Abstract

Optical microfibers drawn from conventional fibers have attracted considerable interests and have found many novel applications. Here, we review recent advances in ultrafast fiber lasers based on optical microfibers. Starting with characteristics and fabrication of optical microfibers, which are closely related to ultrafast fiber lasers, we show that characteristics of large portion of evanescent field, tailorable dispersion, high optical nonlinearity, very low optical loss and full compatibility with conventional fibers are greatly beneficial to novel ultrafast fiber lasers. We then highlight recent works on ultrafast fiber lasers based on optical microfibers in terms of fast saturable absorbers made from optical microfiber-supported nanomaterials, dispersion management and high optical nonlinearity, as well as some other novel ultrafast fiber lasers. Finally, we briefly discuss future opportunities for optical microfiber-based ultrafast fiber lasers, such as high-order dispersion management, nonlinearity management and applications for sensing and measurement.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Ultrafast fiber lasers have attracted extensive attentions and great advances have been witnessed in the last 20 years. Benefitted from the merits of high beam quality, excellent heat dissipation, low weight, small size, high stability, low cost, turnkey operation and the least maintenance, ultrafast fiber lasers are becoming commonplace in chemistry, biology and physics laboratory, and find wide applications ranging from nonlinear frequency conversion, optical spectroscopy, ultrafast imaging and precision metrology. The striking advances in ultrafast fiber lasers are stemmed from well understanding and controlling the intracavity nonlinear pulse evolution, and two of the great achievements in the recent 20 years are dispersion management-enabled new types of mode-locked lasers and the discovery of novel saturable absorbers (SAs) bases on nanomaterials.

In ultrafast fiber lasers, the intracavity dispersion is the principal factor for the pulse dynamics and performance. Well understanding has been established on the role of the intracavity dispersion and its landscape on the pulse shaping [1,2,3], and the flexibility of the dispersion management by combining different types and lengths of fibers have brought numerous novel laser operation regimes, pulse performance and the underlying nonlinear dynamics. We recommend the interested readers to refer to Refs. [1,2,3] for insightful reviews.

Saturable absorbers have great impact on the pulse dynamics, and historically they were recognized responsible for self-starting and pulse shaping of passive mode-locked lasers [4]. In ultrafast fiber lasers, widely adopted artificial SAs include nonlinear polarization evolution, nonlinear loop mirror and nonlinear amplifying loop mirror due to their ultrafast response on the fs scale and the fiber-based structures which were easy to implement. However, the non-monotonical transmittance/reflectance with optical power would lead to overdriven artificial SAs, and the birefringence in fibers susceptible to bend, stress and temperature changes would result in a poor mode-locking stability. As an alternative to semiconductor saturable absorber mirror (SESAM) that has been widely adopted in solid-state mode-locked lasers, nanomaterial-based fast SAs have made great progress in the last decades. They have been demonstrated with large modulation depth, low saturation intensity, fast relaxation time of excited carriers and a wide spectral range, from the ultraviolet to the mid-infrared, even to terahertz and radio-wave regimes [5,6,7], thus promising a convenient, reliable and low-cost mode-locked fiber laser.

Optical fibers with specially designed geometric profiles on micro- or nanoscale can show optical waveguiding properties that are significantly different from conventional optical fibers and, therefore, they can be used for dispersion management [8, 9]. In parallel, optical microfibers drawn from conventional fibers, with much simpler design and fabrication techniques than that of microstructured optical fibers, have attracted considerable attentions due to the high optical confinement, large portion of evanescent field, low optical loss and full compatibility with optical systems [10, 11]. A great many applications have been demonstrated ranging from miniatured optical devices, optical sensing [12, 13], optical spectroscopy [14, 15], nonlinear optics [16,17,18], quantum optics and atomic optics [19, 20]. Other than these demonstrations, recent research works show that optical microfibers could also find applications in ultrafast fiber lasers due to the considerably large evanescent field, which enables fast SAs when decorated with novel nanomaterials, and the diameter-dependent dispersion that would be very useful for intracavity dispersion management.

In this review, we mainly focus on recent works on novel ultrafast fiber lasers in which optical microfibers were employed for hybrid fast SAs and the intracavity dispersion management. We first briefly review the characteristics and fabrication of optical microfibers relevant to novel ultrafast lasers in Sect. 2, and we then highlight recent works on ultrafast fiber lasers based on optical microfibers for the fast SAs in Sect. 3, and for the intracavity dispersion management in Sect. 4. We then briefly summarize other novel optical microfiber-based ultrafast lasers in Sect. 5. Finally, we present the related future opportunities in Sect. 6.

2 Characteristics and fabrication of optical microfibers

Optical microfibers show many characteristics that are greatly beneficial for ultrafast fiber lasers, including large portion of evanescent field, tailorable dispersion, low optical insertion loss and high optical nonlinearity. Figure 1 summarizes these characteristics and relevant applications in ultrafast fiber lasers.

2.1 Strong evanescent field

Air-clad optical microfibers are always accompanied by evanescent field around. The electric field in the vicinity of the microfiber surface is considerably large and carries a non-negligible electromagnetic energy. This evanescent field would be beneficial for the interaction between the guided mode with the surrounding materials and enables all-fiber format hybrid SAs, shown in Fig. 2.

Note that directly deposited SAs onto the optical microfiber will become strong scattering centers, leading to a high optical loss, and too strong interactions between the absorbers and the evanescent field could also bring optical damage to both the SA and the optical microfiber. Therefore, SAs can be either deposited on a thicker microfiber, or be dispersed in the polymer solvents, which could be coated onto optical microfibers with high surface quality [21, 22].

2.2 Tailorable dispersion

Ultrafast lasers at around 1 μm and 2 μm can be very useful for many applications, such as laser machining, nonlinear optical frequency conversion and nonlinear optics, optical imaging and spectroscopy, as well as precision metrology. Ytterbium/neodymium and thulium/holmium-doped silica fibers can provide efficient optical gain at 1 μm at 2 μm, respectively. However, material dispersion in these active fibers as well as passive fibers is usually very large, dominating over relative weak waveguide dispersion in conventional fibers, Therefore, dispersion management required in ultrafast fiber lasers was usually achieved by bulky free space optics with careful optical alignment and relative high insertion loss.

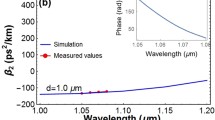

Optical microfibers have large waveguide dispersion that are greatly dependent on the diameter [23]. This waveguide dispersion can be very strong and dominate over the material dispersion that cannot be achieved in conventional fibers. Therefore, optical microfibers can counterbalance the dispersion of conventional fibers and can be used for dispersion management in ultrafast fiber lasers. Figure 3a, b shows the second-order dispersion (β2) of optical microfibers around 1 μm and 2 μm, respectively. The β2 of conventional passive fibers was also displayed in the figures for comparison. It can be seen that the optical microfiber shows a much larger β2 than conventional fibers in magnitude, but with opposite sign, and thus would be very efficient for dispersion management. In addition, the slope of β2 (i.e., the third-order dispersion) is also diameter dependent, so that the third-order dispersion could also be compensated by a proper choice of the diameter.

2.3 Low insertion loss

Optical microfibers can show a very low optical loss due to the ideal surface quality and can continuously connect with conventional optical fibers via adiabatic tapers, enabling highly efficient light launching in and out with almost no optical loss and full compatibility with conventional optical fiber components and systems. Figure 4 shows the measured insertion loss of optical microfibers with a diameter about 1 μm, including the optical loss at the waist of the optical microfibers, the adiabatic tapers and two splices, and a very low insertion loss of less than 0.1 dB on average at around 1000 nm was obtained. A bit higher insertion loss at around 2000 nm (about 0.4 dB in Fig. 4b) may come from a much stronger evanescent field and possible air absorption. Therefore, optical microfibers can serve as low-loss fiber-format functional components. Combined with characteristics of dispersion management and high nonlinearity, this kind of low-loss functional components would be very useful in ultrafast fiber lasers for nonlinear spectral broadening, which would account for ultrabroadband ultrashort pulse generations and diverse intracavity nonlinear dynamics.

2.4 High nonlinearity

The large index contrast of the air-clad optical microfibers enables a tight optical confinement and thus a high nonlinear coefficient γ defined as

where n2 is the nonlinear refractive index, and Aeff is the effective area of the waveguide mode that can be calculated according to [23] and [24]. It can be seen in Fig. 5 that for optical microfibers with a diameter of about 1 μm, γ can be as large as 0.2 and 0.03 m−1W−1at 1 μm and 2 μm, respectively, much higher than that of conventional fibers (i.e., ~ 0.001 m−1W−1). Therefore, optical nonlinear interactions could be much stronger in optical microfibers.

Although high nonlinearity in fiber lasers is a big obstacle for high energy ultrashort pulse generation, enhanced local nonlinearity would be advantageous for ultrabroadband ultrashort pulse and intracavity supercontinuum generations [25], and would be helpful for investigations of nonlinear dynamics such as noise-like pulses, rogue waves, and soliton explosions [26,27,28].

2.5 Fabrication

Optical microfibers with features mentioned above can be very useful for ultrafast fiber lasers. Common fabrication techniques resort to heating and stretching a section of standard optical fiber with a well-controlled heating source, which can be oxygen–butane or oxygen–hydrogen torch flames, focused CO2 laser [29], electric strip heaters [30] and heated sapphire tubes [31], as detailed in [32]. The most widely used technique is a well-developed computer-aided traveling-stage taper-drawing scheme [33, 34], which can produce tens of centimeters long uniform optical microfibers with very low optical loss and well-controlled diameters.

In this scheme shown in Fig. 6, single-mode fibers are usually used as the preform, and hydrogen–oxygen flame serves as the heater providing a high temperature up to ~ 1000 °C. The gases are regulated by mass flow controllers to ensure a finely controlled temperature and heating zone. The fused silica melted from single-mode fibers at high temperature would froze into high-quality surface with a roughness on the order of angstroms that is determined by the surface capillary wave [35, 36], and this guarantees very low optical loss.

Typical experimental setup for traveling-flame taper-drawing scheme [34]

Diameter control is very important for many applications. To achieve well-defined diameter, fiber preforms are hold by traveling stages that are precisely controlled by elaborately designed computer programs. During the drawing process, a single-frequency laser is launched into the optical microfiber by the connected single-mode fibers, and the transmitted power is used to estimate the diameter in real time [34]. With such a scheme, the diameter control accuracy of 5 nm can be achieved; this would guarantee a well-designed dispersion, evanescent field and nonlinearity required in ultrafast fiber lasers. It is worth to mention that after the drawing process, fine diameter tuning, and therefore fine dispersion tailoring, can also be achieved by a modified dip-coating method [37, 38].

3 Ultrafast fiber lasers enabled by microfiber-supported SA

Recent years, great advances have been made in diverse low-dimension nanomaterial-based SAs, including carbon nanotubes, graphene and graphene-like two-dimensional materials, quantum dots and many others. They can show a fast recovery time ranging from 100 fs to a few picoseconds due to the carrier dynamics, and can be conveniently deposited on the surface of fiber connectors to be fully compatible with fiber components, showing advantages of wavelength insensitivity, easy fabrication and low cost. However, they are prone to optical damage, especially for high power lasers. One of the good alternatives is to be supported by optical microfibers. In this case, the low-dimension nanomaterials interact with the evanescent field of optical microfibers with a much lower power to alleviate the optical damage; meanwhile, the interaction length can be extended to achieve a strong enough absorption required for mode-locking.

3.1 Optical microfiber-supported carbon nanotubes

The earliest work of optical microfiber-based (or fiber taper-based) SA was reported by Kieu et al. in 2007 [39]. They deposited single wall carbon nanotubes/polymer composite on an optical microfiber with a diameter of 3–7 μm to initiate mode-locked laser at 1.5 μm, shown in Fig. 7a. The microfiber-supported carbon nanotube/polymer composite showed evident feature of saturable absorption in Fig. 7b. The output power was measured to be 23 mW at a pump power of 260 mW, and the pulse duration was 594 fs with a pulse energy of 1.73 nJ.

a Schematic for the mode-locked fiber laser based on carbon nanotube/polymer composite. b Saturable absorption of the microfiber-based SA. c Interferometric autocorrelation trace at a pump power of 260 mW [39]

In [40], Song et al. used a very similar laser setup and demonstrated obvious advantages of optical microfiber-supported carbon nanotubes for mode-locking, including (1) all-fiber configuration, (2) long interaction length for efficient and intensive passive mode-locking, and consequently low carbon nanotube density to achieve the mode-locking, (3) polarization insensitive operation and (4) easy fabrication.

Kashiwagi et al. demonstrated that carbon nanotubes could be adsorbed on the surface of a microfiber by evanescent fields guided along the fibers [41]. This method could area-selectively deposit desired quantity of carbon nanotubes around microfibers, and could be realized using a simple process and setup.

Optical microfiber-supported carbon nanotubes usually suffer from a high linear loss and poor saturable to non-saturable absorption ratio; this is detrimental for mode-locking. Martinez et al. dispersed carbon nanotubes into low-index polymer, 2,2,2-trifluoroethyl methacrylate (PTFEMA), to achieve a low linear loss of 15% and high saturable to non-saturable ratios approaching 1:1, and this enabled mode-locking startup at a pump power around 10 mW [42].

Optical microfiber-supported SA can also be used for bidirectional mode-locking [43] and can be very useful in intracavity phase interferometry such as real-time absorption spectroscopy measurements [44, 45] and gyroscopic effect detection [46], exempting the complex phase locking apparatus usually required in dual-comb spectroscopy.

Although pulse durations of hundreds of femtoseconds or even picoseonds were demonstrated in the above-mentioned works, it has been shown that ultrashort pulses with a duration of 74 fs could be generated in carbon nanotube-based mode-locked fiber laser by additional dispersion management [47]. Yu et al. showed that this kind of single wall carbon nanotube microfiber SA enabled a 66 fs ultrashort pulse generation [48]. This is the shortest pulse achieved in carbon nanotube mode-locked fiber lasers so far.

3.2 Optical microfiber-supported graphene and its derivatives

Graphene and its derivatives have drawn great attentions because of the unique electronic band structure and resultant electronic and photonic properties. Graphene, graphene oxide and reduced graphene oxide show very broadband saturable absorption for light ranging from near-infrared to mid-infrared, and even for terahertz and microwave [5,6,7], with a fast recovery time of about hundreds of femtoseconds associated with carrier thermalization and a slow one of a few picoseconds due to the interband transition [49, 50]. When they are supported by optical microfibers, the interaction strength between the low-dimensional material and the evanescent field is greatly reduced alleviating from optical damage, while the interaction length is extended profoundly to achieve a large amount of optical nonlinearity.

Wu et al. have demonstrated an effective approach to transfer micron-size CVD graphene layers into freestanding optical microfibers with diameters about 1 μm [51]. The coating length and position of the graphene films could be precisely controlled by micro-manipulation, and the optical transmission and modulation depth can be as high as 73% and 17%, respectively, and the threshold of saturable absorption was greatly lowered compared with that supported on a thicker optical microfiber. This is among the thinnest optical microfiber used for hybrid SAs, but with the highest transmission and modulation depth. When this optical microfiber-supported graphene incorporated into Er-doped fiber laser cavity, they observed mode-locking with a repetition rate of 8.6 MHz, and a pulse duration of 970 fs, shown in Fig. 8.

a Schematic for mode-locked fiber laser based on optical microfiber-supported graphene. b Pulse train and auto-correlation trace of the mode-locked laser [51]

Besides, optical microfiber-supported graphene could show enhanced nonlinearity and can be used for harmonic mode-locking. Zhu et al. have demonstrated a high-order harmonic mode-locking fiber laser using an optical microfiber-supported graphene SA [52]. Depending on the pump power level, up to 101st harmonic mode-locking (at 555 MHz) was obtained.

The repetition rate can be further increased by incorporating optical filters. Qi et al. demonstrated that optical microfiber-supported graphene enabled dissipative four-wave mixing at a low pump power when a Fabry–Perot filter was incorporated inside the cavity and thus mode-locked fiber laser with an ultrahigh repetition rate of 100 GHz was achieved [53]. Optical microfiber-supported graphene could also show polarization-dependent loss, forming a birefringent filter with wavelength selection. In this way, Yang et al. demonstrated a mode-locked laser with a wide tunable range from 1880 to 1940 nm [54].

For graphene oxide and reduced graphene oxide, the presence of oxygen-containing functional groups makes graphene oxide strongly hydrophilic and water soluble, offering superior flexibility and processability for large-scale production, and the bandgap is proportional to the concentration of the oxygen atoms. Optical microfiber-supported graphene oxide and reduced graphene oxide have also been demonstrated in mode-locked fiber lasers. He et al. demonstrated passively mode-locked fiber laser based on reduced graphene oxide deposited on optical microfiber for ultra-wideband doublet pulse generation [55].

3.3 Other low-dimensional materials deposited on optical microfibers

Many other low-dimensional materials, such as transition metal dichalcogenides, topological insulators, black phosphorus, gold nanorod and bismuthene, can show saturable absorption for ultrafast fiber lasers. They can be deposited on optical microfibers with techniques mentioned above. We list these research works in Table 1, and the readers are encouraged to go the references for the details. These results show that optical microfibers are versatile and convenient fiber-compatible platforms for ultrafast fiber lasers, as well as for investigating optical nonlinearities and saturable absorption of various low-dimensional materials.

4 Ultrafast fiber lasers based on dispersion management of optical microfibers

The earliest work for dispersion management in ultrafast fiber lasers by virtue of optical microfibers was reported in Ref. [74]. In this work, a 20 cm-long optical microfiber with a diameter of 1.8 μm was used to offset the normal dispersion of the linear laser cavity, formed by a SESAM and a loop mirror. Soliton mode-locking was enabled by optical microfiber and a pulse duration was a few ps, shown in Fig. 9.

Cavity setup of the mode-locked fiber laser in (a) and the output pulse spectrum and the intensity autocorrelation trace in (b) [74]

Optical microfibers could enable a much shorter pulse duration. In [75], a 25 cm long optical microfiber with a diameter of 1 μm was integrated into a nonlinear polarization evolution-based Yb-doped ultrafast fiber ring laser, shown in Fig. 10a. In addition to intracavity dispersion management, optical microfiber was also used as a dechirping element outside the cavity. It can be observed that typical stretched-pulse spectra were obtained in contrast to the rectangular-like spectrum without optical microfibers shown in Fig. 10b.

a Schematic for Yb ultrafast fiber laser integrated with optical microfibers inside and outside the laser cavity. b Output optical spectra for lasers with (red solid) and without (blue solid) dechirping optical microfiber. Those for lasers with no optical microfiber inside (black dashed) are also shown for comparison. The pump power was about 150 mW and the output power was measured to be 60 mW. c The interferometric autocorrelations for lasers with (red) and without (blue) dechirping optical microfiber [75]

Other than dispersion management, optical microfibers could also be utilized for nonlinearity enhancement due to the tight optical confinement, resulting ultrashort pulses with a broad optical spectral span. The first evidence can be found in Fig. 11b, in which the optical microfiber-dechirped ultrashort pules showed a broader optical spectrum. Yang et al. [76] showed that 18 cm long optical microfibers with a diameter of 1.8 μm could be used for dispersion management and nonlinearity enhancement. This brought to ultrashort pulses with a wide optical spectrum of 37 nm (Fig. 11a), and the intensity autocorrelation showed a pulse duration of 65 fs after dechirped by an optical microfiber with a diameter of 2 μm and a length of 22 cm (Fig. 11b).

a Optical spectrum for mode-locked Yb-doped fiber laser with (red) and without an optical microfiber. The diameter was 2 μm and the length was 18 cm. b Intensity autocorrelation traces for the ultrashort pulses dechirped by a grating pair (red) and optical microfiber (blue) [76]

It is well known that fiber lasers can generate noise-like pulses, with a typical fs/ps double scale autocorrelation traces, under a stronger pump condition and appropriate cavity settings, and the broad optical spectrum can be ascribed to the high intracavity nonlinearity. For microfiber-integrated Yb-doped fiber lasers as shown in Fig. 10a, noise-like pulse generations could be observed under a pump power of 800 mW, and the optical spectrum, spanning from below 1000 nm to beyond 1300 nm, was much broader than that of the lasers without optical microfibers (Fig. 12).

Optical microfibers would also provide large positive dispersion around 2 μm, and this is a very simple and low-loss fiber-format dispersion management solution for Tm-doped and Ho-doped fiber lasers, as demonstrated in [77]. Here, a 10 cm long optical microfiber with a diameter of about 1 μm was incorporated inside a Tm-doped fiber laser to provide a large normal dispersion as high as 2700 ps2/km. This enabled dissipative soliton generation around 2 μm with 50 nm FWHM spectrum and a pulse duration of 195 fs (Fig. 13) after dechirped by a piece of single-mode fiber. Numerical simulations showed that the wide flat-top optical spectrum in Fig. 13b could be ascribed to simultaneous third-order dispersion compensation of optical microfibers.

a Optical spectrum for dissipative soliton in Tm-doped fiber lasers enabled by optical microfiber. b The intensity and interferometric autocorrelations for the dechirped dissipative solitons [77]

5 Other applications

Combining the intrinsic high nonlinearity of the SA and elongated interaction length provided by optical microfiber, these kinds of SAs can show strong nonlinearity and can be highly beneficial to nonlinear dynamics of ultrafast fiber lasers, such as soliton molecule [78, 79], dissipative optical rogue wave [80], soliton rains [81], and noise-like pulses [82].

It is surprising that bare optical microfiber can also show saturable absorption. Ref. [83] used I-scan technique to show that optical microfibers with a diameter of 25 μm behaved like SA with a contrast of 1.78% and a saturated intensity of 251.91 MW/cm2. Mode-locking was obtained by incorporating this optical microfiber inside the Er-doped fiber laser cavity.

Optical microfiber could also be used to assemble polarization-sensitive components. All-fiber mini-polarizer can be formed by overlapping two optical microfibers. The strong polarization-dependent transmission can be used in ultrafast fiber lasers based on nonlinear polarization evolution [84].

6 Summary and outlook

Optical microfibers have diameter dependent-evanescent field which could provide a fiber-compatible optical interface for the interaction between the deposited nanomaterials and intracavity optical field. This enables optical microfiber-supported SAs that would be very important for self-starting stable mode-locking operating for ultrafast lasers and lasers with ultrahigh repetition rates. The tailorable dispersion and high optical nonlinearity due to the high optical confinement can be very useful for dispersion management that could not be achieved with conventional fibers. Combined with the high optical nonlinearity, low optical loss and negligible splicing loss, ultrafast lasers based on optical microfibers can also show a very broad spectrum, promising a short pulse duration and many interesting intracavity nonlinear dynamics. Features such as tunable optical filtering and polarization sensitivity would promise many other interesting ultrafast lasers.

Beside the advances shown in this review, we would like to mention that future progress could be made as below:

-

(1)

design and fabrication of cascaded optical microfibers or optical microfibers with precisely controlled profile to cope with high-order dispersion. This would promise to fully exploit the dispersion capability of optical microfibers, which are impossible, or at least not easy, for conventional dispersion management techniques.

-

(2)

Optical microfiber-supported nanomaterials with low saturable absorption threshold, high optical damage threshold and high nonlinearity. This would provide a new avenue for intracavity nonlinearity enhancement and promise rich nonlinear dynamics unexplored before. In addition, nanomaterials can also show a large negative Kerr nonlinearity [85]. This could be used to cancel the excessive nonlinear phase accumulation in conventional fiber ultrafast lasers and increase the ultrashort pulse peak power.

-

(3)

Multi-functionalized optical microfiber-based ultrafast lasers for applications optical sensing, precision spectroscopy due to the evanescent field and interaction with the environment. In this scenario, optical microfibers not only serve as dispersion management and fiber-format SA support for ultrafast lasers, but also provide a platform for interaction with the environment, and therefore promising applications based on reliable all-fiber ultrafast lasers [45, 86].

References

L.E. Nelson, D.J. Jones, K. Tamura, H.A. Haus, E.P. Ippen, Appl. Phys. B. 65, 277 (1997)

A. Chong, W.H. Renninger, F.W. Wise, J. Opt. Soc. Am. B. 25, 140 (2008)

W.H. Renninger, A. Chong, F.W. Wise, IEEE. J. Sel. Top. Quantum. Electron. 18, 389 (2012)

B.K. Garside, T.K. Lim, J. Appl. Phys. 44, 2335 (1973)

Y.W. Wang et al., Nanoscale. 9, 4683 (2017)

Z. Zheng et al., Opt. Express. 20, 23201 (2012)

V. Bianchi et al., Nat. Commun. 8, 15763 (2017)

W.H. Reeves et al., Nature. 424, 511 (2003)

K. Saitoh, M. Koshiba, T. Hasegawa, E. Sasaoka, Opt. Express. 11, 843 (2003)

L.M. Tong, M. Sumetsky, Subwavelength and Nanometer Diameter Optical Fibers (Zhejiang University Press, China, 2009)

L.M. Tong, F. Zi, X. Guo, J.Y. Lou, Opt. Commun. 285, 4641 (2012)

J. Lou, Y. Wang, L. Tong, Sensors. 14, 5823 (2014)

G.Y. Chen, M. Ding, T.P. Newson, G. Brambilla, Open. Opt. J. 7, 32 (2013)

A. Godet et al., Optica. 4, 1232 (2017)

J.-C. Beugnot et al., Nat. Commun. 5, 5242 (2014)

T.A. Birks, W.J. Wadsworth, P.S. Russell, Opt. Lett. 25, 1415 (2000)

M.A. Foster, A.C. Turner, M. Lipson, A.L. Gaeta, Opt. Express. 16, 1300 (2008)

Y.H. Li, Y.Y. Zhao, L.J. Wang, Opt. Lett. 37, 3441 (2012)

P. Schneeweiss, S. Zeiger, T. Hoinkes, A. Rauschenbeutel, J. Volz, Opt. Lett. 42, 85 (2017)

K.P. Nayak, M. Sadgrove, R. Yalla, F.L. Kien, K. Hakuta, J. Opt. 20, 073001 (2018)

Z.Y. Xu, Y.H. Li, L.J. Wang, Opt. Lett. 39, 34 (2014)

C. Daengngam et al., Opt. Express. 19, 10326 (2011)

L.M. Tong, J.Y. Lou, E. Mazur, Opt. Express. 12, 1025 (2004)

A. Coillet, G. Vienne, P. Grelu, J. Opt. Soc. Am. B. 27, 394 (2010)

M. López-Ripa, S. Jarabo, F.J. Salgado-Remacha, Opt. Lett. 44, 2016 (2019)

P. Grelu, N. Akhmediev, Nat. Photon. 6, 84 (2012)

N. Akhmediev, J.M. Soto-Crespo, M. Grapinet, P. Grelu, Opt. Fiber. Technol. 11, 209 (2005)

Y. Jeong, L.A. Vazquez-Zuniga, S. Lee, Y. Kwon, Opt. Fiber. Technol. 20, 575 (2012)

J.M. Ward et al., Rev. Sci. Instrum. 77, 083105 (2006)

L. Ding et al., Appl. Opt. 49, 2441 (2010)

M. Sumetsky, Y. Dulashko, A. Hale, Opt. Express. 12, 3521 (2004)

J.M. Ward, A. Maimaiti, V.H. Le, S.N. Chormaic, Rev. Sci. Instrum. 85, 111501 (2014)

G. Brambilla et al., Adv. Opt. Photon. 1, 107 (2009)

Y. Xu, W. Fang, L. Tong, Opt. Express. 25, 10434 (2017)

G. Zhai, L. Tong, Opt. Express. 15, 13805 (2007)

M. Sumetsky, Opt. Lett. 31, 870 (2006)

J. Lou, L. Tong, Z. Ye, Opt. Express. 13, 2135 (2005)

Z.Y. Xu, Y.H. Li, L.J. Wang, Opt. Express. 22, 28338 (2014)

K. Kieu, M. Mansuripur, Opt. Lett. 32, 2242 (2007)

Y.-W. Song, K. Morimune, S.Y. Set, S. Yamashita, Appl. Phys. Lett. 90, 021101 (2007)

K. Kashiwagi, S. Yamashita, Opt. Express. 17, 18364 (2009)

A. Martinez et al., APL. Photon. 2, 126103 (2017)

K. Kieu, M. Mansuripur, Opt. Lett. 33, 64 (2008)

L. Arissian, J.-C. Diels, Laser. Photon. Rev. 8, 799 (2014)

S. Mehravar, R.A. Norwood, N. Peyghambarian, K. Kieu, Appl. Phys. Lett. 108, 231104 (2016)

A.A. Krylov, D.S. Chernykh, E.D. Obraztsova, Opt. Lett. 42, 2439 (2017)

D. Popa et al., Appl. Phys. Lett. 101, 153107 (2012)

Z. Yu et al., Laser. Phys. 24, 15105 (2014)

S. Yamashita, J. Lightwave. Technol. 30, 427 (2012)

S. Yamashita, APL. Photon. 4, 034301 (2019)

X. Wu et al., Carbon. 96, 1114 (2016)

P.-F. Zhu et al., Laser. Phys. Lett. 10, 105107 (2013)

Y. Qi et al., Opt. Express. 23, 17720 (2015)

G. Yang et al., Laser. Phys. Lett. 13, 65105 (2016)

X. He et al., J. Lightwave. Technol. 30, 984 (2012)

J. Du et al., Sci. Rep. 4, 06346 (2014)

M. Liu et al., Opt. Express. 22, 22841 (2014)

F. Lu, Mod. Phys. Lett. B. 31, 1750303 (2017)

P. Yan et al., Opt. Mater. Express. 5, 479 (2015)

W. Liu et al., Nanoscale. 9, 5806 (2017)

W. Liu et al., Opt. Express. 25, 2950 (2017)

Z.-C. Luo et al., Opt. Express. 23, 20030 (2015)

H. Yu, X. Zheng, K. Yin, X. Cheng, T. Jiang, Appl. Opt. 54, 10290 (2015)

F. Lu, Mod. Phys. Lett. B. 31, 1750206 (2017)

J. Yin et al., Opt. Express. 25, 30020 (2017)

J. Wang et al., Photon. Res. 6, 535 (2018)

J. Wang et al., Opt. Lett. 43, 1998 (2018)

K. Zhang et al., Photon. Res. 6, 893 (2018)

Z.-C. Luo et al., Opt. Lett. 38, 5212 (2013)

P. Yan, R. Lin, S. Ruan, A. Liu, H. Chen, Sci. Rep. 5, 08690 (2015)

J. Du et al., Sci. Rep. 7, 42357 (2017)

B. Guo et al., Opt. Express. 26, 22750 (2018)

X. Wang et al., Laser Phys. 26, 65105 (2016)

M. Rusu, R. Herda, S. Kivisto, O. G. Okhotnikov, Opt. Lett. 31, 2257 (2006)

L. Wang et al., Sci. Rep. 8, 4732 (2018)

P. Yang et al., Opt. Lett. 43, 1730 (2018)

Y. Li, L. Wang, Y. Kang, X. Guo, L. Tong, Opt. Lett. 43, 6105 (2018)

B. Liu et al., Appl. Phys. B. 124, 151 (2018)

A. Luo et al., Opt. Express. 22, 27019 (2014)

M. Liu et al., Opt. Lett. 40, 4767 (2015)

Z. Wang et al., Appl. Phys. Express. 11, 072504 (2018)

Z. Wang et al., Laser. Phys. Lett. 15, 85103 (2018)

R. Zhao, G. Li, B. Zhang, J. He, RSC. Adv. 8, 912 (2018)

Z. Zhang et al., Opt. Lett. 40, 784 (2015)

N. Vermeulen et al., Phys. Rev. Appl. 6, 044006 (2016)

K. Krzempek, G. Dudzik, K. Abramski, Opt. Express. 26, 28861 (2018)

Acknowledgements

This work is supported by the National Natural Science Foundation of China (NSFC) (11527901, 61475140, 61505096), Fundamental Research Funds for the Central Universities and Open Foundation of the State Key Laboratory of Modern Optical Instrumentation.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

This article is part of topical collection on Optical Nanofibers and Microresonators by Síle Nic Chormaic, Misha Sumetsky, Lan Yang.

Rights and permissions

About this article

Cite this article

Li, Y., Wang, L., Li, L. et al. Optical microfiber-based ultrafast fiber lasers. Appl. Phys. B 125, 192 (2019). https://doi.org/10.1007/s00340-019-7303-z

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00340-019-7303-z