Abstract

Recently, OH planar laser-induced fluorescence (PLIF) using the broadband, ultrashort femtosecond-duration (fs-duration) and the thermally assisted vibrational transfer in excited state has been investigated in flames. In this present work, we first measured temperature by thermally assisted OH laser-induced fluorescence (TALF) method with a single ultrashort broadband fs laser. In the experiment, the fs excitation of OH at ultraviolet wavelength is followed by fluorescence detection from two different vibrational bands. The ratio of two measured (1–0) and (0–0) band fluorescence is calibrated with calculated temperature using Chemkin PRO PRIMIX. The calibrated results are used in measuring temperature distributions in different laminar flames. It is found that TALF method using the fs laser can detect 2D temperature distribution in the burnt area with high OH fluorescence signal. However, OH chemiluminescence brings inevitable noise at the flame front that the TALF method does not perform well. And because (1–0) band fluorescence is so weak, the noise from the camera sensor and imaging intensifier (I.I.) remains at the measured temperature imaging. In conclusion, quantitative temperature measurement based on OH TALF based on a single broadband, ultrashort fs laser can be applied in laminar flames with high frequency by a simple experiment setup.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Investigation of temperature and intermediate species’ concentration in a variety of reacting flows has significant meaning to understanding the reacting process [1], heat release features [2], and turbulent characteristics [3]. To measure the temperature and intermediate species with high spatial and temporal precision in gaseous fluid, laser-based diagnostic technologies have been introduced and applied in various combustion experiments. Over the past few decades, several laser diagnostic technologies, like tunable diode laser absorption spectroscopy (TDLAS) [4], Rayleigh scattering [5], Raman scattering [6], coherent anti-Stokes Raman scattering (CARS) [7], and laser-induced fluorescence (LIF), have been developed.

As one of the laser diagnostic technologies, hydroxyl (OH) radical two-line LIF temperature measurement method has been applied and extended for planar and even volumetric measurements in several combustion diagnostics. OH is a key intermediate species in hydrogen and hydrocarbon combustion, which widely exists in burnt gas. From last century, several quantitative measurements of temperature based on OH LIF have been developed and applied in investigating flame characteristics [8, 9]. In recent studies, to eliminate the non-simultaneous nature of the two-line OH PLIF thermometry technique and to avoid the need for two narrow-band tunable laser sources, OH thermal assisted PLIF (TALF) temperature measurement is under development. Thermal assisted vibrational energy transfer (VET) is a well-studied phenomenon, and its mechanism was well described in Copeland’s work [10]. Copeland et al. [10] developed the TALF measurement method in a laminar flame and presented high-resolution two-dimensional results with a measured range between 1300 to 1900 K. TALF method use a single laser source to populate molecules to an excited state and collisional transfer then redistributes that population among other excited energy states. For OH TALF, the redistribution happens between rotational states within the vibrational levels at \({A^2} {\Sigma ^+}\) state. Following the redistribution, the spontaneous emission from these energy levels can be related to the local temperature, pressure and concentration of species. Based on this theory, TALF temperature measurement method is developed and applied in several flames. Dulin et al. [11] developed TALF thermometry based on OH (1–0) band in \({A^2} {\Sigma ^+} - {X^2}\Pi\) system using a single narrow bandwidth ns-duration Nd: YAG based laser system and compared with two-line OH LIF method in turbulent flames. At the same time, Dulin et al. [11] also reported the collisional quenching effect between N\(_{2}\)/O\(_{2}\)/OH also played a primary role in temperature measurement process, which resulted in inevitable deviation.

In recent research, broad bandwidth, ultrashort picosecond (ps), and femtosecond (fs) lasers have been developed for use in OH Laser-Induced Fluorescence (LIF) experiments to enable quantitative measurements. Stauffer’s work [12] reported two-photon excitation of the OH \({A^2} {\Sigma ^+} - {X^2}\Pi\) system, and calibrated the single lines’ intensity in two-photon OH absorption spectrum to the local temperature and OH number density. However, the fluorescence signal in Stauffer’s work was deemed too weak. Consequently, a point photomultiplier tube (PMT) was employed, and more than 30,000 averaged pulses were necessary to achieve an acceptable signal-to-noise ratio (SNR). This approach was insufficient for high-frequency single-shot 2D imaging in combustion studies. As a result, an ongoing development focuses on a one-photon OH fs-LIF technique based on a single femtosecond laser. Due to its ultrashort duration (less than 500 fs) and wideband characteristics, the fs laser-based LIF technique outperforms in measuring key species concentrations and enabling simultaneous measurement of multiple species [13,14,15,16]. Jain et al. [14] performed simultaneous measurements of H and OH in laminar flames with a single fs laser source. In another study by Wang et al. [15], CO LIF and OH LIF were measured instantaneously by using a single fs laser pulse. Wang’s research [16] involved one-photon excitation through the (1–0) band by a single fs laser in laminar flames. The fluorescence of OH (1–0) band in \({A^2} {\Sigma ^+} - {X^2}\Pi\) was first quantitatively investigated, and the fs OH LIF signal was compared with OH number density and temperature. The results revealed that the measured OH number density profiles in flames with different fuels and a wide range of equivalence ratios were in good agreement with model predictions. At the same time, the thermal assisted vibrational transfer in excitation level was first observed in fs scale. While Wang’s work [16] reported the vibrational transfer between the \({ v'}=0\) and \({ v'}=1\) energy level was mainly non-thermal assisted, resulting in a large deviation of the measured vibrational temperature from the model predictions, the vibrational energy transfer between the \({ v'}=1\) and \({ v'}=2\) remains understudied. These experimental findings collectively indicate that the LIF technique based on a single fs laser can simultaneously measure the concentration of multiple species, temperature field, and even velocity field in the flame with a single laser source. Therefore, the development of temperature measurement techniques based on femtosecond lasers is deemed essential.

In the current study, we conducted an investigation into vibrational transfer between \({ v'}=0\) and \({ v'}=1\) vibrational band. It was found by utilizing the single-photon excitation of the (0–0) band in \({A^2} {\Sigma ^+} - {X^2}\Pi\) system by a single broadband, ultrashort fs-duration laser pulse, the ratio of the spontaneous emissions from (0–0), \({ I}_{(0-0)}\) and (1–0), \({ I}_{(1-0)}\) had a linear relationship with the local temperature. Building on these findings, OH fs TALF temperature thermometry was developed and the 2D temperature distributions in different methane-air laminar flames were measured by utilizing a single fs-duration laser source. The experimental setup is described in Sect. 2, and the detailed measurement results are discussed in Sect. 3. To our knowledge, it is the first time to apply OH TALF method by using the one-photon excitation by a broadband fs-duration laser.

2 Experimental setup

A schematic of experimental setup of fs OH PLIF measurement system based on (0–0) band. An OPA and femtosecond laser system is applied to generate 615 nm laser. An SHG is used to double the laser’s frequency. Two sets of detection sets (camera, I.I., and lens) are used to capture two bands’ fluorescence imaging side by side

The experimental setup is shown in Fig. 1. For the excitation system, a broad bandwidth, ultrashort fs pulse laser (Coherent, Vitara-S, 800 ± 10 nm) was employed as the laser source, which can generate 20 fs-duration laser pulses at 1 kHz. An ultrafast Ti-Sapphire Amplifier (Coherent, Astrella, \(\le\) 100 fs/pulse) was employed to amplify the energy of one pulse to 2.40 W. The amplified laser beam was used to pump an optical parametric amplifier (OPA, Coherent, OPerA Solo) with SH package (580 nm to 800 nm) for generating the fundamental output beam near 615 nm (615 ± 10 nm, \(\le\) 100 fs/pulse, \(\ge\) 0.2 W). The 615 nm beam was directly led to a second harmonic generator (SHG) Beta-Barium Borate (BBO) crystal, and the wavelength was adjusted to around 307 nm, while the pulse intensity was 0.056 W. After the SHG crystal, the 307 nm laser beam was directed through three UV mirrors ( \(\le\) 330 nm: transmissivity \(\ge\) 99\(\%\), \(\ge\) 600 nm: transmissivity \(\le\) 1\(\%\)) to filter out remained 617 nm laser. After these mirrors, a cylindrical lens of 500 mm focal length was employed to generate the laser sheet, of which thickness was about 100 \(\mu\)m and the height was about 2 mm.

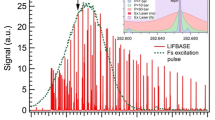

The measured spectrum of excitation fs laser beam and OH (0–0) and (1–1) excitation band are shown in Fig. 2. The calculated OH LIF excitation spectrum was obtained at 1 atm pressure and 2200 K by using LIFBASE 1.5 [17]. In Fig. 2, it can be found the highest peak in (0–0) band is at 309 nm, and the main absorption ranges from 305.25 nm to longer than 315 nm. At the same time, the (1–1) band begins from 312 nm, and the highest peak is at 312.2 nm. To effectively excite OH radical in \({ v}"=0\) energy level and to avoid excitation from \({ v}"=1\), the central wavelength of the excitation fs laser source was set at 307.7 nm, and its half-width was 2.7 nm, which can cover from about 304.7 nm to 312 nm. Therefore, OH radicals distributed in the \({ J}"{\le }0\), \({ v}"=0\) rovibrational ground levels can be excited effectively and avoid the undesirable transitions in (1–1) band.

The detecting system contains two sets of subsystems equipped with different bandpass filters. Each subsystem contains a high-speed CMOS camera (Photron, SA-X2, 1024 pixel \(\times\) 1024 pixel, 1 kHz) and an image intensifier (I. I.) (Hamamatsu Photonics, C10880-03F, Gating time 30 ns). The optical system contains a UV lens (Sodern Cerco, 100 mm/F2.8) and an extension tube. The fluorescence from (1–0) band was collected through an optical filter of 285 nm center wavelength and 14 nm FWHM bandwidth (Semrock, FF01–285/14–25). And the fluorescence from (0–0) band was collected through two optical filters of 300 nm edge wavelength (Semrock, FF01–300/LF-25) and of 301.5 nm center wavelength and 28.6 nm FWHM bandwidth (Semrock, FF01–302/26–25). The fs LIF images were recorded by the two cameras instantaneously, calibrated with physical coordinates to the same physical size in the post process.

An atmosphere methane-air laminar flame was generated on a slot burner. The outlet of the slot burner is 10 mm \(\times\) 50 mm. The flow velocity was 0.37 m/s, and the equivalence ratio, \(\phi\) was set as 0.8, 0.9, 1.0, 1.1, 1.2.

3 Results and discussion

3.1 fs OH LIF images

Two example imaging of different fluorescence shots in the atmosphere CH4/air flame, \(\phi\) = 1.0 with 1000 shot-average: (a) (1–0) band at image intensifier’s gain: 810, exposure time: 30 ns, (b) (0–0) band at image intensifier’s gain: 750, exposure time: 30 ns. Each imaging contains three shots where the centrals of laser sheets are set at three different positions: \(y\) = 1.20 mm, 2.95 mm, and 5.24 mm (0 point is set at the lower edge of the observation area) and the height of each laser sheet is 2 mm. The resolution of imaging is 22 \(\mu\)m/pixel. The intensity profiles at the yellow dot line are shown in Fig. 4

Fs OH LIF signal \(I_{(1-0)}\) (a) and \(I_{(0-0)}\) (b) at yellow dotted line in Fig. 3. The red line is 1000-shot averaged result, and error bar is root mean square (rms) in time direction, green dotted line is an example of one-shot result

a Measured intensity profiles of ethanol cell at y = 35 mm in Fig. 5. b Normalized amplification ratio of different gain setting of the image intensifier at different positions

The example fluorescence images of (0–0) and (1–0) bands are shown in Fig. 3. Figure 3 shows the 1000-shot averaged fs OH LIF signal, \(I_{(0-0)}\) and \(I_{(1-0)}\), where the observation area is \(x{\times }y= 12\) mm \(\times\) 6 mm and the resolution is 22 \(\mu\)m/pixel. The observation area is focused on the flame foot and contains three laser sheets. The heights of the three laser sheets’ centrals are \(y\) = 1.20 mm, 2.95 mm, and 5.24 mm, while the 0 point is set at the lower edge of the observation area, and the outlet of the burner is at \(y\) = \(-\)0.55 mm.

Figure 4 shows the one-shot and 1000-shot averaged fs OH LIF distribution, \(I_{(0-0)}\) and \(I_{(1-0)}\), at \(y\) = 1.20 mm. And the fluctuation in Fig. 4 was primarily attributed to the I.I. and the camera. To confirm that the signal counts are proportional to the OH LIF signal under different I.I. gain settings, a series of Planar Laser-Induced Fluorescence (PLIF) images of an ethanol cell were collected with various I.I. gain settings while maintaining a constant laser excitation. These PLIF images, acquired without any filters, are presented in Fig. 5. At the same time the measured intensity profiles of ethanol cell at y = 35 mm in Fig. 5 is shown in Fig. 6a, and the normalized amplification ratio of different gain setting of the image intensifier at different positions is shown in Fig. 6. In Fig. 6b, the amplification ratio at I.I. gain is 600 is recognized as 0, while the amplification ratio at I.I. gain is 850 is recognized as 1. It can be found when I.I. gain is smaller than 850, the amplification ratios at low-signal and high- signal regions grows at the same rate. However, when I.I. gain is 900, the amplification ratios at low-signal is obviously higher than that at the high-signal regions. At this point, the amplification of I.I. has an effect on the shape of the fluorescent image. However, when I.I. gain is smaller than 850, the shapes of the cell remain consistent across different I.I. gain settings, indicating that the gain settings do not impact the structure of the PLIF data.

For an in-depth evaluation of the amplification and SNR of I.I. under different gain settings, fluorescence measurements of an ethanol cell were conducted. In this test, a constant laser source was employed, and the fluorescence was captured using the same filter, lens, I.I., and camera system detailed in Sect. 2. The normalized measured intensity profiles of averaged intensity of the entire field with different I.I. gain settings for different wavelength light are shown in Fig. 7, where the measured intensity (I.I. gain: 900) is normalized 1 respectively. The profile for 300–314 nm light in Fig. 7 corresponds to the wavelength range of \(I_{(0-0)}\), while the profile for 274–288 nm corresponds to the wavelength range of \(I_{(1-0)}\). The amplification ratio for \(I_{(0-0)}\) signal is found to be 0.173 when the I.I. gain is set to 750, and 0.386 for \(I_{(1-0)}\) when the I.I. gain is set to 810. Consequently, the actual magnification ratio for the fluorescence ratio, \(R = I_{(1-0)}/I_{(0-0)}\), is determined to be 2.23, while the difference in I.I. quantum efficiency (QE) for different wavelength light is ignored. The standard deviation for \(I_{(1-0)}\) signal, \(\sigma _{(1-0)}\), is 0.023, whereas the standard deviation for \(I_{(0-0)}\) signal, \(\sigma _{(0-0)}\), is 0.004. Hence, the SNR of the measured fluorescence ratio induced by I.I. can be evaluated as \(\sqrt{\sigma _{(1-0)}^{2}+\sigma _{(0-0)}^{2}}\), resulting in 0.0233. It is noteworthy that camera scan lines also contribute minimally to the measured \(I_{(1-0)}\). The peaks observed at \(x=\) \(-\)4.73 mm, \(-\)3.06 mm, \(-\)2.79 mm, \(-\)0.200 mm, and 5.08 mm on the left side of the measured \(I_{(1-0)}\) in Fig. 4 are noise induced by camera scan lines.

3.2 Calibration process

In the calibration process, a 1D laminar flame model in ANSYS Chemkin Pro [18], employing GRI-Mech 3.0 [19], was utilized to calculate the equilibrium temperature (\(T\)). Consequently, the local \(R\) at the point with the highest \(I_{(0-0)}\) signal on the yellow dotted line in Fig. 3 (\({y}= 1.2\) mm), positioned at the middle of the lower laser sheet, was employed for calibration against the calculated equilibrium \(T\). In Fig. 8, the ratio of two fs LIF signals, denoted as \(R\), is presented as a function of \(\phi\) in five CH\(_{4}\)/air stabilized laminar flames, and is compared with the calculated \(T\). All the measured data in Fig. 8 were averaged over 1000 shots. The comparison revealed that the calculated equilibrium \(T\) aligns well with the measured data in five conditions, with the exception of \(\phi =0.8\). It was observed that \(R\) increases with the rising \(\phi\) until reaching stoichiometric conditions, subsequently decreasing as the CH\(_{4}\) becomes richer and the equilibrium \(T\) decreases. The discrepancy in the prediction at \(\phi =0.8\) may be attributed to the flame front being significantly stretched under lean conditions. Additionally, the height of the yellow dotted line is not sufficiently elevated and is too close to the flame foot, making it susceptible to the temperature at the outlet.

Therefore, \(R\) are directly calibrated with \(T\), and no quenching corrections are applied [16].

According to Copeland’s work [10], the relationship between \(R\) and \(T\) can be described as:

where \(V_{10}\) is the downward vibrational transfer rate between \({ v}' = 0\) and \({ v}' = 1\) excited vibrational levels in \(A^2 \Sigma ^+\) state. \(\bigtriangleup E_{10}\) is the quantum energy difference between \({ v}'=0\) and \({ v}'=1\). \(k\) is Boltzmann constant. However, because the emission fluorescence wavelengths of (0–0) band partially overlap with those of (1–1) band, and the molecular species are more complex in the flame, the actual \(\bigtriangleup E_{10}\) and \(Q_{1}/V_{10}\) obtained from measurements in the flame are diffenrent from the theoretical values [10, 11, 24]. Therefore, in this work, we take to fit \(\bigtriangleup E_{10}\) and \(Q_{1}/V_{10}\) in the flame with an equivalence ratio of 1 to obtain values suitable for methane air flames. With reference to Eq. 1, the fitting equation in this experiment was set as

where \(p=\frac{1}{-\bigtriangleup E_{10}/k}\) and \(q=\frac{\ln {[A_{0}/A_{1}\times (1+Q/V_{10})] } }{-\bigtriangleup E_{10}/k }\)

During the fitting procedure, the least squares method has been used. p and q are set as floating parameters, while the sum of squares for error is used to evaluate the fitting effect. The fitting is considered to be completed when squares for error becomes smallest, at which time the coefficient of determination is 0.99, where \(p = -1.12 \times 10^{-4}\), \(q = 1.65 \times 10^{-4}\).

The calibration results are shown in Fig. 9. It is shown that the fitted profile of T and R has good agreement with the measured results between 2000 K and 2160 K.

3.3 Measurement results

Figure 10 presents the measurement results based on a 1000-shot averaged fluorescence signal. Notably, in rich equivalence ratio conditions, the remaining CH\(_{4}\) reacts with the surrounding air, leading to an increase in OH concentration and resulting in the flame front being less stretched compared to lean conditions. Additionally, it is evident from Fig. 10 that TALF, using fs-duration laser pulses, effectively measures temperature in the range of 1600 K to 2200 K. However, there are several vertical noise lines present in the time-averaged measured images, primarily caused by the camera. Despite the camera undergoing auto-calibration before calibration, its inherent noise contributes to fluctuations of about 100 K in the measured results, as discussed earlier.

Figure 11 provides a comparison between the calculated and measured temperature (\(T\)) profiles around the flame front for different equivalence ratios. Here, \(l\) represents the perpendicular direction to the flame front on the left side of the inner area at the yellow dotted line in Fig. 3, extending from the unburnt area to the burnt area. The results demonstrate that the TALF method, based on the fs-duration laser, accurately predicts the temperature profile around the flame front, where the local temperature ranges from 1600 to 2150 K. Figure 11 further indicates that \(R\) effectively predicts the variation of \(T\) around the flame front. Although the fluorescence signal ratio to temperature model was calibrated over the temperature range 1950–2150 K, where there is good OH-PLIF signal levels. The temperature profile at the flame front (1600–2150 K) match a one-dimensional calculation results very well, which indicates this thermometry can be applied in various methane air flames in 1600–2150 K. However, beyond the flame front, as the distance increases, the measured \(T\) decreases more rapidly than that calculated by Chemkin. This discrepancy is attributed to the estimated heating loss after the flame front being smaller than the experimental conditions. In summary, the TALF method based on the fs-duration laser demonstrates its capability to accurately predict the temperature profile around the flame front.

Calculated (line) and measured (dot) \(T\) profiles around flame front (1600–2200 K) in the inner area at yellow dotted line in Fig. 3 at \(\phi = 0.8, 0.9, 1.0.\) l is perpendicular to the flame front (\(dI_{(0-0)}/dx=max\)) of inner area

The OH chemiluminescence significantly contributes to the deviation observed in the measured temperature (\(T\)) around the flame front. In all cases, the top of the measured \(T\) profile surpasses the calculated results due to the reinforcement of the measured \(I_{(1-0)}\) signal by OH chemiluminescence around the flame front. Consequently, in the burnt area, where the temperature should exhibit a smooth decrease, the measured results display fluctuations, manifested as vertical high-temperature lines. The primary source of this fluctuation is attributed to the I.I. and the camera, as detailed in the following section.

The measured \(I_{(1-0)}\) in the burnt area exhibits periodic fluctuations, leading to corresponding periodic variations in Fig. 10. This periodicity is attributed to the inherent noise of the camera. Although the imaging is conducted with a 12-bit resolution, maintaining the noise below 50, the averaged maximum intensity of \(I_{(1-0)}\) being 200 implies an averaged camera SNR of 11.2% and a variance in the deviation between calculated and measured \(T\) (\(\sigma _T\)) of 96 K.

To mitigate the influence of the camera’s scan lines on temperature measurements, a low-pass Gaussian filter is applied to the frequency domain of the 1000-shot averaged temperature measurement results [21], as illustrated in Fig. 12. In this process, a fast Fourier transform is employed on the temperature measurement results in both the \(x\) and y directions within the frequency domain, with the cut-off wavenumber of the bandpass filter set to 50 [21]. It’s worth noting that while this Gaussian filter helps reduce the impact of scan lines, it also eliminates high-frequency components in the burnt area. To provide a visual comparison, Fig. 13 compares the 1000-shot averaged measurement results on the right side of the flame at \(\phi =1.0\), both with and without the Gaussian filter, at three different \(y\) positions (8.0 mm, 5.4 mm, and 1.2 mm). The comparison indicates that the Gaussian filter effectively removes high-frequency fluctuations in the burnt area. However, due to limitations in the measurement range (1600–2500 K) and camera resolution, the temperature profile of the flame front can only be detected within a very short range, making it challenging to assess the influence of the Gaussian filter on the measured temperature profile at the flame front.

To investigate the fs TALF method in high-frequency measurements, Fig. 14 displays temperature measurement results at five different time points based on single-shot fluorescence signals in the \(\phi =1.0\) case. Corresponding \(I_{(0-0)}\) intensity distributions are also depicted in Fig. 15. In Fig. 14, temperature calculations are limited to areas where the ratio, \(R\), is larger than 0.015, which corresponds to a temperature of 1200 K as shown in the calibration plot in Fig. 9. In the instantaneous measurement results, the noise from the camera scan lines is hardly observable. At the same time, it is evident that temperature fluctuations increase with the distance from the flame front. In all five figures, the temperature near the flame front consistently registers at 2200 K. However, in the burnt area, which is relatively distant from the flame front, the temperature exhibits instability. Specifically, in Fig. 14, at \(t\) = 0.02 s, the temperature in the burnt area on the right side reaches 2400 K, but drops to 1900 K at \(t\) = 0.05 s. The primary reason for this variation is that the burnt area close to the flame front is relatively stable, while with increasing distance, it becomes more susceptible to surrounding air flow influences.

In Fig. 16, an example of the measured instantaneous temperature in the burnt area on the left side is presented, where \(x\) = \(-\)1.5 mm (a) and \(x\) = \(-\)2.0 mm (b), with \(y\) = 1.2 mm in the flame, under \(\phi\) = 1.0 conditions. For the position \(x\) = \(-\)1.5 mm (a), the mean temperature is 2205.7 K, with a standard deviation of the measured temperature, \(\sigma _{ T}\), of 56.4 K. At the position \(x\) = \(-\)2.0 mm (b), the mean temperature is 2228.6 K, with \(\sigma _{ T}\) being 62.4 K. Considering the SNR of the detection system as 0.0233 (discussed in Sect. 3.1), resulting in 34 K measurement noise (depicted as the blue dotted line in Fig. 16). Assuming that the primary error sources are from the detection system and flame fluctuations, and that their errors follow a multiplicative superposition relationship (\(\sigma _{ T}^2=\sigma _{ system}^2+\sigma _{ flame}^2\)), the actual temperature fluctuation caused by flame, \(\sigma _{ flame}\), is estimated to be 45.1 K at \(x\) = \(-\)1.5 mm and 52.3 K at \(x\) = \(-\)2.0 mm.

3.4 Uncertainty of PILF measurement

In this section, the uncertainty associated with the instantaneous temperature measurement method is discussed. The minor effect is from Estimation of \(-k/{\bigtriangleup E_{10}}\). In the previous studies, Copeland et al. [10] and Dyer and Crosley [24] indicates a general trend of rising vibrational population ratios with the increase in rotational energy of the laser pump level. Copeland et al. [10] investigated Q\(_1\)(3), Q\(_1\)(6), Q\(_1\)(10), Q\(_1\)(11), Q\(_1\)(12) and Q\(_1\)(13) in methane/air laminar flames with different equivalence ratios. Dyer and Crosley [24] also examined this issue and found that for three selected laser-populated rotational levels, there was a smooth increase in the population ratio. Dulin et al. [11] also found that population ratios changed when the excitation line was varied, while temperature sensitivity \(-k/{\bigtriangleup E_{10}}\) also changed with temperature, but trends are not adequately discussed. Dulin et al. [11] attributed this to collision effect due to a non-uniform environment and considered that OH radicals at high rotational energy levels are more susceptible, but still does not fully explain why \(-k/{\bigtriangleup E_{10}}\) changed. So far, the transition between ro-vibrational levels of excited OH radicals at different temperature in non-standard environments is not still fully investigated. However, the previous works experimentally demonstrated that although the quantum energy difference between \(\nu '\) = 0 and \(\nu '\) = 1 is constant, the measured vibrational population ratios of rotational energy of the laser pump levels at the same condition are still not the same.

In this work, to eliminate the effect of different rotational levels, OH radicals on multiple rotational energy levels are excited at different levels simultaneously. However, the measured \(-k/{\bigtriangleup E_{10}}\) still has a large error with the actual value. The theoretical value of \(-k/{\bigtriangleup E_{10}}\) is \(2.31 \times 10^{-4}\), which is about twice the value of the present work fit. The main reason comes from four aspects. First, the collected fluorescence signals are affected by the bandpass filters. The transmission wavelength of the bandpass filter is not wide enough for \(I_{(1-0)}\), as at 292–295 nm part of the signal is not collected efficiently. On the contrary, due to the significant overlap between the signals of the (0–0) band and the (1–1) emission band, the intensity of the \(I_{(0-0)}\) collected is higher. The error can be estimated by simulating the OH fluorescence spectrum using LIFBASE 1.5. The results indicate that (1–1) fluorescence causes about a 5% deviation in temperature measurement results at 2200 K and 2% at 1700 K. Although the fluorescence signal was not spectroscopically measured in this experiment, the fringe attenuation of the bandpass filter in the spectrum also has an effect on the measured fluorescence signal. Secondly, as outlined in Sect. 2, it is important to note that the width range on the spectrum of the laser pulse does not cover the entire (0–0) band. OH radicals in \(J" \in [1, 6]\) level are excited through transitions in P, Q, R branches, \(J" \in [7, 12]\) are excited through transitions in Q, R branch, and \(J" \in [13, 15]\) are excited through transitions in R branch instantaneously. Rotational and vibrational energy transfers occur at multiple rotational vibrational levels in the excited state, the effects of which are difficult to quantitatively estimate, but it is clear that these ro-vibrational energy transfers deviate the fitted \(-k/{\bigtriangleup E_{10}}\) from its theoretical value. However, this issue hinges on one’s perspective. Thirdly, the occurrence of non-thermally assisted vibrational energy transfer (VET) within the excited state introduces temperature errors. A fraction of excited OH radicals in the \(\nu '\) = 1 vibrational level undergoes transition to the lower state, \(\nu '\) = 0, through non-thermally assisted VET caused by other molecules, resulting in a value of \(V_{10}\) in Eq. 1 that is smaller than expected. At the same time, since the concentration of most of the intermediate products in the flame is obviously affected by the temperature, such as CO, NO, etc., \(Q/V_{10}\) is also affected by the temperature change, which also leads to the deviation of the temperature sensitivity \(-k/{\bigtriangleup E_{10}}\) from the theoretical value. The influence of non-thermally assisted VET on TALF thermometry has been mentioned in ns scale [10, 11], and Wang’s work [16] reports that non-thermally assisted VET occurs in the \(v'=1\) level at the fs scale. Unfortunately, there is currently no quantitative evaluation of non-thermally assisted VET with fs laser excitation, making it challenging to estimate this error quantitatively. Forth, the use of two channels to collect fluorescence signals separately also had an impact on the results. Although, during the experiments, the I.I. and camera used for both channels were of the same model in order to minimize errors. However, there are small differences in the actual photoelectric conversion efficiencies, especially the sensitivity of the photographic surface of the I.I. is affected by the length of use, and these errors also have an effect on the measured \(-k/{\bigtriangleup E_{10}}\). when viewed through the lens of an engineering experimentalist, there may be some ambiguity in employing detailed balancing to articulate ro-vibrational energy transfer. However, as long as the same wavelength of excitation laser source and the same detection system are employed for both calibration and experimental purposes, the ensuing fs TALF theory remains applicable and robust, particularly when the fuel species remains consistent.

In addition to the errors discussed above that are difficult to assess quantitatively, the following systematic errors should also be taken into account. Systematic errors originate from two main sources: laser source and detection system. The error caused by the detection system is discussed in Sect. 3.1. Also, since only a single light source was used in this work, the effect of the laser sheet can be neglected, but the absorption effect due to the flame should be taken into consideration. The absorption effect serves as another minor error source in this experiment. Liu’s study [23] investigated fs OH (0–0) band absorption spectroscopy in a propane-air flame under atmospheric conditions using a Bunsen burner. In that experiment, the average temperature was 1780.1 K, and the OH concentration was 722.9 ppm. The results showed that the highest absorption occurred at 309.12 nm, and the absorption rate was about 11%. In the current experiment, where CH\(_{4}\) is used as the fuel, the highest calculated OH concentration by Chemkin exceeds 30,000 ppm, and the average temperature is approximately 1300 K. According to the Beer-Lambert law, the absorption rate is higher than 30%, resulting in a significant decrease in fluorescence intensity along the laser path. In Fig. 14, it is observed that the fluorescence intensity decreases from the right side to the left side as the measured temperature increases. Additionally, in Fig. 4, it can be seen that the root mean square (rms) of the two fluorescence signals also increases as the intensity decreases. The scattering effect introduces an inevitable error. As the spectrum position of (0–0) fluorescence overlaps with the excitation laser pulse, the scattering effect must be taken into account. In this study, Rayleigh scattering from the three laser sheets was measured in air at 1 atm and room temperature (298 K) and removed from the measured \(I_{(0-0)}\) as background noise. However, in flame cases, where the temperature is higher and species are more complex, the actual scattering effect may differ from the measured scattering. This aspect was not explicitly addressed in this research, as the difference in scattering signals caused by air and flame is small enough compared to LIF signal or other noise sources, such as camera noise. Additionally, OH chemiluminescence also contributes to an inevitable error. Despite setting the exposure time to 30 ns, the OH chemiluminescence signal can still be observed in both detection channels. In this work, OH chemiluminescence was measured without laser excitation and removed from the measured fluorescence images as background noise before camera calibration for optimal removal. However, due to the fluctuation of the flame front, the noise caused by OH chemiluminescence cannot be entirely eliminated, leading to a relatively larger deviation in the measured temperature at the flame front.

To evaluate these errors’ influence to the final measurement results, the temperature sensitivity is calculated as:

It can be observed that the sensitivity of measured temperature is influenced by the local temperature. The error in measured temperature at different local temperatures, with errors of 5%, 10%, and 20% in R, is presented in Table 1. In the temperature range of 1700 K to 2300 K, when the error in measured R is below 5%, the maximum measured temperature error is 68.77 K at 2300 K, and it remains below 50 K when the local temperature is lower than 2000 K. However, with errors larger than 10% in measured R, the measured temperature error exceeds 100 K. In this study, when the local temperature surpasses 1700 K, the local \(I_{(0-0)}\) exceeds 270, and the maximum standard variance of R, \(\sigma _{R}\), is 0.09, indicating that \(\partial T\) is approximately 70 K. Conversely, when the local temperature is below 1500 K, where the local \(I_{(0-0)}\) is less than 150, \(\sigma _{R}\) surpasses 0.2, and \(\partial T\) exceeds 170 K. In summary, the fluorescence signal intensities determine the uncertainty of the measured R, while the local temperature influences the sensitivity of the measured temperature to the measured R. Therefore, the fs OH-TALF method demonstrates good performance when the temperature is around 2000 K. The error in measured temperature can be controlled within 50 K between 1600 K and 2090 K, with \(\partial R/R\) less than 5%. If applied in a higher-temperature range, improving the quality of the two fluorescence signals is necessary to minimize the error in measured R. In the low-temperature range, the relatively low OH concentration results in a high rms of measured R. Even though the error in measured temperature becomes gradually insensitive to the error in R, the high rms of R still leads to a large deviation between the measured T and the local real temperature.

4 Conclusion

In this study, two-dimensional temperature distributions were measured in methane-air laminar flames by analyzing the ratios of (0–0) and (1–0) band fluorescence of OH radicals excited from the \(\nu "=0\) ground state using a single ultrafast broadband femtosecond laser. The planar OH TALF method demonstrated the ability to measure temperature with low noise in high-frequency measurements. Sensitivity analysis revealed better sensitivity to the fluorescence ratio with increasing temperature, indicating higher sensitivity to noise when measuring high-temperature areas. In this experiment, when local temperatures exceeded 2300 K, a 5% bias in the ratio led to noise-induced disruptions in the measured temperature exceeding 50 K. At 1700 K, the same level of bias resulted in a temperature measurement bias of only 20 K, demonstrating that this method is suitable for investigating temperature distributions in hydrocarbon combustions where local temperatures vary from 1700 K to 2300 K. However, for applications involving high-temperature flames, such as hydrogen flames, reducing noise in the high-temperature region must be carefully considered to avoid increasing measurement bias. While the fs OH TALF method performed well in the burnt area, limitations in the calibration range and camera resolution prevented the full detection of temperature profiles in the reactive zone of laminar premixed flames. Further improvements are needed to detect temperature changes at the flame front.

In future work, the fs OH TALF measurement method based on a femtosecond laser will be tested in turbulent flames to verify its ability to measure temperature in high frequency and explore its performance in more complex combustion environments.

Data availability

Experimental data generated during the current study are available from the corresponding author on reasonable request. The simulation software for OH spectrum in the ultraviolet band data is available at https://www.sri.com/platform/lifbase-spectroscopy-tool/. The Chemkin Pro product is available at https://www.ansys.com/ja-jp/products/fluids/ansys-chemkin-pro. The data of chemical mechanism is available at http://combustion.berkeley.edu/gri-mech/version30/text30.html.

References

F.N. Egolfopoulos, P. Cho, C.K. Law, Laminar flame speeds of methane-air mixtures under reduced and elevated pressures. Combust. Flame 76(3–4), 375–391 (1989)

J.C. Hermanson, P.E. Dimotakis, Effects of heat release in a turbulent, reacting shear layer. J. Fluid Mech. 199, 333–375 (1989)

S.R. Turns, F.H. Myhr, Oxides of nitrogen emissions from turbulent jet flames: part I-Fuel effects and flame radiation. Combust. Flame 87(3–4), 319–335 (1991)

G. Zhang, G. Wang, Y. Huang, Y. Wang, X. Liu, Reconstruction and simulation of temperature and CO\(_{2}\) concentration in an axisymmetric flame based on TDLAS. Optik 170, 166–177 (2018)

R. W. Pitz, R. Cattolica, F. Robben, L. Talbot, Temperature and density in a hydrogen air flame from Rayleigh scattering, Combust. Flame, 27(C), 313-320 (1976)

M.C. Drake, G.M. Rosenblatt, Flame temperatures from Raman scattering. Chem. Phys. Lett. 44(2), 313–316 (1976)

H. Zhao, Z. Tian, T. Wu, Y. Li, H. Wei, Dynamic and sensitive hybrid fs/ps vibrational CARS thermometry using a quasi-common-path second-harmonic bandwidth-compressed probe. Appl. Phys. Lett., 118(7) (2021)

Y. Saiki, N. Kurimoto, Y. Suzuki, N. Kasagi, Active control of jet premixed flames in a model combustor with manipulation of large-scale vortical structures and mixing. Combust. Flame 158(7), 1391–1403 (2011)

R. Cattolica, OH rotational temperature from two-line laser-excited fluorescence. Appl. Opt. 20(7), 1156–1166 (1981)

C. Copeland, J. Friedman, M. Renksizbulut, Planar temperature imaging using thermally assisted laser induced fluorescence of OH in a methane-air flame. Exp. Therm. Fluid. Sci. 31(221), 221–236 (2007)

V. Dulin, D. Sharaborin, R. Tolstoguzov, A. Lobasov, L. Chikishev, D. Markovich, S. Wang, C. Fu, X. Liu, Y. Li, Y. Gao, Assessment of single-shot temperature measurements by thermally-assisted OH PLIF using excitation in the \(A^{2}\Sigma ^{+}-X^{2}\Pi\) (1–0) band. Combust. Flame 38(1), 1877–1833 (2021)

H.U. Stauffer, W.D. Kulatilaka, J.R. Gord, S. Roy, Laser-induced fluorescence detection of hydroxyl (OH) radical by femtosecond excitation. Opt. Lett. 36(10), 1776–1778 (2011)

P. Parajuli, T. Paschal, M. Turner, Y. Wang, E. Petersen, W. Kulatilaka, High-speed hydroxyl and methylidyne chemiluminescence imaging diagnostics in spherically expanding flames. AIAA J. 56(8), 3118–3126 (2021)

A. Jain, Y. Wang, W. Kulatilaka, Simultaneous imaging of H and OH in flames using a single broadband femtosecond laser source. Proceed. Combust. Ins. 38, 1813–1821 (2021)

Y. Wang, A. Jain, W. Kulatilaka, Simultaneous measurement of CO and OH in flames using a single broadband, femtosecond laser pulse. Combust. Flame 214, 358–360 (2020)

Y. Wang, A. Jain, W. Kulatilaka, Hydroxyl radical planar imaging in flames using femtosecond laser pulses. Appl. Phys. B Lasers Opt., 125(6) (2019)

J. Luque, D. R. Crosley, LIFEBASE: Database and Spectral Simulation Program (Version 1.5), SRI International Report MP 99-009 (1999)

CHEMKIN-PRO 15112, Reaction Design: San Diego (2011)

G. P. Smith, M. D. Golden, M. Frenklach, E. N. Moriarty, B. Eiteneer, M. Goldenberg, C. T. Bowman, R. K. Hanson, S. Song, W. R. Gardiner, V. V. Lissianski, Z. Qin, http://combustion.berkeley.edu/gri-mech/

G.H. Dieke, H.M. Crosswhite, The ultraviolet bands of OH fundamental data. J. Quant. Spectrosc. Radiat. Transfer 2(2), 97–199 (1961)

C.G. Rafael, E.W. Richard, Digital Image Processing, 3rd edn. (Prentice-Hall Inc., New York, 2006)

A.A. Neuber, J. Janicka, E.P. Hassel, Thermally assisted fluorescence of laser-excited OH \(A^{2}\Sigma ^{}\) as a flame diagnostic tool. Appl. Opt. 35, 4033–4040 (1996)

N. Liu, T. Y. Chen, H. Zhong, Y. Lin, Z. Wang, Y. Ju, Femtosecond ultraviolet laser absorption spectroscopy for simultaneous measurements of temperature and OH concentration. Appl. Phys. Lett. 120(20) (2022)

D.R. Crosley, G.P. Smith, Vibrational energy transfer in laser-excited \(A^2\)\(\Sigma ^+\) OH as a flame thermometer. Appl. Opt. 19, 517–520 (1980)

Acknowledgements

This research kindly thanks to the financial support from Tokyo Tech Academy of Energy and Informatics.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declared no potential conflicts of interest with respect to the research, authorship, and/or publication of this article.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Huang, S., Shimura, M. & Tanahashi, M. Development of thermally assisted OH PLIF temperature measurement method based on a single femtosecond laser. Appl. Phys. B 130, 65 (2024). https://doi.org/10.1007/s00340-024-08199-9

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00340-024-08199-9