by Clostridium thermoaceticum. Appl Environ Microbiol 47:294–298

Kwon Y, Engler C (2005) Kinetic models for growth and product formation on multiple substrates. Biotechnol Bioprocess Eng 10:587–592

Dowe N, McMillan J (2008) SSF experimental protocols-lignocellulosic biomass hydrolysis and fermentation, laboratory analytical procedure (LAP) NREL/TP-510-42630. http://www.nrel.gov/biomass/pdfs/42630.pdf

Yao KZ, Shaw BM, Kou B et al (2003) Modeling ethylene/butene copolymerization with multi-site catalysts: parameter estimability and experimental design. Polym React Eng 11:563–588. doi:10.1081/PRE-120024426

Schwartz RD, Keller FA (1982) Acetic acid production by Clostridium thermoaceticum in pH-controlled batch fermentations at acidic pH. Appl Environ Microbiol 43:1385–1392

Sugaya K, Tusé D, Jones J (1986) Production of acetic acid by Clostridium thermoaceticum in batch and continuous fermentations. Biotechnol Bioeng 28:678–683

Acknowledgments

This project is supported by Agriculture and Food Research Initiative Competitive Grant No. 2011-68005-30407 from the USDA National Institute of Food and Agriculture. Any opinions, findings, conclusions, or recommendations expressed in this publication are those of the author(s) and do not necessarily reflect the view of the U.S. Department of Agriculture. The University of Washington Denman Professorship Fund provided financial support.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Schmitt, E., Bura, R., Gustafson, R. et al. Kinetic modeling of Moorella thermoacetica growth on single and dual-substrate systems. Bioprocess Biosyst Eng 39, 1567–1575 (2016). https://doi.org/10.1007/s00449-016-1631-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00449-016-1631-8