Abstract

Polymer droplets subjected to a heated environment have significance in several fields ranging from spray drying, powder formation, and surface coating. In the current work, we study the evaporation of an acoustically levitated high-viscoelastic aqueous polymeric droplet under radiative heating. Depending on the irradiation intensity, we observe bubble nucleation in dilute regime of polymer concentration, contrary to previously observed nucleation in semi-dilute entangled regime for low-viscoelastic polymer droplets. After bubble nucleation, a quasi-steady bubble growth occurs depending on the irradiation intensity and polymer concentrations. Our scaling analysis reveals that initial bubble growth follows Plesset–Zwick criteria, independent of the viscoelastic properties of the polymer solution. Further, we establish that the onset of bubble growth has an inverse nonlinear dependence on the irradiation intensity. The droplet oscillations are primarily driven by the presence of multiple bubbles and, to some extent, by the rotational motion of the droplet. At high polymer concentrations and irradiation intensities, we report the expansion and collapse of polymer membrane without rupture, indicating the formation of an interfacial skin of significant strength. Finally, depending on the nature of bubble growth, different types of precipitate form contrary to the different modes of atomization observed in low-viscoelastic polymer droplets.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Polymer droplet and thin polymer film evaporation continue to evoke scientific curiosity in various applications such as thin films, coatings, surface patterning, drug delivery, etc. (Wilms 2005; Pathak and Basu 2016a). It is important to understand the dynamics of evaporating polymer droplets for leveraging practical applications. The complex events involved in drying polymer droplets are evaporation of the solvent, subsequent polymer concentration build-up at the regressing air–liquid interface, and precipitate formation (Littringer et al. 2012; Al Zaitone et al. 2020). A gel-type skin layer is formed due to the aggregation of solute at regressing droplet interface. The formation of skin layer depends on initial polymer concentration and solvent evaporation rate. (Okuzono et al. 2006; Pauchard and Allain 2003b, 2003c). In general, the precipitate morphology of the polymer droplet can be in various structures such as wrinkled (Pauchard and Allain 2003b), buckled (Pauchard and Allain 2003c), ring pattern (Raghuram et al. 2021), and smooth solid precipitate (Raghuram et al. 2021), which depends on the properties of the polymer and drying kinetics of droplets.

Evaporating polymer droplets in contact environment under natural drying conditions have been investigated by several research groups (Baldwin and Fairhurst 2014; Mamalis et al. 2015; Baldwin et al. 2011, 2012; Pauchard and Allain 2003a). The formation of skin layer in evaporating sessile polymer droplets has been reported by Pauchard et al. (2003a). The skin layer encapsulates the evaporating liquid, and subsequent skin deformation leads to buckling instability. The parameter variation in the experimental space leads to different shape instabilities on the droplet surface ranging from buckled structure to wrinkled pattern. Baldwin et al. (2011, 2012, 2014) and Mamalis et al. (2015) studied the effect of concentration and molecular weight on the final precipitate formation. They observed formation of pillars and the puddle-like final precipitates on glass surfaces. The competing effect between advective polymer build-up and diffusive flux near the three-phase contact line drives the final precipitate formation.

The bubble dynamics in multi-component droplets through external heating (laser-induced evaporation and combustion) has been reported across various experimental configurations (Mura et al. 2014; Rao et al. 2018, 2017; Pathak and Basu 2016b; Miglani et al. 2014; Antonov and Strizhak 2019; Restrepo-Cano et al. 2022). In particular, Rao et al. (2018, 2017) investigated the bubble dynamics and breakup characteristics of burning multi-component miscible droplets. Different modes of bubble-induced droplet shape oscillations were reported depending on the size of the bubble, volatility differential, and concentration of the components. It was shown that a significantly larger volatility difference leads to severe shape oscillations induced by the breakup of a large bubble, whereas lower volatility differential results in mild shape oscillations caused by the breakup of a relatively small bubble.

Most experimental studies have been performed primarily to understand the dynamics of evaporating polymer droplets in a contact environment (hydrophilic substrates), and the literature on the evaporation of isolated polymer droplets (non-contact environment) of broad viscoelastic natures is scarce. The contact-free environment, i.e., through acoustic levitation (Rao et al. 2022; Gannena et al. 2022), provides the ability to precisely capture the droplet oscillations and distinct instabilities at the vapor–liquid interface (Gonzalez Avila and Ohl 2016). With regards to acoustic levitation, Rao et al. (2020a, 2020b) studied emulsion droplets evaporating under the effect of radiative heating. Three types of droplet breakup are observed, namely bubble growth-induced breakup, sheet breakup, and catastrophic breakup. In the case of nanoparticle-laden droplets, Pathak et al. (2016b) studied evaporation dynamics of nanoparticle-laden fuel droplets under external radiative heating. Orthokinetic aggregation of nanoparticles during droplet evaporation leads to nucleation, bubble growth, and subsequent droplet breakup.

Previously, we investigated the coupled effect of the skin layer and bubble in evaporating low-viscoelastic modulus polymer (polyacrylamide) droplets under radiative heating. During evaporation, bubble nucleation in the semi-dilute entangled regime of polymer concentration results in membrane growth, followed by its rupture at low to medium irradiation intensities. At high irradiation intensities, the PAM droplets undergo universally observed ligament-mediated and sheet breakup (Gannena et al. 2022). However, it is essential to understand how the bulk viscoelasticity of polymer droplets can affect the underlying bubble and droplet dynamics. The current study explores the nature of skin layer and its interaction with a bubble growing in an evaporating high-viscoelastic modulus polymer (PEO) droplet. The present work majorly describes the various physical mechanisms using optical diagnostics and a scaling analysis. The exact analytical/numerical modeling of the underlying governing equations is outside the scope of the study. The choice of polymer (PEO and PAM) was made to ensure that we were dealing with similar molecular weights with different viscoelastic properties. However, it is important to note that studying the role of polymer molecular weight in bubble–droplet interaction is beyond the scope of the current work.

The organization of the article is as follows: Materials and methods for polymer solution preparation and its properties are described in Sect. 2.1. Section 2.2 describes the experimental apparatus in detail. The global observation, droplet evaporation, steady bubble growth, droplet shape oscillations, and precipitate formation are discussed in Sects. 3.1–3.4, respectively. The article concludes its discussion in Sect. 4.

2 Materials and methods

2.1 Polymer solution preparation and properties

PEO (Sigma-Aldrich) solutions of different concentrations ranging from 0.06 to 2% (w/w) of molecular weight (\({M}_{W}\)) 4 \(\times\) 106 g mol.−1 are prepared by dissolving polyethylene oxide (PEO) powder in deionized water. PEO solutions are stirred at 600 rpm for 24 h to ensure proper mixing. The preparation methodology of PAM solutions can be found in (Gannena et al. 2022). Throughout the current experimental study concentration of the polymer solution, \(\left(c\right)\) is normalized with overlap concentration \(\left({c}^{*}\right)\). The value of the critical overlap concentration of PEO is \({c}^{*}=0.071\% (w/w).\) It is obtained by applying the Flory relation \({c}^{*}= \frac{1}{\left[n\right]}\), where \(\left[n\right]=0.072{M}_{W}^{0.65}\) is obtained from the Mark–Houwink–Sakurada correlation (Tirtaatmadja et al. 2006). Entanglement concentration for the current polymer is obtained as \({c}_{e}= 0.42\%\) w/w by using the relation \({c}_{e}= 6{c}^{*}\). The solutions having concentration ratios \(c/{c}^{*}<1\), \(1<c/{c}^{*}<{c}_{e}/{c}^{*}\), and \(c/{c}^{*}>{c}_{e}/{c}^{*}\) are dilute regime, semi-dilute unentangled regime, and semi-dilute entangled regime, respectively. More information on the definition of regimes of polymer concentrations and non-dimensionalization of concentrations for PAM can be found in (Gannena et al. 2022). To confirm the viscoelastic nature of PEO and PAM solutions, rheological tests (amplitude sweep) are performed on a rheometer (Anton Paar, MCR 702) with cone and plate geometry. The diameter and angle of the cone and plate are 50 mm and 1°, respectively. The amplitude sweep is performed at 10Hz frequency. Figure 1 shows the inherent viscoelastic nature of PAM and PEO bulk solutions. Here, \({G}{\prime}\) and \({G}^{{\prime}{\prime}}\) represent storage and loss modulus, respectively. It can be seen that the storage and loss modulus of the PAM solution are in the \(O ({10}^{-2}-{10}^{-1}) Pa\), whereas for PEO, storage and loss modulus are in the \(O ({10}^{1}) Pa\). The viscoelastic modulus of the polymer solutions depends on the entanglements present in the solution. A higher value of entanglements corresponds to a higher viscoelastic modulus of the polymer solution. The quantitative criteria governing the entanglements in each polymer solution are given by entanglement density \({N}_{e}\) (it is a measure of the number of entanglement junctions per polymer chain) which is given as (Rajput et al. 2023)

Here, \({M}_{W}\) and \({M}_{e}\) represent the molecular weight and entanglement molecular weight of the polymer, respectively. The \({M}_{e}\) value for PEO and PAM is 2000 g mol−1 (Rubinstein and Colby 2003) and 9000–23,000 g mol−1 (Plastics Technology), respectively. Although \({M}_{W}\) and \(c/{c}^{*}\) are in the same range for PAM and PEO, the lower value of \({M}_{e}\) for PEO gives higher value of \({N}_{e}\) for PEO compared to PAM. However, the current study focuses on exploring the effect of laser heating in high-viscoelastic modulus polymer droplets without dwelling too much on the rheological differences between PAM and PEO solutions.

2.2 Experimental methodology

The experimental setup is shown in Fig. 2. A single-axis acoustic levitator (Tec5) with 100kHz frequency is used to levitate the droplets of PEO solutions comprising of different concentrations. A tunable continuous CO2 laser (Synrad 48; wavelength ∼10.6 µm, max power (Pmax) ∼ 10 W) with a beam diameter of 3.5 mm is used to externally heat the levitated droplets. A high-speed camera (Photron SA5) and a pulsed laser for illumination (CAVILUX® Smart UHS, 640 nm) are used to capture droplet evaporation, bubble–droplet interactions, and subsequent droplet shape oscillation. High-speed image sequences are captured at 10,000 fps, and the pixel resolution of the images is 6.7 μm/pixel. The recorded grayscale images were contrast-enhanced and converted to binary images. The droplet shape was then reconstructed using an edge detection methodology to obtain its maximum horizontal and vertical lengths \({D}_{H}\) and \({D}_{V}\), respectively. Using \(D= \sqrt[3]{{D}_{H}^{2}{D}_{V}}\), the equivalent droplet diameter is calculated. It is important to note that deviation of the droplet from equilibrium spherical shape is due to the effect of acoustic pressure differential acting across the poles and equator of the droplet. The above-mentioned measurement is taken using "Analyze particle" plugin in the "ImageJ (version 2.0)" software. The approximate diameter of the droplets used in the current study is 0.95 ± 0.05 mm. The precipitates formed after evaporation are analyzed using a scanning electron microscope (SEM) (VEGA3, TESCAN) at EHT of 5 kV, using a secondary electron detector. The irradiation intensity from the laser is defined as \(I= 4P/\pi {D}_{b}^{2}\) where \(P\) represents laser power, and \({D}_{b}\) indicates beam diameter. In the current study, the irradiation intensity from the laser is non-dimensionalized with the enthalpy of vaporization. It is defined as \({I}^{*}= \frac{1.5{D}_{0}I}{{h}_{lv}{\alpha }_{l}{\rho }_{l}}\) where \({D}_{0}\) is the initial diameter of the droplet, \({h}_{lv}\) represents latent heat of vaporization, and \({\alpha }_{l}\) and \({\rho }_{l}\) indicate thermal diffusivity and the density of liquid, respectively. An infrared camera (FLIR SC5200) is used to measure the evolving droplet surface temperature at 50 frames per second (fps) with spatial resolution of 6.42 μm/pixel. The IR camera was pre-calibrated with an emmisivity of 1 with ± 1 °C tolerance. Water has an emissivity between 0.95 and 0.98 (Mikaél’A 2013; Wolfe and Zissis 1978). The sensitivity of the IR camera due to change in emissivity is 0.03 °C. ALTAIR software (FLIR Systems, version 5.91.10.797) is used to postprocess the raw IR images to obtain the droplet temperature. A linear region of interest along the drop diameter is used to obtain the maximum temperature for each captured frame. The volumetric nature of the absorption process leads to a higher temperature at the droplet’s core compared to its surface (Abramzon and Sazhin 2006). Further, the temperature at the interface is lower due to evaporative cooling effects.

Schematic depicting a side view and b top view of the experimental setup. A single-axis acoustic levitator is used to levitate the droplet, and it is evaporated using a continuous CO2 laser. A high-speed camera is used to capture the droplet evaporation and bubble dynamics, and the backlighting is provided by pulsed laser light source. The surface temperature of the droplet is captured using an IR camera. Here, \({D}_{H}\) and \({D}_{V}\) depict maximum horizontal and vertical lengths of droplets, respectively

3 Results and discussion

3.1 Global observations

Figure 3 shows the global overview highlighting the important physical processes that occur during drop evaporation and bubble–drop interaction with polymer concentration and irradiation intensity as experimental parameters. For concentrations above the entangled regime (\(c/{c}^{*}=28.2\)) and at a high irradiation intensity \({I}^{*}= 3.5\), after a period of smooth evaporation (Phase A), we observe bubble growth (Phase B), followed by shape oscillations and precipitate formation (Phases C and D). The bubble growth observed in Phase B can be attributed to asymmetric membrane growth, which occurs in the early stages of evaporation with growth time scales of \(O \left({10}^{-4}\right) s.\) Phases C and D are dominant in the later stages of evaporation. Similar phases are observed at \(c/{c}^{*}=28.2\) for \({I}^{*}= 1.5\) and \(c/{c}^{*}=2.8\) for all the irradiation intensities. The observations indicate that the dynamics in Phases B, C, and D is significantly affected by bubble growth depending on irradiation intensity and polymer concentration. The observed bubble dynamics differs from the previously reported membrane development, rupture, and breakup in evaporating low-viscoelastic modulus (PAM) droplets (Gannena et al. 2022). Figure 3b schematically represents the effect of skin layer formation in nucleating a bubble and its subsequent effect on global droplet dynamics depending on irradiation intensity \({I}^{*}\) and polymeric concentration \(c/{c}^{*}\). The detailed discussion on skin layer formation will be carried out in droplet evaporation (Phase A).

a Global overview of drop evaporation and bubble dynamics. The effect of PEO concentration and laser irradiation intensity is depicted. The scale bar depicts 1 mm, and the O () symbol denotes the order of magnitude of the various temporal scales. b Schematically illustrates the effect of skin layer in nucleating a bubble and subsequent effect of bubble in global polymeric droplet dynamics

Figure 4 shows the variation of normalized diameter (\(D/{D}_{0})\) with normalized time (\(t/{t}_{d})\) at \({I}^{*}=1.5\) for PAM and PEO. Here, \({t}_{d}\) denotes the time scale for thermal diffusion and is defined as \({t}_{d}=\frac{{R}_{0}^{2}}{{\alpha }_{l}}=\frac{{\rho }_{l}{{c}_{p}R}_{0}^{2}}{k}\) where \({R}_{0}\) is the initial radius of the droplet, \({\alpha }_{l}\) is the thermal diffusion coefficient, \({\rho }_{l}\) is the density of liquid, \({c}_{p}\) is the specific heat capacity, and \(k\) is the thermal conductivity of the liquid. Note that in typical naturally evaporating droplet (in the absence of any heat source), the regression time is normalized with mass diffusion time scale or evaporation time scale. However, in the current work, we are studying laser-induced droplet evaporation, associated asymmetric bubble nucleation, and growth dynamics which critically depends on volumetric heat generation and diffusion of heat within the droplet; hence, we use thermal diffusion time scale for temporal non-dimensionalization. The interaction of a typical PAM droplet with an IR laser in an acoustically levitated field consists of smooth evaporation, nucleation of bubble, bubble expansion, rupture of viscoelastic membrane, and subsequent fragmentation of the polymeric droplet through various pathways (see inset Fig. 4a). The dynamics is significantly different from PEO droplets. The regression data for \(c/{c}^{*}=28.2\) and \({I}^{*}=1.5\) (PEO droplet) encapsulate phenomena like droplet evaporation, bubble growth, and droplet rotation, which is visible due to the entrapped bubble. Whether evaporation curve constitutes rotational motion of the droplet can be established as follows: The equivalent diameter of the droplet is given as \(D= \sqrt[3]{{D}_{H}^{2}{D}_{V}}\). It is a function of \({D}_{H}\) and \({D}_{V}\). Figure S4 (refer to supplementary) depicts temporal variation of major \(\left({D}_{H}\right)\) and minor \(\left({D}_{V}\right)\) axes of polymer droplet over a small time interval of 0.1 s, and hence, the overall size reduction in \(D\) due to evaporation could be neglected. We observe from the figure that \({D}_{H}\) has significantly higher-amplitude (\(\Delta {D}_{H}/D\sim 0.22\)) oscillations compared to \({D}_{V}({\Delta D}_{V}/D\ll 1)\) which is almost constant and exhibits no oscillations. The small variations in \({\Delta D}_{V}\) are not physical oscillations but are the artifacts of image processing pixel uncertainties. It is important to note that for considerable droplet vibration to occur \({\Delta D}_{H}/\Delta {D}_{V}\sim {0.5D}_{H}/{D}_{V}\approx 0.5\) (for almost spherical droplets, i.e., \({D}_{H}/{D}_{V}\sim 1\)) due to volume conservation (note that considered time scale of oscillation is considerably smaller than evaporation time scale) which we did not observe. Therefore, oscillatory nature of major axis diameter \({D}_{H}\) compared to minor axis diameter \({D}_{V}\) indicates rotational motion of the droplet in the levitator field. For evaporating PEO droplets at \(c/{c}^{*}=28.2\) and \({I}^{*}=1.5\), we observe two frequency bands of \(O \left({10}^{0}\right)\) Hz and \(O \left({10}^{1}\right)\) Hz (see Fig. 4 (b)) where low-frequency band has higher power compared to high-frequency band. The low-frequency band is an indication of overall evaporation dynamics. This observation is consistent with previously observed low-frequency band in spectral decomposition of evaporation curve for radiatively heated fuel droplets under acoustic levitation (Pathak et al. 2015). It is important to understand that low frequency does not represent any physical oscillations but corresponds to the inverse evaporation time scale expressed in frequency units. The high-frequency band, on the other hand, represents physical periodic motion related to the rotational dynamics. Also, irrespective of irradiation intensity and polymer concentration, we only observe two frequency bands of \(O \left({10}^{0}\right)\) Hz and \(O \left({10}^{1}\right)\) Hz (see Supplementary Figure S5). However, for evaporating PAM droplets at \(c/{c}^{*}=33.3\) and \({I}^{*}=1.5,\) the only dominant frequency mode is in \(O \left({10}^{0}\right)\) Hz indicating that rotational dynamics is absent (see inset Fig. 4a). Furthermore, bubble nucleation occurs for \(c/{c}^{*}>10\) in a semi-dilute entangled regime for evaporating PAM droplets (Gannena et al. 2022). However, bubble nucleation occurs even in the dilute regime for evaporating PEO droplets. The essential physical mechanisms and their theoretical scales will be elucidated in subsequent sections.

3.2 Droplet evaporation (Phase A)

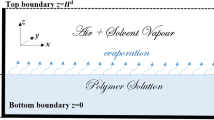

The formation and subsequent dynamics of the vapor bubble during the evaporation of the high-viscoelastic modulus polymeric droplet PEO is shown schematically in Fig. 3 (b). During polymeric droplet evaporation, the regressing air–liquid interface accumulates polymer to form an interconnected network that transforms into a skin layer at a critical gelation concentration. This is followed by subsequent bubble nucleation as evaporation proceeds. At low irradiation intensities, we observe the growth of a stationary bubble while protruding the droplet (see Fig. 3b and Supplementary Movie 2). At higher irradiation intensities, membrane expansion and collapse are observed (see Fig. 3b and Supplementary Movie 1). The membrane expansion and collapse without rupture signify the creation of a significantly higher-strength skin layer. The skin layer formation criteria are quantitatively described by the Peclet number (Pe). The Peclet number is defined as \(Pe= {t}_{dp}/t\), where \({t}_{dp}\) is the diffusion time scale of polymer molecules in the droplet, while \(t\) represents the time scale of the droplet evaporation. Here, \({t}_{dp}= {D}_{0}^{2}/{D}_{P}\), where \({D}_{0}\) is the initial diameter of the droplet, and \({D}_{P}\) indicates the self-diffusion coefficient of the polymer molecule. The self-diffusion coefficient of the polymer can be expressed as \({D}_{P}= \frac{{K}_{B }{T}_{R}}{6\pi \mu \varepsilon }\), where correlation length is expressed as \(\varepsilon = {R}_{g}{\left(\frac{c}{{c}^{*}}\right)}^{\frac{\vartheta }{1-3\vartheta }}\). Here \({K}_{B}\), \(\mu\), \({T}_{R}\), and \(\vartheta\) represent the Boltzmann constant, dynamic viscosity of the solvent, room temperature, and excluded volume coefficient, respectively. For the present work, \(\vartheta\) is set to 0.588 (Raghuram et al. 2021). In the present experimental investigation, \(Pe\gg 1\) for all the irradiation intensities, and it has been previously demonstrated that \(Pe\gg 1\) results in the creation of a skin layer (Gannena et al. 2022). The skin layer thickness \({h}_{0}\) is calculated using the conservation of mass of polymer in the liquid droplet. It is defined as

where \({\varnothing }_{p}\) and \({\varnothing }_{g}\) represent initial polymer mass fraction and gelation mass fraction, respectively. \(\widetilde{\rho }\) indicates the ratio of polymer density to liquid density. \({\varnothing }_{g}\) is equal to 1, where the polymer concentration is the highest throughout the droplet. In general, \({\varnothing }_{g}\) is taken as parametric value, and dependence of skin thickness on gelation mass fraction is minimal (refer to Supplementary Figure S6). More details on Eq. (2) can be referred from our previous work (Gannena et al. 2022). The skin layer thickness \(\left({h}_{0}\right)\) is used for explaining the bubble dynamics (see Sect. 3.3). Depending on the concentration regime, the bubble nucleation differs significantly for low-viscoelastic modulus (PAM) and high-viscoelastic modulus (PEO) droplets. Figure 5 compares high-speed images of evaporating PEO and PAM droplets for \(c/{c}^{*}=2.8\) and \(c/{c}^{*}=3.3\) (at \({I}^{*}=2.2\)), respectively. Here, both the chosen concentrations fall inside the semi-dilute unentangled regime of polymer solutions. At \(c/{c}^{*}=3.3\), for a fluid with a low viscoelastic modulus (PAM), the droplet evaporates without bubble nucleation (Fig. 5b). However, for high-viscoelastic modulus (PEO) droplets, after a period of evaporation, a bubble starts to grow at around \(t=1500 {\text{ms}}\) (Fig. 5a). This can be further corroborated by the temporal variation of non-dimensional diameter \(\left(D/{D}_{O}\right)\) with non-dimensional time \(\left(t/{t}_{d}\right)\) (see Fig. 5c). The pronounced oscillatory behavior in the evaporation curve for PEO at \(c/{c}^{*}=2.8\) and \({I}^{*}=2.2\) indicates droplet rotation. However, the evaporation curve is smooth for PAM at \(c/{c}^{*}=3.3\). The entanglement density \({N}_{e}\) increases more steeply for PEO than PAM (see Fig. 5d). PEO leads to more entanglements than PAM, even at semi-dilute and dilute limits. This leads to the skin layer formation at a much earlier concentration regime (dilute and semi-dilute unentangled regime) and subsequent bubble nucleation at a given irradiation intensity. Note that various microscopic interactions (like solvent–polymer, solvent–solvent, and polymer–polymer interactions) for PEO/PAM manifest themselves into different macroscopic observable rheological properties like viscosity and viscoelastic parameters. Bubble nucleation is a non-equilibrium thermodynamic physical process and does not directly depend on the chemical/reactive properties of the polymer/solvent (in general) since we are dealing with chemically non-reactive systems. See Figure S7 for further evidence of bubble nucleation in dilute and semi-dilute unentangled regimes of polymer concentrations in PEO fluid droplets at a specific irradiation intensity.

a High-speed snapshots of PEO droplet at \(c/{c}^{*}=2.8\) and \({I}^{*}=2.2\). b High-speed snapshots of PAM droplet at \(c/{c}^{*}=3.3\) and \({I}^{*}=2.2\). The scale bar indicates 1 mm. c Temporal variation of drop diameter at \({I}^{*}=2.2\). d Variation of entanglement density with non-dimensional concentration

The experimental temporal surface temperature evolution of a polymer droplet and the experimental evidence of bubble expansion on the illuminating face of the droplet (toward laser direction) are provided through IR thermography. It is important to note that IR imaging provides droplet surface temperature measurement and does not provide depth average temperature measurement owing to the opaque nature of polymer solution with respect to IR band. Figure 6 displays the time evolution of the surface temperature of evaporating PEO droplets under varying irradiation intensities and concentrations. At a concentration, \(c/{c}^{*}=14.1\), and irradiation intensities \({I}^{*}\) ranging from 0.7 to 3 (see Fig. 6a), surface temperature of the polymer droplet increases with time, reaches a saturation limit, and then abruptly peaks. The peak temperature signifies bubble expansion close to the skin layer of the evaporating polymer droplet (see inset Fig. 6a). At higher irradiation intensities, the surface temperature of the polymer droplet rapidly increases, and vice versa at lower irradiation intensities. Also, the peak temperature is attained much earlier for higher irradiation intensities compared to lower irradiation intensities indicating that the bubble nucleation occurs significantly earlier in the droplet’s lifetime (assuming negligible time difference between nucleation and discernible bubble detection).

Temporal evolution of the droplet surface temperature corresponding to a \(c/{c}^{*}=14.1\) and b \({I}^{*}= 3\). The dotted circle represents the bubble expansion after bubble nucleation. In figure (a), the inset represents high-speed snapshots of bubble expansion after bubble nucleation. The inset in figure (b) represents experimental IR images of evaporating polymer droplets at \(c/{c}^{*}=14.1\) and \({I}^{*}= 3\)

At an irradiation intensity of \({I}^{*}= 3\), irrespective of the concentrations (\(c/{c}^{*})\) ranging from 0.84–14.1), the initial increase in surface temperature of the polymer droplet remains nearly constant. However, the peak temperature is attained much quicker for higher concentrations compared to lower concentrations, indicating that bubble nucleation occurs much early (see Fig. 6b). Further, evidence of bubble nucleation close to the illuminating face of the droplet can be explained through experimental IR images (see inset Fig. 6b). We can observe a high-temperature zone (> 100 °C), further confirming bubble nucleation and expansion on the illuminating face.

Figure 7a depicts the normalized droplet diameter (\(D/{D}_{0})\) regression as a function of normalized time (\(t/{t}_{d})\) at various irradiation intensities for \(c/{c}^{*}= 14.1\). The droplet regression is faster for high intensities as compared to small intensity values. The time-varying amplitude of the evaporation curve represents bubble growth, whereas time-varying oscillations represent the droplet's rotational motion. The exact extraction of bubble growth scales, its variation with irradiation intensities, concentrations, and their theoretical comparisons will be elucidated in Sect. 3.3. With regard to different concentrations at a particular irradiation intensity (see Supplementary Figure S8), the diameter reduction remains the same, implying evaporation time scales remain similar, irrespective of polymer concentration. This enables a comparison of theoretical and experimental evaporation time scales for a particular concentration \(c/{c}^{*}= 14.1\) at different irradiation intensities (see Fig. 7b). The theoretical evaporation time scales can be established from a diffusive law proposed by Sobac et al. (2019). The differential equation of the evolving drop radius can be written as

Knowing the initial condition \(D\left(t=0\right)={D}_{0}\), integrating Eq. 3 gives

where \({d}_{va}\) indicates the diffusion coefficient of vapor in air, \({c}_{g}\) represents the gas molar concentration, \(D\) represents the droplet diameter, and \({X}_{i}\) and \({X}_{\infty }\) represent the mole fraction of vapor in the gas phase at the regressing air–liquid interface and far field, respectively.

Using the slope of the above equation, an approximate theoretical evaporation time scale can be written as

where \({X}_{i}\) can be written as

where \({T}_{b}\) is the temperature of the liquid at the boiling point, and \({T}_{i}\) is the temperature at the air–liquid interface. \({L}^{*}\) is the molar latent heat of vaporization of the liquid, and \({R}_{g}\) represents the universal gas constant. Here, \({X}_{i}\) is calculated using the saturation interface temperature obtained from infrared thermography. The experimental and theoretical evaporation time scales are in good agreement with each other, especially at higher irradiation intensities (see Fig. 7b). Note that the effect of acoustic streaming and skin layer formation will have an impact on evaporation time scales for \({t}_{e}>{t}_{d}\). However, for \({t}_{e}\sim {t}_{d}\), the evaporation time scales are governed by the diffusion time scales, perhaps indicating a close agreement of experimental and theoretical evaporation time scales at high irradiation intensities. Further, the characteristic frequency of evaporation is given by \({f}_{e}\sim 1/{t}_{e,theoretical}\) which is in \(O {(10}^{0})\) Hz. It closely matches the lower-frequency band observed in Fig. 4b, confirming that it represents overall evaporation dynamics.

3.3 Bubble growth (Phase B)

The energy interaction between the aqueous polymer droplet and the infrared laser is electromagnetic in origin. The droplet beam interaction could be understood based on the Mie-size parameter (Gannena et al. 2022) \(2\pi {R}_{0}/{\lambda }_{0}.\) For small value of Mie-size parameter, the source function (distribution of electromagnetic energy) distributed throughout the droplet volume is uniform corresponding to a uniform thermal energy evolution throughout the droplet. For large droplets, the Mie-size parameter increases resulting in the source function developing peaks (hotspots), and the thermal energy evolution shows inhomogeneities. Different hydrodynamic and thermodynamic processes are observed based on the internal thermal energy evolution inside the droplet. Bubble nucleation is an example of one such process. The aqueous polymer, being infrared opaque, interacts with the incident laser beam's electromagnetic field and absorbs most of the incident photons. The various energy interactions that occur during droplet beam interactions are radiative heating of the droplet, thermal diffusive processes throughout and at the interface evaporative, and diffusive cooling of the droplet in general. However, the diffusive process occurring over the droplet length scale is typically slower than the radiative heating of the droplet. Therefore, at an intermediate and high intensity (evaporation time is shorter than the thermal diffusive time scale), the diffusive cooling process is too slow, and the temperature at the hotspots keeps increasing before nucleation occurs due to the formation of the skin layer at the droplet interface.

The average temperature of the droplet can be modeled using the energy equation with a volumetric source term. The volumetric source term represents the absorption process (Gannena et al. 2022). Droplets irradiated by lasers are typically in a metastable state. Therefore, the phase transition from liquid water to vapor does not occur at 100 °C. In case of rapid heating, the maximum temperature the liquid water can achieve (i.e., the superheat limit) preserving its liquid state is close to 305 °C, beyond which spontaneous nucleation to vapor phase begins. The droplet, hence, can be in a liquid state beyond the boiling point at standard atmospheric pressure. As the temperature inside the droplet increases beyond the boiling point and once the skin layer forms, bubble nucleation occurs much before the superheat temperature of liquid water is in a metastable state. The general Rayleigh–Plesset equation describing the growth of a bubble in a confined viscoelastic medium is given in the supplementary material (see supplementary section on generalized Rayleigh–Plesset equation).

Equation 1 in supplementary (Gaudron et al. 2015, Vincent and Marmottant 2017) is simplified by using \(\varphi \sim O(1)\) and neglecting small-order quantities (logarithmic term on the LHS and the last term on RHS) to the standard Rayleigh–Plesset equation with the elastic terms as

We can therefore observe that the effect of confinement size is negligible for the bubble growth regime under consideration in the present work. Usually, modeling the elastic stress for polymers mainly focuses on Maxwell-based models. However, systems that relax back to their original configuration are better modeled by Kelvin–Voigt polymeric models. Due to large deformations in polymeric systems, the infinitesimal strain assumption in most real-world scenarios is mainly invalid. This necessitates replacing the linear elasticity models with nonlinear finite strain elasticity models. Various nonlinear strain energy functions like neo-Hookean and Mooney–Rivlin approximations could be used. For the current experiments, where the material relaxes back to its original state (PEO droplets, see Supplementary Movie 1), neo-Hookean models are much better suited to model the elastic stress. The elastic stress \(E\), therefore, can be written as

Notice that \(E\) is directly proportional to the modulus \(\eta\). \({R}_{b*}\) is the bubble size at the instant of nucleation and is typically of the order radius of gyration of polymer (it is in \(O \left(nm\right)\)). In addition, for the bubble initiation phase, when the ratio \({R}_{b*}\)/\({R}_{b}\) is close to unity, the correction terms are essential, and elastic stress becomes time-varying and nonlinear. However, when the bubble has already grown to a size large enough such that the ratio \({R}_{b*}\)/\({R}_{b}\) is much smaller than unity, the elastic stress is not dependent on the bubble radius and becomes a constant. Therefore, the elastic term becomes important only during the initial stage of the nucleation process. Further, owing to the very high ratio of the driving pressure \(O \left({10}^{5}\text{ Pa}\right)\) compared to the shear modulus \(O \left({10}^{1}\text{ Pa}\right)\), the elastic term in the Rayleigh–Plesset equation could be neglected (for low shear modulus). The authors also want to highlight that the effects of confinement and elasticity become important, when the bubble has grown to its maximum allowable size possible in comparison with the confinement length scale (i.e., \({R}_{b}/{R}_{\text{c}}\sim \text{O}(1)\), and hence, \(\varphi\) is significantly smaller than unity (refer to supplementary)). Further, the effect of confinement and elasticity is also important when the dynamics has slowed down considerably (near to its quasi-equilibrium length scale, i.e., when both \(\ddot{{R}_{b}}\approx 0\) and \(\dot{{R}_{b}}\approx 0\)), both of which occurs at time scales much larger than a single bubble growth time scale. In such scenarios due to very slow dynamics (i.e., almost at quasi-steady state), the second-order and first-order time derivative term becomes negligible in comparison with other terms such as the LHS elastic term and pressure difference, confinement term in the RHS of the generalized Rayleigh–Plesset equation.

The right-hand side of the Rayleigh–Plesset Eq. (7) is the driving pressure difference across the bubble and is of the order of the atmospheric pressure. \({p}_{B}\) is the pressure inside the bubble, and \({p}_{\infty }\) is the pressure in the liquid phase (polymeric droplet). Refer to the supplementary for an in-depth discussion on the coupling of pressure difference to the temperature.

During phase change at approximately atmospheric pressure, all the properties could be evaluated at the saturated temperature corresponding to atmospheric pressure (boiling point). The scale for \(({T}_{B}-{T}_{\infty })\) (refer to supplementary, discussion on the coupling of pressure difference to the temperature) is estimated using the thermal energy equations. In the current context, the liquid temperature is majorly dependent on radiative heating, as shown in our previous work at time scales smaller than the diffusive scales, which is valid for most bubble growth processes in the present context (Gannena et al. 2022). The average liquid temperature is therefore given by

where

and

Using Eq. (9), \(({T}_{B}-{T}_{\infty })\) could be computed and can be approximated by the degree of superheat \(({T}_{l}-{T}_{b})=\Delta T\) where \({T}_{b}\) is the boiling point of the liquid at atmospheric pressure. The approximate bubble growth length can be obtained as a scaling consequence of thermal boundary condition at the bubble interface and by employing the thin boundary layer assumption due to the Plesset–Zwick approximation (refer to supplementary, discussion on Plesset–Zwick).

The thermal boundary layer scales as \({\delta }_{T}\sim \sqrt{{\alpha }_{l}t}\) in general. Using the time-varying thermal boundary length scale, the boundary condition at the wall can be written in terms of dominant scales as

Simplifying Eq. (13) further, we have

Integrating Eq. (14), we have

Multiplying and dividing the RHS of Eq. (15) by \(\sqrt{{\alpha }_{l}}\), we have

Dividing by \({R}_{0}\), we have

Using \({\alpha }_{l}={k}_{l}/{\rho }_{l}{c}_{l}\) in Eq. (17) and simplifying further, recognizing the diffusion time scale \({t}_{d}={\text{R}}_{0}^{2}/{\alpha }_{l}\), we have

It is important to note that the bubble radius scale obtained from Plesset–Zwick approach (Plesset and Zwick 1954) (shown in Eq. (19) is exactly the same as obtained in Eq. (18) (refer to supplementary, discussion on Plesset–Zwick)

After the initial fast bubble growth phase near the nucleation point, the bubble growth rate relatively slows down and grows as \({R}_{b}\sim (t{)}^{1/2}\) (refer to Eq. 19). As the bubble grows to a size comparable to the droplet radius, a noticeable bump can be observed on the illumination face of the droplet. The bubble always appears on the IR-illuminated face of the droplet because the temperature of the droplet is higher on the illumination face compared to the shadow face. The axial temperature inside the droplet decreases exponentially as the laser beam traverses from the illumination to the shadow face due to Beer-Lamberts law (Gannena et al. 2022). The time it takes to observe a detectable bump in the droplet is known as the onset time \(\left({t}_{onset}\right)\), and the corresponding droplet length scale is known as onset radius \(\left({R}_{onset}\right)\) or diameter \(\left({D}_{onset}\right)\). The approximate length scale of the bubble could be computed using a unique feature of the experimental configuration. Generally, the droplet in a levitated field rotates about its center of mass axis due to the conservation of angular momentum. Figure 8(a) shows the droplet and the bump caused by the bubble growing inside during various phases of its rotation. Once the bubble nucleates and grows, we observe a bump on the illumination face of the droplet (\(t=2000 {\text{ms}}\) here) and measure its horizontal length scale \({D}_{2}\). As the droplet rotates, we see the view as it appeared at \(t= 0 {\text{ms}}\). Thus, an approximate bubble length scale is estimated as \({D}_{2}-{D}_{1}\). Note that the bubble remains stationary once it nucleates due to the low Reynolds number (Re) flow inside the droplet. The approximate liquid Reynolds number can be determined as follows: From the mass conservation boundary condition at the bubble–liquid interface, the approximate liquid velocity \(\left({V}_{l}\right)\) can be written as \({V}_{l}\sim {V}_{b}\left({\rho }_{v}/{\rho }_{l}\right)\), where \({V}_{b}\sim \frac{{\text{d}}{R}_{b}}{{\text{d}}t}\) and \({\rho }_{v}\) represent bubble velocity and vapor density, respectively. The Reynolds number \(\left(Re\sim {\rho }_{l}{V}_{l}{D}_{onset}/{\mu }_{l}\right)\) comes out to be in \(O ({10}^{-7})\) implying low Reynolds number and very high viscous dissipation causing negligible flow conditions inside the droplet. Further continuous reduction of Reynolds number occurs due to an increase in polymer drop viscosity as a result of the rise of average polymer concentration due to droplet evaporation. The experimental bubble length scale is plotted in Fig. 8(b). The theoretical scale of bubble growth according to Eq. (18) is plotted, and it agrees well with the experimental data within the experimental uncertainty range for various irradiation intensities. Note that the bubble growth follows \({t}^{1/2}\) dependence; however, the plot seems linear due to a very limited data range in the temporal axis (the absence of bubble growth data during the very initial bubble nucleation growth phase), i.e., the experimental data fall on a relatively linear (tangent line approximation) region of the square root curve. Higher values of \({I}^{*}\) correspond to a higher degree of superheat for various \({I}^{*}\). The degree of superheat enters the bubble growth equation in the coefficient of \((t{)}^{1/2}\). The onset times \(\left({t}_{onset}\right)\) can also be related to the irradiation intensity \({I}^{*}\) through the bubble growth Eq. (18) and through the degree of superheat \(\Delta T\). The degree of superheating is related to \({I}^{*}\). This can be understood from Eq. (9) and Eq. (10) of the liquid temperature.

a High-speed images of bubble growth for \(c/{c}^{*}= 14.1\) and \({I}^{*}=0.7\). b Effect of irradiation intensity on bubble growth scales and its theoretical comparison. c Effect of irradiation intensity on the onset time of bubble growth at different irradiation intensities and its theoretical comparison. d Effect of polymer concentration on the bubble growth at \({I}^{*}=0.7\)

From Eq. (18), we have

Using Eq. (20) in Eq. (21) and realizing that at the onset time \({R}_{b}\propto {R}_{\text{onset}}\), we have

Simplifying further, we have

The irradiation intensity can be expressed in its non-dimensional form as

where \({D}_{0}\) is the initial diameter of the droplet, and \({h}_{lv}\) represents the latent heat of vaporization.

The theoretical \({t}_{onset}\) curves obtained for various non-dimensional irradiation intensities and concentrations pass closely through the experimentally observed \({t}_{onset}\) values (see Fig. 8c). The constant of proportionality for Eq. (25) is obtained by calibrating the onset radius and onset time scale appearing in Eq. (25) at the lowest value of \({I}^{*}\). Furthermore, at a specific irradiation intensity, the bubble growth scales are higher for larger \(c/{c}^{*}\) compared to a lower \(c/{c}^{*}\) (see Fig. 8d). The critical gelation concentration \({\varnothing }_{g}\) to form a skin layer reaches much earlier in the evaporation time scale, thus leading to earlier nucleation of bubble and subsequently larger bubble growth scales for high \(c/{c}^{*}\) compared to lower \(c/{c}^{*}\) at a particular irradiation intensity.

3.4 Shape oscillations and precipitate formation (Phases C and D)

The shape oscillations are majorly driven by the presence of a bubble inside the droplet and, to an extent, by the rotational motion of the droplet.

The bubble growth close to the illuminating face of the droplet causes the evaporating polymer droplet to become asymmetric. This enabled us to quantify the rotational motion of the evaporating polymer droplet in a levitation field. The time-varying frequencies of the rotational motion of the droplet are obtained by performing power spectrum operation on the droplet size data (diameter) within short time intervals. Once we know the temporal variation of diameter and frequency of droplet rotation, the relation between them in a levitated experimental configuration can be obtained as follows: From the principle of angular momentum conservation of the droplet (assuming negligible losses due to air resistance at the air–droplet interface),

where \(I=m{D}^{2}/10\) represents the moment of inertia of the droplet, m is the mass of the droplet, D is the diameter of the droplet, and \(\omega =2\pi f\) represents the frequency of rotation of the droplet.

Here, \(f({t}_{ref})\) and \(D({t}_{ref})\) represent frequency and diameter at the reference initial time scale in the evaporation process of the droplet. The relation between rotation frequency and droplet diameter is implicitly independent of concentration and rotation. Hence, the experimental and theoretical comparison of diameter variation with rotational frequency of droplet is carried out for \(c/{c}^{*}= 14.1\) and \({I}^{*}= 1.5\). The experimental and theoretical values show reasonable agreement within the experimental uncertainty (see Fig. 9). Further, the theoretical frequency scale closely matches the higher-frequency band in the power spectrum of diameter regression (see Fig. 4b).

Further, we observe vigorous droplet shape oscillations primarily due to the presence of bubble. The droplet shape oscillations are quantified by estimating the change in the droplet position (x-coordinate and y-coordinate) with time. The shape oscillations over a wide range of irradiation intensities and concentrations are characterized through a non-dimensional parameter referred as bubble growth index (\(\alpha )\), which is defined as \(\alpha = {\left({D}_{b,max}/{D}_{onset}\right)}^{3}\), where \({D}_{b,max}\) represents the maximum expansion diameter of the polymer droplet due to the bubble growth, and \({D}_{onset}\) represents the diameter of the polymer droplet at the onset of nucleation. It is observed that the major shape oscillations are characterized by \(\alpha >=1\), which are predominant at high concentrations and high irradiation intensities (\(c/{c}^{*}=\text{14.1,28.2} \, and\, {I}^{*}=\text{3,3.5})\). Similarly, mild shape oscillations are characterized by \(0.5<=\alpha <1\). These small-scale oscillations are dominant at high concentrations and low irradiation intensities \((c/{c}^{*}=\text{14.1,28.2} \, and\, {I}^{*}=0.7-2.2)\). Finally, \(\alpha <0.5\) signifies minor shape oscillations observed at low concentrations and all irradiation intensities \((c/{c}^{*}<10 \,{\text{and}}\, {I}^{*}=0.7-3.5)\). Figure 10a shows a typical major shape oscillation event. The oscillations start when the bubble/membrane expands and collapses into the polymer droplet. The major shape oscillations are characterized by volumetric shape distortions, stretching, and reorientation of the polymer droplet (see inset Fig. 10a). The shape oscillations of the droplet are majorly due to bubble–droplet interaction. The bubble interaction wih the droplet during the oscillation event is correlated to the droplet mass distribution and its corresponding centroid motion. Figure 10a depicts the typical centroid trajectory of the polymer droplet when the membrane (bubble) collapses back into the parent droplet. The normalized centroid coordinates of the polymer droplet are defined as \({X}^{*}= (X-{X}_{onset})/{X}_{onset}\) and \({Y}^{*}= (Y-{Y}_{onset})/{Y}_{onset}\) where \({X}_{onset}\) and \({Y}_{onset}\) represent centroid coordinates of the polymer droplet when membrane (bubble) collapse occurs. As evident from Fig. 10a, once the membrane (bubble) collapses into the parent droplet, the droplet oscillates vigorously along both the horizontal and vertical directions.

a Typical trajectory of the centroid of levitated polymer droplet for \(\alpha >1\). b Typical trajectory of the centroid of levitated polymer droplet for \(0<\alpha <0.5\). c Power spectrum of X-center of mass (X-CM) of evaporating polymer droplet at \({I}^{*}=1.5\) and \(c/{c}^{*}= 14.1\) . d Power spectrum of Y-center of mass (Y-CM) of evaporating polymer droplet at \({I}^{*}=1.5\) and \(c/{c}^{*}= 14.1\). The frequencies of centroid motion remain the same, irrespective of concentration and irradiation intensity

The maximum non-dimensional displacement in the centroid's positive x-coordinate and y-coordinate position is 2.4 and 0.4, respectively, while the non-dimensional displacement in the negative coordinates is − 2 and − 0.6, respectively. In contrast, centroid displacement for mild to minor shape oscillations is comparatively smaller than for major shape oscillations. For mild shape oscillations, the maximum non-dimensional displacement in the positive x-coordinate and y-coordinate position of the centroid is 0.1 and 0.15, respectively, while the non-dimensional displacement in the negative coordinates is − 1.5 and − 0.3, respectively (see Supplementary Figure S9), whereas for very mild shape oscillations, the maximum non-dimensional displacement in the centroid's positive x-coordinate and y-coordinate position is 1.6 and 0.15, respectively, while the non-dimensional displacement in the negative coordinates is − 1.3 and − 0.15, respectively (see Fig. 10b). In the case of \(\alpha >1\), nucleation of multiple bubbles and their subsequent coalescence leads to a complex "Dumbbell" shape. This leads to droplets experiencing vigorous motion in both horizontal and vertical directions. In the regime \(\alpha <1\), the expanding bubble remains stationary, close to the illumination face of the droplet for most of the droplet evaporation lifetime, resulting in only minor shape oscillations. Power spectrum density operation on X-center of mass (X-CM) and Y-center of mass (Y-CM) revealed that the dominant frequencies of droplet oscillations are in \(O ({10}^{1}-{10}^{2})\) Hz. The frequencies remain independent of concentration and irradiation intensity, implying that these oscillations time period is driven by levitation system parameters contrary to the amplitude of the oscillations (trajectories), which are guided by the bubble growth and evaporation dynamics.

When the concentration of PEO is large (\(c/{c}^{*}>10)\) and at high irradiation intensities, a significant amount of nucleation sites are formed, resulting in large bubble formation. The expanding bubble eventually stretches the skin layer and expands as a viscoelastic membrane (Gannena et al. 2022). Due to significantly higher elasticity (note that the macroscopic property strength of the membrane occurs due to various interactions like solvent–polymer, solvent–solvent, and polymer–polymer), the membrane stretches and collapses into the parent droplet. These events are observed intermittently throughout the evaporation phase in the event \(\alpha >1\). For \(\alpha <1\), due to smaller bubble growth, the unique membrane expansion and collapse are not observed. The bubble size substantially affects the polymer droplet's final morphology. At high concentrations and irradiation intensities, where the bubble diameter is significantly large (\(\alpha >1)\), the final structure of the polymer droplet resembles a shell structure (Fig. 11). For \(\alpha <0.5\), where the size of the bubble is significantly smaller owing to fewer nucleation sites, the final structure is a smooth solid precipitate. The bubble nucleation in multi-component, polymeric droplets with the low viscoelastic modulus (PAM) results in different modes (ligament-mediated, catastrophic, and micro-explosion) of atomization of droplets which has not been observed in polymeric droplets with the high-viscoelastic modulus (PEO) even at significantly high concentrations and irradiation intensities. The significantly higher strength of the skin layer hampers the droplet atomization process.

4 Conclusions

A detailed experimental study is conducted to understand the bubble dynamics and droplet shape oscillations in acoustically levitated polymer droplets under external radiative heating. The conclusions are as follows:

-

1.

High-viscoelastic polymer droplets experience evaporation and shape oscillations without atomization, in contrast to the occurrence of previously reported distinct modes of atomization in low-viscoelastic polymer droplets. This is attributed to the increased entanglement density at the skin layer, which directly correlates with the higher skin layer strength. The steeper increase in entanglement density \(\left({N}_{e}\right)\) for high-viscoelastic (PEO) droplets leads to the nucleation of vapor bubbles in dilute and semi-dilute unentangled regimes contrary to the occurrence of bubble nucleation in low-viscoelastic (PAM) droplets in the semi-dilute entangled regime.

-

2.

Four temporal phases (A–D) are observed depending on the parametric values of irradiation intensity and polymer concentration. Phase A corresponds to evaporation of the droplet. Phase B represents nucleation of vapor bubble, followed by bubble and membrane growth. Phases C and D depict shape oscillations and precipitate formation. Droplet evaporation time scale is of the order of \(O\left( {10^{0} {-}10^{1} } \right) {\text{s}}\). The theoretical time scale obtained from a diffusive evaporative law predicts the experimental evaporation time scale. This corroborates to the low-frequency band observed in the power spectrum of diameter regression.

-

3.

The scaling analysis shows that the quasi-steady bubble length scale \({R}_{b}\) varies temporally as \({\left(t\right)}^{1/2}\) for low irradiation intensities. Further, it is observed that the onset time \(\left({t}_{onset}\right)\) of bubble growth varies with irradiation intensity as \({t}_{onset}\propto {\left({R}_{onset}/{I}^{*}\right)}^{2}\).

-

4.

From the principle of conservation of angular momentum, it is shown that the frequency of rotation varies with droplet diameter as \(f\propto 1/{D}^{5}\). In addition, the theoretical rotation frequency agrees well with the high-frequency band observed in the power spectrum of diameter regression.

-

5.

Finally, a bubble growth index \(\alpha\) is defined, which characterizes the final precipitates formed after evaporation. \(\alpha >1\) and \(0.5<\alpha <1\) are characterized by shell-like precipitates, whereas for \(\alpha <0.5,\) solid precipitates are observed. These findings are contrary to the different atomization modes observed for low-viscoelastic polymer droplets in similar concentration regimes, further deciphering the role played by the skin layer in the dynamics of evaporating polymeric droplets.

Availability of data and materials

The data that support the findings of this study are available from the corresponding author upon reasonable request.

References

Abramzon B, Sazhin S (2006) Convective vaporization of a fuel droplet with thermal radiation absorption. Fuel 85(1):32–46

Al Zaitone B, Al-Zahrani A, Al-Shahrani S, Lamprecht A (2020) Drying of a single droplet of dextrin: drying kinetics modeling and particle formation. Int J Pharm 574:118888

Antonov DV, Strizhak PA (2019) Heating, evaporation, fragmentation, and breakup of multi-component liquid droplets when heated in air flow. Chem Eng Res Des 146:22–35

Avila SRG, Ohl CD (2016) Fragmentation of acoustically levitating droplets by laser-induced cavitation bubbles. J Fluid Mech 805:551–576

Baldwin KA, Fairhurst DJ (2014) The effects of molecular weight, evaporation rate and polymer concentration on pillar formation in drying poly(ethylene oxide) droplets. Colloids Surf A 441:867–871

Baldwin KA, Granjard M, Willmer DI, Sefiane K, Fairhurst DJ (2011) Drying and deposition of poly (ethylene oxide) droplets determined by Peclet number. Soft Matter 7(17):7819–7826

Baldwin KA, Roest S, Fairhurst DJ, Sefiane K, Shanahan ME (2012) Monolith formation and ring-stain suppression in low-pressure evaporation of poly (ethylene oxide) droplets. J Fluid Mech 695:321–329

Gannena KR, Rao DCK, Roy D, Kumar A, Basu S (2022) Bubble dynamics and atomization in evaporating polymeric droplets. J Fluid Mech 951:A48

Gaudron R, Warnez MT, Johnsen E (2015) Bubble dynamics in a viscoelastic medium with nonlinear elasticity. J Fluid Mech 766:54–75

Littringer EM, Mescher A, Eckhard S, Schröttner H, Langes C, Fries M, Urbanetz NA (2012) Spray drying of mannitol as a drug carrier—the impact of process parameters on product properties. Dry Technol 30(1):114–124

Mamalis D, Koutsos V, Sefiane K, Kagkoura A, Kalloudis M, Shanahan ME (2015) Effect of poly (ethylene oxide) molecular weight on the pinning and pillar formation of evaporating sessile droplets: the role of the interface. Langmuir 31(21):5908–5918

Miglani A, Basu S, Kumar R (2014) Insight into instabilities in burning droplets. Phys Fluids 26(3):032101

Mikaél’A B (2013) Infrared radiation: a handbook for applications. Springer, Berlin

Mura E, Calabria R, Califano V, Massoli P, Bellettre J (2014) Emulsion droplet micro-explosion: analysis of two experimental approaches. Exp Thermal Fluid Sci 56:69–74

Okuzono T, Ozawa KY, Doi M (2006) Simple model of skin formation caused by solvent evaporation in polymer solutions. Phys Rev Lett 97(13):136103

Pathak B, Basu S (2016a) Modulation of buckling dynamics in nanoparticle laden droplets using external heating. Langmuir 32(11):2591–2600

Pathak B, Basu S (2016b) Phenomenology of breakup modes in contact free externally heated nanoparticle laden fuel droplets. Phys Fluids 28(12):123302

Pathak B, Sanyal A, Basu S (2015) Experimental study of shape transition in an acoustically levitated and externally heated droplet. J Heat Transfer 137(12):121006

Pauchard L, Allain C (2003a) Buckling instability induced by polymer solution drying. Europhys Lett 62(6):897

Pauchard L, Allain C (2003b) Mechanical instability induced by complex liquid desiccation. C R Phys 4(2):231–239

Pauchard L, Allain C (2003c) Stable and unstable surface evolution during the drying of a polymer solution drop. Phys Rev E 68(5):052801

Plastics Technology. Retrieved from https://www.polymerdatabase.com/

Plesset MS, Zwick SA (1954) The growth of vapor bubbles in superheated liquids. J Appl Phys 25(4):493–500

Raghuram GK, Bansal L, Basu S, Kumar A (2021) Suppression of coffee ring effect in high molecular weight polyacrylamide droplets evaporating on hydrophobic surfaces. Colloids Surf, A 612:126002

Rajput AS, Varma SC, Kumar A (2023) Sub-Newtonian coalescence in polymeric fluids. Soft Matter 19(26):4847–4858

Rao DCK, Karmakar S, Basu S (2017) Atomization characteristics and instabilities in the combustion of multi-component fuel droplets with high volatility differential. Sci Rep 7(1):8925

Rao DCK, Basu S (2020a) Phenomenology of disruptive breakup mechanism of a levitated evaporating emulsion droplet. Exp Thermal Fluid Sci 115:110086

Rao DCK, Basu S (2020b) Atomization modes for levitating emulsified droplets undergoing phase change. Exp Fluids 61:1–20

Rao DCK, Karmakar S, Basu S (2018) Bubble dynamics and atomization mechanisms in burning multi-component droplets. Phys Fluids 30(6):067101

Rao DCK, Singh AP, Basu S (2022) Laser-induced deformation and fragmentation of droplets in an array. Int J Multiph Flow 148:103925

Restrepo-Cano J, Ordonez-Loza J, Guida P, Roberts WL, Chejne F, Sarathy SM, Im HG (2022) Evaporation, break-up, and pyrolysis of multi-component Arabian Light crude oil droplets at various temperatures. Int J Heat Mass Transf 183:122175

Rubinstein M, Colby RH (2003) Polymer physics (vol. 23, p. 259). Oxford University Press, New York

Sobac B, Larbi Z, Colinet P, Haut B (2019) Mathematical modeling of the drying of a spherical colloidal drop. Colloids Surf, A 576:110–122

Tirtaatmadja V, McKinley GH, Cooper-White JJ (2006) Drop formation and breakup of low viscosity elastic fluids: effects of molecular weight and concentration. Phys Fluids 18(4):043101

Vincent O, Marmottant P (2017) On the statics and dynamics of fully confined bubbles. J Fluid Mech 827:194–224

Wilms J (2005) Evaporation of multi-component droplets

Wolfe WL, Zissis GJ (1978) The infrared handbook. The Office

Acknowledgements

S.B. would like to thank the support from the Pratt and Whitney Chair professorship.

Funding

Not applicable.

Author information

Authors and Affiliations

Contributions

G.K.S. R. contributed to methodology, investigation, data curation, formal analysis, validation, writing—original draft, and writing—review and editing. D.R contributed to formal analysis, validation, writing—original draft, and writing—review and editing. D.C.K contributed to methodology, investigation, validation, writing—original draft, and writing—review and editing. A. K and S. B. contributed to conceptualization, methodology, supervision, validation, writing—original draft, and writing—review and editing.

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare no conflict of interest.

Ethical approval

Not applicable.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Supplementary file1 (MP4 1176 kb)

Supplementary file2 (MP4 1873 kb)

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Raghuram, G.K.S., Roy, D., Rao, D.C.K. et al. Insights into bubble–droplet interactions in high-viscoelastic evaporating polymer droplets. Exp Fluids 65, 105 (2024). https://doi.org/10.1007/s00348-024-03842-9

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00348-024-03842-9