Abstract

We demonstrate an interesting modulation of fast electron temperature and yield as a function of the thickness of nanocrystalline coating on a dielectric target, in femtosecond, intense laser interaction with a solid target. We measure the fast electron energy spectrum for fused silica targets coated with ultrathin, nanocrystalline Cu films with thickness ranging from 30 to 100 nm and compare them with those from a planar, uncoated polished silica surface. The fast electron temperature exhibits an unexpected dependence on the film thickness, peaking at 30 and 45 nm and falling off for films with higher thicknesses. During these experiments, the size of the Cu nanograins was kept constant and only the film thickness was varied. We find that—in the low thickness limit—the target thickness acts as an additional length scale, independent of the surface topography, and needs to be separately optimized for maximizing the generation of fast electrons from high-intensity, ultrashort laser–matter interaction.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

High-intensity, femtosecond laser pulse interaction with solid matter creates extreme states of matter that are otherwise difficult to obtain in the laboratory. The resulting hot, near-solid density plasma is generated via several collective processes [1], leading to relativistic electron jets [2], MeV energy ions [3, 4], high harmonics [5, 6] and electromagnetic radiation in the X-ray [7] and visible (plasma fluorescence, Cherenkov [8], transition radiation [9,10,11]) and terahertz [12] region. Several standard diagnostics are employed in characterizing such plasma emissions and determining the coupling efficiency of the laser with the pre-formed plasma. Electron spectrometry (ESM) [13] is used to directly measure the energy spectra of fast electrons. The distribution curve is a typical bi-Maxwellian [14] with two distinct electron temperatures (owing to the electrons originating from different acceleration and heating mechanisms) that scale as either the square root [15] or one-third [16] power of the laser intensity, depending on the process.

The role of nanostructures on the target surface in these emissions is a topic of major interest in the high-power laser and nanoscience community. It has been shown [17,18,19,20,21] that nanostructures are far more efficient in coupling light than smooth, polished (unstructured) surfaces. At high intensities, the enhancement in coupling is manifested in higher fast electron temperatures, increase in maximum proton energy [22, 23] and greater X-ray yields from the nanostructures. This is attributed, among other factors, to the local electric field enhancement related to the high curvatures of the nanostructures due to the “lightning rod effect” [24] and surface plasmon excitation [18, 25, 26]. In this paper, we study sputter-deposited, nanocrystalline Cu films with different sub-wavelength thicknesses in the range of 30–100 nm, but almost identical size of the Cu nanograins (10–12 nm), which were deposited on 100 \(\mu\mathrm{ m }\) thick, fused silica targets. Our objective was to investigate the effect of the film thickness on the conversion efficiency of laser energy into fast electrons, with reference to uncoated, polished fused silica targets. It is important to note here that for such a comparison to be meaningful, a very high contrast (peak-to-pedestal intensity ratio) laser pulse with very little pre-pulse is necessary; otherwise, the target surface would undergo pre-ionization due to the pedestal before the main pulse which can destroy the nanoparticle coating even before the arrival of the main pulse. We must also point out that the role of coating thickness in double-layer, foam-coated targets has been earlier discussed both numerically [27] and experimentally [28]. Earlier studies mostly involved foam and metal layers that were several microns thick. A previous publication from our own group describes how the ion yield of specific ions can be modulated by varying the crystallite size of Cu between 7 and 25 nm for nanostructured Cu targets of constant thickness (= 0.25 μm) deposited on thick, polished Cu discs. The novelty of the current work lies in the fact that it reports the thickness dependence of nanostructured films in the range of tens of nm while keeping the crystallite size almost constant. This is the range in which we can expect to start observing finite size effects (which is not possible in micron-thick systems) and we do—in fact—observe an unexpected increase in the fast electron temperature with decreasing thickness.

2 Target fabrication and characterization

Nanocrystalline thin films of Cu were deposited on the 100 µm-thick fused silica substrates by dc magnetron sputtering from 99.9% pure, 2-inch diameter, cylindrical targets in an argon atmosphere. The base pressure before deposition was about 1 × 10–6 Torr. Sputtering was carried out in current-controlled mode at 100 mA, while the pressure of the Ar gas was kept constant at 10 mTorr. The rate of deposition was 1.065 ± 0.015 nm/s. Deposition time was varied to obtain films with different thicknesses (30 nm, 45 nm and 100 nm). Field emission scanning electron microscopy (FESEM) was used to measure the film thickness (from cross-sectional samples) and the crystallographic domain size was determined from X-ray diffraction (XRD) line broadening.

X-ray diffraction: The samples were analyzed using a Panalytical Pro powder XRD system. The samples exhibit only the < 111 > diffraction peak in the 2θ-scan range of 20°–80°. Observation of a single peak is not uncommon in sputter-deposited nanocrystalline films that often exhibit a preferred crystallographic orientation [29, 30]. Figure 1 displays the XRD scans of all three samples. The data show shorter 2θ-scans (34°–52°) for the sake of better statistics.

XRD Line profile analysis was performed using the X’Pert Highscore plus 3.0e routine, which uses a modified Scherrer method to calculate the average crystallographic size (which we term as ‘crystallite size’) from the size broadened component of the < 111 > reflection of copper. This method has routinely been used before to estimate the particle size of samples [17, 31]. Following these analyses, we reach the conclusion that the average crystallite size for our samples is ≈ 5 nm.

Topography analysis with SEM: The surface microstructure was further investigated using a high-resolution Zeiss Ultra FESEM. A statistical analysis of the micrographs clearly shows that the mean grain size is centered around (10.5–11.5) nm. In Fig. 2b, we present high magnification SEM images along with histograms of the size distribution obtained from analyses of around 100 randomly chosen grains from each micrograph. Table 1 clearly shows that the three samples have very similar topography in terms of mean grain size and polydispersity despite their different thicknesses.

We should point out that the “particle size” seen by SEM appears larger than the average crystallographic size obtained by the Scherrer method (XRD line broadening). This is because the “particle” in an SEM is often an agglomerated cluster of a small number of crystallites. This is particularly true for particles smaller than ~ 10 nm, which have a stronger tendency to agglomerate. We also expect some “charging” due to the insulating silica overlayer, which tends to artificially increase the size to some extent. Overall, the Scherrer size is the more reliable and self-consistent measure of particle size. It is also averaged over at least 103–104 particles.

Estimate of thickness: Not only does the insulating substrate (fused silica) get charged under the electron beam, but it is also amorphous. Therefore, it is impossible to cleave the sample and image the cross-section under SEM. To measure the thickness, we heated a standard Si < 100 > wafer at 700 °C to produce a thin layer of amorphous SiO2, on top of which we deposited Cu under identical deposition conditions as before. We present a cross-sectional view of this comparison sample in Fig. 3. Since the deposition took place at room temperature, we rule out any significant chemical reaction at the film–substrate interface.

3 Experimental set-up

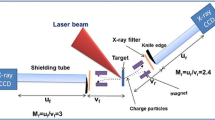

The experiment was carried out with the 100 TW laser facility at Tata Institute of Fundamental Research (800 nm, 25 fs, 10 Hz) which uses the Chirped Pulse Amplification (CPA) technique [32, 33] to deliver ultrahigh-intensity pulses. The nanosecond pulse contrast was measured to be ~ 10–9. An off-axis parabolic (OAP) mirror was used to focus the p-polarized laser beam on the target at an angle of incidence of 45° to a spot size of ~ 10 µm, producing an intensity ~ 1018 W/cm2. Calibrated electron spectrometers (ESM) were placed along target front normal, rear normal and laser propagation (\(\overrightarrow{\mathbf{J}}\times \overrightarrow{\mathbf{B}}\)) direction (Fig. 4) simultaneously to obtain information on the energy spectra of the relativistic electrons along the respective directions. The target is moved with the help of a motorized stage after each laser shot so that the next shot lands on a fresh surface.

4 Results and discussion

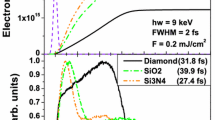

The electron energy spectra along the different directions are shown in Fig. 5 and the fast electron temperatures are summarized in Table 2. Each experimental data point is averaged over tens of laser shots. The fast electron energy distribution is a two-temperature Maxwellian distribution owing to more than one absorption mechanism playing an active role during the interaction. The spectrum is plotted in semi-log scale and fitted with two decaying exponentials (corresponding to a tail of the Maxwellian distribution) to obtain two electron temperatures for the two components. For a semi-log plot, the exponential fitting gives a straight line with slope inversely related to the electron temperature, i.e. T \(\propto -\)(1/slope) and a temperature uncertainty related to the standard deviation (SD) as ΔT \(\propto \) (SD/slope2).

The front normal electron energy spectra (Fig. 5a) show only a single temperature for all the targets (since a good fit cannot be obtained) except plane fused silica. The electron temperature is highest for 100 nm nanocrystalline coating (586 ± 12.1 keV) and all the others exhibit lower electron temperature than uncoated fused silica (60.8 ± 0.1 keV, 148.3 ± 0.7 keV). For the \(\overrightarrow{\mathbf{J}}\times \overrightarrow{\mathbf{B}}\) electron energy spectrum (Fig. 5b), the enhancement in integrated electron flux in the energy range (0.3–0.9) MeV is 3.6 times for 30 nm coating, 2.9 times for 45 nm coating and 2.6 times for 100 nm coating. While the 30 nm coating shows the highest temperature first component (82.8 keV), the 100 nm coating exhibits a temperature component (1154 keV) higher than that for 30 nm coating (828 keV) as well as 45 nm coating (1107 keV) (Table 2), although the difference is marginal in the 45 nm case.

The flux enhancement in the energy range (0.3–0.9) MeV in this case is of the same order as that for the \(\overrightarrow{\mathbf{J}}\times \overrightarrow{\mathbf{B}}\) (laser direction) and rear normal direction (Table 3). Therefore, transport of the fast electrons through fused silica has little role to play in influencing the observed enhancement. It is noteworthy that the enhancement for \(\overrightarrow{\mathbf{J}}\times \overrightarrow{\mathbf{B}}\) and rear normal are higher than that of front normal. This is due to the characteristic angular distribution of fast electrons which shows prominent peaks along the rear normal, laser direction (\(\overrightarrow{\mathbf{J}}\times \overrightarrow{\mathbf{B}}\)), target surface and laser specular directions [34]. Since no such peak occurs along the front normal, the flux along that direction is consequently lower.

Another interesting feature in these results is the element-independent nature of the temperature enhancement. The experiment was repeated with targets coated with nanocrystalline silver with average crystallite sizes in the range 11–41 nm. Although the size was quite different from that of the nanocrystalline Cu (5 nm), the enhancement trend in both cases appears to be similar. This is also an affirmation of the fact that the nanocrystalline metal indeed survives long enough to interact with the main peak. For a low contrast (\(\sim {10}^{-6}\)) laser pulse, Cu nanoparticles, due to their smaller average size, would absorb low-intensity light (laser pre-pulse) more efficiently [23] and form longer pre-plasmas due to its lower melting point than larger sized nanoparticles [35], which would be detrimental to the enhancement. Significantly, these data strongly suggest that the coating thickness plays a dominant role in the enhancement. Depositing nanocrystalline films with thickness below 30 nm (but the grain size held at ≈10 nm) is unfeasible, because the films no longer remain continuous over large areas and show large uncertainties in the thickness. It is, therefore, not clear yet whether this trend of rising electron temperature with decreasing coating thickness continues for even smaller thicknesses or reaches an optimum somewhere. However, it is evident that in the low thickness limit, the thickness itself provides a length scale in addition to the morphology or roughness of the coating which can possibly play an important role in control and optimization of fast electron generation in laser–solid interactions.

In our experiments, we have assumed the absence of any parametric instability mechanism (two-plasmon decay, stimulated Raman scattering) affecting the fast electron generation due to the high peak-to-pedestal ns- contrast of the laser pulse and requirement of high intensity threshold for the SRS to occur [36, 37]. Furthermore, all ion motions and related instabilities (ion-acoustic waves, Langmuir decay instability) were disregarded due to the extremely short interaction time-scales involved.

At the current stage, we are unable to explain the significant thickness dependence of the hot electron temperature and electron yield in the low-thickness limit, and the possible existence of an optimal thickness. Particle-in-cell (PIC) simulations have earlier been successfully used to model micro/nanostructured targets [22, 38], but these studies were exclusively focused on the effects of local surface structure or roughness, typically at the scale of micrometers. The nanostructured targets studied by us are relatively much smoother and since the mean sizes of the nanoparticles on the surface do not change from sample to sample, we can assume that the surface roughness remains approximately constant. Therefore, PIC simulations of the type applied earlier can only be of limited utility in our case, where only the thickness was varied, while keeping the local topography of the surface essentially unchanged.

An interesting recent study has shown that size-dependent changes in the band structure in gold nanoparticles below 30 nm lead to a 100-fold enhancement in multiphoton photoemission at modest intensities [39]. Although this observation has been made at a much lower laser intensity and the explanation is based on a solid-state model, we point out this result as an allusion to the fact that it predicts a similar thickness-dependent enhancement of a non-linear signal. We, therefore, believe that it is important for the community to learn of our experimental results and investigate them further, leading to the unraveling of the origins of the impressive enhancements of fast electrons and X-ray emission observed at extremely high intensities. The above study clearly implies that at small enough dimensions, one would need to incorporate finite size effects and not merely the effect of the surface microstructure.

5 Conclusion

In summary, we have investigated experimentally the laser-plasma coupling efficiency for intense, femtosecond laser interaction in targets coated with nanostructured metal thin films. These experiments were performed with fused silica samples coated with nanocrystalline Cu films of different thicknesses, but with similar particle sizes. We observed higher electron temperature for 30 and 45 nm thick coatings with the 30 nm spectra always higher than the others along all the directions studied, suggesting a higher electron yield and hence a stronger coupling with the laser. This indicates a particle-size (and hence topography) independent enhancement trend in the electron energy and the possible existence of a length scale apart from the particle size, which can be optimized to control the generation of fast electrons in high-intensity laser–matter interaction. Our results should prove useful in designing high-energy, pulsed electron sources, in addition to stimulating the development of more sophisticated modelling techniques, possibly including the effects of size quantization.

References

P. Gibbon, Short Pulse Laser Interactions with Matter (World Scientific Publishing Company, Singapore, 2004)

P.K. Kaw, Rev. Mod. Plasma Phys. 1, 2 (2017)

M. Hegelich, S. Karsch, G. Pretzler, D. Habs, K. Witte, W. Guenther, M. Allen, A. Blazevic, J. Fuchs, J.C. Gauthier, M. Geissel, P. Audebert, T. Cowan, M. Roth, Phys. Rev. Lett. 89, 85002 (2002)

A. Macchi, M. Borghesi, M. Passoni, Rev. Mod. Phys. 85, 751 (2013)

A. Tarasevitch, A. Orisch, D. von der Linde, P. Balcou, G. Rey, J.-P. Chambaret, U. Teubner, D. Klöpfel, W. Theobald, Phys. Rev. A 62, 23816 (2000)

M. Zepf, G.D. Tsakiris, G. Pretzler, I. Watts, D.M. Chambers, P.A. Norreys, U. Andiel, A.E. Dangor, K. Eidmann, C. Gahn, A. Machacek, J.S. Wark, K. Witte, Phys. Rev. E 58, R5253 (1998)

J.D. Kmetec, C.L. Gordon, J.J. Macklin, B.E. Lemoff, G.S. Brown, S.E. Harris, Phys. Rev. Lett. 68, 1527 (1992)

F. Brandl, G. Pretzler, D. Habs, E. Fill, EPL Europhys. Lett. 61, 632 (2003)

S.D. Baton, J.J. Santos, F. Amiranoff, H. Popescu, L. Gremillet, M. Koenig, E. Martinolli, O. Guilbaud, C. Rousseaux, M. Rabec Le Gloahec, T. Hall, D. Batani, E. Perelli, F. Scianitti, T.E. Cowan, Phys. Rev. Lett. 91, 105001 (2003)

M. Manclossi, J.J. Santos, D. Batani, J. Faure, A. Debayle, V.T. Tikhonchuk, V. Malka, Phys. Rev. Lett. 96, 125002 (2006)

J.J. Santos, F. Amiranoff, S.D. Baton, L. Gremillet, M. Koenig, E. Martinolli, M. Rabec Le Gloahec, C. Rousseaux, D. Batani, A. Bernardinello, G. Greison, T. Hall, Phys. Rev. Lett. 89, 025001 (2002)

H. Hamster, A. Sullivan, S. Gordon, R.W. Falcone, Phys. Rev. E 49, 671 (1994)

K.A. Tanaka, T. Yabuuchi, T. Sato, R. Kodama, Y. Kitagawa, T. Takahashi, Y. Honda, S. Okuda, Rev. Sci. Instrum. 76, 13507 (2004)

B. Bezzerides, S.J. Gitomer, D.W. Forslund, Phys. Rev. Lett. 44, 651 (1980)

S.C. Wilks, W.L. Kruer, M. Tabak, A.B. Langdon, Phys. Rev. Lett. 69, 1383 (1992)

F.N. Beg, A.R. Bell, A.E. Dangor, C.N. Danson, A.P. Fews, M.E. Glinsky, B.A. Hammel, P. Lee, P.A. Norreys, M. Tatarakis, Phys. Plasmas 4, 447 (1997)

P.P. Rajeev, P. Taneja, P. Ayyub, A.S. Sandhu, G.R. Kumar, Phys. Rev. Lett. 90, 115002 (2003)

S. Kahaly, S.K. Yadav, W.M. Wang, S. Sengupta, Z.M. Sheng, A. Das, P.K. Kaw, G.R. Kumar, Phys. Rev. Lett. 101, 145001 (2008)

S. Mondal, I. Chakraborty, S. Ahmad, D. Carvalho, P. Singh, A.D. Lad, V. Narayanan, P. Ayyub, G.R. Kumar, J. Zheng, Z.M. Sheng, Phys. Rev. B Condens. Matter Mater. Phys. 83, 1 (2011)

P. Kumar Singh, G. Chatterjee, A.D. Lad, A. Adak, S. Ahmed, M. Khorasaninejad, M.M. Adachi, K.S. Karim, S.S. Saini, A.K. Sood, G. Ravindra Kumar, Appl. Phys. Lett. 100, 244104 (2012)

P.K. Singh, I. Chakraborty, G. Chatterjee, A. Adak, A.D. Lad, P. Brijesh, P. Ayyub, G.R. Kumar, Phys. Rev. Spec. Top. Accel. Beams 16, 1 (2013)

D. Margarone, O. Klimo, I.J. Kim, J. Prokůpek, J. Limpouch, T.M. Jeong, T. Mocek, J. Pšikal, H.T. Kim, J. Proška, K.H. Nam, L. Štolcová, I.W. Choi, S.K. Lee, J.H. Sung, T.J. Yu, G. Korn, Phys. Rev. Lett. 109, 1 (2012)

M. Dalui, W.-M. Wang, T.M. Trivikram, S. Sarkar, S. Tata, J. Jha, P. Ayyub, Z.M. Sheng, M. Krishnamurthy, Sci. Rep. 5, 11930 (2015)

P.P. Rajeev, P. Ayyub, S. Bagchi, G.R. Kumar, Opt. Lett. 29, 2662 (2004)

T. Ceccotti, V. Floquet, A. Sgattoni, A. Bigongiari, O. Klimo, M. Raynaud, C. Riconda, A. Heron, F. Baffigi, L. Labate, Phys. Rev. Lett. 111, 185001 (2013)

L. Fedeli, A. Sgattoni, G. Cantono, A. Macchi, Appl. Phys. Lett. 110, 51103 (2017)

A. Sgattoni, P. Londrillo, A. Macchi, M. Passoni, Phys. Rev. E 85, 36405 (2012)

I. Prencipe, A. Sgattoni, D. Dellasega, L. Fedeli, L. Cialfi, I.W. Choi, I.J. Kim, K.A. Janulewicz, K.F. Kakolee, H.W. Lee, Plasma Phys. Control Fusion 58, 34019 (2016)

R. Banerjee, E.A. Sperling, G.B. Thompson, H.L. Fraser, S. Bose, P. Ayyub, Appl. Phys. Lett. 82, 4250 (2003)

S.K. Mohanta, S.N. Mishra, S. Sarkar, P. Ayyub, Phys. Rev. B 89, 224410 (2014)

S. Bagchi, P. Prem Kiran, M.K. Bhuyan, S. Bose, P. Ayyub, M. Krishnamurthy, G. Ravindra Kumar, Appl. Phys. Lett. 90, 14 (2007)

D. Strickland, G. Mourou, Opt. Commun. 55, 447 (1985)

G.A. Mourou, T. Tajima, S.V. Bulanov, Rev. Mod. Phys. 78, 309 (2006)

P.K. Singh, Y.Q. Cui, A. Adak, A.D. Lad, G. Chatterjee, P. Brijesh, Z.M. Sheng, G.R. Kumar, Sci. Rep. 5, 17870 (2015)

S.L. Lai, J.Y. Guo, V. Petrova, G. Ramanath, L.H. Allen, Phys. Rev. Lett. 77, 99 (1996)

H.A. Baldis, C.J. Walsh, Phys. Fluids 26, 1364 (1983)

W. Seka, B.B. Afeyan, R. Boni, L.M. Goldman, R.W. Short, K. Tanaka, T.W. Johnston, Phys. Fluids 28, 2570 (1985)

L. Fedeli, A. Formenti, L. Cialfi, A. Pazzaglia, M. Passoni, Sci. Rep. 8, 3834 (2018)

S. Großmann, D. Friedrich, M. Karolak, R. Kullock, E. Krauss, M. Emmerling, G. Sangiovanni, B. Hecht, Phys. Rev. Lett. 122, 246802 (2019)

Acknowledgements

GRK acknowledges partial support from the J.C. Bose Fellowship grant JCB-037/2010 from the Science and Engineering Research Board, Government of India.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Sarkar, D., Adak, A., Sarkar, S. et al. Dependence of fast electron characteristics on the thickness of the nanocrystalline film target in intense, ultrashort laser–solid interaction. Appl. Phys. B 126, 151 (2020). https://doi.org/10.1007/s00340-020-07499-0

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00340-020-07499-0