Abstract

A ridge waveguide is manufactured by the technique of O5+-ion irradiation combined with diamond-blade dicing of a zinc sulfide (ZnS) crystal. The waveguide supports single-mode transmission at mid-infrared wavelength of 4 μm. The refractive index distribution of the waveguide is modeled and fits well with the experimental result. After annealing treatment, the propagation loss of the ridge waveguide decreases to 0.4 dB/cm for the TE mode. The measured Raman spectra of the modified region demonstrate that no prominent lattice damage occurs after O5+-ion irradiation in ZnS crystal.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Optical waveguides, as the fundamental components of integrated optics, can restrict light propagating within very small volumes. As a consequence, the light intensity confined within the waveguide volume is much higher than that in the bulk material [1, 2]. Particularly, compared with one-dimensional waveguides, two-dimensional ridge waveguides possess compact geometries and show superior light confinement, which can be used to construct complex integrated photonic system [3, 4]. Currently, there have been several techniques used to fabricate optical waveguides in all kinds of materials, for instance, femtosecond laser writing, ion exchange, film deposition, thermal in-diffusion, and ion irradiation/implantation [5,6,7,8,9,10,11,12,13]. Furthermore, combining ion irradiation with diamond-blade dicing has become an efficient technique to fabricate high-quality two-dimensional waveguide structures in several crystals, such as TGG [14], Yb:YSGG [15], ZnSe [16], etc.

Mid-infrared (MIR) lasers at wavelength range of 2–5 μm cover the atmospheric transmission window. The laser and optical waveguide devices working at this band have significant applications in many fields, such as medical diagnosis, environment monitoring, space optical communication and radar detection [17,18,19,20], etc. As a significant II–VI compound semiconductor material, ZnS possesses outstanding physical properties, such as good refractive index uniformity, wide band gap, excellent transmittance, and image transmission performance in the MIR band [21, 22]. Due to its high hardness, high fracture strength and strong ability to resist harsh environment, ZnS is widely used in the manufacture of infrared windows, fairings, and optical elements. Currently, ZnS waveguide devices with low propagation loss and high thermal stability have been widely investigated in many aspects due to their excellent features in MIR band. As of now, several techniques have been used to manufacture various waveguide structures in ZnS crystal, such as metal organic vapor phase epitaxy (MOVPE) [23, 24], femtosecond laser inscription [25,26,27,28], and ion implantation [29].

Ridge waveguide of mid-infrared crystal can confine mid-infrared light propagation in the waveguide region and prevent the light leaking to the substrate, which can realize the low-loss light propagation and has important applications in mid-infrared optical communication. We aim to find the best preparation parameters of mid-infrared ridge waveguide by ion irradiation technology. However, the investigation on ridge waveguide guiding properties using ion irradiation combined with diamond-blade dicing in ZnS crystal at mid-infrared wavelength range has not been reported up to now. In our work, a ridge waveguide in ZnS crystal has been constructed by the technique of oxygen-ion irradiation combined with diamond-blade dicing. The refractive index distribution, optical transmission characteristics, and Raman spectra of the sample are studied in detail.

2 Experiments in details

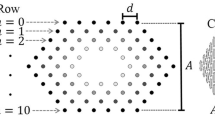

First, a ZnS sample with the size of 10 × 10 × 2 mm3 was irradiated by O5+-ions (25 MeV and 2 × 1014 ions/cm2) using a 6 MV tandem accelerator at the Institute of Semiconductors, Chinese Academy of Sciences. To avoid the channeling effect during irradiation, the ion beam was set at a normal deflection angle of 7°. As well, to reduce the charging and heating effect to the sample, we kept the ion current density within range of 10–30 nA/cm2. In such a way, a planar waveguide layer was generated beneath the sample surface. Afterward, precise diamond-blade dicing technique was utilized through the Automatic Dicing Saw Machine in DISOC Shanghai Corporation. The roughness of DISCO diamond-blade (Technical Specifications: RBT-6669 SD6000R10B01) dicing of a ZnS crystal is 4 nm. The diamond-blade moved on the sample surface to create parallel grooves and the spacing between the two adjacent air grooves was the width of the ridge waveguide. The moving speed and rotating velocity of diamond-blade were set to be 0.05 mm/s and 15,000 rpm, respectively. The minimal width of ridge waveguides can be provided with diamond-blade dicing method is 10 µm. Consequently, we fabricated a ridge waveguide in ZnS crystal. Figure 1 depicts the sketch map of fabrication process of ridge waveguide in ZnS crystal. The guiding properties of ZnS waveguides at MIR wavelength of 4 µm were studied in detail using the end-face coupling system, as shown in Fig. 2.

We used a mid-infrared solid-state laser system at a wavelength of 4 µm (MIR™8025, Daylight Solutions, Inc.). The light beam for TE or TM mode was focused through an MIR microscope objective lens (ZnSe, LFO-5-12-3.75, N.A. = 0.13) and was coupled into and out of the waveguide, and then was focused through another MIR microscope objective lens (ZnSe, LFO-5-12-3.75, N.A. = 0.13). Finally, an MIR camera (Tigris-640, Xenics) and power meter (PM125D, Thorlabs) were employed to record the output modal profile and power of the waveguide, respectively. The nature of propagation loss comes from the roughness of the ridge waveguide sidewall, as well as the defects and color centers in ZnS crystal induced by ion irradiation. As thermal annealing treatment can eliminate the color centers and point defects of the waveguide, it can reduce the propagation loss of the waveguide. We carried out a series of thermal annealing treatments in an annealing oven at 170 ℃ (Step 1), 210 ℃ (Step 2), 250 ℃ (Step 3), 290 ℃ (Step 4), and 330 ℃ (Step 5) in sequence for 30 min each step and measured the propagation loss and near-field modal profile of the waveguide after each step. To investigate the lattice damage of the sample after ion irradiation, we used a confocal micro-Raman spectrometer (Horiba/Jobin Yvon HR800) to detect the micro-Raman spectra of the waveguide and substrate region. We chose a solid-state laser with excitation wavelength of 473 nm and set the measurement range within 100–1000 cm−1.

3 Results and discussion

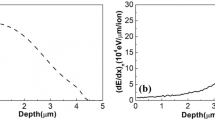

We use stopping and range of ions in matter (SRIM) 2010 software to study the nuclear (Sn) and electronic (Se) stopping powers along the irradiated ion track in ZnS crystal, and then simulate the refractive index distribution of the waveguide. Figure 3a depicts the diagram of Se and Sn curves as a function of the depth of 25 MeV O5+-ions irradiation in ZnS crystal. It can be seen that Sn is almost zero in the depth range of 0–10 μm, and the maximum value of Sn climbs to ~ 0.24 keV/nm at the depth of 12.9 μm. Meanwhile, Se is significantly higher than Sn in the depth range of 0–13 μm, and the maximum value of Se reaches ~ 2.2 keV/nm at the depth of 8.5 μm. Therefore, we can clearly infer that compared with the nuclear damage, electronic damage plays a major role in the formation of waveguide layer.

As the waveguide fabricated by O5+ ion irradiation has higher irradiation energy and deep buried layer, we cannot measure the refractive index distribution of the waveguide by dark mode spectroscopy directly. To obtain the maximum refractive index change value Δn in the waveguide region, we use the equation [30]

in which n = 2.2527 is the refractive index of ZnS substrate at the wavelength of 4 μm, and Θm is the maximum divergence angle of the beam when it leaves or enters the waveguide by rotating a cubic glass. An error of 30% is estimated due to uncertainty of the measured maximum incident angular deflection. By measuring the maximum angle of light Θm (TE) = 11.6° and Θm (TM) = 9.5°, the maximum refractive index contrast of the waveguide can be estimated to be: Δn (TE) = + 0.009 and Δn (TM) = + 0.006. As Δn (TE) > Δn (TM), and it indicates that the waveguide ability to confine light propagation for the TE mode is better than TM mode. The maximum refractive index variation combined with electronic stopping power curve can be used to simulate the refractive index distribution of the waveguide for the TE or TM mode (see Fig. 3b).

Figure 4a shows the cross-sectional image of the ridge waveguide (with width of 20 µm and depth of 13 µm) in ZnS crystal observed using a microscope (Axio imager, Carl Zeiss). We can see that the thickness of the waveguide region is about 13 µm, which is consistent with the simulation of projected range of 25 MeV O5+-ion irradiation in ZnS crystal by SRIM-2010 software. Figure 4b, d shows the measured near-field intensity distribution of the ridge waveguide in ZnS crystals at wavelength of 4 μm before annealing along TE and TM polarizations, respectively. It can be seen that the experimental near-field modes of waveguide at 4 µm exhibit single-mode both along TE and TM polarizations. Based on the reconstructed two-dimensional refractive index profiles along TE and TM polarizations, we used RSoft©Beam Prop software to simulate the near-field light intensity distributions of waveguide, as shown in Fig. 4c, e, respectively. We can find that there is a good agreement between the simulated and experimental results, which verifies that the simulated refractive index distribution is correct.

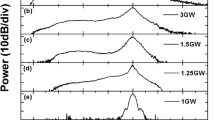

To improve the transmission performance of the waveguide, a series of annealing treatments were carried out and the propagation losses and near-field modal profiles after each annealing were measured, as shown in Fig. 5a, b. As we can see, the near-field modal profiles exhibit single-mode guidance both along TE and TM polarizations after each step of annealing treatment. For the waveguide at TE mode, the propagation loss before annealing was 6.2 dB/cm. After annealing, the propagation loss was reduced to 4.3 dB/cm (step 1), 3.6 dB/cm (step 2), 2.0 dB/cm (step 3), 0.8 dB/cm (step 4), and 0.4 dB/cm (step 5) in sequence. For the waveguide at TM mode, the propagation loss before annealing was 7.3 dB/cm. After annealing, the propagation loss was reduced to 5.1 dB/cm (step 1), 4.4 dB/cm (step 2), 2.5 dB/cm (step 3), 1.1 dB/cm (step 4), and 0.6 dB/cm (step 5) in sequence. These results show that the propagation loss for the TE mode is lower than TM mode, which conforms to the measurement of Δn (TE) > Δn (TM). At the same time, the reason for the waveguide propagation loss reduction is that annealing treatment is helpful to decrease the degree of lattice damage caused by O5+-ion irradiation and optimize the guiding properties of the waveguide. In conclusion, the propagation loss of the waveguide is prominently decreased after annealing, which indicates that annealing treatment is an efficient method to improve the light transmission performance of the waveguide. Compared with the previously reported cladding waveguide fabricated by femtosecond laser inscription in ZnS crystal, the propagation loss of the ridge waveguide in our work is relatively lower [25].

We measured the Raman spectra of the waveguide as well as the substrate and studied the damage of 25 MeV O5+-ion irradiation to the ZnS lattice, as shown in Fig. 6. As it can be seen from the comparison of Raman spectra between waveguide and substrate, the peak intensity, peak position, and peak width did not change significantly, indicating that there is no obvious lattice disorder or stress in ZnS crystal induced by 25 MeV O5+-ion irradiation.

4 Summary

A ridge waveguide is fabricated in ZnS crystals by O5+-ion irradiation combined with diamond-blade dicing. The light conduction characteristics of the waveguide at a mid-infrared wavelength of 4 µm are studied. According to the refractive index reconstruction curve, there is a good agreement between the calculated near-field modal profile and the experimental result. After annealing, the waveguide propagation loss at wavelength of 4 µm is reduced to ~ 0.4 dB/cm for the TE mode. The measured Raman spectra showed that the lattice structure of ZnS crystals does not change significantly after swift irradiation of O5+ ions. This work suggests that the combination of ion irradiation with diamond-blade dicing is an efficient technique to fabricate high-quality ridge waveguides in ZnS crystal and the present results show the potential applications in MIR photonic devices. Further work will concentrate on optimizing fabricating parameters of waveguides with more complex configurations and functions.

References

Y. Jia, F. Chen, Chin. Opt. Lett. 17, 012302 (2019)

Y. Jia, S. Wang, F. Chen, Opto-Electron. Adv. 3, 190042 (2020)

L. Lehmann, L. Grossard, L. Delage, F. Reynaud, M. Chauvet, F. Bassignot, Opt. Express 27, 19233 (2019)

L. Peng, X. Li, Z. Liu, X. Liu, J. Zheng, C. Xue, B. Cheng, Photon. Res. 8, 899 (2020)

B. Zhang, S. He, Q. Yang, H. Liu, L. Wang, F. Chen, Appl. Phys. Lett. 116, 111903 (2020)

Y. Tan, Y. Yao, J.R. Macdonald, A.K. Kar, H. Yu, H. Zhang, F. Chen, Opt. Lett. 39, 5289 (2014)

Y. Jia, L. Wang, F. Chen, Appl. Phys. Rev. 8, 011307 (2021)

G.B. Montanari, P. De Nicola, S. Sugliani, A. Menin, A. Parini, A. Nubile, G. Bellanca, M. Chiarini, M. Bianconi, G.G. Bentini, Opt. Express 20, 4444 (2012)

P. Mutter, C.C. Kores, M. Widarsson, A. Zukauskas, F. Laurell, C. Canalias, Opt. Express 28, 38822 (2020)

R. Tellez-Limon, F. Gardillou, V. Coello, R. Salas-Montiel, J. Opt. 23, 025801 (2021)

J. Huang, J.L. MacManus-Driscoll, H. Wang, J. Mater. Res. 32, 4054 (2017)

Y. Ren, N. Dong, F. Chen, D. Jaque, Opt. Express 19, 5522 (2011)

F. Chen, Laser Photon. Rev. 6, 622 (2012)

Y. Wang, X. Shen, Q. Zhu, C. Liu, Opt. Mater. Express 8, 3288 (2018)

L. Ma, Y. Tan, S. Wang, S. Akhmadaliev, S. Zhou, H. Yu, H. Zhang, F. Chen, J. Lightwave Technol. 35, 2642 (2017)

Y. Cheng, J. Lv, F. Chen, Opt. Mater. Express 5, 2292 (2015)

J. Hu, J. Meyer, K. Richardson, L. Shah, Opt. Mater. Express 3, 1571 (2013)

B. Jean, T. Bende, Solid-state mid-infrared laser sources, I. T. Sorokina and K. L. Vodopyanov 89, 530 (2003)

S. Kameyama, M. Imaki, Y. Hirano, S. Ueno, S. Kawakami, D. Sakaizawa, M. Nakajima, Opt. Lett. 34, 1513 (2009)

U. Willer, M. Saraji, A. Khorsandi, P. Geiser, W. Schade, Opt. Lasers Eng. 44, 699 (2006)

S. Chen, R. Yu, L. Song, R. Zhang, X. Cao, B. Wang, P. Zhang, Appl. Surf. Sci. 498, 143876 (2019)

P.C. Patel, N. Srivastava, P.C. Srivastava, J. Mater. Sci. Mater. Electron. 24, 4098 (2013)

T. Yokogawa, T. Fujita, M. Ogura, T. Kajiwara, J. Cryst. Growth 93, 708 (1988)

E.A. Karhu, C.R. Ildstad, S. Poggio, V. Furtula, N. Tolstik, I.T. Sorokina, J.J. Belbruno, U.J. Gibson, Opt. Mater. Express 6, 2947 (2016)

Q. An, Y. Ren, Y. Jia, J.R. Vázquez de Aldana, F. Chen, Opt. Mater. Express. 3, 466 (2013)

R.R. Gattass, E. Mazur, Nature Photon. 2, 219 (2008)

A. Okhrimchuk, Femtosecond fabrication of waveguides in ion-doped laser crystals, in Coherence and ultrashort pulse laser emission, ed. by F.J. Duarte (InTech, 2010), pp. 519–542

J.R. Macdonald, S.J. Beecher, A. Lancaster, P.A. Berry, K.L. Schepler, S.B. Mirov, A.K. Kar, Opt. Express 22, 7052 (2014)

T. Liu, Y. Yao, F. Liu, L. Cheng, Y. Bao, W. Kong, M. Qiao, T. Wang, Opt. Mater. 112, 110733 (2021)

J. Siebenmorgen, T. Calmano, K. Petermann, G. Huber, Opt. Express 18, 16035 (2010)

Acknowledgements

The work is supported by National Natural Science Foundation of China (NSFC) (No. 11805113), Natural Science Foundation of Guangdong Province (No. 2018A030313280), Project funded by China Postdoctoral Science Foundation (No. 2017M622192), Postdoctoral Innovation Special Foundation of Shandong Province (No. 201703008), Future Program for Young Scholars of Shandong University, and Fundamental Research Funds of Shandong University.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Cheng, Y., Zhang, X. & Song, H. O5+-ion irradiated ridge waveguide operating at mid-infrared wavelength in ZnS crystal. Appl. Phys. B 128, 94 (2022). https://doi.org/10.1007/s00340-022-07817-8

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00340-022-07817-8