Abstract

In this paper, a diode pumped mid-IR laser based on a singly resonant intracavity backwards optical parametric oscillator (SR IC-BOPO) is proposed and a simulation model is established. The model takes into account light emission from a laser crystal (e.g., Nd:YVO4), a SR IC-BOPO from a periodically poled nonlinear crystal (e.g., periodically poled lithium niobate (PPLN)), linear loss resulting from optical components, nonlinear loss due to the pump depletion in the BOPO process, thermal lens effect in the laser crystal, and optical mode overlapping between pump, signal and idler beam in PPLN nonlinear crystal. It is shown that the proposed mid-IR laser is capable of generating continuous wave (CW), narrow linewidth, mid-IR light, ranging from 2.1 to 4.5 μm, by employing PPLN with the fifth-order quasi-phase matching (QPM). It is found that a mid-IR laser with an output power as high as 0.47 W can be achieved using a 10 W 808 nm pump laser diode and PPLN crystal with the fifth-order QPM. To the best of our knowledge, this is the first time that a manufacturable SR IC-BOPO is modeled using PPLN, while also taking into account the nonlinear depletion losses in the cavity.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Atmospheric greenhouse gas (GHG) detection and monitoring has become increasingly important in recent years due to ever growing concerns with climate change and the resulting run-away feedback loops when certain GHG concentration milestones are reached [1]. A significant body of work details the thresholds for these “points-of-no-return” for the Earth’s climate [1]. As a result, real time, accurate measurement of atmospheric GHG concentrations is needed. Optical techniques, such as light detection and ranging (LiDAR), are well suited for gas monitoring due to the presence of strong absorption lines, which can be used as a fingerprint to identify GHG gasses and their concentrations in the atmosphere provided the laser source has an emission spectrum which matches with an absorption peak of the gas in question [2,3,4,5]. Optical detection methods such as differential absorption LiDAR (DIAL) or integrated path differential absorption (IPDA) are attractive optical methods for atmospheric gas monitoring due to the possibility for space-borne monitoring [4, 5]. These methods have the benefit of being able to provide real-time data for atmospheric gas concentrations around the globe on a weekly basis, allowing for monitoring in remote locations where placing a physical device would be impractical [4].

Laser sources capable of providing narrow emission linewidth and high output power with compact size and low power consumption are required in the aforementioned GHG detection methods [3,4,5,6,7]. Theoretical studies have been completed, determining that approximately watt-level output is required for continuous wave sources to be used in these techniques for daytime detection [4,5,6,7]. Furthermore, the absorption lines of the gasses of interest are narrow, generally having a full width half maximum (FWHM) on the order of picometers. As such, laser sources with linewidths that are narrower than the absorption lines are required [8]. Additionally, for the laser to be integrated into a satellite, low power consumption, room temperature operation, compact size, and robustness are required. A variety of lasers capable of GHG detection have been developed in the near infrared (NIR [0.8–1.7 µm]) wavelength range and have been used to demonstrate LiDAR-based gas detection [5]. However, many of the important GHGs such as methane and nitrous oxide have their fundamental absorption peaks in the mid-infrared (mid-IR) wavelength range, while the NIR absorption peaks are much weaker [2]. Due to lack of mid-IR laser sources that can achieve high power and narrow linewidth emission, sources emitting in the suboptimal NIR have been used instead, limiting the sensitivity of the GHG gas sensors [8]. To achieve the highest performance possible, high output power, narrow emission linewidth mid-IR lasers with compact size and low power consumption are required [9, 10]. Figure 1 shows the absorption cross-section of various GHGs at the standard pressure taken from the HITRAN database. As shown in Fig. 1, the absorption cross-sections of the relevant GHGs are 2–3 orders of magnitude higher in the mid-infrared region than those in NIR region, clearly demonstrating the need for high-quality mid-IR laser sources to achieve high measurement accuracy.

Currently, quantum and interband cascade lasers (QCLs and ICLs) are the most commercially mature laser sources emitting in the mid-infrared wavelength range. Recent developments have allowed for QCLs with watt-level output powers that can operate at room temperature, greatly reducing the cost of operation [11]. However, achieving both high output powers and narrow emission linewidths simultaneously remains challenging with QCLs and ICLs. For example, high-power CW QCLs have been demonstrated with linewidths of approximately 0.5–1 nm at 3.8 μm but this linewidth remains too broad for use in gas detection [11]. Other QCLs have demonstrated narrow enough linewidths for use in gas detection, but at the cost of insufficient output power, also making them unacceptable [12].

Mid-IR generation based on nonlinear optical processes is a promising alternate method to achieve mid-IR emission. Periodically poled materials that exhibit a large second-order nonlinear coefficient, such as periodically poled lithium niobate (PPLN), can be used to achieve high conversion efficiencies. Forward optical parametric oscillators (FOPOs) have been used to achieve high output power in the mid-IR wavelength range. For example, singly resonant intracavity (SR IC) FOPOs have been reported to achieve watt-level output in the mid-IR [15]. However, due to the large phase matching bandwidth, FOPOs have broad emission linewidths [13,14,15], which is not suitable for GHG detection. It is worth noting that the FOPO described here is simply refered to as an OPO in most of the literature.

Backwards optical parametric oscillators (BOPOs) are also capable of generating mid-IR light. BOPOs have attracted significant interest since they can generate narrow linewidth mid-IR light, which potentially avoids some of the pitfalls of the FOPOs [16, 17]. In a BOPO, one of the two generated waves counter propagates relative to the pump and the other generated wave [16]. As a result of the backwards traveling wave, effective oscillation can occur within the nonlinear crystal without the need for external mirrors, greatly simplifying the laser structure [16]. For this reason, BOPO is also called mirrorless optical parametric oscillator (MOPO) in the literature. Furthermore, the emission linewidth of the counterpropagating wave is narrow, within the pm range [17]. However, the counterpropagating waves impose a large momentum mismatch requirement for quasi-phase matching (QPM) that can only be satisfied by sub-micron poling periods [16,17,18,19]. As such, BOPOs have only been demonstrated in periodically poled potassium titanyl phosphate (PPKTP) due to the sub-micron poling period required [17, 18]. Additionally, only pulsed operation has been achieved due to the required high pump threshold as a result of the low nonlinear coefficient and short length of available PPKTP [17, 18], and the single pass configuration of the pump beam employed in the experiment.

PPLN is an attractive nonlinear material for BOPO due to its high nonlinear coefficient (d33 = 27 pm/V for LN vs 16.9 pm/V for KTP) [20, 21], free of the laser induced gray tracking (different from KTP) [22], and low material loss [23]. PPKTP crystals with sub-micron poling are limited by the short length (< 10 mm) over which uniform poling can be achieved [17, 18]. As a result, PPKTP is unable to be used in a continuous wave (CW) BOPO where long crystal lengths are required. Recently, sub-micron poling periods have been achieved in PPLN thin films [24]. However, it has not yet been demonstrated in bulk PPLN. One option to realize a CW BOPO in bulk PPLN is to use higher order QPM, such as the fifth-order QPM, which results in periods large enough to be manufactured with high quality. In fact, PPLN with a period below 5 µm and a length up to 5 cm is currently commercially available. However, higher order phase matching results in reduced efficiency, and thus we must employ a proper laser structure and model the laser to investigate if a practical CW BOPO can be made from PPLN using current manufacturing methods. In this paper, we establish a theoretical model to design and simulate the performance of a proposed CW SR IC-BOPO structure based on PPLN using the fifth-order QPM and show that CW operation can be achieved. Furthermore, we show that output power as high as 100’s of mW in the mid-IR can be achieved with the proposed design by employing.

2 Theory

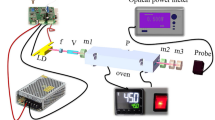

Figure 2 shows a diagram of the proposed SR IC-BOPO structure. A 10 W 808 nm laser diode is used to pump a Nd:YVO4 crystal to generate 1064 nm light (lp), which acts as the pump light in the following BOPO process. As shown in Fig. 2, the pump light (lp) is confined within a laser cavity formed by the high reflection (HR) coatings at the input facet of Nd:YVO4 (coating 1) and an optical coupler (OC, coating 5). The signal light (with a near infrared (NIR) wavelength ls) is confined within an optical resonator formed by the HR coatings on the input facet of the PPLN (coating 3) and the OC (coating 5). For these reasons, this structure is called singly resonant intracavity (SR IC) structure. The idler light (with a mid-IR wavelength li), traveling in both the forward and backward direction, remains single pass and is not confined. The input facet (left-hand side) of the Nd:YVO4 has a high reflection (HR) coating at 1064 nm and an anti-reflection (AR) coating at 808 nm while the output facet (right-hand side) has an AR coating at 1064 nm. The nonlinear crystal used is PPLN, with the input facet (left-hand side) having an AR coating at 1064 nm and an HR coating at the signal wavelength. The output facet (right-hand side) has an AR coating at all wavelengths (pump, signal, and idler). Finally, the OC is HR coated at the pump and signal wavelength, and AR coated at the idler wavelength.

As mentioned above, PPLN was chosen as the nonlinear crystal due to its high nonlinear coefficient, low material loss, and available long device length. A focusing lens is placed between the 808 nm pump laser diode and the Nd:YVO4 crystal to tightly focus the pump beam, guaranteeing a small beam diameter of the 1064 nm light within the PPLN. To ensure that thermal fracture is not an issue in the Nd:YVO4 crystal, a dopant concentration of 0.5 at% was assumed, allowing for absorbed pump powers of up to at least 23.5 W without causing thermal fracture [25]. To avoid optical damage, 5 mol% MgO-doped PPLN can be used [26].

There are several features in the proposed structure. First, the BOPO pump light (lp = 1064 nm) is confined within a laser cavity created by the two HR coatings (numbered 1 and 5) as shown in Fig. 2. By confining the 1064 nm light within the laser cavity, the circulating power is able to reach the threshold of BOPO using watt-level 808 nm pumping to achieve CW output at the generated wavelengths. Second, the signal light (ls with a NIR wavelength) is confined within an optical resonator (coatings 3 and 5) which allows for CW operation to be achieved at low pump powers. Third, room temperature operation is achievable as none of the components require extensive cooling to operate and the QPM condition required for efficient BOPO nonlinear interaction can be satisfied at room temperature. Last, due to the nature of the BOPO process, the idler wave (li) is expected to have a narrow linewidth, removing the need for any spectrum limiting elements such as etalons. It is worth noting that although similar SR IC structure has been reported and studied for FOPO, to the best of our knowledge, SR IC-BOPO has not been investigated. To date, BOPO has been studied only under a configuration without confinement of either pump or signal light [27, 28].

We start the analysis of the proposed mid-IR laser shown in Fig. 2 by assuming that the pump, signal, and idler waves are all plane waves. It is assumed that the forward propagating waves travel in the + z direction (left to right in Fig. 2) while the backwards or counterpropagating waves travel in the − z direction (right to left in Fig. 2). The first-order coupled wave equations for the pump, signal, and counterpropagating idler wave are given by [28]

where As, Ai, and Ap are the slowly varying signal, idler, and pump wave amplitudes, respectively. The substitution \(A = \sqrt {n/\omega } E\) was made to enable the use of a single coupling constant κ, where

where dPPLN is the second-order nonlinear coefficient d33 of LN, c is the vacuum speed of light, ω is the angular frequency of the respective wave, and n is the refractive index of the respective wave in PPLN. Δk is the momentum mismatch given by Δk = kp − ks + ki. P(z) is a function used to account for the periodic poling in the crystal and takes a value of either + 1 or − 1, depending on if the region has a positive or negative nonlinear coefficient. αs, αi, αp are the material loss coefficients for PPLN at the signal, idler, and pump wavelengths, respectively.

As is evident from the above equations, only having an initial value for the pump field will result in no output for the signal and idler fields. We followed a similar treatment to other authors and attribute the initial signal and idler field values to the flux of a single photon with energy equal to ħω/2 [28,29,30]. The factor ½ results from the lowest possible energy of a quantum harmonic oscillator. Following this, and making the same substitution for the electric field as above, the initial field value for the signal wave is:

while for the idler, the initial value is:

where L is the PPLN crystal length and w0 is the beam radius of the pump beam in the PPLN crystal.

To properly model the intracavity behavior, the loss of 1064 nm power due to the nonlinear conversion process (αnl) was considered in addition to the linear losses resulting from material loss (αPPLN) and facet reflection of components involved in the cavity (αcav). Different from the aforementioned material loss coefficients αs, αi, αp at corresponding wavelengths (which is the loss per cm), αPPLN is the total loss of the 1064 nm beam that occurs from traveling through the PPLN crystal twice, once forward and once backward. The nonlinear conversion process (converting the pump to signal and idler photon pairs) can be modeled as an additional loss in the cavity, αnl, for the pump. We assume that each pump photon is converted into a pair of signal and idler photons as determined by the QPM condition. Thus, the number of idler and signal photons are equal (\({N}_{i}={N}_{s}\)). Then the input pump power and output idler power from the model are converted into the total number of pump and idler photons, and the ratio of idler to pump photons gives the nonlinear loss. The nonlinear loss was calculated using the equation:

where αnl is the nonlinear loss, Ni is the total number of idler photons generated by the forwards and backwards traveling fields, and Np is the number of pump photons incident on the PPLN crystal. With the inclusion of the above nonlinear loss term, the total loss at 1064 nm can be calculated as:

where αtot is the total loss, αcav the cavity loss, αPPLN is the loss in PPLN. It is important to include this nonlinear loss term, as otherwise the performance of the device will be overestimated. Note that the loss coefficient αPPLN includes both the material absorption loss and the scattering loss in PPLN. The total loss term is calculated at each step to determine the new circulating 1064 nm power, based on the number of idler photons, until steady state is reached. To the best of our knowledge, this is the first time that both linear and nonlinear loss is considered in modeling the BOPO process. As will be shown below, nonlinear loss plays an important role in determining mid-IR output power of the SR IC-BOPO structure.

The simulation combines two separate models: an intracavity laser model (used to calculate the circulating 1064 nm pump power), and a coupled wave equation solver (used to calculate the signal and idler fields). The first step was the calculation of the circulating 1064 nm power using a previously reported model [31]. The calculated 1064 nm power was used as the initial value for Ap in the coupled wave equations, which were then solved using the Lax–Wendroff method to determine the output power of the signal and idler waves [32]. The nonlinear loss term was calculated at each step and added into the intracavity laser model to determine an updated 1064 nm power.

When modeling laser resonators, it is common to break down the resonant light into two components: a forward traveling wave and a backward traveling wave. In this context, forward is traveling from the HR end mirror to the output coupler (left to right in Fig. 2), and backward is traveling from the OC to the HR end mirror (right to left in Fig. 2). This applies to the pump, signal, and idler in the cavity. Since we are considering a BOPO, the phase matching convention assumes the pump and signal are always traveling in the same direction, and the generated idler will travel in the opposite direction. As an example, a forward propagating pump and signal will generate a backward propagating idler wave. It is also common to assume that the forward and backward traveling waves are equal in magnitude when cavity losses are low, which is a reasonable approximation for many practical cavities. An important note is that the backward traveling idler often cannot be accessed due to absorption in the gain medium and interference effects between the forward and backward waves. For this reason, in the following discussion, we will focus on the forward propagating idler wave (i.e., output mid-IR light shown in Fig. 2) and backward propagating pump and signal waves.

To increase the speed at which the coupled wave equations can be solved, an effective nonlinear coefficient was calculated by integrating the domain function, P(z), the phase mismatch term, \(\mathrm{exp}\left[-i\Delta kz\right]\), and the nonlinear coefficient across the entire length of the crystal and then dividing this value by the length of the crystal. This allows for a step size to be used that is much larger than a single period, greatly decreasing the calculation time. The period size was determined based on the desired idler output wavelength.

Two different types of boundary conditions are needed to solve the coupled wave equations, input and output boundary conditions. The input conditions for the forward signal and pump fields are the respective field values at the left-hand side (z = 0) of the nonlinear crystal, while the input value for the backward traveling idler is the idler field value at the right-hand side (z = L), of the nonlinear crystal. Since the numerical scheme of the Lax–Wendroff method requires knowledge of the spatial value of node N + 1 to evaluate the field at node N, a polynomial interpolation was used to calculate the output boundary conditions, which occur at the right-hand side of the crystal for the signal and pump wave and at the left-hand side of the crystal for the idler wave [33]. The value determined at the output boundary (right-hand side) for the forward signal and pump is used as the input value for the backward traveling signal and pump wave. The value of the backward traveling signal field at z = 0 is added to the initial condition of the forward traveling signal wave at z = 0 to account for the intracavity confinement.

On the other hand, the coupled wave equation solver was validated by comparing the results to previously reported simulation results for a single pass pulsed BOPO based on PPLN without a laser cavity structure [28], which were found to be in excellent agreement. Furthermore, the combination of the intracavity laser model and the coupled wave equation solver was validated by simulating an SR IC-FOPO. It was found that our simulation on the SR IC-FOPO output power matches well with previously reported experimental results [15].

3 Discussion

Figure 3 shows the plot of the output wavelengths of the signal and idler wave vs. the period of the PPLN crystal based on the phase mismatching in the BOPO process for (a) the first-order and (b) the fifth-order QPM, respectively. Figure 3 does not mean to tune the wavelength with a single device. Instead, it only shows the range of signal and idler wavelengths that can be achieved in the transparency region of PPLN by selecting an appropriate period through the BOPO process. The refractive index of 5 mol% MgO-doped lithium niobate at the three wavelengths was calculated using an appropriate Sellmeier equation at a temperature of 20 °C [34]. As shown in Fig. 3, the generated signal wavelength (orange curve) decreases from 2.128 to 1.5 mm with the increase of PPLN period, while the generated idler wavelength (blue curve) increases from 2.128 to 4.5 mm when PPLN period increases from 0.5 to 1 mm (for the first-order QPM) and 2.5 to 5 mm (for the fifth-order QPM), respectively. Different from the well-known horseshoe-shaped signal/idler wavelength—period curve for a FOPO, there exists a sudden turning point in the signal/idler wavelength—period curve for BOPO at the degeneracy point. The wave which counter propagates has a negative wavevector, compared to the wave which co-propagates with the pump wave, as can be seen in the phase matching equation. Due to this negative sign, the change in momentum mismatch is substantially different when varying the wavelength of the two waves, even at the degeneracy point, which leads to two completely different wavelength curves when plotted against the period. In the signal/idler wavelength— period curve of a FOPO, the curves of the signal and idler are nearly mirror images of each other at the degeneracy point which is to be expected due to their wavevectors having the same sign. This results in a smooth curve, as opposed to the observed acute angle at the degeneracy point in Fig. 3 for BOPO.

As shown in Fig. 3a, it is necessary to use a very short period (0.5–1 mm) for mid-IR light generation in a PPLN-based BOPO with the first-order QPM. However, when using the fifth-order QPM, the acceptable period is five times that of the first-order QPM, as shown in Fig. 3b, at the cost of overall nonlinear conversion efficiency due to a factor of 5 reduction in the effective nonlinear coefficient. This tradeoff is necessary to make a practical mid-IR IC-BOPO, considering the fact that PPLN with periods below 5 μm are commercially available on the market.

Figure 4 shows simulated forward idler output power vs. the input 808 nm LD power. In the simulations, 100% output coupling of the forward idler wave (at mid-IR wavelength) from the laser cavity was assumed. Since the idler beam is not confined within a cavity, this assumption does not change the output power by a noticeable amount if the actual output coupling efficiency is slightly less than 100%. The duty cycle of the domain inversion was assumed to be 50/50, with a uniform period of 3.75 μm (for a fifth-order QPM). The beam profiles of the pump, signal, and idler were calculated using an ABCD matrix method. The mode overlap between the three beams is taken into account when calculating the output idler power reported below by multiplying an appropriate overlap factor in each coupled wave equation. The beam radius of the 808 nm pump LD was set to 40 μm inside the Nd:YVO4 laser crystal. The signal, idler, and pump wavelengths used in the simulation were 1.59 μm, 3.21 μm, and 1.064 μm, respectively. An idler wavelength of 3.21 μm was chosen as this wavelength matches with a known absorption line of methane. The parameters for the Nd:YVO4 crystal were the same as those were used in a previously reported theoretical model for a Nd:YVO4 laser [35] except the length was set to 0.7 cm and the doping was set to 0.5 at% to prevent thermal fracture. The intracavity model has been validated previously against reported Nd:YVO4 diode pumped lasers to good agreement [35]. In the simulations, the thermal lens effect within Nd:YVO4 and optical mode overlapping between pump, signal, and idler beam in PPLN were considered. The BOPO model has been validated against previously reported experimental results for single pass BOPOs [17, 28] as well as SR IC-FOPOs as reported above. The material loss coefficients of the signal, idler, and pump in PPLN were assumed to be 0.002 cm−1, 0.07 cm−1, 0.0035 cm−1 [23], respectively. A cavity loss of 1% was assumed for both the signal and pump beams. The HR coatings for both the signal and pump were assumed to be 99.85%. Miller’s rule was used to determine the nonlinear coefficient for the wavelengths of interest in the present simulation [36], resulting in a nonlinear coefficient of 22.2 pm/V at the desired wavelengths.

As shown in Fig. 4, it is possible to achieve continuous wave, mid-IR emission with the proposed SR IC-BOPO structure. The threshold 808 nm LD powers for the 3 cm, 4 cm, and 5 cm PPLN lengths were approximately 8.5 W, 7 W, and 6.5 W, respectively. Below the threshold input powers, the output power of the idler was negligible, with a rapid rise in output power (several orders of magnitude) occurring near the 808 LD threshold power. The maximum idler output power for the 3 cm, 4 cm, and 5 cm PPLN lengths was 0.23 W, 0.42 W, and 0.47 W, respectively. 0.47 W idler power at 10 W pump corresponds to an optical-to-optical conversion efficiency of ~ 5%. The difference in output power between the 3 cm and 4 cm PPLN is much larger than the difference in output power between the 4 cm and 5 cm PPLN which can be explained as follows. First, as the PPLN length increases, the spot size of all three fields also increases, leading to a reduction in the field intensity which reduces the conversion efficiency. Second, the overlap between the three fields also decreases as the PPLN length increases which further reduces the conversion efficiency. Finally, as the PPLN length increases the spot size of the 1064 nm beam in the Nd:YVO4 crystal also increases, which reduces the 1064 nm output power as the 808 nm LD spot size was held constant.

It is worth noting that only the forward traveling idler wave is shown in Fig. 4, instead of the backward traveling idler wave, for the following reason. To extract the backward traveling idler, a dichroic mirror would have to be placed within the cavity between the PPLN and Nd:YVO4 crystal. This would add another cavity loss source and increase the cavity size resulting in the pump beam waist increasing and pump power decreasing. The overall reduction in performance from the dichroic mirror offsets the potential gain in output power from coupling both the forward and backward idler out of the cavity using this approach. It is possible to instead use an HR coating (at coating 2 or 3 shown in Fig. 2) to reflect the backward traveling idler field so that both the backward and the forward traveling field can be extracted to increase total output mid-IR light power. In this case, PPLN length needs to be selected carefully so that the forward and the backward traveling idler field can add constructively. This output coupling problem with the backward idler wave is similar to the problems described by Smith in coupling out the backward second harmonic wave in intracavity second harmonic generation 532 nm lasers [37]. Intuitively, it would seem the mirror/coating would double the available output idler power, but in practice, the multiplier is much closer to one given destructive interference and cavity losses. As such, it is typically not worth the added complexity. It is important to note that while the term forward is used to describe the idler here, it is still a counterpropagating wave, as it counter propagates relative to the signal and pump field it interacts with.

Due to the small period required for QPM in PPLN for the BOPO process, even in the case of fifth-order QPM, we do not expect other nonlinear processes to have a noticeable impact on device performance. The period required for the BOPO interaction as stated previously is 3.75 μm, which is substantially smaller than the period required for any other nonlinear interaction. Second harmonic generation with a 1064 nm pump, for example, would require a period of approximately 6.9 μm, which is substantially larger than the one used for the fifth-order BOPO, and thus SHG from 1064 nm pump is negligible since the QPM condition for 1064 nm SHG is not satisfied. Similarly, other nonlinear interactions, such as sum-frequency generation (SFG) using any of the three present wavelengths, require different periods, and thus would not impact device performance. Additionally, these SFG nonlinear processes would be single pass only, which would further reduce their efficiency.

We expect the linewidth of the idler wave to be on the order of tens of pm based on previously reported results [17]. The counterpropagating wave, which in this case is the idler, is expected to have a linewidth roughly 100 times smaller than that of the pump wave. Intracavity Nd:YVO4 lasers emitting at 1064 nm have a linewidth that is approximately a few nm without the inclusion of a wavelength selective element [38]. As such this would result in the idler wave having a linewidth on the order of tens of pm. Another important performance parameter of the laser is the wavelength temperature tuning coefficient. In order for the laser to be useful for gas detection, the idler wavelength must be insensitive to temperature changes in the PPLN. Methane’s absorption peaks have a FWHM of approximately 300 pm at 3.2 µm. The wavelength–temperature tuning coefficient for the idler wavelength was calculated to be 400 pm/K, approximately 4× lower than in the forward OPO case (~ 1600 pm/K). Based on the FWHM of the methane absorption spectrum, it is reasonable to consider that the maximum wavelength shift that could be allowed is approximately half of the FWHM (i.e.,150 pm). Beyond this, the absorption coefficient will drop down to a level that results in poor device performance. For the BOPO, this would require PPLN temperature control of roughly 0.3 K, which would ensure the idler wavelength remains with the absorption spectrum of methane. This level of temperature control can be achieved in PPLN with the standard thermoelectric coolers.

It would be interesting to check the achievable mid-IR power with a low-order QPM PPLN, although the required period is not commercially available at this moment. Figure 5 shows the expected output power of the forward idler for PPLN with a third-order QPM period. The simulation was identical to the one described for the fifth-order QPM except for the change in PPLN period (2.25 mm for third-order QPM). The threshold 808 nm LD powers for the 3 cm, 4 cm, and 5 cm PPLN lengths were approximately 4 W, 3.5 W, and 3 W, respectively. The maximum forward idler output powers were 0.77 W, 0.81 W, and 0.82 W, respectively. As can be seen in Fig. 5, changing the length does not have a drastic effect on the output power of the forward idler wave, with the three lengths having roughly the same output power. This is due to the depletion of the forward pump beam increasing as the length of the crystal increases, resulting in a higher nonlinear loss. This shows the importance of including the nonlinear loss term in the modeling, as intuitively one may expect the output power to grow linearly with crystal length, which is not the case of intracavity structure. We can see the jump in nonlinear loss when comparing the two simulations. Looking at the 3 cm long PPLN case for the fifth-order QPM, a nonlinear loss of 0.6% was calculated, with the forward idler having a power of 0.27 W. For the third-order QPM case, the calculated nonlinear loss was 5.5% while the output power was roughly 0.77 W. However, despite the improvement in performance, achieving third-order QPM in PPLN would currently be quite difficult with current manufacturing capabilities, and would have limitations on the selectable wavelengths. For the third-order QPM, the acceptable period is 3× larger than the first-order QPM shown in Fig. 3a, resulting in a maximum period of approximately 3 μm, which is currently not commercially available. However, with advances in poling technology, it is likely that periods small enough to satisfy the third-order QPM condition could be manufactured in the future, allowing for a drastic improvement in performance compared to the fifth-order QPM.

4 Conclusion

In this paper, we have theoretically studied a singly resonant intracavity backward optical parametric oscillator (SR IC-BOPO) using commercially available PPLN, while considering the effects of nonlinear depletion on the circulating pump beam in the laser cavity. We believe that this is the first time that a physically realizable BOPO structure, using off-the-shelf PPLN, has been studied for CW mid-IR laser, taking into account the nonlinear losses. The proposed mid-IR laser is able to achieve an optical-to-optical conversion efficiency as high as ~ 5% at 3.21 m\(\upmu\) with 10 W of input 808 nm pump power using an Nd:YVO4 gain medium, producing up to 470 mW of output power with a narrow linewidth in the hundreds of pm.

The output power, linewidth, and emission wavelength satisfy all the requirements for a source that could be used in daytime gas detection through LiDAR methods. The proposed mid-IR source is capable of achieving emission throughout the entire transparency region of the PPLN crystal via modification of period or by modifying the operating temperature, enabling it to be used for detection of different gas species. The proposed mid-IR source provides a drastic improvement over current technology emitting in the mid-IR wavelengths in terms of cost and output power, while maintaining a comparable emission linewidth. It is expected that the results presented in this paper can provide guidelines in developing mid-IR sources based on PPLN for GHG detection/monitoring.

Data availability

Data underlying the results presented in this paper are available upon request.

References

J. Randers, U. Goluke, An earth system model shows self-sustained thawing of permafrost even if all man-made GHG emissions stop in 2020. Sci. Rep. 10(1), 18456 (2020)

D. Popa, F. Udrea, Towards Integrated mid-infrared gas sensors. Sensors 19(9), 2076 (2019)

L. Joly, V. Zéninari, T. Decarpenterie, J. Cousin, B. Grouiez, D. Mammez, G. Durry, M. Carras, X. Marcadet, B. Parvitte, Continuous-wave quantum cascade lasers absorption spectrometers for trace gas detection in the atmosphere. Laser Phys. 21(4), 805–812 (2011)

L. Mei, M. Brydegaard, Continuous-wave differential absorption lidar. Laser Photon. Rev. 9(6), 629–636 (2015)

G.A. Wagner, D.F. Plusquellic, Ground-based, integrated path differential absorption LIDAR measurement of CO2, CH4, and H2O near 1.6 μm. Appl. Opt. 55(23), 6292–6310 (2016)

L. Mei, P. Guan, Z. Kong, Remote sensing of atmospheric NO2 by employing the continuous-wave differential absorption lidar technique. Opt. Express 25(20), A953–A962 (2017)

I. Esquivias, A. Consoli, M. Krakowski, M. Faugeron, G. Kochem, M. Traub, J. Barbero, P. Fiadino, X. Ai, J. Rarity, M. Quatrevalet, and G. Ehret, High-brightness all semiconductor laser at 1.57 μm for space-borne lidar measurements of atmospheric carbon dioxide: device design and analysis of requirements. Proc. SPIE 9135 (2014)

G. Ehret, C. Kiemle, M. Wirth, A. Amediek, A. Fix, S. Houweling, Space-borne remote sensing of CO2, CH4, and N2O by integrated path differential absorption lidar: a sensitivity analysis. Appl. Phys. B 90(3), 593–608 (2008)

S. Yakovlev, S. Sadovnikov, O. Kharchenko, N. Kravtsova, Remote sensing of atmospheric methane with IR OPO lidar system. Atmosphere 11(1), 70 (2020)

Z. Du, S. Zhang, J. Li, N. Gao, K. Tong, Mid-infrared tunable laser-based broadband fingerprint absorption spectroscopy for trace gas sensing: a review. Appl. Sci. 9(2), 338 (2019)

M. Razeghi, High power, high wall-plug efficiency, high reliability, continuous-wave operation quantum cascade lasers at Center for Quantum Devices. SPIE Conf. Proc. 11296, 112961C-112961C–15 (2020)

S. Borri, G. Insero, G. Santambrogio, D. Mazzotti, F. Cappelli, I. Galli, G. Galzerano, M. Marangoni, P. Laporta, V. Di Sarno, L. Santamaria, P. Maddaloni, P. De Natale, High-precision molecular spectroscopy in the mid-infrared using quantum cascade lasers. Appl. Phys. B 125(1), 18 (2019)

Y.F. Peng, X.B. Wei, G. Xie, J.R. Gao, D.M. Li, W.M. Wang, A high-power narrow-linewidth optical parametric oscillator based on PPMgLN. Laser Phys. 23(5), 55405 (2013)

J. Zhao, P. Cheng, F. Xu, X. Zhou, J. Tang, Y. Liu, G. Wang, Watt-level continuous-wave single-frequency mid-infrared optical parametric oscillator based on MgO:PPLN at 3.68 µm. Appl. Sci. 8(8), 1345 (2018)

K. Wang, M. Gao, S. Yu, J. Ning, Z. Xie, X. Lv, G. Zhao, S. Zhu, A compact and high efficiency intracavity OPO based on periodically poled lithium niobate. Sci. Rep. 11(1), 5079 (2021)

S.E. Harris, Proposed backward wave oscillation in the infrared. Appl. Phys. Lett. 9(3), 114–116 (1966)

C. Canalias, V. Pasiskevicius, Mirrorless optical parametric oscillator. Nat. Photonics 1(8), 459–462 (2007)

R.S. Coetzee, A. Zukauskas, C. Canalias, V. Pasiskevicius, Low-threshold, mid-infrared backward-wave parametric oscillator with periodically poled Rb:KTP. APL Photonics 3(7), 71302 (2018)

Y.J. Ding, J.B. Khurgin, Backward optical parametric oscillators and amplifiers. IEEE J. Quantum Electron. 32(9), 1574–1582 (1996)

R.W. Boyd, Nonlinear Optics (Academic, London, 2020)

I. Shoji, T. Kondo, A. Kitamoto, M. Shirane, R. Ito, Absolute scale of second-order nonlinear-optical coefficients. J. Opt. Soc. Am. B 14(9), 2268–2294 (1997)

B. Boulanger, I. Rousseau, J.P. Feve, M. Maglione, B. Menaert, G. Marnier, Optical studies of laser-induced gray-tracking in KTP. IEEE J. Quantum Electron. 35(3), 281–286 (1999)

M. Leidinger, S. Fieberg, N. Waasem, F. Kühnemann, K. Buse, I. Breunig, Comparative study on three highly sensitive absorption measurement techniques characterizing lithium niobate over its entire transparent spectral range. Opt. Express 23(17), 21690–21705 (2015)

B.N. Slautin, H. Zhu, V.Y. Shur, Submicron periodical poling in Z-cut lithium niobate thin films. Ferroelectrics 576(1), 119–128 (2021)

Y.-F. Chen, Design criteria for concentration optimization in scaling diode end-pumped lasers to high powers: influence of thermal fracture. IEEE J. Quantum Electron. 35(2), 234–239 (1999)

P. Sen, P.K. Sen, R. Bhatt, S. Kar, V. Shukla, K.S. Bartwal, The effect of MgO doping on optical properties of LiNbO3 single crystals. Solid State Commun. 129(11), 747–752 (2004)

A. Godard, M. Guionie, J.-B. Dherbecourt, J.-M. Melkonian, M. Raybaut, Backward optical parametric oscillator threshold and linewidth studies. J. Opt. Soc. Am. B 39(2), 408–420 (2022)

C.E. Minor, R.S. Cudney, Mirrorless optical parametric oscillation in bulk PPLN and PPLT: a feasibility study. Appl. Phys. B 123(1), 38 (2017)

G. Rustad, G. Arisholm, Ø. Farsund, Effect of idler absorption in pulsed optical parametric oscillators. Opt. Express 19(3), 2815–2830 (2011)

A. Fix, R. Wallenstein, Spectral properties of pulsed nanosecond optical parametric oscillators: experimental investigation and numerical analysis. J. Opt. Soc. Am. B 13(11), 2484–2497 (1996)

W.P. Risk, Modeling of longitudinally pumped solid-state lasers exhibiting reabsorption losses. J. Opt. Soc. Am. B 5(7), 1412–1423 (1988)

P. Lax, B. Wendroff, Systems of conservation laws. Commun. Pure Appl. Math. 13(2), 217–237 (1960)

Z. Du, J. Li, A two-stage fourth order time-accurate discretization for Lax-Wendroff type flow solvers II. High order numerical boundary conditions. J. Comput. Phys. 369, 125–147 (2018)

O. Gayer, Z. Sacks, E. Galun, A. Arie, Temperature and wavelength dependent refractive index equations for MgO-doped congruent and stoichiometric LiNbO3. Appl. Phys. B 91(2), 343–348 (2008)

L. Flannigan, T. Kashak, C.-Q. Xu, Study of fundamental wave depletion in intracavity second harmonic generation. Opt. Express 29(5), 6810–6823 (2021)

R.C. Miller, Optical second harmonic generation in piezoelectric crystals. Appl. Phys. Lett. 5(1), 17–19 (1964)

R.G. Smith, Theory of intracavity optical second-harmonic generation. IRRR J. Quantum Electron. 6(4), 215–223 (1970)

V.N. Burakevich, V.A. Lisinetskii, A.S. Grabtchikov, A.A. Demidovich, V.A. Orlovich, V.N. Matrosov, Diode-pumped continuous-wave Nd:YVO4 laser with self-frequency Raman conversion. Appl. Phys. B 86(3), 511–514 (2007)

Acknowledgements

The authors would like to thank Dr. Daniel Poitras from the NRC for helpful discussion and design of the AR and HR coatings, and Drs. Lewis and Emslie for the discussions on epitaxial growth techniques.

Funding

The Ontario Research Fund—Research Excellence (ORF-RE); NSERC Alliance; NSERC Discovery.

Author information

Authors and Affiliations

Contributions

All authors wrote the main manuscript text.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Kneller, J., Flannigan, L. & Xu, CQ. Theoretical study of diode pumped intracavity backward optical parametric oscillator based on periodically poled lithium niobate. Appl. Phys. B 129, 99 (2023). https://doi.org/10.1007/s00340-023-08045-4

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00340-023-08045-4