Abstract

Background gas in a rubidium vapor cell coated with paraffin as an anti-spin-relaxation coating was investigated. The cell was opened in a vacuum chamber to release background gas that was analyzed with a quadrupole mass spectrometer. The background gas was mainly composed of hydrocarbons of C3 and higher, as well as hydrogen.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Some materials that coat the inner surfaces of alkali-metal vapor cells suppress the spin relaxation of gaseous alkali-metal atoms when they collide with cell walls. Paraffin, which consists of long chains of saturated hydrocarbons, has been one of the most popular materials for cell coatings since the discovery of its anti-relaxation performance back in the late 1950s [1]. Alkali vapor cells with anti-spin-relaxation coatings are currently used for various purposes, such as atomic clocks [2, 3], ultra-sensitive magnetometry [4,5,6], quantum memory [7], and studies of light propagation [8]. Although the presence of background gas has been paid attention to and carefully avoided in some cases [9, 10], the cells are usually considered free of buffer gas, in which alkali-metal atoms travel without colliding with background gas between the cell walls [11]. Recently, it has been shown that in paraffin-coated cells, alkali-metal atoms actually suffer velocity-changing collisions (VCCs) in background gas, the pressure of which was estimated to be on the order of 1 Pa [12]. This relatively high pressure must be taken into account in precision frequency standard applications [13] and for the transport of alkali-metal vapor [14]. Thus, identification of possible gas species in paraffin-coated cells is necessary.

In this paper, we directly analyzed the background gas molecules in a paraffin-coated rubidium (Rb) vapor cell. The cell was fabricated in the work described in Ref. [12]; its basic properties, such as the spin-relaxation rate and the VCC rate of Rb atoms, are already known. The cell was opened in a vacuum chamber in which background gas was released and analyzed using a quadrupole mass spectrometer (QMS). The background gas was composed mainly of hydrocarbon molecules as well as hydrogen. Similar measurements have been performed for Rb vapor cells coated with Surfasil, an isomeric mixture of dichlorooctamethyltetrasiloxane [15]. Here, the main mass peaks were identified at 2 (\(\hbox {H}_2^+\)), 58 ((\(\hbox {CH}_3\))\(_2 \hbox {Si}^+\)), 43 (\(\hbox {CH}_3 \hbox {Si}^+\)), 28 (\(\hbox {Si}^+\)), 15 (\(\hbox {CH}_3^+\)), 85/87 (\(^{85} \hbox {Rb}^+\), \(^{87} \hbox {Rb}^+\)), and 101/103 (\(^{85} \hbox {RbO}^+\), \(^{87} \hbox {RbO}^+\)) in atomic mass units (amu), with possible detected ion species indicated in parentheses. There are other reports of gas analyses for silicon compound films, such as octadecyltrichlorosilane [16] and polydimethylsiloxane [17], but not for paraffin to date.

2 Experiments and discussion

The cell examined in this study was the paraffin-coated Rb vapor cell reported as cell #6 in Ref. [12] when the fabrication procedure of the cell was described in detail. Briefly, commercial paraffin wax (Sasolwax H1) was distilled at between 220\(^{\circ }\)C and 240\(^{\circ }\)C and used as a coating material. The former trademark of Sasolwax H1 is Paraflint H1 [18, 19]. It is expected to consist of linear hydrocarbon molecules mostly. Its molecular weight is 880 g/mol, and thus, the average number of carbon is about 60. The inner walls of the cell were coated by heating an evacuated cell containing a piece of the paraffin at 380\(^{\circ }\)C, and then, a small amount of Rb metal was introduced. The cell was cylindrical and made of Pyrex glass, with an inner diameter of 17 mm and length of 24 mm. The spin-relaxation time of Rb atoms was 0.24 s, corresponding to about 5000 collisions with the cell walls without relaxation. VCCs were also measured. Under the assumption of strong collisions, the VCC rate was estimated to be \(2.6\times 10^6\) \(\hbox {s}^{-1}\). This was the highest VCC rate among cells investigated in Ref. [12]. Assuming a typical collision cross-section of \(1 \times 10^{-14}\) \(\hbox {cm}^2\) and a typical relative mean velocity of \(1 \times 10^{5}\) cm/s, we estimated the corresponding mean free path and pressure to be 0.4 mm and 11 Pa, respectively. Similar VCC rates have been observed for other coated cells made in our laboratory using the same procedure, as well as one produced in a different laboratory, indicating that relatively high pressure of background gas in paraffin-coated cells is normal.

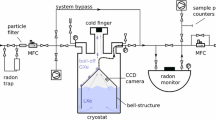

Figure 1 shows a schematic drawing of the experimental setup. The chamber where the cell was placed was connected to a QMS through a variable leak valve. The pressure of the chamber, measured using a cold cathode ion gauge, reached 6 \(\times 10^{-5}\) Pa by pumping through the main valve with a turbomolecular pump backed by a scroll pump. The cell was broken by pressing the arm of the cell with a metal block attached to the linear motion drive. The main valve was closed before breaking the cell, and the leak valve was kept open. The released gas then moved into the QMS through the leak valve and was detected. The vacuum gauge was turned off during gas measurement to prevent consumption of the released gas.

The QMS was operated with a secondary electron multiplier (SEM) to increase the detection sensitivity. It was repeatedly scanned from 1 to 60 amu during the measurement. Each scan took 3.4 s. We limited the mass range to 60 amu to minimize the evacuation of the released gas during the scanning time.

Figure 2 shows mass spectra. The vertical axis represents calibrated current, which is proportional to the product of the SEM output current and the square root of the mass, according to a general rule for rough calibration for the ion mass dependence of the gain of the SEM [20]; the calibrated current is, thus, roughly proportional to impinging ion current. Data were recorded one scan before and after a scan during which the cell was broken. The spectrum taken before the cell was broken shows the main components of the residual gas in the chamber at 18 amu (\(\hbox {H}_2 \hbox {O}^+\)), 28 amu (\(\hbox {N}_2^+\), \(\hbox {CO}^+\)), 30 amu (\(\hbox {NO}^+\), \(\hbox {C}_2 \hbox {H}_6^+\)), and 44 amu (\(\hbox {CO}_2^+\)). After the cell was broken, the released gas was detected. Notably increased peaks in the spectrum occurred at 2, 15, 26–29, 39–43, and 53–57 amu. The 2-amu component corresponds to \(\hbox {H}_2^+\), indicating that the gas released from the cell contained hydrogen molecules. The 15, 26–29, 39–43, and 53–57 amu peaks are very likely \(\hbox {CH}_3^+\), \(\hbox {C}_n \hbox {H}_{\mathrm{m}}^+\) with \(n = 2, 3\), and 4, respectively. These peaks originate from hydrocarbon molecular gases.

Although the measured relative intensities of the peaks do not directly reflect the composition of the background gas for several reasons, such as differences in transportation and QMS detection efficiencies among molecules, the main hydrocarbon gas components can be roughly estimated by referring to a database of mass spectra [21]. Methane, \(\hbox {CH}_4\), shows the strongest fragment peak at 16 amu, rather than 15 amu, as measured in the experiment; therefore, we can exclude \(\hbox {CH}_4\) from the main gas components. The C2 hydrocarbons, \(\hbox {C}_2 \hbox {H}_6\), \(\hbox {C}_2 \hbox {H}_4\), and \(\hbox {C}_2 \hbox {H}_2\), can also be excluded because their strongest peaks are at 28, 28, and 26 amu, respectively, rather than 27- and 29-amu peaks as measured in the experiment. Note that the strongest fragment mass peaks do not necessarily match the masses of parent molecules. C3 and higher hydrocarbons appear to be the main components of the background gas. High peaks at mass 41 and 55 indicate that the background gas contains unsaturated hydrocarbon molecules, such as pentene (\(\hbox {C}_5 \hbox {H}_{{10}}\)) and hexene (\(\hbox {C}_6 \hbox {H}_{{12}}\)); alkanes do not have strong fragment peaks at these two masses.

The presence of relatively large hydrocarbon molecular gas in paraffin-coated cells was shown from our measurements. This result may require larger VCC cross-sections and smaller relative velocities than \(1\times 10^{-14}\hbox { cm}^2\) and \(1\times 10^5\hbox { cm/s}\), respectively, to estimate background gas pressures from measured VCC rates. Regarding spin relaxation, hydrocarbon molecules have generally small spin-relaxation cross-sections for alkali-metal atoms [22] and do not affect spin-relaxation times under present background gas pressures. However, the properties of alkali-metal atoms colliding with large hydrocarbon molecules have not been well investigated, and may be required for high-precision applications. For example, larger hydrocarbon molecules cause larger hyperfine pressure shifts at a given pressure [13], and should, thus, be paid more attention to for frequency standard applications, in addition to interactions with coatings [3, 23, 24].

We consider that the background gas components depend on the type of paraffin. The cell analyzed above was coated with a distilled commercial paraffin wax that was a mixture of hydrocarbon molecules with a typical molecular weight of 880 g/mol. For comparison, we put Rb metal and triacontane \(\hbox {C}_{{30}} \hbox {H}_{{62}}\) (analytical standard, Sigma-Aldrich) into an evacuated Pyrex glass ampoule, which was then sealed to be heated for 16 h at 80\(^{\circ }\)C, in a manner similar to the ripening process of the cell [12]. We expected that the ripening process produced background gas as reported in Ref. [12]. The triacontane was melt during the ripening process, because its melting temperature is 65\(^{\circ }\)C. We then opened the ampoule in an apparatus similar to the one described above for mass analysis. We found mass peaks mainly at 2 and 28 amu. Mass peak groups around 41 and 55, corresponding to \(\hbox {C}_n \hbox {H}_{\mathrm{m}}^+\) (\(n = 3, 4\)) were detected but not prominent. In addition, the peaks of the mass group around 55 were much smaller than those of the mass group around 41. Although quantitative comparison between the coated cell and the ampoule is not straightforward, because they were prepared using different procedures, this notable difference strongly implies that background gas components depend on the paraffin type.

3 Conclusions

In this paper, we analyzed the background gas components in anti-spin-relaxation-coated cells for Rb vapor. We found that the main components were C3 and higher hydrocarbon molecules, including unsaturated ones, as well as hydrogen. We also showed that background gas components very likely depend on the paraffin type.

The reaction between alkali-metal and anti-spin-relaxation coatings can be a source of background gas in coated cells; however, the mechanism is not well understood. It has been reported that alkene-based coatings transform from \(\alpha\)- to \(\beta\)-olefin by interaction with alkali metal [25]. This process may play an important role in extraordinary long spin-relaxation times of over 1 min [26]. Our results and further investigations on different types of hydrocarbon coatings will provide useful information to elucidate the chemical processes between alkali-metal vapor and hydrocarbon films, as well as for the application of coated cells to high-precision measurements.

References

H.G. Robinson, E.S. Ensberg, H.G. Dehmelt, Bull. Am. Phys. Soc. 3, 9 (1958)

H.G. Robinson, C.E. Johnson, Appl. Phys. Lett. 40, 771 (1982)

T. Bandi, C. Affolderbach, G. Mileti, J. Appl. Phys. 111, 124906 (2012)

J. Dupont-Roc, S. Haroche, C. Cohen-Tannoudji, Phys. Lett. A 28, 638 (1969)

D. Budker, D.F. Kimball, S.M. Rochester, V.V. Yashchuk, M. Zolotorev, Phys. Rev. A 62, 043403 (2000)

D. Budker, M. Romalis, Nat. Phys. 3, 227 (2007)

B. Julsgaard, J. Sherson, J.I. Cirac, J. Fiurasek, E.S. Polzik, Nature 432, 482 (2004)

D. Budker, D.F. Kimball, S.M. Rochester, V.V. Yashchuk, Phys. Rev. Lett. 83, 1767 (1999)

M.A. Bouchiat, J. Brossel, Phys. Rev. 147, 41 (1966)

S.J. Seltzer, M.-A. Bouchiat, M.V. Balabas, in Surface Coatings for Atomic Magnetometry, eds, by D. Budker, D.F. Jackson Kimball. Optical Magnetometry (Cambridge University Press, Cambridge, 2013) pp. 205–224

M. Klein, M. Hohensee, D.F. Phillips, R.L. Walsworth, Phys. Rev. A 83, 013826 (2011)

N. Sekiguchi, A. Hatakeyama, Appl. Phys. B 122, 81 (2016)

C.W. Beer, R.A. Bernheim, Phys. Rev. A 13, 1052 (1976)

M. Giraud-Carrier, T. Decker, J. McClellan, L. Bennett, A. Hawkins, J. Black, S. Almquist, H. Schmidt, J. Vac. Sci. Technol. A 35, 031602 (2017)

J.C. Camparo, R.P. Frueholz, B. Jaduszliwer, J. Appl. Phys. 62, 676 (1987). (4008 (1987) (Erratum))

Y.W. Yi, H.G. Robinson, S. Knappe, J.E. Maclennan, C.D. Jones, C. Zhu, N.A. Clark, J. Kitching, J. Appl. Phys. 104, 023534 (2008)

S.N. Atutov, R. Calabrese, A.I. Plekhanov, L. Tomassetti, Eur. Phys. J. D 68, 6 (2014)

N. Castagna, G. Bison, G. Di Domenico, A. Hofer, P. Knowles, C. Macchione, H. Saudan, A. Weis, Appl. Phys. B 96, 763 (2009)

S.J. Seltzer, D.J. Michalak, M.H. Donaldson, M.V. Balabas, S.K. Barber, S.L. Bernasek, M.-A. Bouchiat, A. Hexemer, A.M. Hibberd, D.F. Jackson Kimball, C. Jaye, T. Karaulanov, F.A. Narducci, S.A. Rangwala, H.G. Robinson, A.K. Shmakov, D.L. Voronov, V.V. Yashchuk, A. Pines, D. Budker, J. Chem. Phys. 133, 144703 (2010)

J.F. O’hanlon, A User’s Guide to Vacuum Technology (Wiley, New York, 1980)

E. Stenhagen, S. Abrahamsson, F.W. McLafferty (eds.), Atlas of Mass Spectral Data (Interscience Publishers, Geneva, 1969)

R.J. McNeal, J. Chem. Phys. 37, 2726 (1962)

R.G. Brewer, J. Chem. Phys. 38, 3015 (1963)

E.P. Corsini, T. Karaulanov, M. Balabas, D. Budker, Phys. Rev. A 87, 022901 (2013)

OYu. Tretiak, J.W. Blanchard, D. Budker, P.K. Olshin, S.N. Smirnov, M.V. Balabas, J. Chem. Phys. 144, 094707 (2016)

M.V. Balabas, T. Karaulanov, M.P. Ledbetter, D. Budker, Phys. Rev. Lett. 105, 070801 (2010)

Acknowledgements

We thank A. Matsumura for his technical support. N.S. is a Research Fellow of the Japan Society for the Promotion of Science (JSPS). This work was supported by a Grant-in-Aid for Scientific Research on Innovative Area, “Nano Spin Conversion Science” (Grant no. JP15H01013) from MEXT, Japan, and by JSPS KAKENHI Grant numbers JP17J03089 and JP17H02933.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Hatakeyama, A., Kuroda, T., Sekiguchi, N. et al. Analysis of background gas in an alkali-metal vapor cell coated with paraffin. Appl. Phys. B 125, 133 (2019). https://doi.org/10.1007/s00340-019-7243-7

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00340-019-7243-7