Abstract

It is believed for a long time that optical quality of liquid gain-medium (dye solution) of high pulse-repetition-frequency dye laser is degraded by its turbulent flow but so far this belief is not verified by direct experiment. We have devised a novel experiment to study the exclusive effect of turbulent flow on the optical quality of the dye solution pumped by copper vapour laser. The experiment, based on interferometry, shows that the turbulent flow does not degrade the optical quality of the flowing dye solution.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Tunable dye laser pumped by copper vapour laser (CVL) has found extensive applications in diverse areas of basic and applied sciences due to its continuous tunability over a wide spectral range, efficient narrowband operation, high pulse-repetition-frequency and high average-power. Liquid solutions of dyes are preferred as gain-medium in dye lasers due to many reasons viz.; liquids are optically homogeneous that makes the optical quality of the gain medium very high, concentration of the active species can be controlled conveniently, efficient cooling of the gain-medium can be achieved easily, etc. However, the non-uniform deposition of heat by the pump beam generates refractive-index gradients in the liquid solution and form thermal lens, which deflects the dye laser beam away from the resonator axis. In case of high pulse-repetition-frequency operation of dye laser pumped by CVL, the effect of thermal lensing is cumulative and severe, which degrades the beam quality, reduces the output and ultimately terminates the laser action if stagnant dye solution is used. The problem is solved by changing the pumped dye solution between successive pulses of CVL and pulse-repetition-frequency of CVL governs the flow speed of the dye solution. The hot dye solution, flowing through a dye-cell, is cooled in a dye reservoir in a closed loop circulation system. The requirement that the heated dye solution should be completely removed from the pumped region before arrival of the next CVL pulse makes the flow of the dye solution turbulent at the laser axis in high pulse-repetition-frequency dye lasers pumped by CVL. It is reported that laminar flow of the dye solution across the laser axis is essential to obtain good optical homogeneity of the dye medium [1]. It is also reported that the flow turbulence leads to refractive index non-uniformities in the medium that degrades the optical quality of the gain-medium [2]. Though it is believed for a long time and many papers are published on the assumption that turbulent flow degrades the optical quality of the dye solution but there is no direct experimental evidence for this belief. The observations of these reports are based on the combined effect of turbulent flow and deposited heat on the optical beam quality of flowing dye solution [1, 2]. We have devised a novel experiment to observe the exclusive effect of turbulent flow on the optical quality of the dye solution pumped by high pulse-repetition-frequency CVL. The method is based on interferometry, which is the best way to check the optical quality of a medium. The experiment and the new interesting results are discussed in this paper.

2 Experimental details

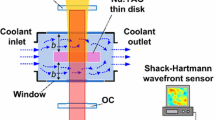

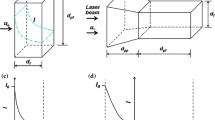

The dye solution was 2 mM solution of Rhodamine 6G in ethanol, which was flowing through an indigenously developed dye-cell [3]. The basic geometry of the flow channel of the dye-cell is shown in Fig. 1.

The flow channel consists of five sections, the first section, where dye solution enters the dye-cell is an inlet rectangular straight duct (ABCDEFGH), the second section is a converging duct (EFGHIJKL), where the speed of the flowing dye solution increases due to gradual reduction of cross-section of the duct, the third section is a narrow rectangular straight duct (IJKLMNOP), where the increased speed of the flowing dye solution remains constant, the fourth section is a rectangular diverging duct (MNOPQRST), where the speed of the flowing dye solution decreases, and the fifth section, where the dye solution flows out of the dye-cell is an outlet straight rectangular duct (QRSTUVWX). The central region of the planar narrow rectangular duct (IJKLMNOP) is the most important region because the dye solution is pumped in this region. The breadth (x), width (y) and height (z) of this section of the flow channel are 20, 0.7 and 30 mm, respectively, and dye solution attains maximum speed here due to constriction of the area. An indigenously developed closed-loop circulation system with a flow-meter (Electronet Equipments Pvt. Ltd, India) was used to flow the dye solution through the dye-cell. In the experiment, the measured flow rate of the dye-solution was 4 L/min. The dye solution was transversely pumped by an indigenously developed CVL, which was operated at a pulse-repetition-frequency of 6.25 kHz. An off-axis confocal positive branch unstable resonator (PBUR) of magnification 100 was applied to the CVL. The schematics of the experimental set-up is shown in Fig. 2.

The output beam of CVL consists of two wavelengths, 510.6 nm (green) and 578.2 nm (yellow) but in a Rhodamine 6G dye laser, the 578.2 nm component is removed from the pump beam because its presence reduces its overall conversion efficiency [4]. The output of CVL was passed through a dichroic mirror (DM) to filter out the 578.2 nm from the beam and only the 510.6 nm was allowed to pump the Rhodamine 6G dye solution. The 510.6 nm beam, folded by two 100% reflecting mirrors (M1 and M2), was line-focussed on the flowing dye solution by a cylindrical lens (CL) of the focal length of 10 cm through dye-cell window W1. The 578.2 nm component of CVL, which is not used in pumping Rhodamine 6G and wasted, was utilized as a probe beam because it is not absorbed by Rhodamine 6G dye solution. It was folded by two 100% reflecting mirrors (M3 and M4) and passed through a convex lens (L1) of the focal length of 20 cm, which was mounted on a translational stage to focus it near the optical-window W3 of the dye-cell. The probe beam was aligned in such a way that it was incident at grazing angle on the inner surface of optical-window W1 of the dye-cell. In this arrangement, the inner surface of the optical-window W1 behaved like a Lloyd mirror and interference between direct-beam and reflected-beam from the inner surface of optical-window W1 of dye-cell produced interference fringes [5]. The interference fringes are observed at the optical-window W4 of the dye-cell. The interferogram, generated in this way, is a measure of optical homogeneity of the gain medium, which is formed near the inner surface of the optical-window W1 of dye-cell. This is the region, which is exposed to the highest fluence of the CVL. The inset figure of Fig. 2 shows the formation of interferogram by the interference of direct and reflected beams of the 578.2 nm probe beam. The interferogram of the gain region was observed under three conditions of the dye solution. In the first condition of the dye solution, it was not flowing and the pump beam was blocked before the cylindrical lens. In the second condition, the pump beam remained blocked but the dye solution was flowing with a volume flow rate of 4 L/min. In the third condition, the dye solution remained flowing but the pump beam was unblocked. In the third condition, the average pump power of 510.6 nm beam, measured by a power meter (Ophir Optronics Inc., Israel), was 130 mW before the cylindrical lens. The interferograms were imaged on the photo-sensor of the CCD (Pixelfly qe, Germany) by a convex lens (L2) of the focal length of 25 cm. An aperture (A) was placed before the CCD camera to block the undesired light and appropriate neutral density filters (NDF) were used to attenuate the beam intensity below the saturation limit of the CCD camera. The CCD camera was used in the internally triggered mode to acquire the image frames of the interferogram and stored in a personal computer (PC) for analysis. The pulse-repetition-frequency of CVL was 6.25 kHz which means that the pulse separation between two consecutive pulses of CVL was 160 μs. In the experiment, the exposure time of CCD was set at 140 μs to ensure that only a single-pulse is recorded. In this experimental arrangement, the nature of interference fringes in the single-pulse interferogram provided an assessment of the optical quality of the gain-medium under three conditions; (a) unpumped dye solution is stagnant (b) unpumped dye solution is turbulently flowing and (c) pumped dye solution is turbulently flowing.

3 Results and discussion

The flow of the dye solution at the laser axis would be turbulent if its Reynolds number is greater than 4000. The Reynolds number (Rn) is defined by the following equation [6],

where ρ is the mass density of the fluid (kg/m3), v is average velocity of the fluid (m/s), μ is dynamic (or absolute) viscosity of the fluid (Ns/m2), and the hydraulic diameter, Dh is defined as

Thus,

where Q is the volume flow rate (m3/s) of the fluid. The Reynolds number of the solution of Rhodamine 6G in ethanol (ρ = 789.4 kg/m3, μ = 1.078 × 10–3 Ns/m2), flowing with a volume flow rate of 4 L/min (6.67 × 10–5 m3/s) through the wetted perimeter (41.4 mm) is 4719, which implies that the flow of the dye-solution is turbulent at the gain region. The interferograms, obtained under the three experimental conditions of dye solution; (a) stagnant and unpumped (b) turbulently-flowing and unpumped (c) turbulently-flowing and pumped, are shown in Fig. 3. These interferograms are used to examine and compare the optical quality of the dye solution in these three conditions. The interferogram, shown in Fig. 3a, contains straight-line fringes of uniform thickness, which indicates that the optical quality of the stagnant and unpumped dye solution does not have refractive index non-uniformities. The straight-line fringes of the interferogram in the vertical direction are not affected by internal bents of the dye-cell because the constricted region (IJKLMNOP of Fig. 1) of the dye-cell along z direction is made sufficiently long (30 mm). The interferogram, shown in Fig. 3b, does not show any distortion of straight-line fringes and is similar to interferogram of Fig. 3a. The similarity of interferograms of Figs. 3a and b establish that the optical qualities of the unpumped dye solutions are the same in stagnant and turbulently-flowing conditions. Consequently, the turbulent flow of the dye solution does not degrade the optical quality of the gain medium.

Figure 3c shows the interferogram of the turbulently flowing dye solution, which was transversely pumped by 510.6 nm of CVL of pulse-repetition-frequency of 6.25 kHz and average power of 130 mW. The interferogram was generated in a single pulse of CVL during which the dye gain medium was not replaced. The CCD camera setting was the same for the earlier two cases also (Fig. 3a, b). A comparison of interferograms, shown in Fig. 3b and c, indicate that when the unpumped, turbulently-flowing dye solution is pumped, the uniform-thickness, straight-line fringes become non-uniform and curved. The optical quality of the turbulently-flowing, pumped dye solution is degraded by the formation of refractive index gradients. The physical factors responsible for the change of refractive index upon non-uniform heating of the flowing dye solution pumped by copper vapour laser are well-reported [7]. It should be noticed that the variation of the refractive index, shown in Fig. 3c, has occurred when pump power was only 130 mW. Generally, dye solutions in dye lasers are pumped by much more power and consequently it would result in large non-uniform variation of refractive index and significant degradation of the optical quality of the gain-medium. This observation explains why key beam quality parameters of dye laser (beam divergence, beam pointing instability, line-width and wavelength fluctuation) become poorer with an increase of pump power of CVL from 2 to 8 W [8].

The novelty of our experiment is that it clearly and unambiguously separates out the effect of turbulent flow on the optical quality of dye solution pumped by high pulse-repetition-frequency CVL. The observation of earlier reports is based on flowing-pumped-dye-solution, which provides the combined effect of turbulent flow and deposited heat. This experiment provides an interferometric evidence that the optical quality of the turbulently flowing dye solution is as good as that of the stagnant dye solution and it is the non-uniform deposition of heat by the pump beam, which is responsible for the degradation of the optical quality of the flowing dye solution.

4 Conclusions

A novel experiment to study the exclusive effect of turbulent flow on the optical quality of turbulently-flowing dye solution pumped by high pulse-repetition-frequency copper vapour laser is proposed, demonstrated and analysed. The method is based on interferometry, which is the best way to check the optical quality of a medium. The method utilizes both spectral components of the output of the copper vapour laser; the 510.6 nm is used for pumping dye solution of Rhodamine 6G and 578.2 nm (which is otherwise wasted in pumping Rhodamine 6G dye solution) as the probe beam due to its non-absorbance in Rhodamine 6G. Contrary to common belief, this interferometric experiment clearly and unambiguously establishes that the turbulent flow of the dye solution does not degrade the optical quality of the gain-medium of high pulse-repetition-frequency dye laser pumped by copper vapour laser.

References

R. Bhatnagar, N. Singh, R. Chaube, H.S. Vora, Rev. Sci. Instrum. 75, 5126 (2004).

R. Bhatnagar, R. Chaube, N. Singh, Appl. Opt. 44, 6962 (2005)

R. Khare, P.K. Shukla, V.K. Shrivastava, J. Kumar, S.R. Daultabad, S.V. Nakhe, Design, Simulation, and Development of Flowing Dye-Cell for High Repetition Rate Liquid Dye Lasers, Transversely Pumped by Copper Vapour Laser (RRCAT Report, RRCAT/2013-07, 2013).

R. Khare, S.R. Daultabad, R. Jain, R. Bhatnagar, Appl. Opt. 37, 4921 (1998)

F.A. Jenkins, H.E. White, Fundamentals of Optics (McGraw-Hill Book Company Inc., New York, 1957)

R.C. King, in Piping Handbook, ed. by R.C. King, S. Crocker. Fluid Mechanics (McGraw-Hill Book Company, New York, 1973).

M. Amit, G. Bialolenker, D. Levron, J. Appl. Phys. 63, 1293 (1988)

R. Mahakud, J. Kumar, O. Prakash, H.S. Vora, S.V. Nakhe, S.K. Dixit, Opt. Laser Technol. 44, 412 (2012)

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Khare, R., Shukla, P.K., Shrivastava, V.K. et al. Optical quality of turbulently flowing dye solution. Appl. Phys. B 126, 123 (2020). https://doi.org/10.1007/s00340-020-07470-z

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00340-020-07470-z