Abstract

We present results on the lasing properties of the Bi-doped high-germania glass fibers thermally treated at different heating and cooling conditions. The absorption and luminescence spectra, the luminescence lifetime of bismuth-related active centers (BACs) formed in the Bi-doped fibers before and after treatment were measured. Analyzing the results, it was shown that the concentration of the BACs could be increased by approximately two times after treatment at certain conditions. A series of experiments regarding laser action at 1730 nm using pristine and treated Bi-doped fibers was performed. From the dependencies of the slope efficiencies of the Bi-doped fiber lasers on the length of the active fibers obtained at various cooling conditions, it was found that the optimal length \({L}\approx 20\) m of the treated active fibers required for the realization of the Bi-doped fiber lasers is two times shorter than that of the pristine fibers. In addition, the efficiency of the developed lasers being \(\approx 18\, \%\) with respect to the absorbed pump power is greater than that of the lasers based on the pristine fibers (\(\approx 10\%\) at \({L} = 20\) m), but it is lower than their maximum efficiency (\(\approx 25 \,\%\) at the optimum lengths of 45 m). From the numerical simulation of the Bi-doped fiber laser, a number of parameters needed for estimation of the native and thermally induced BAC concentrations were determined.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Near-IR broadband luminescence in glass doped with bismuth was observed for the first time 20 years ago [1]. Since then, a significant breakthrough was made in this field, which led to the development of new bismuth-doped optical fibers providing amplification at various IR bands [2,3,4]. Four types of bismuth-related active centers (BACs) named as BAC-Si, BAC-Ge, BAC-P, BAC-Al in accordance with the glass host compositions were identified [5]. The diagrams of low-lying energy levels of these centers were established and presented in [6]. All these fibers have successfully been used for the creation of different optical devices, including CW and pulsed lasers, amplifiers, broadband superluminescent sources, etc. Despite the obvious advantages of the bismuth-doped fibers, there is an unsolved important problem regarding the fabrication of an efficient fiber with a high Bi content (more than 0.1 mol.\(\%\)) that would extend the number of their practical applications. Until now, these fibers have not been manufactured because of the increase of the unsaturable absorption originated from bismuth cluster forms. By now, significant progress in solving this problem has not been achieved.

Considering the key features of the Bi-doped fibers fabricated by the MCVD technique, it should be noted that even at an extremely low Bi content (\(10^{-3}\)–\(10^{-4}\) wt\(\%\)), only a small part of Bi ions participates in the formation of the BACs; while, the other Bi ions remain inactive. Therefore, the conversion of these Bi ions into the active centers seems to be promising. However, it is a difficult task because there is no clear understanding of the structure of the BACs and the valence states of bismuth ions stabilized in a glass host during the technological process. Nevertheless, an approach providing the formation of additional BACs in bismuth-doped fibers by means of treatment under certain thermal conditions was recently demonstrated [7]. It was revealed that the thermally induced growth of the BACs content strongly depends on the initial Bi concentration. Using this technique, the BACs content in Bi-doped high-germania-glass core fibers could be increased by more than two times [8]. The thermally activated processes taking place in the bismuth-doped fibers and the possible mechanisms responsible for the BACs formation were studied using the demarcation energy concept [9]. In [10, 11], it was demonstrated that repeatable quenching process can be used for the formation of additional luminescent centers in Bi-doped aluminosilicate fibers. Further research showed that, besides the formation of the BACs, thermal treatment of Bi-doped fibers initiates the production of Bi centers responsible for the unsaturable absorption. Thus, an improvement of the optical properties of the treated fibers could be achieved by an optimization of the thermal conditions. By now, it has been shown that only heat-treated Bi-doped germanosilicate fibers are capable of providing the net gain and can be used to obtain laser action [7]. Due to this fact, this type of Bi-doped fibers is of interest for a systematical study of the lasing properties of the treated bismuth-doped fibers, which up to date has not been reported in the literature. Therefore, the scope of this paper is to study the spectroscopic and laser properties of the Bi-doped high-\(\hbox {GeO}_2\)-glass core fibers before and after treatment. Our attention mainly focuses on the investigation of the thermal treatment effect on the output characteristics of the lasers based on the Bi-doped fibers treated at different conditions.

2 Experimental

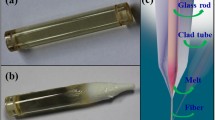

We used a single-mode bismuth-doped high-germania-glass core fiber with an outer diameter of \(125 \,\upmu \hbox {m}\) as an experimental sample. A preform of this fiber was fabricated by the conventional MCVD technique. A high Ge content of \(\approx 50\hbox { mol}.\%\) was required to increase the concentration of the BACs associated with Ge. However, it also led to a high refractive index difference between core and cladding of up to 0.06. As a result, the examined fiber had a very small core diameter of \(2{-}2.5 \,\upmu \hbox {m}\) that was needed to provide a single-mode operation at wavelengths greater than \(1.4{-}1.5 \,\upmu \hbox {m}\). The total concentration of bismuth in the core was estimated to be lower than \(10^{-3}\) wt\(\%\). The small-signal absorption spectra of the investigated fibers were measured by the well-known cut-back technique. The spectroscopic measurements, including the luminescence spectra and decay curves, were performed using the experimental scheme described in detail in [12]. This scheme allows monitoring the change of the luminescence spectra and decay curves of the fibers during heating and cooling processes. The luminescence spectra excited by a Nd-doped fiber laser operating at a wavelength of 925 nm was recorded using an optical spectrum analyzer HP70004A. The recording and collection of the luminescence decay data were conducted by a LeCroy WavePro 7100 oscilloscope, and an InGaAs (PDA 10CS-EC) photodetector. In this case, a semiconductor laser diode at 975 nm used as an excitation source operated in the pulsed regime with a pulse duration of 1 ms. For the laser experiments, we realized a simple scheme consisting of the active fiber spliced with a highly reflective fiber Bragg grating at 1730 nm. It should be noted that despite the fact that, the active fiber had a small core diameter in comparison with an SMF-28-type fiber, we could splice it to the conventional fibers, including the fiber with the Bragg grating, with a relatively low loss of \(\approx 0.5\) dB using a fiber fusion splicing machine of Fujikura FSM-100P. Besides the fiber Bragg grating, feedback in the laser cavity was provided by Fresnel reflection from the opposite end-face of the active fiber. The output power of the bismuth-doped fiber laser was measured by an Ophir Nova II power meter with a 3A-FS detector. All the tested lasers were pumped by a home-made Yb/Er-codoped fiber laser operating at 1568 nm with an output power of several watts.

Thermal treatment of the fibers under investigation was performed using the following furnaces: NAKAL for the spectroscopic measurements; SNOL 40/1180 for the testing of laser characteristics. In the former case, the length of active fibers did not exceed 0.4 m; whereas, in the latter case, tens-meters-long fibers can be used for thermal treatment. A heating rate of both furnaces was kept \(25 \,^\circ \hbox {C/min}\) when a cooling rate varied depending on the temperature range, in particular, \(5{-}10\,^\circ \hbox {C/min}\) for \(300\, ^\circ \hbox {C}< {T} < 500\, ^\circ \hbox {C}\) and \(0.4{-}1\, ^\circ \hbox {C/min}\) for \(25 \,^\circ \hbox {C}< {T} < 300 \,^\circ \hbox {C}\). Before placing the fibers into the furnaces, the polymer coating was mechanically removed. In the luminescence experiments, the investigated fibers placed into the camera of the furnaces were heated up to a certain temperature and then cooled down. The lasing characteristics of the Bi-doped fibers were studied at various cooling conditions after heating. In particular, we used the active fibers heated to a temperature of \(500\, ^\circ \hbox {C}\) and cooled down to a certain temperature and then quickly pulled out from the furnace. In this case, the fiber Bragg grating and the output end of the active fiber were outside of the heating camera. All the measurements of laser characteristics were carried out at room temperature.

3 Results and discussion

3.1 Optical characteristics

The absorption spectra of the bismuth-doped fibers before and after thermal treatment are presented in Fig. 1. The measured spectrum of the pristine Bi-doped fiber in the spectral region of 750–1700 nm consists of two pairs of the bands peaked at 1630, 920 nm, and 1400, 830 nm assigned to BAC-Ge and BAC-Si, correspondingly [5, 6]. One can see that the absorption spectrum of the fiber after thermal treatment changed. This is mainly due to an increase in the intensities of the BAC-Ge bands and the background loss (unsaturable absorption). It was found that both the active and unsaturable absorption increased by two times.

In paper [5], it was revealed that the BAC-Ge is characterized by the luminescence bands at 950 and 1680 nm resulting from the radiative transitions from the second and first excited states to the ground state, correspondingly. Figure 2 shows the emission spectra of the pristine and treated fibers excited at 925 nm where both the characteristic bands belonging to the BACs-Ge can be observed. As it was expected, the intensities of the corresponding luminescence bands increased after thermal treatment. It should be noted that the spectral positions of the maximum and the shapes of the luminescence bands of the BACs-Ge were unchanged. All the observed changes can be explained by the thermally induced formation of the same type of the BACs, namely, BAC-Ge. It is worth noting that the BACs-Si content was almost unaltered.

a Typical decay curves of luminescence peaked at 1680 nm of the Bi-doped high-germania-glass core fibers at different heating temperatures (solid—experimental; dotted—fitting using a double-exponential function); b average lifetime of luminescence as a function of temperature for the heating (squares) and cooling (circles) stages

The decay curves of luminescence peaked at 1680 nm measured at various temperatures of the fibers are demonstrated in Fig. 3a. All the curves obtained can be fitted with reasonable accuracy by a double-exponential function \(I \sim {A}_{1} \cdot \mathrm{exp}(t/{\tau }_{1}) + {A}_{2} \cdot \mathrm{exp}(t/{\tau }_{2})\). For room temperature, the characteristic times of luminescence decays were \(\tau _{1}=450\) (\({A}_{1} \sim 0.6\)) and \(\tau _{2}=970\, \upmu \hbox {s}\) (\({A}_{2} \sim 0.4\)). Both the characteristic times notably decrease (\(\sim 1.5{-}2\) times) with the increase of the temperature as a result of temperature quenching. We calculated the average luminescence lifetime as \({\overline{\tau }} =\frac{ { A }_{ 1 }\cdot { \tau }_{ 1 }^{ 2 }+{ A }_{ 2 }\cdot { \tau }_{ 2 }^{ 2 } }{ { A }_{ 1 }\cdot { \tau }_{ 1 }+{ A }_{ 2 }\cdot { \tau }_{ 2 } }\). In Fig. 3b, one can see that the average lifetime of the studied fiber monotonically decreased from 750 to \(300 \,\mu \hbox {s}\) during the heating stage. The reverse situation, i.e., the growth of the average luminescence lifetime up to the initial value, was observed during the cooling stage. For a better interpretation of the obtained data, we also tried to analyze integrals under the luminescence decay curves. It is well known that in a luminescence decay measurement, the recorded signal is proportional to a function:

where \({ \varGamma }_{ \mathrm{tot} }^{ \mathrm{short}/\mathrm{long} }={ \varGamma }_{ \mathrm{rad} }^{ \mathrm{short}/\mathrm{long} }+{ \varGamma }_{ \mathrm{nrad} }^{ \mathrm{short}/\mathrm{long} }\) is the total decay rate, \({ \varGamma }_{ \mathrm{rad} }^{ \mathrm{short}/\mathrm{long} }\) and \({ \varGamma }_{ \mathrm{nrad} }^{ \mathrm{short}/\mathrm{long} }\) is the radiative and non-radiative decay rates for short or long processes, correspondingly, and \({ \alpha }_{ \mathrm{short}/\mathrm{long} }\) are the relative contributions of these processes.

Equation (1) was obtained using the expression describing a cumulative distribution function with a probability density function presented in [13]. In this case, we excluded a factor containing the part concerning non-radiative processes which are usually negligible for the tested fibers.

So, the total probability for emission at any time between t=0 and t \(\rightarrow \infty\) (i.e., the area under the luminescence decay curve) is given by

where QY is the total quantum yield of luminescence [14]. Thus, the integral under a luminescence decay curve fitted by a double-exponential function is proportional to the total quantum yield of luminescence which is an important characteristic of luminescent media.

We calculated the areas under the experimental luminescence decay curves (for example, the gray area in Fig. 4, inset). The obtained results in terms of \(\varOmega =\frac{ \int _{ 0 }^{ \infty }{ f\left( t,T \right) \mathrm{d}t } }{ \int _{ 0 }^{ \infty }{ f\left( t,300K \right) \mathrm{d}t }} \sim \frac{\mathrm{QY}(T)}{\mathrm{QY}(300\, \mathrm{K})}\) (where T is a temperature of the fiber studied) for the treated Bi-doped fibers are presented in Fig. 4. The obtained temperature dependence of \(\varOmega\) is similar to that derived from the measured luminescence spectra.

It is seen that \(\varOmega\) decreases monotonically with an increase of the heating temperature starting from \(250 \,^\circ \hbox {C}\). It is probably caused by an increased probability of non-radiative processes. Taking into account the similarity of the average lifetimes of luminescence of Bi-doped fiber before and after treatment, the increase of \(\varOmega\) after cooling is also explained by almost twofold growth of the numbers of the BACs-Ge in the treated fiber.

3.2 Lasing characteristics

The results presented above are promising in terms of laser performance improvement. In the following, a series of experiments on lasing using the treated Bi-doped fiber was carried out. The observed output spectrum of a laser operating near 1730 nm is shown in Fig. 5. It consists of two lines at 1568 nm and 1730 nm, which correspond to the pump and lasing wavelengths, respectively.

Figure 6 shows the dependencies of the output powers of the lasers on the pump power for the pristine and treated bismuth-doped fibers (L \(\approx 20\) m). As can be seen from this figure, the slope efficiency of the laser based on the pristine fiber is as low as 10 \(\%\) and 5 \(\%\) with respect to the absorbed and launched pump powers, correspondingly. This was expected since in this case, the used length of the active fiber is not optimal to achieve the maximum efficiency. The use of much longer active fibers was extremely difficult because it would require a special approach for removing the fiber polymer coating, which was not available for us. Nevertheless, we observed a significant enhancement of the output power of the laser based on the heat-treated fiber (threefold approximately at the same pump power level) in comparison with the one based on the pristine fiber. As a result, the slope efficiency of the laser based on the treated Bi-doped fiber achieved 16\(\%\) and 13\(\%\) with respect to the absorbed and launched pump powers, correspondingly. This result could be anticipated given an increase in the active absorption as a consequence of the formation of additional BACs. In addition, we performed the lasing experiments using the bismuth-doped fibers after various treatment conditions, in particular, rapid cooling (to room temperature) starting from different temperatures \(T_{\mathrm{start}}\) after heating of the studied fibers to a temperature of \(500 \,^\circ \hbox {C}\). The slope efficiency of the Bi-doped fiber lasers as a function of \(T_{\mathrm{start}}\) is shown in Fig. 7. It should be noted that an increase in the slope efficiency of the lasers tested was defined as a ratio between the slope efficiencies of the lasers after and before treatment. It is seen that the efficiency of the Bi-doped fiber lasers becomes greater with a decrease of \(T_{\mathrm{start}}\). Starting from \(T_{\mathrm{start}} \sim 350\, ^\circ \hbox {C}\), it saturates at a maximum value of the 1.5-fold and 2.5-fold increase with respect to the absorbed and launched pump powers, correspondingly. Also, we measured the dependencies of the slope efficiency of the developed lasers on the active fiber length (Fig. 8). One can see that the laser based on the pristine fiber has optimal length close to 45 m and a slope efficiency of 23 and 25\(\%\) with respect to the absorbed and launched pump power, respectively. At the same time, the laser with the treated Bi-doped fiber has two-times shorter cavity, while exhibiting a slightly lower maximum efficiency of \(\sim 18\%\). Nevertheless, if it is necessary to create a short fiber laser with a reasonable efficiency, then this approach could be potentially utilized.

3.3 Numerical simulation

To understand the underlying thermally induced processes affecting the optical properties of the active medium, we performed a numerical simulation of operation of the bismuth-doped fiber lasers. We followed the standard approach solving a set of equations that can be presented in the form [15]:

Here, \(p=P^{p}/P_{\mathrm{sat}}^{p}\), \(s^{\pm }=P^{s^{\pm }}/P_{\mathrm{sat}}^{s}\), where \(P^{p}\) is pump power; \(P^{s^{+}}\), \(P^{s^{-}}\) are co-propagating, and counter-propagating signal powers, respectively; \(P_{\mathrm{sat}}^{(p,s)}\) is saturation power at the pump (p) and signal (s) wavelengths; \(\alpha ^{(p,s)}\) and \(\alpha _{\mathrm{BG}}^{(p,s)}\) are the active and unsaturable (background) absorption at the pump and signal wavelengths, correspondingly; \(\eta ^{(p,s)}\) is emission cross-section to absorption cross-section ratio at the pump and signal wavelengths. It is seen that there are parameters \(\alpha ^{p}\), \(\alpha ^{s}\), \(\alpha _{\mathrm{BG}}^{p}\), \(\alpha _{\mathrm{BG}}^{s}\), which are defined by the characteristics associated with both a single BAC structure and their concentration, and parameters \(P_{\mathrm{sat}}^{p}\), \(P_{\mathrm{sat}}^{s}\), \(\eta ^{p}, \eta ^{s}\) which are determined by only a single BAC structure. The set of Eq. 3 was solved numerically under given the boundary conditions:

where \({ p }_{ 0 }\) is the normalized launched pump power; L is the length of the active fiber; \(\rho\) is the output coupler reflectivity (about \(4\%\) in our case). Using \(P_{sat}^{(p,s)}\), \(\alpha ^{(p,s)}\), \(\alpha _{\mathrm{BG}}^{(p,s)}\), \(\eta ^{(p,s)}\) as the adjustable parameters, we fitted the experimental data presented in Fig. 8 with the solution of Eq. 3 in the form of efficiency \(\eta =P_{\mathrm{out}}/P_{\mathrm{in}}\) as a function of the fiber length L (where \(P_{\mathrm{in}}=p_{0}\cdot P_{\mathrm{sat}}^{p}\), and \(P_{\mathrm{out}}= [s^{+} (z=L)-s^{-} (z=L) ]\cdot P_{\mathrm{sat}}^{s}\)). The obtained results of the simulation for the parameters providing the best fit are plotted in Fig. 8. The best-fit parameters are summarized in Table 1. It should be underlined that \(\alpha \left( { \lambda }_{ p } \right) ={ \alpha }^{ p }+{ \alpha }_{\mathrm{BG} }^{ p }\) and \(P_{\mathrm{sat}}^{p}\) were independently determined using the results of the measurements of the small-signal and large-signal absorption. It was found that the parameters derived from the calculation and those derived from the direct measurements are similar.

As can be seen from Table 1, the parameters determined by the characteristics associated with a single BAC were almost invariant. In contrast, the other types of parameters strongly depend on heat treatment. It is important to note that, besides the BACs growth, the concentration of the Bi centers responsible for the unsaturable absorption is also induced by treatment.

The obtained parameters listed in Table 1 were used to estimate the emission and absorption cross sections and the concentration of the BACs. It is well known that the small-signal absorption of a fiber can be expressed using the BACs concentration \(N_{0}\) and the overlap integral \(\varGamma (\lambda _{p} )\) [15]: \({ \alpha }^{ p }={ \sigma }_{ a }\left( { \lambda }_{ p } \right) \cdot { N }_{ 0 }\cdot \varGamma \left( { \lambda }_{ p } \right)\). In the case of small signal, overlap integral can be presented as:

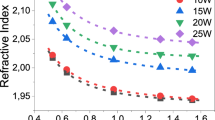

where \({r}_{p}^{2}=2\int _{0}^{\infty }{\psi \left( r,{\lambda }_{p} \right) \cdot r} dr\) is the, so-called, power radius; \(\psi (r, \lambda )\) is the mode envelope, which is introduced according to \(I(r,z)=P(z)\cdot \psi (r,\lambda _{p})/(\pi r_{p}^{2} )\); I(r, z) is the intensity of the light distributed along the transverse, r, and longitudinal, z, direction; n(r) is the normalized distribution of the BACs concentration in the transverse direction. The distribution of n(r) is difficult to measure directly due to a very small overall content of Bi in the fiber core. Nonetheless, we can suppose that as long as Ge is essential to the formation of the BAC-Ge, it is reasonable to assume that to a good approximation concentration profile of the BAC-Ge is similar to that of Ge. Given that Ge was the only element providing the increase of the refractive index of fiber core glass, one can assume that the measured refractive index profile corresponds to n(r). Thus, this assumption can be used for calculation of \(\psi (r, \lambda )\) and then \(\varGamma (\lambda )\) (Fig. 9). Also, the absorption cross section of the BACs-Ge can be independently determined by Eq. 6 using the data from Table 1:

where \(\tau\) is the radiative lifetime of the metastable level. The calculated absorption cross section and concentration values of the BACs-Ge according to this approach are summarized in Table 2. From this table, one can see that the change induced by the thermal treatment is the twofold increase in the concentration of BACs, while the other parameters remained almost unchanged.

Discussing this result, it is important to note that it became possible due to the presence of different states of Bi in the glass host, including various valence states, clusters, etc. However, only a part of the formed centers is laser active. Analysis of the spectral position, the shape of the luminescence/absorption bands and the luminescence decay curves allows us to conclude that the laser-active centers formed after thermal treatment are identical to those existed in the pristine fibers. According to our estimations, the number of bismuth ions in the inactive forms could be \(\sim 1{-}2\) orders of magnitude higher than the concentration of the BACs, which above was evaluated to be equal to \(10^{17} - 10^{18}\) ions per \(\hbox {cm}^{-3}\). However, in reality, we can provide modification of only a small part (\(\sim\) several percents) of the inactive forms to the BACs. This can be explained by various reasons. Firstly, the distribution of the bismuth valence states in the glass is shifted towards strongly the reduced bismuth forms that provide a low content of laser-suitable Bi ions. This is not surprising because of the high temperatures of the MCVD process. In this case, a high content of the precursors of the BACs should not be expected. Secondly, there is only a limited number of sites favorable for the formation of the BACs. The latter assumption follows from the hypothesis that the structure of a BAC consists of a bismuth ion nearby an oxygen-deficiency glass defect. It should be noted that the concentration of these defects in fibers fabricated by CVD technique was estimated as \(\sim 10^{18}\hbox { cm}^{-3}\) that is similar to that of BACs content [16].

Obviously, an increase in the concentration of the BACs leads to a shorter length of the active fiber. Nevertheless, as can be seen in Fig. 8, a maximum efficiency of the lasers, which can be achieved using the treated fibers, decreases in comparison with the lasers based on the pristine fiber. It is caused by the growth of the unsaturable absorption provided by heating process, especially, at the temperatures higher than \(500 \,^\circ \hbox {C}\) [8]. As it was found in [9], the thermally activated reactions leading to the formation of Bi centers are characterized by the different activation energies, namely, 1.1 eV for the BACs and \(>2\) eV for the other Bi centers including the ones responsible for the unsaturable absorption. It is reasonable to assume that given a sufficient number of the BACs precursors in the glass matrix, the annealing process at a relatively low temperature (\(\sim 200\, ^\circ \hbox {C}\)) during a long time has to facilitate predominantly BACs formation. However, in reality, the rate of the formation reaction of the Bi centers responsible for the unsaturable absorption turns out to be significantly greater than that of the BACs formation. That is why any improvements in the laser performance can hardly be achieved using this approach. Moreover, the long-term annealing can cause the undesired crystallization in the core glass of the fiber, which also negatively affects the fiber performance similar to the results obtained in [17]. The observed increase in the slope efficiency with the \(T_{\mathrm{start}}\) (Fig.7) can also be explained by heat-induced changes of the unsaturable absorption, which was revealed earlier [8]. Nevertheless, the origin of this effect is still not understood. It is worth noting that to achieve a higher efficiency, it is necessary to get a sufficient number of the BACs at a minimum growth of the unsaturable absorption that is provided at slow cooling after fiber heating. Rapid cooling starting from \({T}=500\, ^\circ \hbox {C}\), though it is decreasing the unsaturable absorption, is not efficient since the formation of the BACs needs additional time (caused by a low rate of the reaction). All the results described are valid only for this temperature range and this type of Bi-doped fibers. It is important to note that the similar results were obtained in our earlier paper [7] although in that case, we used a bismuth-doped fiber with higher absorption than the one studied here. It allowed us to demonstrate lasing using only \(\sim 9\)-m-long active fiber. Taking into account this result, we might suggest that the number of the Bi centers induced by thermal treatment strongly depends on the conditions for preform fabrication and fiber drawing. However, this study is beyond the scope of the current paper. Perhaps, such a study will be performed in the near future, and the results will be published elsewhere.

4 Conclusion

In summary, the systematical investigation of the optical and lasing properties of the Bi-doped high-germania-glass core fibers thermally treated at different conditions was carried out. It was shown that the intensity of the emission and absorption bands belonging to bismuth-related active centers associated with germanium can be increased by \(\approx 2\) times after heat treatment at certain conditions. It should be noted that the average lifetime of luminescence remained almost the same before and after treatment when the area under the luminescence decay curves proportional to the quantum luminescence yield increased approximately twofold. A series of the experiments regarding laser action in the pristine and treated Bi-doped fibers was performed. The dependencies of the slope efficiencies of the bismuth-doped fiber lasers operating at 1730 nm on the length of the active fibers (heat-treated with different cooling rates) were obtained. It was found that the optimal length of the treated active fibers needed for the realization of Bi-doped fiber lasers is shorter (\(\approx 22\) m) than that of the pristine fibers (\(\approx 45\) m). In addition, the decrease in the maximum efficiency of the Bi-doped fiber lasers based on the active fiber after the treatment was observed and was explained as a result of the growth of the unsaturable absorption in Bi-doped fibers. Numerical simulation of the Bi-doped fiber lasers was performed. The simulated results are in good agreement with the experimental data. Using the parameters derived from the calculation, we estimated the BACs concentrations in the examined fibers, which turned out to be equal to \(\sim 2\,\times \, 10^{17}\,\hbox {cm}^{-3}\) in the pristine fiber and about \(4\,\times \, 10^{17}\,\hbox {cm}^{-3}\) in the heat-treated fiber.

References

K. Murata, Y. Fujimoto, T. Kanabe, H. Fujita, M. Nakatsuka, Bi-doped GeO\(_{2}\) as a new laser material for an intense laser. Fusion Eng. Des. 44(1), 437–439 (1999)

I.A. Bufetov, M.A. Melkumov, S.V. Firstov, K.E. Riumkin, A.V. Shubin, V.F. Khopin, A.N. Guryanov, E.M. Dianov, Bi-doped optical fibers and fiber lasers. IEEE J. Sel. Top. Quantum Electron. 20(5), 111–125 (2014)

N.K. Thipparapu, Y. Wang, S. Wang, A.A. Umnikov, P. Barua, J.K. Sahu, Bi-doped fiber amplifiers and lasers. Opt. Mater. Express 9, 2446–2465 (2019)

S.V. Firstov, S.V. Alyshev, K.E. Riumkin, A.M. Khegai, A.V. Kharakhordin, M.A. Melkumov, E.M. Dianov, Laser-active fibers doped with bismuth for a wavelength region of 1.6–1.8 \(\mu \text{ m }\). IEEE J. Sel. Top. Quantum Electron. 24(5), 1–15 (2018)

S.V. Firstov, V.F. Khopin, I.A. Bufetov, E.G. Firstova, A.N. Guryanov, E.M. Dianov, Combined excitation-emission spectroscopy of bismuth active centers in optical fibers. Opt. Express 19, 19551–19561 (2011)

E.G. Firstova, I.A. Bufetov, V.F. Khopin, V.V. Velmiskin, S.V. Firstov, G.A. Bufetova, K.N. Nishchev, A.N. Guryanov, E.M. Dianov, Luminescence properties of IR-emitting bismuth centres in SiO\(_{2}\)-based glasses in the UV to near-IR spectral region. Quantum Electron. 45, 59–65 (2015)

S. Firstov, A. Kharakhordin, S. Alyshev, K. Riumkin, E. Firstova, M. Melkumov, V. Khopin, A. Guryanov, E. Dianov, Formation of laser-active centers in bismuth-doped high-germania silica fibers by thermal treatment. Opt. Express 26, 12363–12371 (2018)

S.V. Firstov, S.V. Alyshev, V.F. Khopin, A.V. Kharakhordin, A.S. Lobanov, E.G. Firstova, K.E. Riumkin, A.M. Khegai, M.A. Melkumov, A.N. Guryanov, E.M. Dianov, Effect of heat treatment parameters on the optical properties of bismuth-doped GeO\(_2\):SiO\(_2\) glass fibers. Opt. Mater. Express 9, 2165–2174 (2019)

A. Kharakhordin, S. Alyshev, E. Firstova, A. Khegai, M. Melkumov, V. Khopin, A. Lobanov, A. Guryanov, S. Firstov, Analysis of thermally activated processes in bismuth-doped GeO\(_2\)-SiO\(_2\) glass fibers using the demarcation energy concept. Opt. Mater. Express 9, 4239–4246 (2019)

S. Wei, Y. Luo, D. Fan, G. Xiao, Y. Chu, B. Zhang, Y. Tian, M. Talal, M. Lancry, G.-D. Peng, BAC activation by thermal quenching in bismuth/erbium codoped fiber. Opt. Lett. 44, 1872–1875 (2019)

Q. Zhao, Y. Luo, Q. Hao, G.-D. Peng, Effect of thermal treatment parameters on the spectral characteristics of BAC-Al in bismuth/erbium-codoped aluminosilicate fibers. Opt. Lett. 44, 4594–4597 (2019)

S. Firstov, E. Firstova, S. Alyshev, V. Khopin, K. Riumkin, M. Melkumov, A. Guryanov, E. Dianov, Recovery of IR luminescence in photobleached bismuth-doped fibers by thermal annealing. Laser Phys. 26(8), 084007 (2016)

A.F. van Driel, I.S. Nikolaev, P. Vergeer, P. Lodahl, D. Vanmaekelbergh, W.L. Vos, Statistical analysis of time-resolved emission from ensembles of semiconductor quantum dots: Interpretation of exponential decay models. Phys. Rev. B 75, 035329 (2007)

J. Lakwicz, Principles of fluorescence spectroscopy (Springer, Boston, 2006)

E. Desurvire, Erbium-doped fiber amplifiers : principles and applications (Wiley, New York, 1994). “A Wiley-Interscience publication.”

Y. Hosono, H. Abe, D.L. Kinser, R.A. Weeks, K. Muta, H. Kawazoe, Nature and origin of the 5-eV band in \({SiO}_{2}\):\({GeO}_{2}\) glasses. Phys. Rev. B 46, 11445–11451 (1992)

S. Wei, Y. Luo, M. Ding, F. Cai, G. Xiao, D. Fan, Q. Zhao, G. Peng, Thermal effect on attenuation and luminescence of Bi/Er co-doped fiber. IEEE Photonics Technol. Lett. 29, 43–46 (2017)

Acknowledgements

The authors are grateful to A. N. Abramov and N. N. Vechkanov from Institute of Chemistry of High-Purity Substances of RAS for assistance in the fabrication of bismuth-doped fibers. This work was supported by Russian Science Foundation (grant 19-72-10003) (fiber fabrication and investigation of their properties); Russian Foundation for Basic Research (grant 18-32-20003) (lasing experiments using treated fibers).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Kharakhordin, A.V., Alyshev, S.V., Firstova, E.G. et al. Lasing properties of thermally treated \(\hbox {GeO}_{2}\)–\(\hbox {SiO}_{2}\) glass fibers doped with bismuth. Appl. Phys. B 126, 87 (2020). https://doi.org/10.1007/s00340-020-07436-1

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00340-020-07436-1