Abstract

Intra-cavity pumped Ho laser basing on the biaxial YAP host is investigated here for a direct LD pumped compact polarized 2.1 μm laser at room temperature, where the a-cut and b-cut Tm:YAP and Ho:YAP crystals were applied and placed with the same crystallographic orientation. The maximum output power of 2.47 W at 2118 nm was obtained for the b-cut Ho:YAP laser with a slope efficiency of 15.1%, which is higher than that of 1.08 W at 2130 nm for the a-cut Ho:YAP laser with a slope efficiency of 8.9%, attributed to the better spectral overlap between the intra-cavity Tm laser and polarized absorption profile of the Ho:YAP crystal. Scaling up the output power and slope efficiency of the current Ho:YAP laser is predictable via improving heat management of the current structure further by diffusion bonding the Tm:YAP crystal with another un-doped YAP crystal or using a slab Tm:YAP crystal structure for rapid heat transfer.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Solid-state lasers with wavelength above 2.1 µm have wide applications including differential radar systems, remote-sensing, optical communication, and surgeries [1,2,3]. Especially, owing to the wavelength is away from the two-photon absorption band of the non-oxide mid-infrared nonlinear crystals, they are also ideal pump sources for optical parametric oscillators (OPOs) to generate mid-infrared radiations covering the molecular fingerprint region [4,5,6].

Single Ho3+ ion-doped solid-state lasers are suitable for high-power room-temperature 2.1 µm laser operations due to the significant decrement in cooperative up-conversion loss compared with the traditional Tm3+, Ho3+ ions co-doping manner [7, 8]. Hence, in-band pumped Ho lasers received intensively researched for the past two decades, where the pump sources are usually the high-power Tm-doped bulk or fiber laser systems [9, 10]. However, these cascaded pumping schemes are complex, expensive, and bulky [11], which prohibit the development of a compact accessible Ho laser for lidars or medical applications. Another attractive way for an efficient Ho laser at room temperature is to intra-cavity pump Ho-doped gain media by a diode-pumped Tm laser, which facilitates the direct use of commercial GaAlAs laser diodes.

This compact scheme was theoretically proved to be more abstractive in conversion efficiency from absorbed LD power to Ho laser [12], as the 1.9 μm Tm laser generated from an efficient “2 for 1” cross-relaxation process [13] can be well-confined intra-cavity for pumping the Ho-doped gain medium without leakage outside cavity. Therefore, several intra-cavity pumped Ho lasers had been reported since the first demonstration by Stoneman et al. in 1992 [14]. In 2000, Hayward et al. achieved a maximum output power of 7.2 W at 2097 nm with a poor beam quality M2 ~ 6 from a Tm:YAG laser pumped Ho:YAG laser structure [15]. In 2003, Schellhorn et al. replaced the Tm:YAG crystal by a Tm:YLF crystal with the negative thermal lens for reducing the thermal effects, where the output power of 1.6 W at 2090 nm was obtained with a slope efficiency of 21.2% [16]. In 2013, Zhu et al. demonstrated an 8 W Ho:YAP laser intra-cavity pumped with two dual-end pumped Tm:YLF rods. In the complicated hybrid cavity, incident LD power of 135 W was consumed and the slope efficiency was 10.9% [17]. Besides the mature YAG and YLF hosts, novel intra-cavity pumping mechanisms with the combination of other gain media such as Tm:KLuW-Ho:KLuW [18], Tm:LuAG-Ho:CaF2 [19], and Tm:YAP-Ho:SSO [20] had been investigated recently for a potential compact and accessible 2.1 μm laser.

In this paper, YAP host with similar thermal mechanical properties with YAG crystal and the natural birefringence for polarized operation [21,22,23] was considered for achieving a compact polarized intra-cavity pumped Ho laser, where the a-cut and b-cut Tm:YAP and Ho:YAP gain media were applied and placed with the same crystallographic orientation. Maximum output power of 1.38 W and 2.47 W were obtained from the a-cut and b-cut Ho lasers with lasing wavelengths at 2129.7 nm and 2118.2 nm, respectively.

2 Experimental setup

Before the intra-cavity pumped Ho:YAP laser, samples of the 0.5at.% Ho:YAP crystal were cut with thicknesses of 1 mm for measuring polarized absorption spectra of the Ho:YAP crystal with a Perkin Elmer UV–VIS–NIR spectrometer (Lambda-950). As shown in Fig. 1, the existence of several absorption peaks such as 1917 nm (E//a), 1928 nm (E//b), and 1977 nm (E//c) facilitates the selection of resonant pump wavelengths for in-band pumped Ho:YAP lasers [25,26,27]. However, rigorous spectral control on the extra-cavity 1.9 μm pump sources was needed for sufficient pump absorption in a commonly one-way pumping. Regarding the intra-cavity pumping scheme where Tm laser can be well confined without leakage, pump wavelength at absorption sideband of the Ho-doped gain medium with absorption coefficient above 0.1 cm−1 was enough for an efficient Ho:YAG laser pumped by the Tm:YAG laser [28]. Hence, efficient intra-cavity pumped Ho:YAP laser could be predicted as a wide absorption band from 1860 to 2060 nm with absorption coefficient above 0.1 cm−1 was depicted in Fig. 1, which covers the emission band of the Tm:YAP lasers [29].

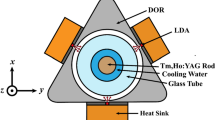

Experimental setup of the Tm:YAP laser intra-cavity-pumped Ho:YAP laser is depicted in Fig. 2. The pump source is a fibre-coupled 792 nm LD with a core diameter of 200 µm and NA of 0.22, which was collimated and focused into the Tm:YAP crystal by a pair of plano-convex lenses F1 and F2 with the focal lengths of 30 mm and 60 mm, respectively. The plano-concave cavity consisted of a pump input mirror (M1) antireflection (AR) coated at 780–810 nm and high-reflection (HR) coated at 1.9–2.15 µm, and an output coupler (M2) with a curvature radius of 200 mm which was HR coated at lasing band of the Tm:YAP laser (1.9–2.02 µm) and had a 10% transmittance at lasing wavelength of Ho:YAP (2.04–2.15 µm). The a-cut and b-cut Tm:YAP (3at.%) and Ho:YAP (0.5at.%) crystals with a cross-section of 3 mm × 3 mm were used, where the Tm:YAP and Ho:YAP crystals were placed with the same crystallographic orientation intra-cavity for seeking potential integrated Tm/Ho:YAP lasers as the reported Tm/Ho:YAG laser in Ref.[24]. End faces of the Tm:YAP and the Ho:YAP crystals were AR coated at the pump wavelength (780–810 nm) and the laser wavelength (1.9–2.15 μm), which were wrapped with the indium foil before mounted into copper heat-sinks for water cooling at 16 °C separately. The a-cut and b-cut Tm:YAP crystals had identical lengths of 17 mm for absorbing the pump light sufficiently. The a-cut Ho:YAP crystals with lengths of 5 mm, 7 mm, and 9 mm and the b-cut Ho:YAP crystals with a length of 5 mm and 7 mm were applied for the a-cut and b-cut Ho lasers, respectively (For simplification, x-cut Ho laser denotes crystallographic x-axes of both Tm-doped and Ho-doped hosts are parallel to the resonator axis). M3 was a dichroic 45°-mirror HR coated at 1.9–2.15 μm and AR coated at 792 nm. The laser power was measured by a power meter (OPHIR, 30 (150) A-LP1-18), and the lasing wavelength was measured by a mid-IR spectrum analyzer (771A-IR, BRISTOL). The total physical length of the plano-concave cavity was 40 mm.

3 Results and discussion

The Tm:YAP laser was studied first before the operation of the Ho laser. In the same experimental setup, M2 was replaced by a plane output coupler with an output coupling of 2% at 1.9–2.02 μm, and the Ho:YAP crystal was removed. The dependences of output power on incident pump power at the temperature of 16 °C was demonstrated in Fig. 3, where maximum output powers of 5.82 W at 1958 nm and 4.18 W at 1999 nm was obtained under incident pump powers of 22 W for the a-cut and b-cut Tm:YAP lasers respectively and the corresponding slope efficiencies were fit to be 32.9% and 23.8%. Polarizations of the a-cut and b-cut Tm:YAP laser were measured to be parallel to the crystallographic c-axis and a-axis of the YAP crystal, respectively.

Output powers and lasing wavelengths of the Tm:YAP lasers: a, b power curves of the a-cut and b-cut Tm:YAP lasers respectively; c, d corresponding lasing wavelength at the maximum output powers of the a-cut and b-cut Tm:YAP lasers respectively. Color regions in (c) and (d) denote polarized absorption curves parallel to crystallographic c-axis and a-axis respectively of the Ho:YAP crystal

In the a-cut Tm:YAP laser pumped a-cut Ho:YAP laser, maximum output powers of 1.08 W, 1.02 W, 0.58 W were obtained with Ho:YAP crystal lengths of 5 mm, 7 mm and 9 mm respectively, where corresponding slope efficiencies were 8.9%, 7.3%, and 5.9%. We attribute the decreased laser efficiency with the increased Ho:YAP crystal length to the increased insertion loss intra-cavity. Although higher lasing efficiency was obtained in the a-cut Tm:YAP laser (Fig. 3), the efficiency of the a-cut Ho:YAP laser was worse compared with the b-cut Ho:YAP laser, where maximum output powers of 2.47 W and 1.38 W were obtained with the 7 mm and 9 mm long b-cut Ho:YAP crystals respectively (Fig. 4b). Moreover, pump thresholds around 5 W of the b-cut Ho:YAP laser were lower than those around 9 W of the a-cut Ho:YAP laser. This is due to the fact that wavelength around 1958 nm of the a-cut Tm:YAP laser (E//c) was fell into the valley of the polarized absorption spectrum (E//c) of the Ho:YAP crystal as depicted in Fig. 3c. Although wavelength around 1999 nm of the b-cut Tm:YAP laser (E//a) also tended to fell into the absorption valley of the Ho:YAP crystal in Fig. 3d, absorption coefficient at 1999 nm was 0.25 cm−1 for laser polarization parallel to the a-axis and larger than that of 1.41 cm−1 at 1958 nm for laser polarization parallel to the c-axis. Hence, lower lasing threshold and the highest slope efficiency of 15.1% can be obtained from the b-cut Ho:YAP laser due to the better spectral overlap between the intra-cavity Tm laser and absorption profile of the Ho:YAP crystal, even though the efficiency of the b-cut Tm:YAP laser was relatively lower (Fig. 3).

As shown in Fig. 5a, wavelengths for the a-cut and b-cut Ho:YAP lasers were stabilized at 2118.3 nm ± 0.6 nm and 2129.3 ± 0.5 nm respectively during the power scaling processes, where typical lasing spectra at each maximum output powers are depicted in Fig. 4a. Beam quality factor M2 measured by a beam quality analyzer (Nanomodescan, Ophir Optronics Ltd.) at the maximum output powers of the a-cut and b-cut Ho:YAP lasers were 2.19 and 1.72 respectively (Fig. 4b). The poor beam quality of the a-cut Ho:YAP laser is attributed to the higher thermal effects due to the low lasing efficiency. Moreover, as the relative lowest thermal conductivity was measured along the b-axis (Pbnm notation) [22], the a-cut Ho:YAP laser with b-axis as the main conduction cooling direction shows weaker heat management and lead to the deteriorated beam quality (as shown in Fig. 5b).

4 Conclusion and perspectives

We have demonstrated a Ho:YAP laser in-band pumped with a diode-pumped Tm:YAP laser in a compact structure, where both Tm:YAP and Ho:YAP crystals were placed with identical crystal orientation intra-cavity. The maximum output power of 2.47 W was obtained at 2118 nm with beam quality factor M2 ~ 1.72. Although lower lasing efficiency of 23.8% was obtained in the b-cut Tm:YAP laser comparing with that of 32.9% in a-cut Tm:YAP laser, a higher Ho laser slope efficiency 15.1% was obtained in the b-cut Ho:YAP laser comparing with that of 8.9% in a-cut Ho laser, attributing to the better spectral overlap between intra-cavity Tm laser and absorption profile of the Ho:YAP crystal. Scaling up the output power and slope efficiency of the current Ho:YAP laser is predictable via improving heat management of the current structure further by diffusion bonding the Tm:YAP crystal with another un-doped YAP crystal or using a slab Tm:YAP crystal structure for rapid heat transfer. The results pave the way to develop a Tm/Ho:YAP laser by diffusion bonding the Tm:YAP crystal with the Ho:YAP crystal and seek the potential Q-switch mode operation [30].

References

T.F. Refaat, U.N. Singh, J. Yu, Appl. Opt. 55, 4232 (2016)

Z. Liu, Y. Chen, Z. Li, J. Lightwave Technol. 33, 1373 (2015)

S. Hein, R. Petzold, R. Suarez-Ibarrola, World J. Urology 38, 753 (2020)

J. Zhang, K. Fai Mak, N. Nagl, Light- Sci. Appl. 7, 17180 (2018)

O.L. Antipov, I.D. Eranov, R.I. Kositsyn, Quant. Electron. 47, 601 (2017)

K.L. Vodopyanov, I. Makasyuk, P.G. Schunemann, Opt. Express 22, 4131 (2014)

G. Rustad, K. Stenersen, IEEE J. Quant. Electron. 32, 1645 (1996)

P. Loiko, R. Soulard, G. Brasse, Opt. Lett. 43, 4341 (2018)

Y.J. Shen, B.Q. Yao, X.M. Duan, Opt. Lett. 37, 3558 (2012)

F. Wang, J. Tang, E. Li, Opt. Lett. 44, 5933 (2019)

S. Lamrini, P. Koopmann, M. Schäfer, Opt. Lett. 37, 515 (2012)

M. Eichhorn, Appl. Phys. B 93, 269 (2008)

E.C. Honea, R.J. Beach, S.B. Sutton, IEEE J. Quant. Electron. 33, 1592 (1997)

R.C. Stoneman, L. Esterowitz, Opt. Lett. 17, 736 (1992)

R.A. Hayward, W.A. Clarkson, D.C. Hanna, Advanced Solid State Lasers (Springer, Davos, 2000).

M. Schellhorn, A. Hirth, C. Kieleck, Opt. Lett. 28, 1933 (2003)

G.L. Zhu, X.D. He, B.Q. Yao, Laser Phys. 23, 015002 (2013)

J.M. Serres, P.A. Loiko, X. Mateos, Appl. Phys. B 120, 123 (2015)

X.M. Duan, X.S. Guo, B.Q. Yao, Laser Phys. Lett. 15, 095802 (2018)

X.T. Yang, W.Q. Xie, L. Liu, Laser Phys. Lett. 14, 085806 (2017)

Y. Lu, Y. Dai, Y. Yang, J. Alloys Compd. 453, 482 (2008)

Q. Dong, G. Zhao, J. Chen, J. Appl. Phys. 108, 023108 (2010)

B. Cole, L. Goldberg, A.D. Hays, Opt. Lett. 43, 170 (2018)

H. Huang, J. Deng, Y. Ge, Opt. Express 27, 13492 (2019)

X.M. Duan, B.Q. Yao, G. Li, Laser Phys. Lett. 6, 279 (2009)

T. Yu, X. Ye, Z. Yang, Fourth International Symposium on Laser Interaction with Matter (International Society for Optics and Photonics, 2017).

L. Guo, S. Zhao, T. Li, Opt. Laser Technol. 126, 106015 (2020)

H. Huang, J. Huang, H. Liu, Opt. Express 26, 5758 (2018)

J. Körner, T. Lühder, J. Reiter, J. Lumin. 202, 427 (2018)

H. Huang, J. Li, J. Deng, Opto-Electron. Adv. 3, 190031 (2020)

Acknowledgements

This work was supported partly by the National Key Research and Development Program of China (Grant No. 2018YFB0407403), the Natural National Science Foundation of China (NSFC) (61875200), and the National Science Foundation for Young Scientists of China (61905246).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Deng, J., Hu, H., Huang, H. et al. Compact Ho:YAP laser intra-cavity pumped by a Tm:YAP laser with identical crystallographic orientation. Appl. Phys. B 127, 76 (2021). https://doi.org/10.1007/s00340-021-07621-w

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00340-021-07621-w