Abstract

The performance of AlGaN-based deep-ultraviolet (DUV) laser diodes (LDs) was investigated by varying the thickness of the upper and lower waveguide (WG) layers. The results show that (1) the asymmetric wide WG layers structure with thick upper and thin lower WG layer can effectively reduce the optical field leakage in the active region and increase the optical confinement factor (OCF) by 31.66% compared to the traditional symmetric wide WG layers structure. (2) The asymmetric wide WG layers improve the stimulated recombination rate, and electro-optical conversion efficiency, increasing the slope efficiency (SE) of the LD to 1.69 W/A at a lower threshold current (Ith) of 30.46 mA. (3) The asymmetric wide WG layers limit the carrier loss, which is due to the improvement of the energy band variation.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

The realization of AlGaN-based semiconductor laser diodes (LDs) emitting deep-ultraviolet (DUV) light is of considerable value in applications such as water disinfection, materials processing, lithography, air purification, bioanalysis, and medical diagnostics [1,2,3]. The direct wide-bandgap tunable characteristics of AlGaN make it an excellent choice for developing ultraviolet (UV) emitters that can cover the entire UV spectrum from 210 to 370 nm [4, 5]. In recent years, the widespread global spread of novel Severe Acute Respiratory Syndrome Coronavirus (SARS-CoV-2) has led to an increasing demand for the inactivation of viruses and bacteria by harmless UV light technology. Studies by Heilingloh et al. showed that irradiation with a light source at a wavelength of 254 nm and a dose of 292 mJ/cm2 DUV resulted in complete inactivation of viruses at a stuffed concentration of 5 × 106 TCID50/mL after 9 min [6]. Saito et al. developed highly efficient UV light-emitting diodes (LEDs) by optimizing the n-type contact layer, which can inactivate 99. 999% of SARS-CoV-2 within 5 s [7]. Compared with the traditional mercury-based DUV lamps, AlGaN-based emitters are more environmentally friendly and chemically stable. They also have the advantages of small size, low power consumption, long life, and tunable wavelength [8, 9].

However, there are still many problems that limit the development and application of algan-based UV emitters, making their development lag behind that of visible spectrum range devices [10]. For example, for LD with an emission wavelength less than 370 nm, the Al mole fraction of the optimized cladding layer (CL) is greater than 20%, and the considerable stress between the cladding layer and the underlying layer will lead to the cracking of the AlGaN epitaxial layer [11]. The mobility difference between Al and Ga atoms leads to a higher defect density in AlGaN layers, inhibits the growth of high crystalline quality AlGaN layers, and weakens the emission efficiency of quantum wells (QWs) [12]. In addition, the high ionization energy of Mg weakens the conductivity of the p region, the higher mobility of electrons relative to holes leads to high electron leakage. The quantum confinement Stark effect (QCSE) caused by the strongly polarized electric field leads to the bending of the semiconductor energy band and the reduction of the overlap of the electron and hole wave functions [13,14,15,16,17]. In response to the above problems, researchers have adopted different approaches to improve the operating performance of emitters. Electron leakage is reduced, and hole injection efficiency is increased by introducing a specially designed electron-blocking layer (EBL) [18,19,20]. Low-defect AlGaN layers were prepared using a free-standing AlN substrate, and LD with the shortest wavelength of 271.8 nm were reported [2]. A superlattice cladding layer is used to achieve strong confinement of transverse light and low optical loss, allowing the diode to maintain a current density of over 4.5KA/cm2 [21]. About improving the optical confinement factor (OCF), the OCF of the 300 nm emission band was optimized using a graded aluminum component p-CL layer and a 50 nm thick waveguide (WG) layer to obtain the lowest threshold current density (Jth) of 13.3 KAcm−2 so far for UV-B, but the internal losses reduced the optical gain[22]. In addition, the researchers employed Al graded silicon doping layer, specially designed WG layer and cladding layer to enhance the OCF [9, 23, 24].

In this study, we simulated LD structures designed with different WG layer thicknesses to enhance the optical confinement in the active region by improving the distribution of the optical field and performed an in-depth comparison and analysis. The results show that the asymmetric wide WG layers structure with thick upper waveguide (UWG) and thin lower waveguide (LWG) layers has the optimal OCF value, reduces the laser threshold current, improves the laser power and electro-optical conversion efficiency, and suppresses the carrier leakage to increase the stimulated recombination rate. It provides a unique solution for improving the performance of DUV LDs.

2 Device structure

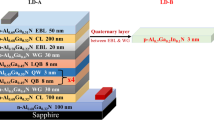

Using sapphire as a substrate, the LD structure used for simulation consists of a 0.1-μm thick n-type Al0.75Ga0.25N buffer layer with the n-doping concentration of 5 × 1019 cm−3, a 1 μm n-type Al0.75Ga0.25N CL layer with the n-doping concentration of 5 × 1018 cm−3, a Al0.68Ga0.32N LWG layer, a 12 nm n-type Al0.88Ga0.12N hole blocking layer (HBL), a two-period multiple quantum well (MQW) (Al0.58Ga0.42N/Al0.68Ga0.32N), a Al0.68Ga0.32N UWG layer, 10 nm p-type Al0.9Ga0.1N EBL, 0.4 μm p-doping concentration of 5 × 1018 cm−3 of p-type Al0.75Ga0.25N CL layer, 0.1 μm of p-doping concentration of 5 × 1019 cm−3 p-type Al0.8Ga0.2N buffer layer. The thickness of the quantum well and quantum barrier (QB) is 3 nm and 8 nm, respectively, and the design of the LD structure is based on the model of Tanaka et al.. The emission wavelength of LD is approximately 267 nm, and the schematic diagram of the LD structure is shown in Fig. 1. The difference between the LDs in the experiment is the UWG layer and the LWG layer, and we named the conventional symmetric wide WG layer structure as LD1 (both upper and lower waveguide layers are 50 nm), and changed the thickness of the upper and lower WG layers respectively on this basis.

In this paper, the LASTIP simulation software from Crosslight Software Inc was used to numerically simulate the various characteristics of LDs. LASTIP is a powerful semiconductor LD simulation software that utilizes the Poisson equation, the drift–diffusion model, the current continuity equation and polarized charge model to calculate the electrical stimulation of LD, and the optical simulation of LD was calculated by the vector Helmholtz fluctuation equation and Adachi refractive index model. The energy bandgap of AlxGa1−xN is estimated,

where b is the bending factor (= 0.94 eV) and x is the Al content, Eg(AlN) = 6.138 eV and Eg(GaN) = 3.415 eV [25]. The cavity length of the laser is fixed at 530 μm, the width is 1.5 μm, the charge of the built-in interface is calculated at 40% of the theoretical value, the mirror reflectivity is 30%, and the reverse loss is 2400 m−1. All simulations are performed at room temperature (300 K) [26, 27].

3 Results and discussion

We can calculate the OCF from the optical field distribution of the LD,

where physical quantity Г refers to the OCF, d is the width of the active region, and φ(x, y) is the wave intensity [28]. The oscillation condition of LD is expressed as

where Jth, \(\eta_{i}\), \({\alpha }_{i}\), L, and R represent the threshold current density, carrier injection efficiency, internal loss, cavity length, and facet reflectivity respectively, and higher OCF in LD can reduce the threshold current density by the laser condition [21]. The low OCF of most LDs is due to the high absorption loss caused by the high Al component in layers other than the active region. Suppressing absorption losses and better confining the optical field to the active region to produce high OCF is a key challenge for DUV AlGaN LD researchers. The variation of the OCF value can be seen in Fig. 2 when the thickness of the UWG layer is gradually increased (each increase interval is 20 nm) and the thickness of the LWG layer is fixed at 50 nm. The OCF value of conventional symmetric wide WG layer structure LD1 is 13.58%. In fact, the OCF increases sharply when the thickness of the UWG layer increases from 50 to 90 nm, and the rate of OCF rise decreases slightly from 90 to 130 nm; then the OCF decreases with a further increase in the thickness of the UWG layer. The OCF reaches the highest value of 17.53% when the thickness of the UWG layer is 130 nm.

We can analyze the optical field distribution in Fig. 3 to get the reason for the above OCF variation with the UWG thickness. For LD1 with UWG of 50 nm, the optical field distribution has a particular simulation result: the optical field penetrates into the n-type AlGaN CL layer to a large extent. However, as the UWG thickness gradually increases from 50 to 130 nm, the optical field entering the n-CL layer decreases dramatically, and the leakage of the light field is suppressed, so the OCF value increases. Although the half-maximum width (FWHM) of the optical field increases, the ratio of optical distribution in the WG layer to that in the CL layer increases. The decrease in OCF when the UWG exceeds 130 nm is due to the excessive shift of the peak of illumination from the MQW region to the p region. It can be seen that not the thicker the UWG is, the better the optical field constraint is, and the optical properties of LD are best when the UWG is 130 nm.

In the following simulation, we fix the thickness of UWG to 130 nm and adjusted the thickness of LWG. From Fig. 4(a), it can be seen that the OCF value peaks at 17.88% when the LWG thickness is 90 nm and drops sharply when the thickness continues to increase. In Fig. 4(b), we excerpted the optical field distribution of three structures with their lower waveguide thicknesses of 50 nm, 90 nm, and 130 nm, respectively. The peak light intensity of LWG 90 nm is closer to the center of MQW than LWG 50 nm, which is the reason for the improved OCF. However, when the LWG layer continues to thicken to 130 nm, another optical intensity peak is seen in the LWG layer from Fig. 4(b), which severely reduces the OCF.

In the above analysis, we found that the structure with a UWG thickness of 130 nm and LWG thickness of 90 nm has the highest OCF, and we named it LD2. The low threshold current during laser oscillation is an important indicator of the continuous wave (CW) output achieved by the laser. The electrical characteristics of LD1 and LD2 were simulated, and their I-P curves are shown in Fig. 5(a). It can be seen that LD2 has a reduced threshold current (Ith) and increased slope efficiency (SE) compared to LD1. The Ith of LD is mainly determined by its optical gain. The optical gain of the resonant cavity is related to the net model gain (gnet), and the net model gain is proportional to the OCF when the gain material is constant, which is why LD2 has better electrical characteristics. Figure 5(b) shows the simulated electro-optical conversion efficiency of the DUV LDs; with the increase of the injected current, the electro-optical conversion efficiency of the symmetric wide WG layers structure LD1 is stable at 35%, and the optimized asymmetric wide WG layers structure LD2 is stable at 37%, which is because the improved LD reduces the Ith and increases the output power. Figure 5(c) shows the current–voltage characteristics and it can be seen that although LD2 has better optical characteristics, the I-V curves of both are basically the same. The threshold voltage of LD1 is 4.57 V, while the introduction of the asymmetric wide waveguide layers slightly increases the threshold voltage, which is 4.58 V for LD2.

Figure 6(a) shows the stimulated recombination rates of LD1 and LD2 in the MQW region. Compared with LD1, the stimulated recombination rate of LD2 is improved by about 6.24% due to the optimization of the WG layers. The high stimulated recombination rate indicates that LD2 provides good electron–hole wave function overlap, an effective increase of the optic radiation, and a reduction of the optical radiation. We can determine the degree of electron and hole leakage by observing the electron concentration in the n-type CL region and the hole concentration in the p-type CL region, respectively. As shown in Fig. 6(b) and Fig. 6(c), LD2 has a lower electron concentration in the p-type CL region and lower hole concentration in the n-type region, which indicates that LD2 has better carrier confinement, allowing more carriers to accumulate for recombination in the MQW region, which ensures the excellent stimulated recombination rate of LD2 and enables the laser to obtain sufficient optical model gain.

We can explain the conclusion that LD2 has good electron and hole confinement by looking at the energy band diagram of the device. As shown in Fig. 7, we compare the energy band arrangement of device LD1 in Fig. 7(a) and device LD2 in Fig. 7(b), and we can see differences in their energy band diagrams. The effective conduction band barrier height (ECBBH) was calculated based on the energy difference between the conduction band and electron quasi-Fermi energy levels. The polarization electric field caused by a large lattice mismatch attracts a larger electron concentration at the heterogeneous interface between the MQW region and the UWG, resulting in a lower ECBBH, and thus a poor electron confinement in the MQW region, which has a detrimental effect on the performance of the DUV LD. The ECBBH of LD2 at the junction of MQW and UWG is 118 meV, which is higher than that of LD1 at 110 meV, which indicates that there is less chance for electrons to escape from the active region in the LD2 device, resulting in less electron spillover. The effective valence band barrier height (ECVBH) was calculated based on the valence band and hole quasi-Fermi energy levels. At the junction of the MQW region and the n region, the ECVBH of LD2, 219 meV, is significantly higher than that of LD1, 202 meV, which indicates that LD2 has a stronger ability to confine holes in the MQW region. It can be concluded that the asymmetric wide WG layers can suppress the energy band deterioration due to QCSE, better achieve carrier confinement, and thus better achieve stimulated emission.

To illustrate the contribution of the asymmetric wide WG layers structure to the performance of the optical resonant cavity, Table 1 summarizes the calculated characteristics of LD1 and LD2. These findings are believed to help the community to develop more efficient AlGaN-based DUV LDs with better luminescence performance for applications.

4 Conclusion

In this study, the introduction of the asymmetric wide WG layers structure improved the optical field distribution of DUV LD at 267 nm, which increased the OCF by 29.08% compared to the conventional symmetric wide WG layers structure, and the better optical performance reduced the Ith of the LD to 30.46 mA. Simulation calculations show that the LD2 with asymmetric wide WG layers effectively increases the laser power, raising the SE to 1.69 W/A and increasing the maximum electro-optical conversion efficiency to 37%. Meanwhile, the high stimulated recombination rate of LD2 ensures better performance of the DUV LD, and its high stimulated recombination rate is due to the optimized WG layers compensating for the energy band bending caused by the polarized electric field, which enhances the carrier confinement capability. The use of asymmetric wide WG layers facilitates the improvement of DUV LD performance and provides ideas for designing efficient DUV LDs.

Data availability

The datasets generated during and/or analysed during the current study are available from the corresponding author on reasonable request.

References

Y. Yamashita, M. Kuwabara, K. Torii, H. Yoshida, A 340-nm-band ultraviolet laser diode composed of GaN well layers. Opt. Express. 21, 3133–3137 (2013)

Z. Zhang et al., A 271 8 nm deep-ultraviolet laser diode for room temperature Operation. Appl. Phys. Express. 12, 124003 (2019)

C. Chu, H. Zhang, H. Sun, Ultraviolet optoelectronic devices based on AlGaN-SiC platform: towards monolithic photonics integration system. Nano Energy 77, 105149 (2020)

C. Chu, K. Tian, Y. Zhang, W. Bi, Z. Zhang, Progress in external quantum efficiency for III-nitride based deep ultraviolet light-emitting diodes. Phys. Status. Solidi (A). 216, 1800815 (2019)

M. Usman et al., Suppressing the efficiency droop in the AlGaN-based UVB LED. Nanotechnology 32, 215703 (2021)

C.S. Heilingloh, U.W. Aufderhorst, L. Schipper, U. Dittmer, O. Witzke, D. Yang, X. Zheng, K. Sutter, M. Trilling, M. Alt, E. Steinmann, A. Krawczyk, Susceptibility of SARS-CoV-2 to UV irradiation. Am. J. Infect. Control. 48, 1273–1275 (2020)

Y. Saito et al., Efficiency improvement of AlGaN-based deep-ultraviolet light- emitting diodes and their virus inactivation application. Jpn. J. Appl. Phys. 60, 080501 (2021)

Z. Zhang, M. Kushimoto, M. Horita, N. Sugiyama, L.J. Schowalter, C. Sasaoka, H. Amano, Space charge profile study of AlGaN-based p-type distributed polarization doped claddings without impurity doping for UV-C laser diodes. Appl. Phys. Lett. 117, 152104 (2020)

M.N. Sharif et al., Performance enhancement of AlGaN deep-ultraviolet laser diode using compositional Al-grading of Si-doped layers. Opt. Laser Technol. 152, 108156 (2022)

J. Yang et al., Realization of 366 nm GaN/AlGaN single quantum well ultraviolet laser diodes with a reduction of carrier loss in the waveguide layers. J. Appl. Phys. 130, 173105 (2021)

D. Zhao et al., Fabrication of room temperature continuous-wave operation GaN-based ultraviolet laser diodes. J. Semicond. 38, 051001 (2017)

K. Takeda et al., Internal quantum efficiency and internal loss of ultraviolet laser diodes on the low dislocation density AlGaN underlying layer. Phys. Status. Solidi. C. 8(2), 464 (2011)

J.L. Lyons et al., First-principles theory of acceptors in nitride semiconductors. Phys. Status. Solidi (b) 252, 900–908 (2015)

Z. Zhang, J. Kou, S.H. Chen, H. Shao, J. Che, C. Chu, K. Tian, Y. Zhang, W. Bi, H. Kuo, Increasing the hole energy by grading the alloy composition of the p-type electron blocking layer for very high-performance deep ultraviolet light-emitting diodes. Photonics Res. 7, B1–B6 (2019)

Z. Liu et al., Polarization-engineered AlGaN last quantum barrier for efficient deep-ultraviolet light-emitting diodes. Semicond. Sci. Technol. 35, 075021 (2020)

Z. Xing et al., Reduction of electron leakage of AlGaN-based deep ultraviolet laser diodes using an inverse-trapezoidal electron blocking layer. Chin. Phys. Lett. 37, 027302 (2020)

Y. Xu et al., Performance improvement of nitride semiconductor-based deep-ultraviolet laser diodes with superlattice cladding layers. Eur. Phys. J. D. (2022). https://doi.org/10.1140/epjd/s10053-022-00506-3

W. Yang et al., Improvement of hole injection and electron overflow by a tapered AlGaN electron blocking layer in InGaN-based blue laser diodes. Appl. Phys. Lett 100, 031105 (2012)

A. Bojarska et al., Role of the electron blocking layer in the graded-index separate confinement heterostructure nitride laser diodes. Superlattices Microstruct. 116, 114–121 (2018)

Y. Wang et al., Reduction of electron leakage in a deep ultraviolet nitride laser diode with a double-tapered electron blocking layer. Chinese Phys. Lett. 36, 057301 (2019)

M. Martens et al., Low absorption loss p-AlGaN superlattice cladding layer for current-injection deep ultraviolet laser diodes. Appl. Phys. Lett. 108, 151108 (2016)

S. Tanaka et al., AlGaN-based UV-B laser diode with a high optical confinement factor. Appl. Phys. Lett. 118, 163504 (2021)

M.N. Sharif et al., Enhancement of the optoelectronic characteristics of deep ultraviolet nanowire laser diodes by induction of bulk polarization charge with graded AlN composition in AlxGa1-xN waveguide. Superlattices Microstruct. 145, 106643 (2020)

K. Arakawa et al., 450nm GaInN ridge stripe laser diodes with AlInN/AlGaN multiple cladding layers. Jpn. J. Appl. Phys. 58, 28 (2019)

N. Nepal, J. Li, M.L. Nakarmi, J.Y. Lin, H.X. Jiang, Temperature and compositional dependence of the energy band gap of AlGaN alloys. Appl. Phys. Lett. 87, 242104 (2005)

I. Vurgaftman, J.R. Meyer, Band parameters for nitrogen-containing semiconductors. J. Appl. Phys. 94, 3675–3696 (2003)

Z. Xing, F. Wang, Y. Wang, J.J. Liou, Y. Liu, Enhanced performance in deep-ultraviolet laser diodes with an undoped BGaN electron blocking layer. Opt. Express. 30, 36446–36455 (2022)

M. Kneissl et al., The emergence and prospects of deep-ultraviolet light-emitting diode technologies. Nat. Photonics. 13, 233–244 (2019)

Acknowledgements

Supported by the National Nature Science Foundation of China (Grant No. 62174148), National Key Research and Development Program (NKRDP Grant No. 2022YFE0112000, Grant No. 2016YFE0118400), Zhengzhou 1125 Innovation Project (Grant No. ZZ2018-45), and Ningbo 2025 Key Innovation Project (Grant No. 2019B10129).

Author information

Authors and Affiliations

Contributions

YX: Conceptualization, Methodology, Software, Investigation, Writing—original draft, Writing—review & editing. LJ: Software, Writing—review & editing, Validation. LL: Investigation, Validation. XS: Software, Resources. FW: Supervision, Project administration, Funding acquisition. JJL: Supervision, Project administration. YL: Supervision, Project administration, Funding acquisition, Writing—review & editing, Validation, Resources.

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Compliance with ethical approval

Not applicable.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Xu, Y., Jia, L., Liu, L. et al. Optical confinement enhancement of AlGaN-based deep-ultraviolet laser diode by using asymmetrically wide waveguide layers. Appl. Phys. B 129, 145 (2023). https://doi.org/10.1007/s00340-023-08088-7

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00340-023-08088-7