Abstract

To meet the increasing demand of short-wavelength red lasers for laser display technology and medical applications, we propose a new short-wavelength red semiconductor laser structure. The laser uses Ge/SiGe as the substrate and GaInP, AlInP and other group III-V materials as the main structural layers. The composition of Ge is adjusted to change the lattice constant of the SiGe layer according to the needs of GaInP strain quantum well design to achieve a short-wavelength red laser. A semiconductor laser with a wavelength of 620 nm is used as an example, and the effect of both the interfacial state and the GaInP-strained quantum well on the device characteristics is discussed through simulation. It is found that the laser structure has the optimal output characteristics when the quantum well is subjected to 0.32% compressive strain under the conditions of the interfacial state, which indicates the feasibility of this laser structure design scheme.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Since the 1990s, the GaInP/AlGaInP quantum well structure has replaced the double heterojunction to achieve room-temperature operation of red semiconductor lasers. Although important breakthroughs had been made in optoelectronic properties and reliability of the red lasers, the emitting wavelength of the lasers was mainly in the range of 655–680 nm at that time[1]. With the increasing demand for shorter wavelength red lasers for laser display technology[2] and red laser medical applications [3], the development of 638–642 nm short-wavelength red semiconductor lasers, and even 620–630 nm ultra-short-wavelength red semiconductor lasers have re-emerged as one of the hot spots in the field of solid-state semiconductor light source.

The present research on short-wavelength red semiconductor lasers is mainly focused on 638–642 nm, and some important progress has been made in terms of material preparation, optimization of growth parameters, laser structure optimization, device fabrication and feature enhancement [4, 5]. Tomoki Ohno et al. reported the fabrication of laser arrays with non-absorbing windows using solid-state Zn diffusion technology, with a maximum output power of 15 W at 20 °C for a single bar and an output wavelength of 636–643 nm [6]. New broad area 638 nm laser was designed and fabricated by Kuramoto et al. The laser chip had triple emitters in one chip with each stripe width of 60 um, and was assembled on ϕ9.0 mm-TO package. The laser emitted exceeding 5.5 W at heat sink temperature of 25 °C and 3.8 W at 45 °C under pulsed operation with frequency of 120 Hz and duty of 30% [7].

For the ultra-short-wavelength red laser within 630 nm based on the GaInP quantum well, there are several research solutions: (1) using quantum well mixing to change the energy band structure of the active region to achieve short-wavelength semiconductor lasers; (2) using pressure and temperature to modulate the energy band structure of the active region to change the wavelength of GaInP quantum well red lasers [8]. Ooi et al. [9] annealed at 900–1000 °C and performed impurity-free vacancy-induced quantum well mixing to blue-shift the entire active region luminescence wavelength to produce a short-wavelength red laser. Although the laser exhibited luminescence characteristics comparable to those of a short-wavelength LED, the scheme was limited by the compositions and strain of the quantum barrier region material itself, and the high-temperature quantum well mixing caused adverse effects on the crystal quality. The reliability and stability of the device are insufficient. Trzeciakowski et al. [8] can adjust the wavelength of 645 nm GaInP quantum well laser to 575 nm by changing the ambient pressure (0–20 kbar), temperature (80–300 K), but this solution also has the disadvantage that the appendages are too complicated for field use.

At present, there is still no industrially mature solution for short-wavelength (< 630 nm) red semiconductor lasers. In the study of red semiconductor lasers based on GaAs substrates, the excitation wavelength is mainly greater than 638 nm. The GaInP material matched with GaAs emits light at a wavelength of about 657 nm, so to obtain red laser at shorter wavelengths, quantum wells are usually constructed with very thin compression strain (around 3.0 nm) or thicker (around 10 nm) tension strain quantum wells. For the short-wavelength of red laser and the 620 nm studied in this manuscript, if the GaAs substrate is still used, the GaInP quantum well will be subject to greater tension strain, and carrier leakage will affect the device characteristics more severely as the device temperature rises. Back in the 1990s, Summers et al. reported a 619 nm tensor-strained GaInP quantum well laser, but it operated under pulsed conditions with a small duty cycle, a large threshold current density of the laser, and low output power [10]. Therefore, based on a variable lattice constant Si1-xGex layer grown on a Ge substrate, we propose a design scheme for a GaInP quantum well short-wavelength red semiconductor laser with high Ga composition. This manuscript verifies the feasibility of the design scheme by the LaserMOD module in Rsoft simulation software, and the laser wavelength is set to 620 nm for related discussion and analysis, which provides a reference for subsequent device fabrication.

2 Laser structure design and basic characteristics simulation

According to the characteristic parameters of compound semiconductor materials, the mainstream approach to develop red semiconductor lasers is to use different strains of GaInP/AlGaInP quantum well structures [11, 12]. Figure 1 shows the wavelengths and lattice constants corresponding to different compositions of GaInP materials. The limit value of Ga composition of direct bandgap GaInP material is about 0.737, and the cut-off wavelength is 544.7 nm. The wavelength of GaInP material with Ga composition of 0.57 is around 620 nm, and its lattice constant is about 5.63 Å.

We propose a short-wavelength red semiconductor laser based on a Ge/SiGe substrate, grow a SiGe layer with variable lattice constant on the Ge substrate, and change the Ge composition in the SiGe layer with reference to the lattice constant of GaInP quantum well material, so as to adjust the lattice constant. However, it is difficult to grow high-quality SiGe layers directly on Ge substrates. Therefore, it is necessary to insert a buffer layer structure between the Ge substrate and the high-quality SiGe layer for stress relaxation and reduction of material defects such as threading dislocations (TDs) and anti-phase domains (APDs). The buffer layer structure can be prepared by low-temperature (LT) buffer layer [13], composition gradient GeSi layer, Ge/GeSi superlattice layer [14], and reverse-graded buffer [15]. The actual preparation of Ge/SiGe materials will be carried out in the later work. The lattice constants of all the structural layers except the quantum well are consistent with the SiGe layer, so that the lattice mismatch and thermal mismatch caused by the high Ga composition GaInP quantum well can be reduced by introducing the SiGe layer to improve the quality of material growth and the optoelectronic properties of the device.

According to this laser design scheme, the lattice constants of the SiGe layer and the remaining layers can be adjusted to subject the quantum well to different strains after determining the Ga composition of the quantum well. Next, we initially set the quantum well in the Ge/Si1-xGex substrate 620 nm semiconductor laser structure to be strain-free, i.e., the lattice constants of all layers except the Ge substrate and GaAs ohmic contact layer are adjusted to be consistent with the quantum well, and the specific structural parameters are shown in Table 1. The structural parameters are based on previous research on red semiconductor lasers in our group [16, 17]. For the setting of the SiGe layer thickness, we refer to the study of Md. Mahfuz Alam et al. on the fabrication of strained SiGe layer on Ge substrate by MBE, which gives the critical thickness of epitaxially strained SiGe layer with different Ge compositions on Ge(100) crystalline phases [18]. The critical thickness can reach about 150 nm when the Ge composition is 0.8. The SiGe layer was simplified and the buffer layer was removed according to the need of simulation, and a high-quality SiGe layer with a thickness of 15 nm was selected for the subsequent simulation.

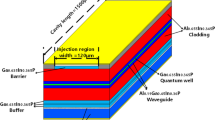

Most traditional short-wavelength red semiconductor lasers use GaAs substrates, and the lattice constant of GaAs is about 5.653 Å. If a laser structural layer with the same lattice constant as Ga0.57In0.43P is grown on a GaAs substrate, the structural layer will be subjected to a tension strain of about 0.4%. According to our proposed laser design scheme, the lattice constant of the SiGe substrate layer is adjusted to about 5.63 Å by changing the Ge composition, thereby reducing the strain caused by lattice mismatch. For comparison, we replaced the Ge/SiGe substrate of this structure with a GaAs substrate as the simulation comparison group, and the cavity length of both structures was set to 1500 μm, the current injection zone width was 120 μm, and the cavity surface reflectance was set to 0.95 and 0.05, respectively. The calculation is set to Fabry–perot cavity in LaserMOD. Figure 2a shows the schematic structure of the 620 nm laser based on the Ge/SiGe substrate, and Fig. 2b shows the near-field distribution of the laser obtained from the simulation, with the spots mainly distributed in the AlGaInP waveguide layer region.

Figure 3 shows the simulated optical power and spectrum of the two structures respectively. Both structures have wavelengths around 620 nm, but the GaAs substrate structure needs to operate at 263 K, while the Ge/SiGe substrate structure operates at 298 K. The threshold current for the GaAs substrate 620 nm laser structure is about 470 mA and the optical power is 189 mW at a current of 750 mA; the threshold current for the Ge/SiGe substrate 620 nm laser structure is about 510 mA and the optical power is 287 mW at a current of 750 mA. The results show that the proposed structure design of the 620 nm semiconductor laser on Ge/SiGe substrate has better characteristics than the laser with a wavelength of 620 nm fabricated on GaAs substrate.

3 Effect of the interfacial state on laser characteristics

The preliminary characterization simulations in Sect. 2 are under relatively ideal conditions, however, according to our design scheme, there are stress problems caused by lattice mismatch and thermal mismatch in growing SiGe layers on Ge substrates with lattice constants matching the laser structure, so that some crystal defects will appear within the SiGe layer and at the interface. After the two materials form a heterojunction due to the mismatch of lattice constants, a dangling bond will be generated at the heterojunction interface, and the dangling bond will cause an interfacial state, which will act as a carrier trap or recombination center and have an impact on the device properties. The effect of the interfacial state on the recombination rate can be expressed as

In Eq. (1) [19], ne, nh, ni are electron, hole concentration, and intrinsic carrier concentration, respectively; ve/h is the recombination velocity of electrons and holes at the interface, respectively; ne/htrap is the captured electron–hole concentration, respectively. Since the actual device fabrication will be carried out in future work, in this manuscript we use the formula for calculating the density of dangling bonds or interfacial state ΔNs contained in the heterojunction grown on the (100) crystal plane to estimate the interfacial density of state at the Ge/SiGe interface.

In Eq. (2), a1 and a2 are the lattice constants of the two semiconductors forming the heterojunction, a1 > a2. Our preliminary design uses a SiGe material with a Ge composition of 0.88, whose lattice constant is about 5.63 Å, while the lattice constant of the Ge substrate is about 5.658 Å. The density of interfacial state at the Ge/SiGe interface is calculated to be about 1.2 × 1013 cm−2. In previous reports of Si-based InGaN blue-violet laser [20], LED devices, there are more defects in the substrate and buffer layer, which in turn extend to the waveguide layer of the device. With this as a reference, we added interfacial state at the Ge/SiGe interface with the laser waveguide layer for characterization, and the density of interfacial state in the two regions was set to 1.2 × 1013 and 1 × 106 cm−2, respectively, and the comparison group was the 620 nm laser structure of the Ge/SiGe substrate without interfacial state.

The output power and conversion efficiency of the 620 nm laser without considering the effect of the interfacial state are shown in Fig. 4, where the threshold current is about 510 mA, the output power can reach 1.2 W, and the conversion efficiency is about 41.2%. After considering the effect of the interfacial state, the threshold current increases to 911 mA and the output power decreases to 0.68 W. The conversion efficiency becomes 24.7%. After adding the interfacial state at the waveguide layer and the Ge/SiGe interface, the output characteristics of the device decreased.

Figure 5a shows the non-radiative recombination rate intercepted along the longitudinal direction of the device. Compared with the case without the influence of the interfacial state, we find that after adding the interfacial state, new non-radiative recombination rate peaks appear in the active region of the device, the Ge/SiGe interface and the GaInP buffer layer. After the interfacial state is added to the waveguide layer, the active region increases two non-radiative recombination rate peaks, and the recombination rate is 1027 order of magnitude, and the non-radiative recombination rate in the quantum well region increases from 4.43 × 1026 to 1.12 × 1028 cm−3 s−1. Figure 5b enlarges the Ge/SiGe interface and the GaInP buffer layer, both of which have peak non-radiative recombination rates in the 1023 order of magnitude. Figure 5c is the radiative recombination rate of the quantum well. After adding the interfacial state, the radiative recombination rate in this region is reduced from 4.54 × 1027 to 2.61 × 1027 cm−3 s−1. It can be seen that the conversion efficiency of the 620 nm laser decreases due to the presence of interfacial state. The influence of interfacial state mainly acts on the carrier transport, and the interfacial state will form a compound center and capture carriers at the added position, where some electrons and holes are recombined, reducing the radiation recombination rate of the quantum well and eventually leading to a decrease in efficiency.

4 Effect of the quantum well strain conditions on laser characteristics

Based on the consideration of the effect of interfacial state, the characteristics of 620 nm semiconductor lasers with different strain quantum wells will be analyzed in this section. The Ga composition of the quantum well is set to 0.57, and the Ge composition of the SiGe layer is changed to 0.92, 0.90, 0.88, 0.85 and 0.80 to adjust the lattice constant, and the buffer, cladding and waveguide layers are also adjusted to keep the same lattice constant as the SiGe layer, so that the quantum well is subjected to different strains, and the thickness of the quantum well is adjusted so that the excitation wavelength remains at 620 nm. The density of interfacial states added at the Ge/SiGe interface is still estimated according to Eq. (2), and the density of interfacial states added at the waveguide layer is kept the same.

Figure 6 shows the optical power and conversion efficiency of the 620 nm semiconductor laser under different quantum well strain conditions, and other parameters such as the thickness of the quantum well and the strain size are listed in Table 2. According to design scheme, when the Ge composition in the SiGe layer is 0.88, the strain on the GaInP quantum well is almost zero, and the threshold current of this laser is about 0.92 A. When the Ge composition is 0.92 and 0.90, the quantum well is subjected to tensile strain, and the tensile strain increases with the increase of Ge composition. The threshold current of these two structures is greater than 1 A. When the Ge composition is less than 0.88, the quantum well is subjected to compressive strain and the laser structure threshold current is reduced to 0.65 A for a Ge composition of 0.80. By comparison, the power and conversion efficiency of the tensile strain quantum well laser structure are low, and the characteristics of the compressive strain quantum well laser structure are improved.

To further analyze the reasons for the change in the characteristics of the 620 nm semiconductor laser under different quantum well strain conditions, we extracted the energy band structure and carrier concentration of the device. Figure 7a, b show the conduction band and valence band extracted along the longitudinal direction of the laser. When the SiGe layer Ge composition is 0.80, quantum well is subjected to a compressive strain of about 0.32%, energy band of the structure is changed, and the depth of quantum well increases. The conduction band order ∆Ec = 0.159 eV and the valence band order ∆Ev = 0.08 eV between the waveguide layer and the quantum well when the Ge composition is 0.88; the conduction band order ∆Ec = 0.228 eV and the valence band order ∆Ev = 0.116 eV between the waveguide layer and the quantum well when the Ge composition is 0.80. The electron and hole concentrations in the waveguide layer of this laser structure are reduced by an order of magnitude compared with other structures when the Ge composition in the SiGe layer is 0.80, and the electron and hole concentrations in the P-type and N-type cladding layers of this structure are also the lowest, as shown in Fig. 7c, d. As the quantum well depth increases, the confinement efficiency of carriers is improved, reducing the carrier leakage in the waveguide and cladding layers. Figure 7e shows the non-radiative recombination rate of the device, which can be seen to decrease with the improvement of carrier leakage.

When Si0.2Ge0.8 layer is used, the thickness of Ga0.57In0.43P quantum well has already reached 12 nm. If the compressive strain magnitude continues to increase on this basis, the thickness of the quantum well needs to be thicker, and an excessively thick quantum well will weaken the quantum effect, which will instead worsen the characteristics of the device. To discuss the effect of larger compressive strain, the Ga composition of the quantum well was reduced and the quantum well thickness was adjusted while keeping the excitation wavelength near 620 nm for the characterization, and the detailed quantum well values are shown in Table 3.

Figure 8 shows the optical power and energy band structure of the larger compressive strain quantum well laser structure. We use two structures with no strain and a compressive strain of 0.32% as a comparison. As the compressive strain continues to increase, the threshold current and optical power of larger compressive strain quantum well lasers remain essentially unchanged. The energy bands of large compressive strain quantum well lasers are also not significantly changed compared to the energy band of the compressive strain 0.32% structure as can be seen in the figures (b) and (c). The comparison shows that continuing to increase the compressive strain on the quantum well does not enhance the output characteristics of the device any more. When the compressive strain on the quantum well is 0.32%, there exists an optimal value for the output characteristics of the device.

5 Conclusion

We propose a design of a short-wavelength red semiconductor laser based on a Ge/SiGe substrate with a wavelength of 620 nm and simulate the characteristics of this structure. The effects of interfacial states and different strain quantum wells on the device characteristics are discussed. It is found that the addition of interfacial states to the simulated structure affects the carrier transport by forming a recombination center in the added region, and the non-radiative recombination rate of the device increases, thus reducing the output characteristics of the device. On this basis, changing the quantum well strain conditions for analysis, the quantum well has the best output characteristics when it is subjected to 0.32% compressive strain, with a threshold current of 0.65 A and an output power of 1.63 W can be achieved. Therefore, based on the simulation results, it can be shown that this short-wavelength red semiconductor laser structure design scheme is achievable.

Data availability

The datasets generated during and/or analysed during the current study are available from the corresponding author on reasonable request.

References

B. Sumpf, J. Fricke, P. Ressel, et al. 100,000 h estimated lifetime of 100-μm-stripe width 650 nm broad area lasers at an output power of 1.2 W. in International Society for Optics and Photonics, SPIE. OPTO, 2012, p. 8277

X.Q. Zhan, F.F. Xu, Z.H. Zhou, Y.L. Yan, J.N. Yao, Y.S. Zhao. 3D Laser Displays Based on Circularly Polarized Lasing from Cholesteric Liquid Crystal Arrays. Advanced materials (Deerfield Beach, Fla.), 2021, 33(37).

W. Kikushima, T. Shijo, Y. Furuhata, Y. Sakurada, K. Kashiwagi, Comparison of the 1-year visual and anatomical outcomes between subthreshold red (670 nm) and yellow (577 nm) micro-pulse laser treatment for diabetic macular edema. Pharmaceuticals 14(11), 1100 (2021)

J. Pohl, F. Bugge, G. Blume et al., Combined Mg/Zn p-type doping for AlGaInP laser diodes. J. Cryst. Growth 414, 215–218 (2015)

M.S. Zediker, L. Bao, M. Grimshaw et al., High power diode lasers emitting from 639 nm to 690 nm. Proc. SPIE Int. Soc. Opt. Eng. 8965, 896512 (2014)

T. Ohno, M. Takiguchi, K. Wakabayashi et al., Characteristics of red-emitting broad area stripe laser diodes with zinc diffused window structures. Proc. SPIE Int. Soc. Opt. Eng. 7583(9), 75830W (2010)

K. Kuramoto, T. Nishida, S. Abe, et al. High-power operation of AlGaInP red laser diode for display applications. in Proc. SPIE 9348, High-Power Diode Laser Technology and Applications XIII, 2015, vol. 9348, p. 93480H

A. Bercha, R. Bohdan, W. Trzeciakowski et al., Pressure and temperature tuning of InGaP/AlGaInP laser diodes from red to yellow. Phys. Stat. Solidi 246(3), 508–511 (2010)

A.A. Al-Jabr, B.S. Ooi, H.M. Oubei et al., First demonstration of InGaP/InAlGaP based orange laser emitting at 608 nm. Electron. Lett. 51(14), 1102–1104 (2015)

H.D. Summers, P. Blood, Room temperature operation of ultrashort wavelength (619 nm) AlGaInP/GaInP tensile strained quantum well lasers. Electron. Lett. 29(11), 1007–1008 (1993)

I. Vurgaftman, J.R. Meyer, L.R. Ram-Mohan, Band parameters for III–V compound semiconductors and their alloys. J. Appl. Phys. 89(11), 5815 (2001)

L. Toikkanen, T. Hakkarainen, A. Schramm et al., Metamorphic growth of tensile strained GaInP on GaAs substrate. J. Cryst. Growth 312(21), 3105–3110 (2010)

G. Lin, D. Liang, J. Wang et al., Strain evolution in SiGe-on-insulator fabricated by a modified germanium condensation technique with gradually reduced condensation temperature. Mater. Sci. Semicond. Process. 97, 56–61 (2019)

Y. Yamamoto, C. Corley, M.A. Schubert et al., Threading dislocation reduction of Ge by introducing a SiGe/Ge superlattice. ECS Trans. 98(5), 185–194 (2020)

V.A. Shah, A. Dobbie, M. Myronov, D.J.F. Fulgoni, L.J. Nash, D.R. Leadley, Reverse graded relaxed buffers for high Ge content SiGe virtual substrates. Appl. Phys. Lett. 93(19), 192103 (2008)

T. Lin, H.Q. Zhang, E.M. Guo, R.J. Sun, Y.P. Duan, N. Lin, X.Y. Ma, Study of N ions implantation induced quantum well intermixing in GaInP/AlGaInP quantum well structures. J. Alloys Compd. 650, 336–341 (2015)

T. Lin, Y.N. Li, J.N. Xie, Z.K. Ma, R.J. Zhao, Y.P. Duan, Quantum well intermixing of tensile strain GaInP quantum well structures induced by ion implantation and thermal annealing. Mater. Sci. Semiconductor Process. 138, 106306 (2022)

M. MahfuzAlam, Y. Wagatsuma, K. Okada, Y. Hoshi, M. Yamada, K. Hamaya, K. Sawano, Critical thickness of strained Si1-xGex on Ge(111) and Ge-on-Si(111). Appl. Phys. Express 12(8), 81005 (2019)

R. Scarmozzino et al., Numerical techniques for modeling guided-wave photonic devices. IEEE J. Sel. Top. Quantum Electron. 6(1), 150–162 (2000)

Y. Sun, K. Zhou, Q. Sun et al., Room-temperature continuous-wave electrically injected InGaN-based laser directly grown on Si. Nat. Photonics 10(9), 595–599 (2016)

Acknowledgements

This work was supported by the scientific research program funded by Shaanxi provincial education department (No. 22JP051), key research and development projects in Shaanxi province (No. 2020GY-044) and the Xi'an Science and technology plan project (No. 2020KJRC0077). Thanks to Synopsys for providing the trial version of RSoft simulation tool.

Author information

Authors and Affiliations

Contributions

Jianan Xie wrote the manuscript and prepared the figures, while Tao Lin proposed the device design and gave comments on the manuscript. Cailin Wang directs responses to reviewers' suggestions. Jiahao Shi and Chaoyang Xie check the revised manuscript for typographical problems. All authors reviewed the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this manuscript.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Xie, J., Lin, T., Wang, C. et al. Study of short-wavelength red semiconductor laser using high Ga composition GaInP quantum well based on Ge/SiGe substrate. Appl. Phys. B 129, 48 (2023). https://doi.org/10.1007/s00340-023-07992-2

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00340-023-07992-2