Abstract

Lipase (LP) was immobilized on electrospun and ethanol-dispersed polystyrene–poly(styrene-co-maleic anhydride) (PS–PSMA) nanofibers (EtOH-NF) in the form of enzyme precipitate coatings (EPCs). LP precipitate coatings (EPCs-LP) were prepared in a three-step process, consisting of covalent attachment, LP precipitation, and crosslinking of precipitated LPs onto the covalently attached LPs via glutaraldehyde treatment. The LP precipitation was performed by adding various concentrations of ammonium sulfate (20–50%, w/v). EPCs-LP improved the LP activity and stability when compared to covalently attached LPs (CA-LP) and the enzyme coatings of LPs (EC-LP) without the LP precipitation. For example, the use of 40% (w/v) ammonium sulfate resulted in EPC40-LP with the highest activity, which was 4.0 and 3.6 times higher than those of CA-LP and EC-LP, respectively. After 165-day incubation under rigorous shaking at 200 rpm, the residual activities of EPC50-LP were 0.5 μM/min mg of EtOH-NF, representing 113 and 75 times higher than those of CA-LP and EC-LP, respectively. When LP was partially purified via a simple ammonium sulfate precipitation and dialysis, both activities and stabilities of EC-LP and EPC-LP could be marginally improved. It is anticipated that the improved LP activity and stability in the form of EPCs would allow for their potential applications in various bioconversion processes such as biodiesel production and ibuprofen resolution.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Lipases (LPs) are one of the widely used enzymes in various applications such as detergents, organic synthesis, food industry, leather industry, and paper industry [1–4]. A variety of approaches have been proposed to achieve highly active and stable enzyme systems, which can improve the enzymatic bioprocesses [5–8]. Especially, the recent developments of nanobiocatalysis have gathered growing attention due to their successful results in achieving high enzyme loading and stability [9]. Various nanostructured materials, such as mesoporous materials [10–15], nanoparticles [16–18], carbon nanotubes [19–23], and electrospun nanofibers [22, 24–33], have been used for enzyme immobilization because their large surface areas can improve the loading and activity of enzymes per unit mass of materials. Among them, polymer nanofibers offer many advantageous features, such as durability, easy recovery, and lower mass transfer limitation by immobilizing enzymes on the nanofiber surface [34, 35].

The approach of enzyme coatings (EC) on polymer nanofibers, consisting of covalent attachment (CA) and enzyme crosslinking, has been successful in stabilizing the trypsin activity by preventing both enzyme denaturation and leaching [24, 27, 28, 31, 32]. Interestingly, however, the EC approach could not stabilize the activity of glucose oxidase (GOx), and an approach of enzyme precipitate coating (EPC) was proposed as a bypass and employed for the successful stabilization of GOx on polymer nanofibers [22]. The EPC approach, consisting of covalent attachment, enzyme precipitation and enzyme crosslinking, enables effective enzyme crosslinking by allowing for close contact between GOx molecules in their precipitate form.

In the present work, EPCs-LP were fabricated on the surface of alcohol-dispersed nanofibers (EtOH-NF) by precipitating LPs in various concentrations of ammonium sulfate, and their activities and stabilities were characterized in comparison of two other control samples of covalently attached LP (CA-LP) and enzyme coating of LP (EC-LP) with no step of enzyme precipitation. It has been demonstrated that all the EPC-LP samples showed higher activity per unit mass of EtOH-NF and better enzyme stabilization when compared to CA-LP and EC-LP. To further improve the results of EPC approach, LP was partially purified via a simple ammonium sulfate precipitation and dialysis, and used for the preparation of EC and EPC with improved activity and stability.

Materials and methods

Materials

Lipase from Candida rugosa (LP), 4-nitrophenyl butyrate (4-NB), glutaraldehyde (GA), tetrahydrofuran (THF), acetone, N,N-dimethylformamide (DMF), and ammonium sulfate were purchased from Sigma (St. Louis, MO, USA). Polystyrene (PS, M w = 900,000) and poly(styrene-co-maleic anhydride) (PSMA, M w = 224,000) were purchased from Aldrich (Milwaukee, WI, USA). Ethanol was purchased from Deajung (Siheung, Korea). The BCA protein assay reagent kit was purchased from Pierce (Rockford, IL, USA). Dialysis kits (MWCO 20 kDa) were purchased from Spectrum Laboratories, Inc. (Rancho Dominguez, CA, USA). All other reagents were purchased from Aldrich (Milwaukee, WI, USA) in the highest grade commercially available.

Preparation of LP-immobilized nanofibers

PS–PSMA polymer nanofibers were prepared via electrospinning the PS–PSMA mixture in a weight ratio of 2:1 in the THF and acetone mixture (4:1 volume ratio), as described previously [27]. The PS–PSMA polymer solution was loaded into a 5-ml plastic syringe equipped with 30-gauge stainless steel needle. Electrospinning was carried out under voltage 7 kV using a high-voltage supply (Ormond Beach, FL, USA). The PS–PSMA polymer solution was fed at a rate of 0.15 ml/h using a syringe pump (PHD-2000 Infusion, Harvard Apparatus, Holliston, MA, USA). The electrospun nanofibers (NFs) were collected on a grounded aluminum foil, placed at suitable distance (7–10 cm) from the tip of the steel needle. The NFs were immersed in aqueous ethanol solution (50%, v/v) and shaken at 200 rpm for 10 min. After the NFs were fully dispersed, ethanol-dispersed NFs (EtOH-NF) were washed with 50 mM sodium phosphate buffer (PB) (pH 7.0). EtOH-NF was kept in the same buffer until use.

The LP solution (1 mg/ml) was centrifuged (10,000 rpm for 10 min) to remove impurities, and the supernatant was used for the LP immobilization. CA-LP was prepared by incubating 1 mg of EtOH-NF in 2 ml of LP solution under shaking at 200 rpm for 2 h. For the preparation of EC-LP, the GA solution was added into the vial for the final concentration of 0.5% (w/v), and the vial was placed on a shaker (100 rpm) at room temperature for 30 min and on a rocker (50 rpm) at 4 °C for 5 h. For the case of CA-LP, PB was added into the vial instead of the GA solution. EPCs-LP were prepared by adding ammonium sulfate for the final concentration of 20, 30, 40, 50% (w/v) just before the step of enzyme crosslinking in the preparation of EC-LP. Then, the same GA treatment was performed as that for the preparation of EC-LP. All samples were washed with 50 mM PB (pH 7.0) three times. Unreacted maleic anhydride groups were capped by incubating the samples in 100 mM Tris–HCl buffer (pH 7.0) for 30 min, and the samples were excessively washed with 50 mM PB (pH 7.0). All the samples were stored in 50 mM PB (pH 7.0) at 4 °C until use.

Activity and stability measurements of CA-LP, EC-LP and EPC-LP

The activities of immobilized LP’s on EtOH-NF were measured by the hydrolysis of 20 mM 4-nitrophenyl butyrate (4-NB) in an aqueous buffer (50 mM PB, pH 7.0) at room temperature. The immobilized LP sample was added to a vial containing 10 ml of 4-NB solution, and the vial was shaken at 200 rpm. At each time point, an aliquot was withdrawn, and the absorbance at 410 nm (A 410) was measured using the UV–Vis spectrophotometer (Shimadzu, UV-2450, Kyoto, Japan). The initial rate was calculated from the time-dependent increase of A 410, and used for the calculation of activity per unit weight of polymer nanofibers.

The stabilities of immobilized LP’s on EtOH-NF under recycled uses were investigated by checking the LP activity time-dependently after incubating each sample in 50 mM PB (pH 7.0) at room temperature under shaking at 200 rpm. After each activity measurement, the samples were excessively washed using 50 mM PB (pH 7.0) to remove unreacted substrate and products, and incubated under rigorous shaking (200 rpm) until the next measurement. The relative activity at each time point was calculated from the ratio of residual activity to the initial activity of each sample.

Scanning electron microscopy (SEM) observation

The samples of EtOH-NF, CA-LP/EtOH-NF, EC-LP/EtOH-NF and EPC50-LP/EtOH-NF were excessively washed with deionized water, coated with thin layer of platinum, and observed using SEM (FESEM, Hitachi, S-4700, Tokyo, Japan).

Partial purification of lipase

LP (1 g) was dissolved in 100 ml of 50 mM PB (pH 7.0), centrifuged at 4 °C for 20 min, and the supernatant was used for the next step. Further purification was performed via ammonium precipitation and dialysis at 4 °C. In detail, ammonium sulfate (40%, w/v) was slowly added into the LP solution under stirring condition for 3 h. The precipitated LPs were centrifuged (10,000 rpm at 4 °C for 20 min), and the supernatant was taken to the next step. Additional ammonium sulfate (60%, w/v) was slowly added into the supernatant under stirring condition for 3 h. The precipitated LPs were centrifuged (10,000 rpm, 20 min, and 4 °C), and the supernatant was discarded. The LP precipitates were dissolved in 50 mM PB (pH 7.0), and dialyzed with the MWCO 20 kDa tubing overnight. The dialyzed LP was stored at 4 °C until use. Protein concentration was measured by BCA assay before and after purification step.

Results and discussion

Preparation and activity of EPCs-LP

The PS–PSMA NFs were prepared by electrospinning the mixture of PS and PSMA (2:1 weight ratio) dissolved in a mixture of THF and acetone (4:1 volume ratio) (Fig. 1). Electrospun NFs were a tightly aggregated clump in an aqueous solution, but could be dispersed via 50% (v/v) ethanol treatment. Ethanol-treated NFs (EtOH-NF) kept its dispersed shape even in distilled water (Fig. 1). The enzyme loadings of covalently attached LP on clumped NF and EtOH-NF were 11 and 66 μg/mg of nanofibers. EtOH-NF provides more accessible surface area and inter-fiber space for the covalent attachment of enzymes, leading to higher enzyme loading [33]. Figure 2 schematically shows the preparation of CA-LP, EC-LP, and EPC-LP. The maleic anhydride groups of PSMA reacted with the amino groups of LPs, leading to an easy covalently attachment of LPs (CA-LP). EC-LP was prepared by performing an additional step of enzyme crosslinking, while EPC-LP was fabricated by inserting the step of enzyme precipitation in the presence of ammonium sulfate between covalent attachment and enzyme crosslinking steps.

The activity of immobilized LP’s was measured by the hydrolysis of 4-NB in an aqueous buffer (50 mM PB, pH 7.0) under shaking (200 rpm). The activities of CA-LP and EC-LP were 1.62 and 2.12 μM/min mg of EtOH-NF, respectively (Fig. 3). This marginal activity increase of EC-LP suggests that the EC approach was not effective in developing multiple-layered LP coatings on the surface of EtOH-NF. When compared to successful results of ECs with highly purified trypsin (TR) [28] and chymotrypsin (CT) [29], a lot of impurities from the LP bottle would prevent the effective enzyme crosslinking. As a bypass, the approach of EPC introduces the enzyme precipitation just before the enzyme crosslinking. By that way, the enzyme precipitates would allow for closer contact between LP molecules that potentially enables more effective enzyme crosslinking, as demonstrated in the case of EPC-GOx [22].

To optimize the EPC protocol for LP immobilization, various concentrations of ammonium sulfate were used for the LP precipitation. Four different EPCs-LP were prepared by performing the LP precipitation in the presence of 20, 30, 40, and 50% (w/v) ammonium sulfate, which were represented by EPC20-LP, EPC30-LP, EPC40-LP, and EPC50-LP, respectively. The activities of EPC20, EPC30, EPC40 and EPC50 were 4.55, 6.02, 7.06 and 4.87 μM/min mg of EtOH-NF, respectively. It suggests that 40% (w/v) ammonium sulfate is the optimal concentration for the preparation of active EPCs-LP. The activity of EPC40-LP was 4.4 and 3.3 times higher than those of CA-LP and EC-LP, respectively. The improved activity of EPCs-LP supports that the close contact between CA-LP and precipitated LP molecules results in more effective crosslinking of LP molecules. In other words, a simple addition of enzyme precipitation step plays a critical role in increasing the activity of LP per unit mass of NFs.

Stabilities of EPCs-LP

The stabilities of CA-LP, EC-LP and EPCs-LP on EtOH-NF under recycled uses were checked by measuring the residual activity after incubation in an aqueous buffer under shaking (200 rpm) at room temperature (Fig. 4). The residual activity of each sample was measured at specified time points by the hydrolysis of 20 mM 4-NB in an aqueous solution. After each measurement of enzyme activity, the sample was excessively washed with 50 mM PB (pH 7.0), and then incubated in an aqueous buffer under shaking (200 rpm) at room temperature until the next measurement of residual activity. The residual activities of both CA-LP and EC-LP decreased rapidly, and EC-LP did not show any improvement in the LP stability when compared to CA-LP. On the other hand, all EPCs-LP showed better stability than CA-LP and EC-LP. Among EPCs-LP, EPC50-LP showed the best stabilization of LP activity. After 165-day incubation under rigorous shaking at 200 rpm, the residual activities of EPC50-LP were 0.5 μM/min mg of EtOH-NF, representing 113 and 75 times higher than those of CA-LP and EC-LP, respectively. The improved LP stability in the form of EPCs suggests that the enzyme precipitation plays an important role for more effective crosslinking of LP molecules, which can reduce the degree of both enzyme denaturation and leaching under shaking and recycled uses. The SEM images of EtOH-NF, CA-LP/EtOH-NF and EC-LP/EtOH-NF did not show big difference while EPC50-LP/EtOH-NF has thick coatings of crosslinked LP (Fig. 5). This SEM result strongly supports the important role of enzyme precipitation in forming crosslinked LP coatings on EtOH-NF.

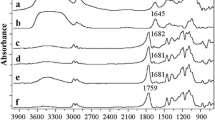

EPC50-LP using partially purified LP

LP from C. rugosa (57 kDa) used in this work contains approximately 30% lactose and some other impurities [36], which can potentially hinder the effective enzyme crosslinking in the preparation of EC and EPC. To remove the impurities, we performed a simple step of partial purification, consisting of centrifugation of LP solution, ammonium sulfate precipitation, and dialysis (MWCO 20 kDa). The specific activity of LP after centrifugation only was 1.6 μM/min mg of LP while that of LP after the above partial purification was 42.7 μM/min mg of LP. This suggests that the purity of LP was increased by approx. 27-fold after purification step (Table 1). Both LP and partially purified LP were used to prepare EC and EPC, and the activity and stability were checked to compare those before and after partial purification of LP. The activity of EC-LP was increased from 2.1 to 3.4 μM/min mg of EtOH-NF by replacing LP with partially purified LP. The activity of EPC50 was also increased from 4.9 μM/min mg of EtOH-NF (just centrifuged LP) to 5.5 μM/min mg of EtOH-NF (partially purified LP). The use of partially purified LP also improved the LP stability in the forms of both EC and EPC. The relative activity of EC-LP after 22 days was increased from 22% (just centrifuged LP) to 37% (partially purified LP), while that of EPC50 was enhanced from 45% (just centrifuged LP) to 53% (partially purified LP) (Fig. 6). These results suggest that the LP purification via ammonium sulfate precipitation and dialysis reduced the impurities, allowing for more effective crosslinking of LP molecules for the preparation of EC and EPC.

Conclusions

EPCs-LP on alcohol-dispersed PS–PSMA nanofibers were successfully fabricated by introducing the LP precipitation step just before enzyme crosslinking. The resulting EPCs improved the enzyme activity and showed better stability than CA-LP and EC-LP. Moreover, the activity and stability of EPC-LP could be further enhanced when partially purified LP was used. Even though the present work is focused on the immobilization of LP on polymer nanofibers, the protocol in the present work can be expanded to the other enzymes and nanostructured materials. Furthermore, stabilized LP in the form of EPC-LP can be employed to LP-related bioprocesses, including biodiesel production and ibuprofen resolution.

References

Gandhi NN, Patil NS, Sawant SB, Joshi JB, Wangikar PP, Mukesh D (2000) Lipase-catalyzed esterification. Catal Rev Sci Eng 42:439–480

Jaeger KE, Eggert T (2002) Lipases for biotechnology. Curr Opin Biotechnol 13:390–397

Schmid RD, Verger R (1998) Lipases: interfacial enzymes with attractive applications. Angew Chem Int Ed 37:1609–1633

Sharma R, Chisti Y, Banerjee UC (2001) Production, purification, characterization, and applications of lipases. Biotechnol Adv 19:627–662

Kondo A, Murakami F, Kawagoe M, Higashitani K (1993) Kinetic and circular-dichroism studies of enzymes adsorbed on ultrafine silica particles. Appl Microbiol Biotechnol 39:726–731

Livage J, Coradin T, Roux C (2001) Encapsulation of biomolecules in silica gels. J Phys Condens Matter 13:R673–R691

Svendsen A (2000) Lipase protein engineering. Biochim Biophys Acta Protein Struct Mol Enzymol 1543:223–238

Tischer W, Kasche V (1999) Immobilized enzymes: crystals or carriers? Trends Biotechnol 17:326–335

Kim J, Grate JW, Wang P (2008) Nanobiocatalysis and its potential applications. Trends Biotechnol 26:639–646

Diaz JF, Balkus KJ (1996) Enzyme immobilization in MCM-41 molecular sieve. J Mol Catal B Enzym 2:115–126

Han YJ, Watson JT, Stucky GD, Butler A (2002) Catalytic activity of mesoporous silicate-immobilized chloroperoxidase. J Mol Catal B Enzym 17:1–8

Kim MI, Kim J, Lee J, Jia H, Bin Na H, Youn JK, Kwak JH, Dohnalkova A, Grate JW, Wang P, Hyeon T, Park HG, Chang HN (2007) Crosslinked enzyme aggregates in hierarchically-ordered mesoporous silica: a simple and effective method for enzyme stabilization. Biotechnol Bioeng 96:210–218

Kim MI, Kim J, Lee J, Shin S, Bin Na H, Hyeon T, Park HG, Chang HN (2008) One-dimensional crosslinked enzyme aggregates in SBA-15: superior catalytic behavior to conventional enzyme immobilization. Microporous Mesoporous Mater 111:18–23

Lee J, Kim J, Jia HF, Kim MI, Kwak JH, Jin SM, Dohnalkova A, Park HG, Chang HN, Wang P, Grate JW, Hyeon T (2005) Simple synthesis of hierarchically ordered mesocellular mesoporous silica materials hosting crosslinked enzyme aggregates. Small 1:744–753

Takahashi H, Li B, Sasaki T, Miyazaki C, Kajino T, Inagaki S (2000) Catalytic activity in organic solvents and stability of immobilized enzymes depend on the pore size and surface characteristics of mesoporous silica. Chem Mater 12:3301–3305

Dyal A, Loos K, Noto M, Chang SW, Spagnoli C, Shafi K, Ulman A, Cowman M, Gross RA (2003) Activity of Candida rugosa lipase immobilized on gamma-Fe2O3 magnetic nanoparticles. J Am Chem Soc 125:1684–1685

Hong R, Fischer NO, Verma A, Goodman CM, Emrick T, Rotello VM (2004) Control of protein structure and function through surface recognition by tailored nanoparticle scaffolds. J Am Chem Soc 126:739–743

Lee J, Lee Y, Youn JK, Bin Na H, Yu T, Kim H, Lee SM, Koo YM, Kwak JH, Park HG, Chang HN, Hwang M, Park JG, Kim J, Hyeon T (2008) Simple synthesis of functionalized superparamagnetic magnetite/silica core/shell nanoparticles and their application as magnetically separable high-performance biocatalysts. Small 4:143–152

Azamian BR, Davis JJ, Coleman KS, Bagshaw CB, Green MLH (2002) Bioelectrochemical single-walled carbon nanotubes. J Am Chem Soc 124:12664–12665

Chen RJ, Zhang YG, Wang DW, Dai HJ (2001) Noncovalent sidewall functionalization of single-walled carbon nanotubes for protein immobilization. J Am Chem Soc 123:3838–3839

Fischback MB, Youn JK, Zhao XY, Wang P, Park HG, Chang HN, Kim J, Ha S (2006) Miniature biofuel cells with improved stability under continuous operation. Electroanalysis 18:2016–2022

Kim BC, Zhao X, Ahn H-K, Kim JH, Lee H-J, Kim KW, Nair S, Hsiao E, Jia H, Oh M-K, Sang BI, Kim B-S, Kim SH, Kwon Y, Ha S, Gu MB, Wang P, Kim J (2011) Highly stable enzyme precipitate coatings and their electrochemical applications. Biosens Bio-electron 26:1980–1986

Zhao XY, Jia HF, Kim J, Wang P (2009) Kinetic limitations of a bioelectrochemical electrode using carbon nanotube-attached glucose oxidase for biofuel cells. Biotechnol Bioeng 104:1068–1074

Ahn HK, Kim BC, Jun SH, Chang MS, Lopez-Ferrer D, Smith RD, Gu MB, Lee SW, Kim BS, Kim J (2010) Robust trypsin coating on electrospun polymer nanofibers in rigorous conditions and its uses for protein digestion. Biotechnol Bioeng 107:917–923

Herricks TE, Kim SH, Kim J, Li D, Kwak JH, Grate JW, Xia YN (2005) Direct fabrication of enzyme-carrying polymer nanofibers by electrospinning. J Mater Chem 15:3241–3245

Jia HF, Zhu GY, Vugrinovich B, Kataphinan W, Reneker DH, Wang P (2002) Enzyme-carrying polymeric nanofibers prepared via electrospinning for use as unique biocatalysts. Biotechnol Prog 18:1027–1032

Jun SH, Chang MS, Kim BC, An HJ, Lopez-Ferrer D, Zhao R, Smith RD, Lee SW, Kim J (2010) Trypsin coatings on electrospun and alcohol-dispersed polymer nanofibers for a trypsin digestion column. Anal Chem 82:7828–7834

Kim BC, Lopez-Ferrer D, Lee SM, Ahn HK, Nair S, Kim SH, Kim BS, Petritis K, Camp DG, Grate JW, Smith RD, Koo YM, Gu MB, Kim J (2009) Highly stable trypsin-aggregate coatings on polymer nanofibers for repeated protein digestion. Proteomics 9:1893–1900

Kim BC, Nair S, Kim J, Kwak JH, Grate JW, Kim SH, Gu MB (2005) Preparation of biocatalytic nanofibres with high activity and stability via enzyme aggregate coating on polymer nanofibres. Nanotechnology 16:S382–S388

Lee JH, Hwang ET, Kim BC, Lee SM, Sang BI, Choi YS, Kim J, Gu MB (2007) Stable and continuous long-term enzymatic reaction using an enzyme-nanofiber composite. Appl Microbiol Biotechnol 75:1301–1307

Lee SM, Jin LH, Kim JH, Han SO, Na HB, Hyeon T, Koo YM, Kim J, Lee JH (2010) Beta-glucosidase coating on polymer nanofibers for improved cellulosic ethanol production. Bioprocess Biosyst Eng 33:141–147

Lee SM, Nair S, Ahn HK, Kim BS, Jun SH, An HJ, Hsiao E, Kim SH, Koo YM, Kim J (2010) Property control of enzyme coatings on polymer nanofibers by varying the conjugation site concentration. Enzyme Microb Technol 47:216–221

Nair S, Kim J, Crawford B, Kim SH (2007) Improving biocatalytic activity of enzyme-loaded nanofibers by dispersing entangled nanofiber structure. Biomacromolecules 8:1266–1270

Bognitzki M, Czado W, Frese T, Schaper A, Hellwig M, Steinhart M, Greiner A, Wendorff JH (2001) Nanostructured fibers via electrospinning. Adv Mater 13:70–72

Huang ZM, Zhang YZ, Kotaki M, Ramakrishna S (2003) A review on polymer nanofibers by electrospinning and their applications in nanocomposites. Compos Sci Technol 63:2223–2253

Brahimihorn MC, Guglielmino ML, Elling L, Sparrow LG (1990) The esterase profile of a lipase from Candida cylindracea. Biochim Biophys Acta Lipids Lipid Metab 1042:51–54

Acknowledgments

Portions of this work were supported by the National Research Foundation (NRF) grants (2009-0082314, 2009-0059861, 2009-0075638, and K20902001448-10E0100-03010) provided by the Korean Ministry of Education, Science & Technology (MEST), and by the Seoul R&BD Program (10920).

Author information

Authors and Affiliations

Corresponding authors

Additional information

H.J. An and H.-J. Lee contributed equally to this work.

Rights and permissions

About this article

Cite this article

An, H.J., Lee, HJ., Jun, SH. et al. Enzyme precipitate coatings of lipase on polymer nanofibers. Bioprocess Biosyst Eng 34, 841–847 (2011). https://doi.org/10.1007/s00449-011-0534-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00449-011-0534-y