Abstract

Anaerobic co-digestion of cow manure (CM) and waste milk (WM), produced by sick cows during treatment with antibiotics, was evaluated in two-stage process under thermophilic condition (55 °C) to determine the effect of WM addition on hydrogen (H2) and methane (CH4) production potentials, volatile solids (VS) removal, and energy recovery. Six CM to WM VS ratios of 100:0, 90:10, 70:30, 50:50, 30:70, and 10:90 were examined using 1-L batch digesters. The WM VS ratio of 30 % was found to be the minimum limit for significant increases in specific H2 and CH4 yields, and VS removal as compared to digestion of manure alone (P < 0.05). The highest specific H2 and CH4 yields, VS removal and energy yield were 38.2 mL/g VS, 627.6 mL/g VS, 78.4 % and 25,459.8 kJ/kg VS, respectively, in CM:WM 30:70. Lag phases to H2 and CH4 productions were observed in CM–WM mixtures, increased with increasing the amount of WM in the feedstock and were greater than 72 h in CM:WM 50:50 and 30:70. The digestion system failed in CM:WM 10:90. The results suggest that CM:WM 30:70 was optimum, however, due to limited amount of WM usually generated and long lag phase at this ratio which may make the process uneconomical, CM:WM 70:30 is recommended in practice.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Development of alternative sources of energy has received considerable attention in recent years, mainly because of unsustainability of current energy system which is based on fossil fuels and global warming resulting from increased use of fossil fuels. Anaerobic digestion, a proven technology for conversion of various biomasses to biogas, is widely regarded as a source of renewable energy and an important technology for achieving pollution reduction. Anaerobic digestion is widely applied for management of animal manure, such as dairy cow manure (CM). However, utilization of animal manure as a sole substrate for biogas production is becoming unpopular due to relatively low biodegradability and biogas yields [1, 2]. Co-digestion with other energy-rich wastes is a possible approach for improving biogas yield. Main reasons for co-digestion of animal manure and other wastes are that the process could provide better carbon and nutrient balance and dilute the inhibiting factor, which will result in increased biogas production.

According to El-Mashad and Zhang [2], the cost-effectiveness of co-digestion of CM and other wastes could be improved if the co-substrate is obtained in the vicinity of dairy farms. In the light of this reason, waste milk (WM) from cows treated for mastitis is a desirable co-substrate to co-digest with CM. Mastitis is a common and costly disease of dairy cow, and it is often treated with therapeutic use of antibiotics. Milk produced during the withdrawal period of antibiotic is usually disposed of as waste. Disposal of WM originating from therapeutically treated cows without appropriate treatment raises some environmental concerns. WM, irrespective of the source, is a high polluting waste that can cause serious contamination of surface and ground waters if discharged directly to the water courses without any treatment [3]. In addition, WM from treated cows could be a potential source of antibiotic resistant bacteria and antibiotic residues to the environment, and both independently or in conjunction could play a role in selection of antibiotic resistance by indigenous bacteria in the vicinity of the farm. Anaerobic co-digestion with dairy cow manure is an environmentally friendly method for disposal of WM [3].

Few reports regarding co-digestion of dairy manure and milk have been published. Callaghan et al. [3], during mesophilic co-digestion of milk and cattle slurry under shock loading conditions, found that methane production rate increased with loading of milk as compared to loading of cattle slurry, though high initial depression of biogas methane concentration was also observed with addition of milk. Wu et al. [4], at 37 °C, found that addition of 1–19 % (v/v) milk from milking operation increased cumulative biogas volume by 5.6–103.8 % when compared with that of dairy manure alone. During batch thermophilic biohydrogen production from co-digestion of CM and WM from cows treated for mastitis, Lateef et al. [5] reported maximum hydrogen yield of 59.5 mL/g VS at WM VS ratio of 70 % and organic load of 40 g VS/L. The results of these studies suggested that increasing the fraction of milk in the feedstock when co-digesting with dairy manure should increase biogas yield. However, given that milk is easily hydrolysable feedstock, addition of large quantity of milk could cause digester failure. In addition, quantity of WM generated as compared to dairy manure is a limiting factor in utilization of WM as a feedstock for anaerobic digestion. It is, therefore, important to determine the possible amount of WM to co-digest with dairy manure for efficient digester performance. Moreover, information on the two-stage hydrogen and methane productions from co-digestion of CM and WM has not been well reported.

Production of methane from the digestate produced by dark fermentation process for hydrogen production is one of the possible ways to recover the total energy content and reduce further the organic matter. The two-stage anaerobic process is an economically feasible alternative in the near future for treating residual biomass from dark fermentation process and attaining significant pollution reduction [6]. The characteristics of WM from cows treated for mastitis can vary widely, depending on factors which include physiology of the animal and the time when the milk is collected. The variation can affect digester performance. Hydrogen production/acidification in the first stage could improve stability of the overall digestion process by avoiding overloading or inhibition of methanogens [7]. However, it is unclear whether phase separation could prevent digester failure at high loading of WM.

The aim of the present work was to examine the effect of various CM to WM ratios on the system performance in terms of specific hydrogen yield (SHY), specific methane yield (SMY), VS reduction and energy recovery. Given that limited amount of WM is usually generated, the data from the experiment will be helpful in determining minimum amount of WM required for significant enhancement in hydrogen and methane productions from CM. In addition, the maximum loading of WM required to produce digester failure will be determined.

Materials and methods

Materials

Cow manure was obtained from reception pit of farm scale thermophilic biogas digester at Obihiro University of Agriculture and Veterinary Medicine, Obihiro, Hokkaido, Japan. Digested slurry obtained from the same biogas digester was used as inoculum for the second stage experiment. They were sieved through 1.6-mm sieve to remove bedding and other coarse materials. WM was collected from cows treated for mastitis on the second day (morning) after the cows were given cefazolin (CFZ) antibiotic. The characteristics of CM, WM, and inoculum are given in Table 1.

Experimental procedure

The hydrogen and methane production potentials of the CM–WM mixtures were examined at six CM:WM volatile solids (VS) ratios of 100:0 (control), 90:10, 70:30, 50:50, 30:70, and 10:90. The experiments were conducted in 1-L batch digesters, working volume of 600 mL. CM was heat-shock pretreated as described by Gilroyed et al. [8]. Treated manure was combined with WM and distilled water to produce mixtures of desired CM:WM ratios and total VS of 40 g/L. The initial pH of the mixtures in each digester was adjusted to 6.2 with 2 M HCl.

Completion of hydrogen production was assumed when no hydrogen gas was detected in produced biogas or no biogas production was observed. Subsequently, each digester was opened and 200 mL of the substrate was removed. The same amount of inoculum was added for second stage methane production and the pH in each digester was adjusted to 7.5 by 2 M NaOH. The duration of methane production experiments was 30 days. Two blank digesters containing only inoculum were operated to measure methane production and VS removal from the inoculum.

In each of the above experiments, the digesters were flushed with argon gas prior to sealing. They were placed in water baths that were maintained at 55 °C and were shaken manually once daily. No supplemental nutrients were added to the substrate. Each experiment was conducted in duplicate. The evolved biogas was collected with gas bag. The volume and composition of biogas were measured periodically. Samples of the mixtures were taken at the beginning and the end of each experiment to analyze for pH, total solids (TS), VS degradation, and volatile fatty acids (VFA).

Analytical methods

Total solids (TS) were determined by drying the samples at 105 °C for 24 h. The solid content was calculated from the difference between weights before and after drying. The dried matter was heated at 550 °C for 4 h, and organic matter (volatile solids, VS) content was calculated from the loss on ignition.

The slurry samples were analyzed for VFA (acetic, propionic, butyric and formic acids) with high performance liquid chromatography (HPLC, Shimadzu LC-10AD) and Shim-Pack SCR-102H column. The column temperature was 45 °C. Mobile phase consisted of 5-mM p-toluene sulfonic acid at flow rate of 0.8 mL/min. Buffer consisted of 5-mM p-toluene sulfonic acid, 20-mM Bis–Tris and 100 μM of EDTA at flow rate of 0.8 mL/min. For the analysis, 3 g sample was mixed with 6 mL of 1.26 M sulfuric acid and 6 mL of 10 % wt/wt tungsten acid. The mixture was homogenized at 10,000 g for 5 min, and then it was centrifuged at 10,000 rpm for 20 min. The supernatant was filtered through 0.45-μm filter before it was used for the analysis.

The volume of biogas produced was measured by wet gas meter. Prior to measuring, gas sample was taken with air-tight micro syringe. The composition was determined using a Shimadzu gas chromatograph (GC-14C) equipped with a thermal conductivity detector (stainless column and Porapak Q packing). The operational temperatures of injector port, column, and the detector were 220, 150, and 220 °C, respectively. Argon was the carrier gas at a flow rate of 50 mL/min.

Data analysis

The results are presented as means of duplicate experiments. Statistical analysis was performed at 0.05 probability level using SAS 9.2 for Windows (SAS Institute Inc., Cary NC, USA).

For kinetic analysis, the modified Gompertz model [Eq. (1)] was used to fit the cumulative hydrogen and methane production data obtained:

where, Y is the cumulative hydrogen or methane production (mL), P is hydrogen or methane production potential (mL), R m is maximum hydrogen or methane production rate (mL/h), e is 2.71828, λ is lag phase time (h) and t is time (h). The parameters of the equation were nonlinearly estimated using “Solver” function in Microsoft Excel 2010.

Results and discussion

Hydrogen potential

This study tested feasibility of enhancing hydrogen and methane production from CM by addition of varying quantities of waste milk. Figure 1 shows hydrogen concentrations in the produced gas and cumulative hydrogen production from the CM:WM ratios. As expected, hydrogen concentration in the produced biogas increased with increase in WM fraction with highest concentration (45.2 %) observed in CM:WM 50:50, which is higher than 41.4 % previously reported from the same ratio [5]. However, further increase of WM fraction slightly decreased the concentration. It was not detected in CM:WM 10:90. Similarly, low concentrations (0.6–4.6 %) were observed in CM:WM 100:0. Manure was heat-shock pretreated to inhibit the activity of methanogenic bacteria. However, methane gas was detected in biogas produced in CM:WM 100:0, 90:10, and 70:30 (data not shown), indicating that methanogenic activity was not totally inhibited in the digesters in these ratios. The amount (0.3–2.3 %) observed in CM:WM 90:10 and 70:30 did not significantly affect hydrogen production as evident from hydrogen concentrations in the produced biogas; however, low concentration of hydrogen in CM:WM 100:0 could be a result of significant methane production (methane concentration of 0.2–41.0 % from 24 to 96 h). Fermentation pH plays a pivotal role in suppressing activity of methanogenic bacteria during hydrogen production [9] and methanogenic activity will likely proceed optimally in pH range of 6.3 and 7.8 [10]. The high alkalinity of manure coupled with initial pH of 6.2 used in this study might have provided optimum condition for survival and increase in concentration of methanogens with time in CM:WM 100:0. However, reduction or absence of methane gas with reduced fractions of manure in the mixtures can be attributed to rapid productions of VFA and reduced alkalinities, which probably reduced the pHs to critical levels for methanogens. These observations are supported by the results of final pH after fermentation (Fig. 2). These reasons show that addition of WM provided balanced condition for hydrogen production from manure.

Parameters of modified Gompertz model obtained from data of hydrogen production are presented in Table 2. The cumulative hydrogen productions measured in the experiment were 98.1–100 % of corresponding P. Hydrogen production rate increased with WM concentration, and the highest rate (24.2 mL/h) was achieved with CM:WM 70:30, which suggests that the best substrate in terms of productivity rate would be one which contains manure VS ratio of 70 %. Further increase in WM reduced the production rate. The absence of lag phase to hydrogen production observed in CM:WM 100:0 and 90:10 (Table 2) was expected since manure served a dual purpose, as inoculant and co-substrate, and higher amount of manure implied that higher numbers of hydrogen-producing bacteria were introduced into the digesters. The lag phase increased disproportionately with further increase in amount of WM. Typically, lag phase increases with decrease in concentrations of inoculum relative to the substrate. However, when the results are compared with that of previous work [5]; the lag phase with increased amount of WM seems to be longer. The lag phases observed in previous work were 23.3, 35.6, and 61.8 h in CM:WM 70:30, 50:50, and 30:70, respectively, and they are less than 44.7, 87.3, and 105.0 h, respectively, in the same ratios in the present study. The observed longer lag phases were probably the result of higher concentrations of antibiotic residue in WM. WM used in the current study was obtained in the morning, while in the previous study it was collected in the evening. Preliminary work in our laboratory indicated that milk sample from treated cow obtained in the morning contains higher concentration of antibiotic than the sample obtained in the evening. The observed lag phases in the present study appear to be indications of inhibitions to hydrogen productions in digesters with high amount of WM. These inhibitions probably occurred as a result of increase in inhibitory materials as amount of WM increased in the mixtures and reduced ability of fermentative bacterial population to cope with inhibitory effect.

The SHYs from CM–WM mixtures are presented in Table 3. Fermentation of manure alone gave a low yield (0.7 mL/g VS), indicating that CM used in this study is not a favorable substrate for hydrogen production. Gilroyed et al. [8] and Yokoyama et al. [11] reported hydrogen yields of 65 and 29 mL/g VS; much higher values, from feedlot cattle manure and mixture of cow feces and urine at 52 and 60 °C, respectively. The higher hydrogen yields reported in those studies compared with that obtained in the present study were most likely due to differences in composition of manures used as substrates, since characteristics of animal manure and their potentials for biogas production vary greatly, depending on species, breed, diets, age, etc. [12]. Compared with manure alone, increase in yield was significant at WM VS ratio of 30 % or more (P < 0.05), indicating that WM VS ratio of 30 % represents lower limit below which the contribution of WM in the mixture would become insignificant. The observed improvement in SHY mainly resulted from addition of WM, a lactose-rich and high-fat substrate, as evident from calculated SHY based on VS of WM added (ca. 29.4, 70.6, 70.9, and 26.4 mL/g VS–WM in CM:WM 90:10, 70:30, 50:50, and 30:70, respectively). However, the values show that the yield was also dependent on the amount of manure added, which further highlights the importance of co-digestion of CM and WM. Maximum yield of 35.8 mL/g VS during the first stage was achieved in CM:WM 50:50. The SHYs achieved with CM:WM 70:30 and 50:50 in this study are higher in comparison with 16.1 and 34.4 mL/g VS, respectively, reported previously from the same ratios [5], indicating that the SHYs were not affected negatively in these ratios, despite longer lag phases. The reverse is the case in CM:WM 30:70, where yield of 18.1 mL/g VS obtained in the current study is lower than 59.5 mL/g VS reported previously from the same ratio [5], which further suggests that inhibition to hydrogen production was more pronounced in digesters with high loading of WM.

The use of CFZ, a β-lactam antibiotic, as a treatment for mastitis in cow leads to antibiotic residues in WM. As stated previously, the observed longer lag phases in the present study as compared with that of the previous study [5] likely resulted from higher concentrations of antibiotic in WM. In our preliminary work, a considerable amount of antibiotic (15.0–16.1 mg/L) was detected in WM sample obtained in the morning from treated cow. Presence of antibiotic or antibiotic metabolites in digestion substrate can inhibit digestion activity of anaerobic bacteria [13, 14]. Little is known about inhibitory effect of CFZ on anaerobic bacteria, especially part of anaerobic community that is mainly affected by its inhibitory effect. Sanz et al. [15] reported that at concentration of 10 mg/L, other β-lactam antibiotics (ampicillin, novobiocin and penicillin) caused a 30–40 % reduction in biogas production. However, a recent study [16] reported that CFZ exerted no significant effect on biogas and methane productions at concentrations of 30, 60, and 90 mg/L. The reason for the absence of significant effect on biogas and methane productions with the use of CFZ in their work could be the type of inoculum used, which was obtained from digester treating mixture of CM and WM from cows treated for mastitis. They, however, observed that at high concentrations of CFZ, lag phase of methane production was present. This could have been a result of significant inhibitory effect of CFZ on acidogenesis stage, which likely supports the observation of long phase of hydrogen production in the present study. From the results of the present study, it appears that in practical application, CFZ residue in the produced WM will impact negatively on hydrogen production from co-digestion CM and WM. Further experimentations would be required to fully understand the inhibitory effect of CFZ on hydrogen production. Given that the changes in SHY as a result of inhibitory effect of CFZ seemed to be less significant at low concentration of WM, it would be reasonable to suggest limiting the percentage of WM to about 30 % (VS basis) for practical application.

The production and distribution of VFA, which reflect changes in metabolic pathway of microorganisms involved in hydrogen production, are determined by factors such as fermentation pH and substrate types [17, 18]. The results in Fig. 2 reveal that the concentration, production, and distribution of VFA were determined by relative amount of WM in the mixture. Generally, high fractions of WM favored butyrate generations, which agree with the results of our earlier study [5]. The results also agree with the observation of Wang et al. [18] that carbohydrate-rich substrates will take butyrate fermentation type, while protein-rich substrates will likely produce more acetate than butyrate. WM is a lactose-rich substrate, which probably explains more generation of butyrate as amount of WM increased in the mixtures. Based on this observation, final concentration of acetic acid was expected to be higher in CM:WM 100:0 than 90:10; however, the reverse was the case. The phenomenon can be explained by significant methane production in CM:WM 100:0. A closer examination of Fig. 2b also reveals that butyric acid concentration was not remarkably higher in CM:WM 30:70 than in 50:50 despite higher amount of WM, a trend that is different from that of previous work [5]. The observed pattern indicates that there was a reduction in the activity of acid-forming bacteria at WM VS ratio above 50 %, which further confirms inhibition to hydrogen production. The pattern of pH reduction among the CM/WM ratios indicates that manure provided alkalinity against pH reduction as similarly observed by Perera and Nirmalakhandan [19] and this illustrates the importance of co-digestion in providing favorable condition for hydrogen production.

Methane potential

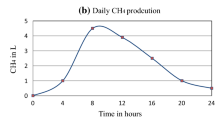

Addition of WM did not only enhance hydrogen production during the first stage, but also improved methane production during the second stage. Methane concentrations in the produced biogas and cumulative methane productions from CM–WM mixtures are presented in Fig. 3. There were no significant differences among average methane contents in biogas at CM:WM 100:0, 90:10, 70:30, 50:50, and 30:70 (P > 0.05). However, when they were considered by the time-point, there were significant differences (P < 0.05). Maximum concentrations of 69, 73, 73, 72, and 78 % were observed at 120, 144, 168, 240, and 432 h in CM:WM 100:0, 90:10, 70:30, 50:50, and 30:70, respectively, indicating that addition of WM increased methane content of the biogas. This agrees with observation of Callaghan et al. [3] who reported that addition of milk to mesophilic digester treating cattle slurry increased methane content of produced biogas. Hydrogen gas, concentration ranging from 1.6 to 23.7 %, was detected in biogas produced at 24 h and 48 h in CM:WM 50:50, 30:70, and 10:90. This indicates that despite the fact that their periods of digestion were prolonged in the first stage, their hydrogen productions were not completed. Methane productions in CM:WM 50:50 and 30:70 were not significantly affected by VFA produced along with hydrogen during the second stage, as evident from the results of methane concentration in the produced gas. However, in CM:WM 10:90, the production ceased at 168 h (day 7) due to accumulation of VFA. When hydrogen production during the second stage is taken into account (Table 3), the combined total in CM:WM 30:70, which was also the maximum hydrogen yield from all the mixtures, was 38.2 mL/g VS. The value is still less than maximum of 59.5 mL/g VS obtained previously with the same ratio [5], which further indicates that hydrogen production was inhibited by antibiotic residue in WM. Cumulative methane yield increased as the amount of WM increased in the feedstock with maximum of 12,954.3 mL in CM:WM 30:70.

The duration of lag phase to methane production is a key factor in determining the efficiency of anaerobic digestion. The lag phases to methane productions calculated with modified Gompertz model are presented in Table 4. Absence of lag phase in CM:WM 100:0 was expected, since methanogenic activity was not successfully suppressed in the first stage. Despite using the same amount of inoculum, lag time increased with increasing WM fraction. This phenomenon was related to high concentration of butyric acid with high amount of WM. VFAs are important intermediate products of anaerobic digestion process and methane is mainly produced from acetic acid degradation. Before being degraded to methane, butyric acid is converted to acetic acid. Degradation of butyric acid probably explains the observed lag phases. Methane production rate increased with WM concentration, and the highest value (64.1 mL/h) was achieved in CM:WM 70:30, which further suggests that optimum ratio in terms of biogas productivity rate would be 70:30. The calculated P in CM:WM 100:0, 90:10, 70:30, and 50:50 were less than experimental data; however, the reverse was the case in CM:WM 30:70.

The SHY (298.5 mL/g VS) obtained from digestion of manure alone in the present study (Table 3) compares well with values previously reported by Giuliano et al. [1] who obtained a 120 mL/g VS methane yield from CM under thermophilic temperature (55 °C), and El-Mashad and Zhang [2] who found out that screened dairy manure gave a methane yield of 302 mL/g VS under mesophilic temperature (35 °C). This indicates that methane yield from manure in the present study is typical of yields from dairy manure and that increases in yields produced by addition of WM are of some real significance. Compared with control, the increases in SMY were statistically significant at 30 % or more than 30 % VS of WM in the feedstock (P < 0.05), indicating that, as similarly observed for hydrogen production in the first stage, VS ratio of 30 % is the lowest limit of WM that can produce appreciable enhancement in methane production. The enhanced yields of 444.4–627.6 mL/g VS obtained from CM–WM mixtures also compare well with values that have been previously reported for co-digestion of manure and other materials in both batch and continuous experiments. El-Mashad and Zhang [2] reported lower values, 282 and 311 mL/g VS, from batch digestion of mixtures of unscreened dairy manure and food waste, at ratios of 68/32 and 52/48 % (VS basis), respectively. Callaghan et al. [20], using mixtures of cattle manure and food and vegetable wastes (FVW) at FVW ratios ranging from 30 to 50 % (wet weight), reported methane yields ranging from 230 to 450 mL/g VS. Other researchers have reported methane yields of 222–343 mL/g VS from co-digestion of CM and cheese whey [21, 22]. The results of the present study show that WM is an important co-substrate that could be used to enhance not only hydrogen production from CM, but also methane production.

The concentrations of VFAs and final pH in all the treatments after 720 h (30 days) digestion are shown in Fig. 4. The final concentrations of total VFA in CM:WM 100:0, 90:10, 70:30, 50:50, and 30:70 were 48.9, 16.1, 58.2, 19.6, and 161.3 mg/L, respectively, which correspond to degradation rates ranging between 96.6 and 99.8 %, if compared with the concentrations at the end of first stage. These results indicate stable performances with WM VS ratios of 10–70 %. High VFA concentrations can inhibit methanogens [23]. Final concentration of VFA in CM:WM 10:90 was 17,089 mg/L with acetic and butyric acids accounting for 56.9 and 32.2 %, respectively, of the total concentration. This explains the cessation of methane production at 168 h (day 7). The digester failure was related to the toxicity of free acetic acid. The observation is supported by result of final pH as excessive acetic acid concentration would cause decrease in bicarbonate alkalinity of the system thereby reducing the pH significantly and consequently affecting the activity of methanogens, which probably was the case in CM:WM 10:90. This implies that the advantage of two-stage process in avoiding organic overloading and inhibition of methanogenic population could not be achieved with WM VS ratio of 90 %. Ammonia may also be the cause of inhibition to methane production in CM:WM 10:90. Callaghan et al. [3] observed that digesters fed with cattle slurry and WM produced higher concentrations of ammonium-nitrogen and free ammonia compared with digester fed with cattle slurry alone. This suggests that toxicity of free ammonia produced as a result of high fraction of WM could have contributed to digester failure in CM:WM 10:90. Whether this is true would be tested in future work.

VS removal efficiency and biogas energy recovery

The benefit of WM in anaerobic co-digestion with dairy manure is highlighted by the results of VS removal efficiency and energy yield (Table 3). The overall VS removal efficiencies in CM–WM mixtures were significantly higher than 42.1 % observed in digestion of manure alone (P < 0.05). These indicate that addition of WM improved the substrate degradation as similarly observed by Wu et al. [4]. The observed VS removals from CM–WM mixtures were due to the fact that the VS in WM were more easily degradable than the VS in dairy manure. The values achieved in the present study are comparable to those obtained in two-stage process, in both batch and continuous digestion, by other workers. Yokoyama et al. [24], using CM mixed with artificial food waste (dog food) for hydrogen and methane production in two-stage batch process, achieved VS removal of 40 %. Schievano et al. [25] reported VS removal of 68.4 % in continuous hydrogen and methane production from thermophilic co-digestion of swine manure and market biowaste. Li et al. [26] obtained highest VS removals of 63.6 % from co-digestion of food waste and dairy manure in two-stage process. For energy yields based on the observed SHYs and SMYs, the heating values of 142 and 55.6 kJ/g, and the densities of 0.09 and 0.72 mg/mL for hydrogen and methane, respectively, were used. Generally, the hydrogen contribution to total energy yield was relatively low (0.1–2.2 % of the total energy produced), except in CM:WM 10:90 where methane production was inhibited. The highest energy recovery was achieved in CM:WM 30:70 which also showed highest VS removal.

Based on the overall results, it would appear that the best mixture would be CM:WM 30:70; however, some factors would limit its practical application. First, the quantity of WM usually produced would make the ratio not practically feasible. In addition, long lag phases to hydrogen and methane productions, may make the process uneconomical. Our results show that WM VS ratio of 30 % had highest productivity rate and is the lowest limit for enhanced hydrogen and methane production. In addition, the ratio would not be adversely affected by inhibitory effect of WM. Thus, it is recommended for practical application. In Field Research Centre at Obihiro University, Japan, slurry, consisting of 1.9–2.9 m3 of CM and 0.10–0.15 m3 of WM, is added to 60 m3 digester daily for single-stage methane production. These correspond to a maximum CM:WM of 90.5:9.5 (VS basis), which thus implies that current ratio of WM, which is based on actual production rate, is less than the recommended ratio (30 % VS of WM). The implication of this is that if first stage hydrogen production is to be coupled to the existing digester, the quantity of manure added would have to be reduced. Alternatively, other carbohydrate-rich waste stream could be added for enhanced hydrogen and methane productions. This area requires further studies.

Conclusions

The work shows that co-digesting CM with WM improves biogas yields, VS reduction and energy recovery. The WM VS ratio of 30 % was found to be the lowest limit for significant enhancement of hydrogen and methane productions, and improved VS removal. Lag phases to hydrogen and methane productions increased with increased amount of WM, while digestion systems in CM:WM 10:90 failed. The highest SHY, SMY, VS reduction, and energy recovery were achieved with CM:WM 30:70; however, because of limited quantity of WM usually generated and long lag phase to biogas production at high loading of WM, CM:WM 70:30 is recommended for large scale application.

References

Guiliano A, Bolzonella D, Pavan P, Cavinato C, Cecchi F (2013) Co-digestion of livestock effluents, energy crops and agro-waste: feeding and process optimization in mesophilic and thermophilic conditions. Bioresour Technol 128:612–618

El-Mashad HM, Zhang R (2010) Biogas production from co-digestion of dairy manure and food waste. Bioresour Technol 101:4021–4028

Callaghan FJ, Luecke K, Wase DAJ, Thayanithy K, Foster CF (1997) Co-digestion of cattle slurry and waste milk under shock loading conditions. J Chem Tech Biotechnol 68:405–410

Wu X, Dong C, Yao W, Zhu J (2011) Anaerobic digestion of dairy manure influenced by the waste milk from milking operations. J Dairy Sci 94(8):3778–3786

Lateef SA, Beneragama N, Yamashiro T, Iwasaki M, Ying C, Umetsu K (2012) Biohydrogen production from co-digestion of cow manure and waste milk under thermophilic temperature. Bioresour Technol 110:251–257

Gomez X, Fernandez C, Fierro J, Sanchez ME, Escapa A, Moran A (2011) Hydrogen production: two stage process for waste degradation. Bioresour Technol 102:8621–8627

Koutrouli EC, Kalfas H, Gavala HN, Skiadas IV, Stamatelatou K, Lybertos G (2009) Hydrogen and methane production through two-stage mesophilic anaerobic digestion of olive pulp. Bioresour Technol 100:3718–3723

Gilroyed BH, Chang C, Chu A, Hao X (2008) Effect of temperature on anaerobic fermentative hydrogen gas production from feedlot cattle manure using mixed microflora. Int J Hydrogen Energy 33:4301–4308

Liu D, Liu D, Zeng RJ, Angelidaki J (2006) Hydrogen and methane production from household solid waste in the two-stage fermentation process. Water Res 40:2230–2236

van Haandel A (1994) Influence of digested COD concentration on alkalinity requirement in anaerobic digesters. Water Sci Technol 30(8):23–24

Yokoyama H, Waki M, Moriya N, Yasuda T, Tanaka Y, Haga K (2007) Effect of fermentation temperature on hydrogen production from cow waste slurry by using anaerobic microflora within the slurry. Appl Microbiol Biotechnol 74:474–483

Moller HB, Sommer SG, Ahring BK (2004) Methane productivity of manure, straw and solid fractions of manure. Biomass Bioenergy 26:485–495

Lallai A, Mura G, Onnis N (2002) The effects of certain antibiotics on biogas production in the anaerobic digestion of pig waste slurry. Bioresour Technol 82:205–208

Alvarez JA, Otero L, Lema JM, Omil F (2010) The effect and fate of antibiotics during digestion of pig manure. Bioresour Technol 101:8581–8586

Sanz JL, Rodriguez N, Amils R (1996) The action of antibiotics on the anaerobic digestion process. Appl Microbiol Biotechnol 46:587–592

Beneragama N, Lateef SA, Iwasaki M, Yamashiro T, Umetsu K (2013) The combined effect of cefazolin and oxytertracycline on biogas production from thermophilic anaerobic digestion of dairy manure. Bioresour Technol 133:23–30

Khanal SK, Chen WH, Li L, Sung S (2004) Biological hydrogen production: effects of pH and intermediate products. Int J Hydrogen Energy 29:1123–1131

Wang W, Xie L, Chen J, Luo G, Zhou Q (2011) Biohydrogen and methane production by co-digestion of cassava stillage and excess sludge under thermophilic condition. Bioresour Technol 102:3833–3839

Perera KRJ, Nirmalakhandan N (2010) Enhancing fermentative hydrogen production from sucrose. Bioresour Technol 101:9137–9143

Callaghan FJ, Wase DAJ, Thayanithy K, Foster CF (2002) Continuous co-digestion of cattle slurry with fruit and vegetable wastes and chicken manure. Biomass Bioenergy 27(1):71–77

Lo KV, Liao PH (1989) Anaerobic-aerobic biological treatment of a mixture of cheese whey and dairy manure. Biol Waste 28:91–101

Comino E, Riggio VA, Rosso M (2012) Biogas production by anaerobic co-digestion of cattle slurry and cheese whey. Bioresour Technol 114:46–53

Siegert I, Banks C (2005) The effect of volatile fatty acid additions on the anaerobic digestion of cellulose and glucose in batch reactors. Process Biochem 40:3412–3418

Yokoyama H, Yamashita T, Ogino A, Ishida M, Tanaka Y (2010) Hydrogen fermentation of cow manure mixed with food waste. Jpn Agric Res Q 44(4):399–404

Schievano A, Tenca A, Scaglia B, Merlino G, Rizzi A, Daffonchio D, Oberti R, Adani F (2012) Two-stage vs single-stage thermophilic anaerobic digestion: comparison of energy production and biodegradation efficiencies. Environ Sci Technol 46:8502–8510

Li R, Chen S, Li X (2010) Biogas production from anaerobic co-digestion of food waste with dairy manure in a two-phase digestion system. Appl Biochem Biotechnol 160:643–654

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Lateef, S.A., Beneragama, N., Yamashiro, T. et al. Batch anaerobic co-digestion of cow manure and waste milk in two-stage process for hydrogen and methane productions. Bioprocess Biosyst Eng 37, 355–363 (2014). https://doi.org/10.1007/s00449-013-1000-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00449-013-1000-9

Acetic acid,

Acetic acid,  propionic acid,

propionic acid,  butyric acid,

butyric acid,  total VFA, and filled circles final pH

total VFA, and filled circles final pH

Acetic acid,

Acetic acid,  propionic acid,

propionic acid,  butyric acid,

butyric acid,  total VFA, and filled circles final pH

total VFA, and filled circles final pH