Abstract

Macroporous poly(N-ethylacrylamide) (PNEAM) hydrogels have been prepared in a methanol-water (1:1, v/v) mixture in the presence of 0, 0.05, 0.1, 0.15, and 0.2 M yttrium trifluoromethanesulfonate [Y(OTf)3] Lewis acid (LA) concentrations. SEM micrographs show that the resulted hydrogels are highly porous. Swelling ratios of all the hydrogels in water decrease with the increase in the temperature, and the hydrogels show lower critical solution temperature (LCST) volume phase transition at around 75 °C. LCST of PNEAM homopolymers gradually increases with the increase in the isotacticity of the polymers. Moreover, the hydrogels show cononsolvency in different methanol-water mixtures at 50 °C. Deswelling rate of the hydrogels prepared in the presence of LA is higher than the gel prepared in the absence of LA and this rate increases with increase in the LA concentration. The reswelling rate of the hydrogels also follows the same order, that is reswelling rate also increases with the increase in the LA loading in the gels. All these results are explained on the basis of the formation of the highly porous hydrogels with a higher isotactic PNEAM chain segment in a methanol-water mixture in the presence of LA.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Stereoregularity is an important parameter for the polymers. Stereoregularity is measured by tacticity. Tacticity is the measurement of degree of stereocontrol in a polymerization reaction. In tacticity, a polymer deals with the relationship between two adjacent monomer units consisting of meso (m) and recimo (r) dyad. The control on stereoregularity affects the polymer properties, like solubility, crystallinity, mechanical properties, melting point, etc. [1]. Generally, there are three types of stereoregular polymers, namely (i) isotactic, (ii) syndiotactic, and (iii) atactic polymers. Isotactic and syndiotactic polymers are highly stereoregular in nature. In this present study, we will discuss about isotactic poly(N-ethylacrylamide) (PNEAM).

Poly(N-isopropylacrylamide) (PNIPAM) is the most widely studied thermoresponsive polymer. Its homopolymer or cross-linked gel undergoes volume phase transition at around 33 °C, its lower critical solution temperature (LCST). It also undergoes volume phase transition in water-miscible organic solvents like methanol-water [2], ethanol-water [3], dimethylformamide (DMF)-water, etc. below its LCST value. This is mainly due to its cononsolvency phenomenon, where a mixture of two good solvents of a polymer behaves as a poor solvent at specific compositions for the same. Due to these natures, it is also very important for both industrial and biomedical applications. Introduction of the stereoregularity in the PNIPAM affects its properties significantly, like cloud point temperature [4–6], glass transition temperature [7–10], upper critical solution temperature (UCST) [11], swelling properties [4, 5], etc. Besides stereoregularity, the introduction of additives also affects the thermoresponsive properties of PNIPAM, as for example, the introduction of silica [12, 13], grafting with polypropylene glycol in the presence of soya bean oil [14] and poly(linoleic acid) or poly(linolenic acid) [15], using poly(N-vinylacetamide) as interpenetrating network [16], using microbial polyesters [17], etc.

PNEAM is another thermoresponsive polymer in poly(N-alkylacrylamide) family. Although it is not as familiar as PNIPAM, its importance to the polymer chemistry increases gradually. Its linear homopolymers and hydrogels undergo volume phase transition (LCST) in water around 73 and 62 °C, respectively [17]. Its LCST is also affected by the presence of electrolytes in the solution [18, 19] and molecular weight of the polymers [18]. There are few reports of the synthesis of PNEAM hydrogel [18–20], microgel [21], and copolymers with vinylferrocene [22], styrene [23], poly(N-alkylacrylamide) [24, 25], poly(N,N-dimethylacrylamide) and poly(N,N-diethylacrylamide) [26], etc. There are also reports about the emulsion polymerization of N-ethylacrylamide (NEAM) in supercritical carbon dioxide [27] and triblock copolymers with poly(N-n-propylacrylamide) and poly(methoxydiethylene glycol acrylate) [28]. Very recently, Hirano et al. studied the effect of composition and stereoregularity on the phase transition temperature of aqueous NEAM/N-n-propylacrylamide copolymer solutions [29].

So far, to our knowledge, there is no report about the synthesis and characterization of stereoregular PNEAM gels in the presence of rare earth yttrium trifluoromethanesulfonate [Y(OTf)3]. In this paper, we have reported the synthesis of stereoregular PNEAM gels in a 1:1 methanol-water mixture (v/v) in the presence of a variable concentration of Y(OTf)3 and the measurements of their properties like morphology by SEM, swelling ratio at different temperatures, deswelling kinetics, reswelling kinetics, and tacticity of the gels are done.

Experimental section

Materials

N-ethylacrylamide (NEAM; Aldrich) was purified by passing through a neutral alumina column. N,N′-methylenebisacrylamide (BIS; Aldrich), ammonium persulfate (APS; Aldrich), N, N, N′, N′-tetramethylethylenediamine (TEMED; Aldrich), and yttrium trifluoromethanesulfonate [Y(OTf)3; Aldrich] were used as received. Methanol (Merck Millipore) was dried and distilled over ignited calcium oxide. Deionized water was prepared by redistillation of distilled water.

Synthesis of PNEAM hydrogels

Two stock solutions were prepared: (i) solution of TEMED in water having a concentration of 107 mmol/dm3 and (ii) solution of APS in water having a concentration of 42 mmol/dm3. At first, the required amount (as specified in Table 1) of NEAM, BIS, Y(OTf)3, and TEMED solution and solvents were taken in a small borosilicate glass tube (8-mm internal diameter × 100-mm length) fitted with rubber septum. Both the pre-gel mixture (of NEAM, BIS, Y(OTf)3, and TEMED) and the APS stock solution in water were purged with argon gas for 30 min. These two mixtures were dipped into an isothermal bath maintained at 5 ± 0.1 °C under argon atmosphere for 30 min. Then, the argon-purged APS stock solution was added to the pre-gel mixture of NEAM, BIS, Y(OTf)3, and TEMED through a rubber septum by a degassed syringe, and the resulting mixture was mixed immediately by tilting the reaction tube up and down and allowed to react at 5 °C for 12 h. The prepared gels were cut into small disk type pieces of 3-mm thickness × 8-mm internal diameter and dipped into the deionized water for dialysis in order to remove the unreacted chemicals, and water was changed twice in a day for 7 days. After the dialysis, the gels were dried under vacuum at 50 °C for 72 h. The conversion (%) was determined gravimetrically.

Synthesis of linear PNEAM homopolymers

Two stock solutions were prepared: (i) TEMED solution in water having a concentration of 107 mmol/dm3 and (ii) APS solution in water having a concentration of 42 mmol/dm3. At first, the required amount (as specified in Table 2) of NEAM, Y(OTf)3, and TEMED solution and solvents were taken in a small borosilicate glass tube (8-mm internal diameter × 100-mm length) fitted with a rubber septum. Both the polymerization mixture of NEAM, Y(OTf)3, and TEMED and the APS stock solution in water were purged with argon gas for 30 min. These two mixtures were dipped into an isothermal bath maintained at 5 °C under argon atmosphere for 30 min. Then, the argon-purged APS stock solution was added to the polymerization mixture of NEAM, Y(OTf)3, and TEMED through a rubber septum by a degassed syringe, and the resulting mixture was mixed immediately by tilting the reaction tube up and down and allowed to react at 5 °C for 12 h. The polymerization was stopped by freezing the reaction mixture at liquid N2 temperature. The resulted polymerization mixture was purified from an unreacted monomer and Y(OTf)3 by using a dialysis membrane. The polymers were dried under vacuum at 50 °C for 72 h. Polymer yield was determined gravimetrically.

The number average molecular weight (M n) and polydispersity index (M w/M n) of the resulted polymers were determined by Viscotek GPC Max VE-2001 Chromatography in DMF at 50 °C with a flow rate of 1 ml/min on two polystyrene gel columns connected in series to Viscotek Gradient Pump and a Viscotek RI detector (VE3580). The columns were calibrated against seven polystyrene standard samples. The gel permeation chromatography (GPC) chromatograms are shown in Fig. 1.

GPC chromatogram of PNEAM homopolymers prepared in a water (run 1′), in b a methanol-water (1:1, v/v) mixture (run 2′) in the absence of LA, and in a methanol-water (1:1, v/v) mixture in the presence of c 0.05 M LA (run 3′), d 0.10 M LA (run 4′), e 0.15 M LA (run 5′), and f 0.20 M LA (run 6′) at 5 °C, for 12 h in absence of cross-linker under argon atmosphere

1H NMR spectra of the resulted polymers were recorded at 80 °C on a Bruker 400 MHz NMR spectrometer with DMSO-d6 as solvent and are reported in parts per million (δ) from residual solvent peak. The diad tacticities of polymer samples were calculated from the methylene proton peaks of the polymers as reported earlier in the literature [29]. The plot of NMR data is shown in Fig. 2.

1H NMR (400 MHz, DMSO-d6, 80 °C) spectra of the linear PNEAM homopolymers prepared in water (run 1′) and in a methanol-water (1:1, v/v) mixture (run 2′) in the absence of LA, and the linear PNEAM homopolymers prepared in a methanol-water (1:1, v/v) mixture in the presence of 0.05 M LA (run 3′) and 0.15 M LA (run 5′)

LCST of the PNEAM homopolymers was determined by cooling 1 % solution of each polymer in water from 95 to 60 °C using a Cary 60 UV-Vis spectrometer with 1 °C interval of temperature at a 500-nm wavelength. At each and every temperature, three data were recorded and the average of these three was taken for the graph plot. The LCST values were considered at the 50 % transmittance of each sample. The plots of LCST determination are shown in Fig. 3.

Surface morphology

Gels were swollen in deionized water at 20 °C for 24 h in order to reach the equilibrium swelling condition. These equilibrium-swollen gels were freeze-dried under vacuum to remove water completely. The surface morphology of the freeze-dried samples was analyzed with FEI-SEM Quanta 200 F (Philips) at an accelerated voltage of 5 kV. Observed morphologies are shown in Fig. 4.

Swelling ratios at different temperatures

Swelling ratios of the different gels at 20, 30, 40, 50, 60, 70, 75, 80, 83, 85, and 90 °C temperatures were measured gravimetrically. The pre-weighed dried gels were immersed in deionized water for 24 h at the desired temperature in order to get the equilibrium-swollen gels. These equilibrium-swollen gels were then taken out and the surface water was soaked with moisten filter paper and weights were taken. The swelling ratio (W s/W d) is calculated as the ratio of the weight of the equilibrium-swollen gel (W s) to that of the dried gel (W d). Results are shown in Fig. 5.

Swelling ratios in different methanol-water mixtures

Swelling ratio of the gels in 0.05, 0.1, 0.15, 0.2, 0.25, 0.3, 0.35, 0.4, 0.5, 0.6, 0.8, and 1.0-mol fractions of methanol (x m) in the methanol-water mixtures at different temperatures were measured gravimetrically. The pre-weighed dried gels were immersed in the methanol-water mixtures at specific x m at required temperatures for 24 h in order to get the equilibrium-swollen gels. These equilibrium-swollen gels were then taken out and the surface water was soaked with moisten filter paper and weights were taken. The swelling ratio (W s/W d) is calculated as the ratio of the weight of the equilibrium-swollen gel (W s) to that of the dried gel (W d). Results are shown in Fig. 6a, b.

Deswelling kinetics at 85 °C

Deswelling kinetics of the equilibrium-swollen gels in water at 20 °C were measured gravimetrically in water at 85 °C. The pre-weighed equilibrium-swollen gels at 20 °C were immersed quickly in the water at 85 °C. With the definite time interval, the gels were taken out and the surface water was soaked with moistened filter paper, and weights were taken and then the gels were quickly immersed back in the water at 85 °C. Water retention (%) is calculated as the weight percentage of the water retained (W t−W d) by the swollen gel (W t) at any definite time interval (t) with respect to that (W s−W d) by the equilibrium-swollen hydrogel (W s) at 20 °C. Results are shown in Fig. 7.

Reswelling kinetics at 20 °C

Reswelling kinetics in water at 20 °C of the equilibrium-swollen gels obtained after immersing in water at 85 °C for 24 h were measured gravimetrically. The pre-weighed equilibrium-swollen gels at 85 °C were immersed quickly in the water at 20 °C. With the definite time interval, the gels were taken out and the surface water was soaked with moistened filter paper, and weights were taken and then the gels were quickly immersed back in the water at 20 °C. Water uptake (%) is calculated as the weight percentage of water absorbed (W t−W d) by the swollen hydrogel (W t) at any definite time interval (t) with respect to that (W s−W d) by the equilibrium-swollen hydrogel (W s) at 20 °C. Results are shown in Fig. 8.

Result and discussion

Synthesis of PNEAM hydrogels in the presence of LA

The synthesis conditions and the characterization of the PNEAM hydrogels are summarized in Table 1. In the run 1, pure water was used as a synthesis medium. In the runs 2–6, methanol and water (1:1, v/v) mixture was used as a medium. In the runs 1 and 2, no LA was used. From run 3 to run 6, the concentration of the LA was increased gradually. As for example, the amount of LA used are 0.05, 0.1, 0.15, and 0.2 M, respectively. The yield of the PNEAM hydrogels are high, 81–98 %. The appearance of all the hydrogels was transparent through the naked eye. It indicates that, unlike PNIPAM, cononsolvency factor is probably absent in the similar synthesis solvent compositions at low temperature [4].

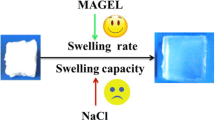

The swelling ratio (W s/W d) in water at 20 °C is larger for the gel prepared in a methanol-water mixture (run 2) than that in water (run 1). This is due to the formation of more porous gel (vide Fig. 4a vs. Fig. 4b) in a methanol-water mixture (1:1 (v/v)). This is because, in pure water, the polymer chains present in a highly solvated coiled conformation owing to the strong interaction among water and PNEAM chain segment. In a 1:1 methanol-water mixed solvent, the PNEAM chain segment slightly presents in an aggregated state due to different kinds of interaction of polymer and solvents in the mixed solvent and also faster rate of polymerization owing to the faster decomposition of ammonium persulfate initiator [30]. After that, swelling ratio increased gradually with the increase in the LA loading for the gel prepared at higher concentrations of Y(OTf)3 (runs 3, 4, 5, and 6). This is mainly due to the gradual increase in the porosity with the gradual increase in the LA loading during synthesis (Fig. 4c–e).

In order to get the idea about the effect of Y(OTf)3 on the tacticity as well as the number average molecular weight (M n) and polydispersity (M w/M n) of the PNEAM chain segment in the formed gel, we have prepared the linear PNEAM homopolymers (runs 1′–6′, Table 2) in the absence of cross-linker BIS keeping other experimental conditions same as mentioned for runs 1–6 in Table 1. The polymer yields are varied in between 81 and 99 %.

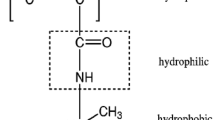

Obtained homopolymers have molecular weights of broad ranges (M n from 1.72 × 105 to 7.44 × 105) and polydispersity dispersity (PDI) from 1.39 to 1.61. The GPC chromatograms of the homopolymers are shown in Fig. 1a–f. The wide range of molecular weights indicates the uncontrolled polymerizations by conventional free radical polymerizations. Isotacticity (meso dyad, m) of the resulted polymers gradually increases from 56 to 69 with the gradual increase in the loading of LA from 0 to 0.2 M (vide Table 2). Isotacticity is determined according to the literature report [29]. The comparison of NMR data for the determination of isotacticity of the homopolymers are shown in Fig. 2. Therefore, the higher the concentration of LA loading for gel synthesis is, the higher the isotacticity of the PNEAM chain segment in the formed gel is.

In the runs 3–6, the presence of LA can affect the PNEAM gel in two ways. Firstly, it increased the porosity of the gels, and secondly, it increased the isotacticity (meso dyad, % of m) of the resulted PNEAM chain of the hydrogel. Here with the increase in the isotacticity, hydrophilicity (water uptake capacity) increases as swelling ratio at 20 °C gradually increases with the increase in the isotacticity of the of the PNEAM chain segments in the gels (Table 1). As the hydrophobic ethyl group at side chain of PNEAM is small, so the probability of intermolecular interaction of amide group of PNEAM with water molecules (H-bonding) is higher. As a result, the possibility of intermolecular interaction of amide H atom of PNEAM with water molecules increases with the increase in the isotacticity. That is why, with the increase in the isotacticity of PNEAM segment in the gel, hydrophilicity gradually increases. Thus, the swelling ratio values of all hydrogels in water at 20 °C varied in the following order: run 6 > run 5 > run 4 > run 3 > run 2 > run 1. Swelling ratios of all the gels at 85 °C are in between 2 and 3 because of the complete collapse of PNEAM network above its LCST value.

In Fig. 3, the measurement of LCST of the PNEAM homopolymers is shown. It is clear from the figure that cloud point gradually increases with the increase in the isotacticity of the polymers. This is mainly due to the increase in the hydrophilicity of the PNEAM segments with the increase in the isotacticity as discussed above. Hysteresis is also observed here and it became prominent with the increase in the isotacticity of the polymers. The increase in the hydrophilicity with the increase in the isotacticity of PNEAM is in contrast with the PNIPAM homopolymers or gels, where with the increase in the isotacticity, the LCST decreases [4–6]. The difference between PNIPAM and PNEAM is only the amide group. In PNIPAM, the amide group contains bulky isopropyl group, whereas in PNEAM the amide group contains small ethyl group. In PNIPAM, with the increase in the isotacticity, hydrophobic interactions among the side chain isopropyl groups increase and hydrophilic interaction (intramolecular H-bonding) among the amide groups also increases at the cost of intermolecular hydrogen bonding among amides and water molecules. As a result, water molecules come out from PNIPAM chains and it turned from coiled to globular state and phase separation takes place [6]. But for PNEAM, as the ethyl group is less bulky in nature than the isopropyl group, so with the increase in the isotacticity, more water molecules can interact with the amide groups of PNEAM. So, intermolecular H-bonding among the amides and water molecules became stronger at the cost of intramolecular H-bonding among amide and water molecules, and hydrophobic interaction among the side chain ethyl groups became weaker. As a result, with the increase in the isotacticity, LCST of PNEAM gradually increases. Similar types of result were also reported previously for PNEAM homopolymers [29].

Surface morphology of the PNEAM hydrogels

Surface morphology of the freeze-dried samples are shown in Fig. 4. The magnification of all the SEM images is ×10,000. For a clear understanding, all the gels except the conventional gel prepared in water (run 1) are shown with focused zoom and with a scale bar. Gels prepared in a methanol-water mixture are more porous than the conventional gel prepared in water where there are no apparently visible pores present (Fig. 4a vs. 4b). This is because, in pure water, the polymer chains present in a highly solvated coiled conformation owing to the strong interaction among water and PNEAM chain segment. In a 1:1 methanol-water mixed solvent, the PNEAM chain segment slightly presents in an aggregated state in the methanol-water mixed solvent due to the different kinds of polymer solvent interaction and faster rate of polymerization as discussed previously. In the mixed solvent, macroporous gels were formed in the presence of LA in a methanol-water (1:1) mixture (Fig. 4c–e). It is mainly due to the presence of LA and with the increase in the LA loading that the porosity of the gels gradually increases as expected.

Swelling ratios of PNEAM hydrogels in water at different temperatures

Swelling ratios of all the PNEAM hydrogels observed at different temperatures are shown in Fig. 5. Below volume phase transition temperature, the swelling ratio of the conventional gel prepared in water (run 1) is lower than that of the gel prepared in a methanol-water (1:1) mixture (run 2). Swelling ratio further increases gradually with the increase in the LA loading in the gel. In general, swelling ratio values of all hydrogels in water at 20 °C varied in the following order: run 6 > run 5 > run 4 > run 3 > run 2 > run 1. These observations are as per the discussion in the “Synthesis of PNEAM hydrogels in the presence of LA” section. In general, for all the gels, swelling ratio values gradually decreases with an increase in temperature due to the release of water owing to the gradual collapse of the PNEAM segment in the gel. This is a thermodynamically favorable process as with the increase in the temperature, the entropy of dehydrated water molecules from polymer is higher than that of the hydrated water molecules with polymers. So, change in entropy is positive or in other words, it is an entropically driven process. But, the rate of decrease of swelling ratio is faster with the gel prepared with higher LA loading. This is because more water is absorbed in the gel network with highly porous structure having higher hydrophilicity owing to the higher isotactic PNEAM chain segment. Moreover, the volume phase transition temperature (LCST) of all the hydrogels prepared with high LA loading is expected to be increased as discussed above. It is clear from Fig. 5 that the volume phase transition of hydrogels prepared with higher LA acid loading is slightly higher than that of hydrogels prepared with lesser amount of LA. This gradual increase in the LCST with the increase in the isotacticity is mainly due to the increase in the hydrophilicity of the PNEAM segment in the resulted gels as discussed earlier. Above LCST, swelling ratio value of all the gels became a minimum and more or less equals 2 due to the complete collapse of PNEAM chain segment. On this note, it is to be mentioned that, to confirm the thermoreversibility of this polymer, we have measured the swelling ratio of the gel synthesized in a 1:1 methanol-water mixture in presence of 0.20 M LA (run 6), at different temperatures during heating and cooling processes using a single gel (result not shown here). In both heating and cooling processes, we found similar values of swelling ratio at each temperature. Thus, swelling and thermoresponsive properties of the gels are changed due to the change in the stereoregularity.

Swelling ratio of PNEAM hydrogels in different compositions of methanol-water mixtures

The change in the swelling ratio values of all PNEAM gels in different mole fractions of methanol at 50 °C is shown in Fig. 6a. From Fig. 5, we have seen that swelling ratio values of all hydrogels in water at 50 °C varied in the following order: run 6 > run 5 > run 4 > run 3 > run 2 > run 1. On the increase in the methanol mole fraction (x m = mole fraction of methanol) from 0 to 0.05, the swelling ratio values of all the hydrogels decreased slightly and, after that, pass through a minimum up to x m = 0.20. These are due to the onset of cononsolvency in methanol-water mixtures. After x m = 0.20, the swelling ratio values gradually started to increase. For the gels prepared in pure water (run 1), in a 1:1 methanol-water mixture in the absence of LA (run 2), and in a 1:1 methanol-water mixture in the presence of 0.05 M LA (run 3), swelling ratio increased up to x m = 0.40 and after that it flattened. For the gels prepared in a 1:1 methanol-water mixture in the presence of 0.10 M LA (run 4) and in the presence of 0.15 M Y(OTf)3 LA (run 5), swelling ratio increased up to x m = 0.50 and after that it flattened. For the gel prepared in a 1:1 methanol-water mixture in the presence of 0.20 M LA (run 6), swelling ratio increased up to x m = 0.60 and then the swelling ratio flattened. That is, for the conventional PNEAM gels prepared in water, the cononsolvency zone is from x m = 0 to 0.35 approximately. With the introduction of stereoregularity, the cononsolvency zone further shifted to methanol heavy zone which is clear from Fig. 6a. That is, the cononsolvency of PNEAM is affected by its stereoregularity. But here one thing is to be noticed: that the appearance of cononsolvency is not very significant like PNIPAM [4, 5, 31, 32]. This indicates that the preferential adsorption of methanol-water mixture toward the PNEAM chain segment is quite different in PNIPAM [33]. On this note, it is to be mentioned that cononsolvency is not clear for PNEAM hydrogels at 20 °C in methanol-water solvent mixtures (not shown here).

To understand the effect of temperature on cononsolvency of PNEAM hydrogels, the cononsolvency study of the gel prepared in pure water in the absence of LA (run 1) is done in three different temperatures: 5, 20, and 50 °C. The fresh sample was first immersed at 5 °C temperature in different methanol-water mixtures. The swelling ratio was measured after 24 h. Then temperature was increased to 20 °C, and swelling ratio measured at that temperature and finally at 50 °C. The results are shown in Fig. 6b.

From the figure, it is clear that, at 5 °C, the swelling ratio gradually decreased up to x m = 0.40, then slightly increased up to x m = 0.60 and, after that, it remained constant. Similar type of observations was also seen at 20 °C. But at 50 °C, the swelling ratio first decreased with an increase in the x m value from 0 to 0.15, then gradually it started to increase up to x m = 0.40 and after that it remained constant. At lower temperatures (that is at 5 and 20 °C), preferential adsorption of solvents is quite similar in all methanol-water mixtures as it is evident from the similar nature of swelling curves. At the composition of mixed solvent where x m ≤ 0.25, the PNEAM molecules may preferentially adsorbed water as swelling ratio is greater than methanol heavy zone. At methanol-rich region (x m ≥0.50), PNEAM molecules mainly adsorbed methanol as there is no sufficient water present to provide clathrate cavity to all the water molecules. Although minimum swelling ratio is observed at around x m = 0.40, no distinct separation in swelling ratio curve is observed to confirm cononsolvency at 5 and 20 °C. At 50 °C, with an increase in the x m value from 0 to 0.15, the swelling ratio gradually decreased and after that it gradually increased up to x m = 0.40. After x m = 0.40, the swelling ratio remained constant. As temperature goes up, the preferential adsorption of water molecules by PNEAM chain segment decreased due to the breaking of intermolecular H-bonding between water and amide group of PNEAM, but hydrophobic interaction among the methyl group of methanol and ethyl group of PNEAM increased like that of PNIPAM [34]. As a result, the final swelling ratio in pure methanol or methanol-rich zone is higher than that in pure water (Fig. 6a, b). But it is opposite in lower temperatures (5 and 20 °C, Fig. 6b) due to the higher preferential adsorption of water. So at 50 °C, a quite clear sign of cononsolvency of PNEAM is observed at methanol-water mixtures. So, it may be concluded that the cononsolvency depends not only on solvent compositions but also on temperature for some polymers like PNEAM. Temperature dependence on cononsolvency was also observed for the cross-linked polyvinyl alcohol gels in dimethylsulfoxide-water mixtures at different temperatures [35].

Deswelling rates of PNEAM hydrogels in water at 85 °C

Time dependence of water retention (%) when temperature was increased instantly from 20 to 85 °C for all hydrogels is shown in Fig. 7. Deswelling rate of PNEAM hydrogel prepared in water (run 1) is the slowest. It is increased slightly for the gel prepared in a water-methanol (1:1, v/v) mixture (run 2). This may be due to the increase in the porosity of the gel and slightly more aggregated state of PNEAM chain segment in mixed alcohol-water mixture (here 1:1 methanol-water) than in pure solvent (here water) where the polymer chains present in swollen state. Higher state of aggregation favors the deswelling rate. So, the ejection of water during deswelling is not easier in the gel prepared in water rather than in that prepared in a methanol-water (1:1, v/v) mixture. Deswelling rate increased further for the gels prepared in the methanol-water mixture in the presence of LA (runs 3–6). It is gradually increased for the gels prepared with the increasing concentration of LA through 0.05, 0.1, 0.15, and 0.2 M LA (runs 3, 4, 5, and 6), respectively, in the water-methanol mixture steadily. This may be due to the increase in the porosity of the resulted PNEAM gels synthesized in the presence of a higher amount of LA loading. Although here with an increase in the LA loading, the hydrophilicity of the gels increases gradually which resists the water molecules to come out from the gel at a faster rate, but here porosity and state of aggregation factor probably minimizes the hydrophilicity factor. As a result, water comes out from the gel network with faster rate for the gels prepared with a higher amount of LA. In other words, deswelling rate increases with the increase in the isotacticity of the PNEAM chain segment in the gels.

Reswelling rates of PNEAM hydrogels in water at 20 °C

Reswelling rates of the gels, after shrinking at 85 °C for 24 h, in water are shown in Fig. 8. The slowest reswelling rate was observed for the gel sample prepared in water (run 1) followed by that prepared in a water-methanol mixture (1:1, v/v) (run 2). This is because the gel formed in a 1:1 water-methanol (v/v) mixture is slightly more porous than the gel prepared in pure water. So, the water uptaken by the gel during reswelling is quicker for the gel prepared in the methanol-water (1:1, v/v) mixture than that prepared in water. Reswelling rate increased with the gels prepared in the presence of LA in the methanol-water mixture. It was increased gradually for the gels prepared with the increase in the concentration of LA from 0.1 through 0.15 to 0.2 M Y(OTf)3 (runs 4, 5, and 6), respectively. This may be due to the increase in the porosity with the increased amount of LA loading and increase in the hydrophilicity of the PNEAM chain segment present in the hydrogels owing to the increase in the isotacticity of the same. So here, with the increase in the LA loading in the gels, both the porosity and hydrophilicity factors work in the favor of reswelling rates of the gels. At the same time, the gels prepared in a 1:1 methanol-water mixture in the presence of LA presents at a slightly higher aggregation state than that synthesized in pure water. But, like deswelling kinetics, this factor is minimized by porosity and hydrophilicity factors. As a result reswelling rate gradually increases with the increase in the isotacticity of the PNEAM gels. This result is opposite to the PNIPAM hydrogel where with the increase in the isotacticity, reswelling rate decreased due to decrease in the hydrophilicity [4, 5]. So reswelling rate of PNEAM hydrogel is affected by its stereoregularity.

Concluding remarks

Macroporous poly(N-ethylacrylamide) (PNEAM) hydrogels have been prepared in a water-methanol (1:1, v/v) mixture in the presence of 0.05, 0.1, 0.15, and 0.2 M Y(OTf)3 LA concentrations. Their corresponding homopolymers reveal that both the isotacticity and LCST gradually increase with the increase in the Y(OTf)3 concentrations used in the synthesis. SEM micrographs show that the resulted hydrogels are highly porous in nature. Swelling ratio of all the hydrogels decreases with the increase in the temperature. Cononsolvency of the gels is observed in methanol-water mixtures at 50 °C. Deswelling rate of the hydrogels prepared in the presence of LA is faster than that of the conventional hydrogels prepared in water. Moreover, deswelling rate is faster with the hydrogels prepared with the higher concentrations of LA. Reswelling rate is also faster with the hydrogel prepared with the higher concentrations of LA. All these results are explained on the basis of the formation of the highly porous hydrogels with a higher isotactic PNEAM chain segment due to the faster polymerization rate in a methanol-water mixture in the presence of LA.

References

Satoh K, Kamigaito M (2009) Stereospecific living radical polymerization: dual control of chain length and tacticity for precision polymer synthesis. Chem Rev 109:5120–5156

Biswas CS, Patel VK, Vishwakarma NK, Mishra AK, BhimiReddy R, Rai RN, Ray B (2012) Synthesis, characterization, and drug release properties of poly(N-isopropylacrylamide) gels prepared in methanol-water cononsolvent medium. J App Polym Sci 125:2000–2009

Biswas CS, Patel VK, Vishwakarma NK, Mishra AK, Ray B (2011) Synthesis and characterization of porous poly(N-isopropylacrylamide) hydrogels prepared in ethanol-water mixtures. J App Polym Sci 121:2422–2429

Biswas CS, Patel VK, Vishwakarma NK, Mishra AK, Saha S, Ray B (2010) Synthesis and characterization of stereocontrolled poly(N-isopropylacrylamide) hydrogel prepared in the presence of Y(OTf)3 Lewis acid. Langmuir 26:6775–6782

Biswas CS, Vishwakarma NK, Patel VK, Mishra AK, Saha S, Ray B (2012) Synthesis and study of the properties of stereocontrolled poly(N-isopropylacrylamide) gel and its linear homopolymer prepared in the presence of a Y(OTf)3 Lewis acid: effect of the composition of methanol–water mixtures as synthesis media. Langmuir 28:7014–7022

Ray B, Okamoto Y, Kamigaito M, Sawamoto M, Seno K, Kanaoka S, Aoshima S (2005) Effect of tacticity of poly(N-isopropylacrylamide) on the phase separation temperature of its aqueous solutions. Polym J 37:234–237

Biswas CS, Patel VK, Vishwakarma NK, Tiwari VK, Maiti B, Maiti P, Kamigaito M, Okamoto Y, Ray B (2011) Effects of tacticity and molecular weight of poly(N-isopropylacrylamide) on its glass transition temperature. Macromolecules 44:5822–5824

Hirano T, Okumura Y, Kitajima H, Seno M, Sato T (2006) Dual roles of alkyl alcohols as syndiotactic-specificity inducers and accelerators in the radical polymerization of N-isopropylacrylamide and some properties of syndiotactic poly(N-isopropylacrylamide). J Polym Sci Part A: Polym Chem 44:4450–4460

Ito M, Ishizone T (2006) Living anionic polymerization of N-methoxymethyl-N-isopropylacrylamide: synthesis of well-defined poly(N-isopropylacrylamide) having various stereoregularity. J Polym Sci Part A: Polym Chem 44:4832–4845

Nuopponen M, Kalliomaki K, Laukkanen A, Hietala S, Tenhu H (2008) A–B–A Stereoblock Copolymers of N-Isopropylacrylamide. J Polym Sci Part A: Polym Chem 46:38–46

Koyama M, Hirano T, Ohno K, Katsumoto Y (2008) Molecular understanding of the UCST-type phase separation behavior of a stereocontrolled poly(N-isopropylacrylamide) in bis(2-methoxyethyl) ether. J Phys Chem B 112:10854–10860

Serizawa T, Wakita K, Akashi M (2002) Rapid deswelling of porous poly(N-isopropylacrylamide) hydrogels prepared by incorporation of silica particles. Macromolecules 35:10–12

Serizawa T, Wakita K, Kaneko T, Akashi M (2002) Thermoresponsive properties of porous poly(N-isopropylacrylamide) hydrogels prepared in the presence of nanosized silica particles and subsequent acid treatment. J Polym Sci Part A: Polym Chem 40:4228–4235

Allı A, Hazer B (2008) Poly(N-isopropylacrylamide) thermoresponsive cross-linked conjugates containing polymeric soybean oil and/or polypropylene glycol. E Polym J 44:1701–1713

Allı A, Hazer B (2011) Synthesis and characterization of poly(N-isopropyl acryl amide)-g-poly (linoleic acid)/poly (linolenic acid) graft copolymers. J Am Oil Chem Soc 88:255–263

Ajiro H, Takemoto Y, Akashi M (2011) Interpenetrating polymer networks of poly(N-vinylacetamide) and stimuli responsive polymers applied to novel amphiphilic gel. J Nanosci nanotech 11:7047–7049

Toraman T, Hazer B (2014) Synthesis and characterization of the novel thermoresponsive conjugates based on poly(3-hydroxy alkanoates). J Polym Env 22:159–166

Xue W, Huglin MB, Jones TGJ (2003) Parameters affecting the lower critical solution temperature of linear and crosslinked poly(N-ethylacrylamide) in aqueous media. Macromol Chem Phys 204:1956–1965

Xue W, Huglin MB, Jones TGJ (2005) Swelling and network parameters of crosslinked thermoreversible hydrogels of poly(N-ethylacrylamide). European Polym J 41:239–248

Cai W, Gupta RB (2001) Poly(N-ethylacrylamide) hydrogels for lignin separation. Ind Eng Chem Res 40:3406–3412

Lowe JS, Chowdhry BZ, Parsonage JR, Snowden MJ (1998) The preparation and physico-chemical properties of poly(N-ethylacrylamide) microgels. Polymer 39:1207–1212

Kuramoto N, Shishido Y, Nagai K (1997) Thermosensitive and redox-active polymers: preparation and properties of poly(N-ethylacrylamide-co-vinylferrocene) and poly(N,N-diethylacrylamide-co-vinylferrocene). J Polym Sci Part A: Polym Chem 35:1967–1972

Nichifor M, Zhu XX (2003) Copolymers of N-alkylacrylamides and styrene as new thermosensitive materials. Polymer 44:3053–3060

Weiss J, Böttcher C, Laschewsky A (2011) Self-assembly of double thermoresponsive block copolymers end-capped with complementary trimethylsilyl groups. Soft Matter 7:483–492

Savoji MT, Strandman S, Zhu XX (2012) Block random copolymers of N-alkyl-substituted acrylamides with double thermosensitivity. Macromolecules 45:2001–2006

Siu MH, Liu HY, Zhu XX, Wu C (2003) Formation of mesoglobular phase of amphiphilic copolymer chains in dilute solution: effect of comonomer composition. Macromolecules 36:2103–2107

Ye W, DeSimone JM (2005) Emulsion polymerization of N-ethylacrylamide in supercritical carbon dioxide. Macromolecules 38:2180–2190

Weiss J, Laschewsky A (2011) Temperature-induced self-assembly of triple-responsive triblock copolymers in aqueous solutions. Langmuir 27:4465–4473

Hirano T, Ono A, Yamamoto H, Mori T, Maeda Y, Oshimura M, Ute K (2013) Effect of composition and stereoregularity on phase-transition behavior of aqueous N-ethylacrylamide/N-n-propylacrylamide copolymer solutions. Polymer 54:5601–5608

Ray B, Mandal B (1999) Dispersion polymerization of acrylamide: part II. 2,2′-Azobisisobutyronitrile initiator. J Polym Sci Part A: Polym Chem 37:493–499

Winnik FM, Ringsdorf H, Venzmer J (1990) Methanol-water as a cononsolvent system for poly(N-isopropylacrylamide). Macromolecules 23:2415–2416

Winnik FM, Ottaviani MF, Bobmann SH, Pan W, Garcia-Garibay M, Turro MJ (1993) Cononsolvency of poly(N-isopropylacrylamide): a look at spin-labeled polymers in mixtures of water and tetrahydrofuran. Macromolecules 26:4577–4585

Tanaka F, Koga T, Kojima H, Xue N, Winnik FM (2011) Preferential adsorption and co-nonsolvency of thermoresponsive polymers in mixed solvents of water/methanol. Macromolecules 44:2978–2989

Chen JH, Chen HH, Chang YX, Chuang PY, Hong PD (2008) Effects of cononsolvency on preferential adsorption phenomenon in poly(N-isopropylacrylamide) ternary solutions. J App Polym Sci 107:2732–2742

Kudo S, Otsuka E, Suzuki A (2010) Swelling behavior of chemically crosslinked PVA gels in mixed solvents. J Polym Sci Part B: Polym Phys 48:1978–1986

Acknowledgments

We gratefully acknowledge the financial support from TUBITAK, Government of Turkey, through 2216 fellowship program for the foreign citizens (CSB). This work was also supported by both TUBITAK (grant no. 211T016) and the Bülent Ecevit University Research Fund (#BEU-2012–10–03–13). We personally thank Elvan Sulu for her technical assistance.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Biswas, C.S., Hazer, B. Synthesis and characterization of stereoregular poly(N-ethylacrylamide) hydrogel by using Y(OTf)3 Lewis acid. Colloid Polym Sci 293, 143–152 (2015). https://doi.org/10.1007/s00396-014-3399-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00396-014-3399-1