Abstract

In laser incubation, the irradiated material reaches the ablation threshold after N pulses at a fluence (energy per unit area) lower than the one required for a single shot. In this work, a new unified picture of incubation is presented describing the growth rate of incubation sites in terms of an analytical expression having four parameters which can be fitted to the experimental data. Our model predicts two crossovers as a function of the pulse number N: \({N}_{\text{c}}^{\text{'}}\) and \({ N}_{\text{c}}\), describing the different incubation behaviors of materials under the action of ‘below-threshold’ laser pulses. For dielectric materials, and metals irradiated with short laser pulses, the first crossover indicates a transition from a dielectric type of surface response towards an increasingly ‘metallic’ behavior, consistent with the experimental observations. The second crossover determines the transition to the final stage of the modified surface. In this large N limit, the absorption coefficient of the surface achieves its saturation. For metals irradiated by long laser pulses, \({N}_{\text{c}}^{\text{'}}\)≃ 0 and \({N}_{\text{c}}\) ≫ 1, yielding an approximate power-law behavior of fluence versus N, over a broad range of N values, in agreement with the observations. It is found that one of the fitting parameters denoted here as the incubation exponent, δ, allows us to classify the material response as a dielectric (δ \(\gtrsim\)1) or a metallic (δ ≪ 1) one.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Laser ablation is a process in which a material is removed from a solid by irradiation with pulsed laser beams. The physical mechanism involved is dependent on the material nature such as dielectric (metal in place of dielectric) [1], semiconductor [2], dielectric [3], and laser characteristics as wavelength [4], pulse duration [5, 6], and repetition rate [7]. However, some general features are common to all of them. The removal of material can occur following two distinct paths such as: (a) thermal evaporation (equilibrium conditions) for ns or longer laser pulses, and (b) Coulomb explosion (out of equilibrium) for fs/ps laser pulses [8, 9].

In (a), the irradiated area is overheated, and once a critical temperature is reached, the material starts evaporating or exploding (thermal explosion), leaving a crater on the surface [10]. In metals, however, ablation generally occurs in equilibrium conditions also for pulses longer than about 100 ps, as the surface temperature is determined by the thermal diffusivity of the material, controlled by the electron–phonon energy transfer time, τep ≃ (1–10) ps [11, 12]. In such cases, the threshold fluence for ablation, \({\varPhi }_{\text{th}},\) has been found to increase with the pulse duration, \({\varPhi }_{\text{th}}\hspace{0.17em}~\hspace{0.17em} \sqrt{\tau }\) [13,14,15,16], and when the latter is much shorter than the characteristic time for thermal diffusion, the damage threshold deviates from such square root scaling [14, 16, 17].

In (b), the Coulomb explosion is a consequence of tunneling ionization, induced by the strong external electric field associated with the laser pulse producing a large distortion of the atomic confining potential barrier. This allows some electrons to escape the material, and others to interact with the nearby atoms producing further ionizations, thus locally bringing the system out of charge neutrality. Therefore, in this case, ablation proceeds under non-equilibrium conditions, and thus, its threshold is expected to become independent of the pulse duration below 100 ps (condition not always verified as reported in [11, 12]).

Laser incubation is the property of a material to increase its absorbing capability and therefore to “store” more energy as a consequence of exposure to multi-pulses with the same (below-threshold) fluence. Now, a second variable enters into play, that is the pulse repetition rate. The accumulation of energy in this case translates into an accumulation of defects that will end up in an ablation process, after a sufficient number of pulses are applied. In the case of laser pulses of ns durations, and after the target gets melted, it takes generally a few ms to recrystallize. For this reason, one needs to consider whether subsequent laser pulses reach the target surface before or after recrystallization. In the former scenario, the repetition rate is denoted as “high-rate” and “low-rate” otherwise, thus allowing the material to partially reconstruct itself.

In a high-rate pulse (HRR) repetition experiment, the material does not have enough time to “relax” after the first laser pulse, and each consecutive shot will increase the target temperature until the ablation threshold is reached. In the case of a low laser repetition rate (LRR), low enough to allow the material to recrystallize (\(\text{LRR}\hspace{0.17em}\ll \hspace{0.17em}1\text{kHz})\), each laser pulse will hit a solid surface with an increasing absorption coefficient.

The change in the value of the absorption coefficient might be due to a possible surface oxidation [18] (if ablation takes place in air), a chemical reaction [19, 20], a change of the crystalline structure (such as the generation of color centers [20, 21]), an increase of the absorption surface area due to the deformation of the surface itself [20, 22, 23], accumulation of thermal stress–strain energy induced by the action of under-threshold laser pulses [24,25,26,27,28], and generation and accumulation of intrinsic defects such as vacancy–interstitial pairs [29, 30]. Incubation of metals in air may be also associated with the formation of voids/cracks in the after exposure recrystallization/solidification process [31,32,33,34]. Correlations have been also found with thermal properties and tensile strength of the metal [35]. In metals, a drastic change of reflectivity and absorption coefficient of the surface due to roughness evolution [36] can alter the laser energy deposition in a heated target, leading to different thermal responses than those predicted by constant reflectivity at room temperature [37]. In dielectrics and semi-conductors, a strong variation of the optical properties is also observed ranging from a fully transparent, non-reflecting material to a metal-like behavior which results in a strong localization of the coupled laser energy, since high electron thermal conductivity is restricted to a narrow surface layer [10].

In this work, we suggest a unified picture of incubation model, which is able to fit the available experimental data, proposing a way to classify different materials according to their dynamic response to laser ablation. The paper is organized as follows. In Sect. 2, we discuss the general fitting model used to describe laser incubation. Section 3 reports a discussion of the general model of Sect. 2, regarding its analytical properties and contact with the previous approaches. Section 4 is entirely dedicated to the experimental results and their fitting using the general model of Sect. 2. Finally, Sect. 5 contains the concluding remarks.

2 General equation for laser incubation

To leave the lattice, ions must overcome their binding energy; in other words, ablation occurs when the energy per unit volume exceeds the energy necessary for the material to undergo “evaporation” meaning not only a thermal process [38] but also the possibility of a Coulomb explosion type of mechanism [8, 9]. This energy can often be well approximated by its dominating term, the binding energy per unit volume ρΩ, where ρ is the material density and Ω is the total binding energy per unit mass. If we assume that the energy per unit area, \(\Phi\) (fluence), released by a laser pulse in the target follows an exponential profile characterized by a penetration depth, ℓ:

then the energy deposited between a depth x and x + dx over a surface S is as follows:

To achieve ablation of the target, the laser pulse energy must overcome the specific binding energy ρΩ in the element of volume dV = Sdx:

where α (0 < α < 1) is the absorption coefficient of the original surface, i.e., before the laser radiation is applied. Equation (3) provides the depth, L, of the ablated material, (x = L), according to the following:

We can then define a threshold, \({\varPhi }_{\text{th}}\), satisfying \(\left(\frac{{\varPhi }_{\text{th}}\alpha }{\rho \varOmega \mathcal{l}}\right)=1\), and thus

and Eq. (4) can be written as follows:

When \({ \varPhi }_{0}<{\varPhi }_{\text{th}}, \text{then}\) L < 0, and thus, one does not get ablation, whereas, for \(L\text{= }\mathcal{l}\text{,}\) a minimum incident fluence for ablation, \({\varPhi }_{0}=e{\varPhi }_{\text{th}}\), is obtained.

We propose a new description of laser incubation phenomena, which is based on the following assumptions: The target material, once irradiated with a minimum intensity, changes its shape, melts down, and recrystallizes. In such a process of incubation, a change of the absorption coefficient of the material surface is expected. The latter may be due to alterations of the lattice structure, its oxidation and of eventual chemically induced modifications of the surface. The structurally modified zone is denoted here as accumulation site. If we assume that the material target dissipates the absorbed energy within a few milliseconds, then, using rather short laser pulses (from ns to fs range) at a constant LRR (far below the kHz), we expect that each new laser pulse will hit a “cold” surface containing an increasing number of accumulation sites.

For an applied single laser shot of fluence \({\varPhi }_{1}\), the material absorbs the quantity

Ablation occurs when \({\varPhi }_{\text{abs}}=\rho {\Omega }\mathcal{l}\), that is \({\varPhi }_{1}={\varPhi }_{\text{th}}\) according to Eq. (5), which, for convenience, will be denoted as \({\varPhi }_{1}={\varPhi }_{\text{th}}\left(1\right)\). Next, we consider the application on N equal laser pulses of fluence \({\varPhi }_{N}\le {\varPhi }_{1}\). To make the N-dependence of the involved quantities explicit, we write

with \(\alpha \left(1\right)=\alpha ,\)where, here, \(\alpha \left(N\right)\) represents the new surface absorbing coefficient after N pulses. Now, the condition for ablation is that at the Nth laser pulse, the absorbed energy density is just:

Therefore, we denote the new threshold after N shots as \({\varPhi }_{\text{th}}\left(N\right)\equiv {\varPhi }_{N}\), and from Eqs. (7, 8), i.e., \({\varPhi }_{\text{abs}}={\varPhi }_{\text{abs}}\left(N\right),\) we get:

where, as we will show below, \(\alpha \left(N\right)\) is given by the four-parameter (\(\alpha , \beta , {N}_{c}, \delta\)) expression:

This is the main result of the present work. Here, δ > 0 is the so-called incubation exponent, and \({N}_{\text{c}}\) is a crossover value for N, in the sense that \(\alpha \left(N\right)\)→β when N >> \({N}_{\text{c}}\). Here, \(\beta <1\) is the asymptotic absorption coefficient of the irradiated surface. From Eq. (11), one thus expects the absorption coefficient of the irradiated material, \(\alpha \left(N\right),\) to increase with N, such that

Hence, \({\varPhi }_{\text{th}}\left(N\right)\) in Eq. (10) will have a maximum at N = 1 and will decrease for N >> \({N}_{\text{c}}\) reaching a plateau

In the following section, we present a discussion of how to obtain Eq. (11) by making contact with the different intermediate models (partially discussed in the Literature) for describing incubation and regarding their context of applicability. The underlying models leading to our main result will be discussed in Sects. 3.1 and 3.2. Then, we show in Sect. 3.3 how Eq. (11) emerges, and present a short discussion of its limiting cases. In addition, we show how a second crossover threshold, denoted as \({ N}_{\text{c}}^{\text{'}}\) (see Eq. 27 below) emerges, and we further suggest that it may describe a transition from a dielectric to a ‘metallic’ behavior. To the best of our knowledge, the latter transition has not been discussed in the literature so far.

3 Contact with the previous incubation models

3.1 Two-site incubation model (I): the limiting absorption coefficients (α, β)

This model, first proposed by Küper et al. [19, 39], links the change of absorption coefficient of a sample to the number of laser shots. The model is based on an experiment performed on polymethyl-methacrylate (PMMA), and considers the ratio between the density of monomers in incubation (irradiated) sites and in non-irradiated areas. The model can be applied to other materials, as well, with different degree of success as we will see below. Essentially, the model assumes an absorption coefficient, β, for the incubation sites which is much higher than that of the non-irradiated areas, α, the effective absorption coefficient of the modified material can then be expressed as follows:

where ninc(N) and n are the density of sites of PMMA monomers in irradiated (incubation sites) and non-irradiated areas, respectively. Here, ninc is expected to depend on the number of pulses N. Notice that, according to our notation in Eqs. (10, 11), \(\alpha \equiv \alpha \left(1\right)\;\text{and}\;\beta \equiv \alpha \left(\infty \right)\), when all sites have large absorption coefficient β and ninc = n.

Here, to elaborate on Eq. (14) further, we consider the surface to be composed of two types of sites: Normal sites having an absorption coefficient α and incubation sites with a larger absorption coefficient β > α (see Fig. 1). The effective absorption coefficient \(\alpha \left(N\right)\) for a total density of surface sites n, is given by the sum:

Schematic representation of the two-site incubation model, displaying the incubation sites with absorption coefficient β (dark zones), randomly distributed on the surface characterized by an absorption coefficient α (white zones). After each laser pulse is applied, new morphologically altered (dark) zones are formed having a larger absorption coefficient than for the original material surface, i.e., β > α. In this model, all the altered zones have the same absorption coefficient β, and only their concentration increases with the number of applied laser pulses N

For N = 1, we have ninc=0. Now, assuming that for N > 1, ninc increases linearly with N, ninc= a + bN, we can find the unknown coefficients (a, b) by further assuming that, for N >> 1, all sites become incubation sites. These two limiting cases can be expressed according to ninc= a + b (for N = 1), and ninc = n ≃ bN (for N > > 1). The former yields a = − b, and the latter b = n/N. Therefore, we find

and

or

where the function \(f\left(N\right)\) contains the N-dependence incubation process and, in this case, it becomes:

Now, according to Eqs. (10, 11), and Eqs. (18, 19), we find

which is displayed for illustration in Fig. 2 for different values of β/α. As one can see from the figure, the ‘transition’ to the asymptotic value α/β < 1 occurs near N = 1 in all the cases.

3.2 Incubation growth lag-rate model (IGLR): crossover value\({\varvec{N}}_{\mathbf{c}}\)

The IGLR is a modification of the two-site incubation model (I) discussed above by introducing a new concept. Essentially the new absorption coefficient \({\alpha }_{\text{IGLR}}\left(N\right)\) has the same form as Eq. (18), that is

where now f(N) displays a crossover behavior towards its asymptotic value f(N) ≈ 1 for N > Nc. This is simply implemented in the model by modifying Eq. (19) as follows:

where \({N}_{\text{c}}\) is the incubator growth lag-rate (IGLR) pulse, and can be interpreted as a crossover value for N. Notice that Eq. (19) for the two-site incubation model (I) corresponds to \({N}_{\text{c}}\) = 1, and the crossover behavior does not show up in that case. It can be shown that, for the IGLR model, the density of incubation sites now obeys the following:

which generalizes Eq. (16) and is displayed for illustration in Fig. 3. In this model, the asymptotic value \({n}_{\text{inc}}=n\) is reached after a crossover value, or lag number of pulses, \({N}_{\text{c}}\), has been overcome.

3.3 Incubation growth lag-rate power-law model (IGLRPL): the incubation exponent δ

The generalization of Eq. (22) is performed by introducing a new parameter δ in the following fashion:

where δ > 0 is the incubation exponent that “amplifies” the dependence of f(N) on N. The introduction of the exponent δ into the expression for \(f\left(N\right)\) somehow contains non-linear effects in the growth of \({ n}_{\text{inc}}\). Despite its simple appearance, the new exponent has a very important effect on \({\varPhi }_{\text{th}}\left(N\right)\), and is able to discriminate between a metallic and a dielectric type of behavior. The complete expression for the ablation threshold now reads the following:

which corresponds to Eqs. (10) and (11), displaying the four parameters (\(\alpha , \beta , {N}_{c}, \delta\)). In what follows, we analyze two limiting behaviors of Eq. (25) and compare them with the results discussed in Sects. 3.1 and 3.2.

3.3.1 The second crossover: \({ N}_{\text{c}}^{\text{'}}\) <\({\hspace{0.17em}N}_{\text{c}}\)

The result in Eq. (25) displays two crossovers: one is \({N}_{\text{c}}\) already discussed in Eq. (22) and the second one is here denoted as \({ N}_{\text{c}}^{\text{'}}\). To define \({N}_{\text{c}}^{\text{'}},\) we consider the case 1 ≤ N ≤ \({N}_{\text{c}}^{\text{'}}\), and Eq. (25) can be written as follows:

where

This is a very useful relation relating \({N}_{\text{c}}^{\text{'}}\) to the other model parameters. Notice that \({N}_{\text{c}}^{\text{'}}<{N}_{\text{c}}\) when β/α ≥ 2, a result which can be used to check the consistency of the values of the fitting parameters. As we will see below, values \({N}_{\text{c}}^{\text{'}}\gg 1\) correspond to dielectric materials, while, for metals, it does not have a physical meaning, since typically the fits yield \({N}_{\text{c}}^{\text{'}}\lesssim 1\).

3.3.2 The Power-Law (PL) approximation

Here, we show that a power-law model discussed in the literature [25] can be derived from Eq. (26) for values of N within the interval \({N}_{\text{c}}^{\text{'}}+1<N<\) \({N}_{\text{c}}\) and assuming that \({N}_{\text{c}}^{\text{'}}\simeq 1\). We obtain the following:

As we will see below, this model describes a metallic behavior.

3.3.3 The Generalized Exponential (GE) approximation

We consider again Eq. (28) for 1 ≤ N ≪ \({N}_{\text{c}}^{\text{'}}\), yielding

Thus, we expect the generalized exponential behavior to be valid for small N when \({N}_{\text{c}}^{\text{'}}\) > 1 (dielectric behavior).

The exponent δ reflects the type of material used for ablation. We show this by defining the auxiliary variable x = (N-1)/\({N}_{\text{c}}^{\text{'}}\) and consider values x → 0. In this limit, Eq. (26) can be written as follows:

Then, performing the derivative of YN with respect to x, one finds the following:

which displays two different behaviors according to whether δ is larger or smaller than 1, represented by the following relations:

In Eq. (31), \({Y}_{N}^{\text{'}}\) → 0 or behaves nearly flat for x → 0, corresponding to long laser pulses (slow response) regime, while, in Eq. (32), \({Y}_{N}^{\text{'}}\) → − ∞, which is observed, in general, for short laser pulses.

4 Fitting to experimental results

In the following, we use Eq. (25) to fit the experimental results for the fluence \({\varPhi }_{\text{th}}\left(N\right)\) and compare it with the model discussed in Sect. 2 to understand the different types of behaviors expected from them. We start with the case of dielectric surfaces.

4.1 Dielectric materials

The fitting results for the fluence thresholds as a function of pulse number N for dielectric materials are displayed in Figs. 4, 5, 6, 7. Each figure is accompanied by a table containing the values of the fitting parameters (Tables 1, 2, 3, 4). Finally, we present a summary of both the crossover values \({N}_{\text{c}}^{\text{'}}\) and \({N}_{\text{c}}\) in Table 5.

Threshold \({\varPhi }_{\text{th}}\) for ablation of polymethyl-methacrylate (PMMA) as a function of the number of laser shots N. The experimental data are obtained after Ref. [40] (laser characteristics: λ = 800 nm, τ = 150 fs, repetition rate 2 Hz). In this case, the fitting curve is derived from the general incubation growth lag-rate power-law model (IGLRPL), Eq. (25)

Threshold \({\varPhi }_{\text{th}}\) for ablation of Indium Phosphide (InP) as a function of the number of laser shots N. The experimental data are from Ref. [41] (laser characteristics: λ = 800 nm, τ = 130 fs, repetition rate 1 Hz)

Threshold \({\varPhi }_{\text{th}}\) for ablation of Polycarbonate (PC) as a function of the number of laser shots. The experimental data are obtained after Ref. [40] (laser characteristics: λ = 800 nm, τ = 150 fs, repetition rate 2 Hz)

Threshold \({\varPhi }_{\text{th}}\) for ablation of PMMA as a function of the number of laser shots. The experimental data are obtained after Ref. [40] (laser characteristics: λ = 800 nm, τ = 150 fs, repetition rate 2 Hz) and [18] (laser characteristics: λ = 240 nm, τ = 300 fs and τ = 16 ns, repetition rate 1 Hz). Experimental data have been fitted using the incubation growth lag-rate power-law model (IGLRPL) (Eq. 25)

In Fig. 4, the case of PMMA is illustrated. The experimental ablation thresholds [40], \({\varPhi }_{\text{th}}\), as a function of the number of laser shots N are plotted against the fitting curves derived from the general incubation growth lag-rate power-law model (IGLRPL), Eq. (25).

We can observe from Fig. 4 how the IGLRPL model fits very well the experimental data. The absorption coefficient saturation is reached after about \({N}_{\text{c}}\simeq\) 86 laser pulses and it is about eight times larger than for the original material (β/α\(\hspace{0.17em}\,\simeq 8\)) (Table 1).

Figure 5 illustrates the experimental ablation threshold [41], \({\varPhi }_{\text{th}}\), for Indium Phosphide (InP) as a function of the number of laser shots N. The absorption coefficient saturation is reached after about \({N}_{\text{c}}\,\simeq\) 34 laser pulses (value) with a value about three times larger than the non-irradiated material (Table 2). The metallic transition occurs for \({N}_{\text{c}}^{\text{'}}\) = 24 (Table 5).

Figure (6) shows the experimental ablation threshold [40], \({\varPhi }_{\text{th}}\), for polycarbonate (PC) as a function of the number of laser shots. The absorption coefficient saturation is reached after about \({N}_{\text{c}}\simeq\)76 laser pulses with a value about four times larger than the non-irradiated material (Table 3). The metallic transition occurs for \({N}_{\text{c}}^{\text{'}}\) = 35 (Table 5).

Figure 7 shows the experimental ablation threshold [18, 40], \({\varPhi }_{\text{th}}\), for PMMA as a function of the number of laser shots. In this case, three different experimental conditions are compared: two different irradiation wavelengths and roughly two pulse time durations. Considering the irradiation at λ = 240 nm, the ablation threshold is strongly influenced by the laser pulse duration, τ, as expected from the relation \({\varPhi }_{\text{th}}~ \sqrt{\tau }\) [13,14,15,16]. Thus, the results shown in Fig. 7 are consistent with a functional proportionality between \({\varPhi }_{\text{th}}\)and τ. In addition, the IGLRPL model gives values δ ≃ 0.73 and δ ≃ 0.9, for τ = 300 fs and τ = 16 ns, respectively. This means that a shorter pulse duration makes the transition from a ‘dielectric’ to a ‘metal’-like behavior faster, meaning that shorter pulses yields higher growth rate of accumulation sites. Similarly, a shorter laser wavelength (see Fig. 7) has the effect of both reducing the threshold \({\varPhi }_{\text{th}}\) and speeding up the accumulation sites growth rate. Both effects translate into lower δ, \({N}_{\text{c}}^{\text{'}}\) and \({N}_{\text{c}}\) values (see Tables 4, 5), and are due to the increased laser photon energy.

Finally, we summarize the results for \({N}_{\text{c}}^{\text{'}}\)and \({N}_{\text{c}}\) in Table 5.

4.2 Metals

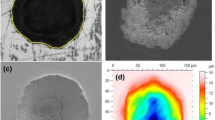

In the following, we discuss the fitting results for the fluence thresholds as a function of pulse number N for the metals summarized in Fig. (8) with the values of the fitting parameters displayed in Table 6. It shows the experimental ablation threshold [22, 38], \({\varPhi }_{\text{th}}\), for different metals as a function of the number of laser shots. The experimental data have been fitted using the IGLRPL model, Eq. (25).

In the case of metals, the crossovers \({N}_{\text{c}}^{\text{'}}\)and \({N}_{\text{c}}\) obey the relations \({N}_{\text{c}}^{\text{'}}\)≈ 0 and \({N}_{\text{c}}\)≫1. The only unknown parameter is δ, and the N-dependent ablation thresholds behave closely to a power-law decay \({N}^{-\delta }\) with exponent δ. In the case of Cu and Al, one can see the effect of the pulse duration τ on the fluence thresholds, displaying a trend as expected from the relation \({\varPhi }_{\text{th}}~ \sqrt{\tau }\), i.e., \({\varPhi }_{\text{th}}\)(Cu(1)) >\(\hspace{0.17em}{\varPhi }_{\text{th}}\)(Cu(2)) and \({\varPhi }_{\text{th}}\)(Al(1)) > \({\varPhi }_{\text{th}}\)Al(2) > \({\varPhi }_{\text{th}}\)(Al(3)).

As for the accumulation sites growth behavior, one has to keep in mind that for pulse durations shorter than the electron–phonon energy transfer time, τep ≃ (1–10) ps, which can be denoted as “fast” process, ablation proceeds under non-equilibrium conditions. In such cases, surface defects are the result of both the non-linear interaction of the strong laser electric field with the material and of thermal effect. This means that the energy released by the laser goes partly on a multi-photon absorption process and partly is stored in the material. The latter is dissipated on longer time scales (τep). In this fast regime, some metals might display a dielectric type of behavior (see Fig. 8), as for Aluminum [Al(2), Al(3)]. This means that, for very short laser pulses, a metal behaves as a dielectric displaying a larger value of δ as compared to the “slow” regime for longer laser pulses. This can be seen for Al(1), Al(2), and Al(3) in Table 6; in particular, for Al(2) and Al(3), one finds δ > 1. In other words, when the laser pulse duration is much longer than τep, the released laser energy undergoes dissipation by thermal processes. In terms of IGLRPL model, this fact is reflected on a rapid transition to “metallic” behavior for irradiated targets with longer pulses [see Table 6: Cu (1) and Al (1)]. Thus, one expects that, for short laser pulses, growth of incubation sites proceeds faster than for longer pulses. In the latter, thermal dissipation reduces, to some extent, damage formation, since part of the laser energy is carried away.

Threshold \({\varPhi }_{\text{th}}\) for ablation of different metallic surfaces as a function of the number of laser shots. The experimental data are obtained after Ref. [38] (laser characteristics: λ = 800 nm, τ = 100 fs (pulse duration), repetition rate up to 1 kHz for W), [22] [laser characteristics: λ = 1064 nm, τ = 10 ns, repetition rate 1 kHz for: Cu (1) and Al (1), and stainless steel (SS); while τ = 10 ps for Cu (2), and Al (2)] and [42] [laser characteristics: λ = 800 nm, τ = 55 fs, repetition rate 1 kHz for Ni Alloy 625 and Al (3)]. Experimental data have been fitted using the incubation growth lag-rate power-law model (IGLRPL), Eq. (25)

5 Conclusions and discussion

In laser incubation processes, the irradiated material changes its absorbing or storing capabilities reaching the ablation threshold after N pulses at a fluence lower than the one required in a single shot. We generalized the model, first proposed by Küper et al. [19, 39], linking the change of absorption coefficient of a sample to the number of laser shots and assuming an absorption coefficient, β, for the incubation sites which is much higher than that of the non-irradiated areas, α. After each laser pulse is applied, new morphologically altered zones result having a larger absorption coefficient than for the original material surface, i.e., β > α. In this model, all altered zones have the same absorption coefficient β; only their concentration increases with the number of applied laser pulses N. Here, we generalize this model in two steps: First we introduce a “lag”, \({N}_{\text{c}}\), (IGLR model) in the incubation model (\({N}_{\text{c}}\hspace{0.17em}\)= 1 corresponding to the model I), and second, an “incubation” exponent, δ, which provides a non-linearity in the IGLRPL model.

Using the analytical expression of the IGLRPL model, the existing experimental data are fitted and presented under a new perspective. The new model predicts two crossovers as a function of the pulse number N: \({N}_{\text{c}}^{\text{'}}\)and\({ N}_{\text{c}}\), describing the different incubation behaviors of the materials under the action of the ‘below-threshold’ laser pulses. The first crossover indicates a transition from a dielectric type of surface response towards an increasingly ‘metallic’ behavior, consistent with the experimental observations. This implies the formation of new conducting paths on the otherwise non-conducting surface. The second crossover corresponds to the final stage of the modified surface just before the saturation of incubation sites. In this large N limit, absorption coefficient of the surface achieves its saturation. In addition, it is found that the incubation exponent, δ, allows us to classify surfaces into dielectric or metallic ones. The response of a material to different laser pulse duration τ is reflected in the exponent δ. Longer laser pulses yield a metallic response of the material as τ > τep, while, for shorter ones, τ < τep, its response is mainly of a dielectric type.

References

S. Nolte, C. Momma, H. Jacobs, A. Tünnermann, B.N. Chichkov, B. Wellegehausen, H. Welling, J. Opt. Soc. Am. B 14, 2716 (1997). https://doi.org/10.1364/JOSAB.14.002716

J.K. Chen, D.Y. Tzou, J.E. Beraun, Int. J. Heat. Mass. Transf. 48, 501 (2005). https://doi.org/10.1016/j.ijheatmasstransfer.2004.09.015

B.C. Stuart, M.D. Feit, S. Herman, A.M. Rubenchik, B.W. Shore, M.D. Perry, Phys. Rev. B 53, 1749 (1996). https://doi.org/10.1103/PhysRevB.53.1749

C.W. Carr, H.B. Radousky, S.G. Demos, Phys. Rev. Lett. 91, 127402 (2003). https://doi.org/10.1103/PhysRevLett.91.127402

B.N. Chichkov, C. Momma, S. Nolte, F.v. Alvensleben, A. Tünnermann, Appl. Phys. A 63, 109 (1996). https://doi.org/10.1007/BF01567637

M. Mero, J. Liu, W. Rudolph, D. Ristau, K. Starke, Phys. Rev. B 71, 115109 (2005). https://doi.org/10.1103/PhysRevB.71.115109

L.A. Emmert, W. Rudolph, in Laser-induced damage in optical materials, 1st ed., ed. by D. Ristau (CRC Press/Taylor & Francis Group, Abingdon, 2016)

R. Stoian, D. Ashkenasi, A. Rosenfeld, E.E.B. Campbell, Phys. Rev. B 62, 13, 167 (2000)

R. Stoian, A. Rosenfeld, D. Ashkenasi, I.V. Hertel, N.M. Bulgakova, E.E.B. Campbell, Phys. Rev. Lett. 88, 097 603 (2002)

C.R. Phipps. Laser ablation and its application. (Springer, New York, 2007)

E.G. Gamaly, A.V. Rode, B. Luther-Davies, V.T. Tikhonchuk, Phys. Plasmas 9, 949 (2002). https://doi.org/10.1063/1.1447555

B.C. Stuart, M.D. Feit, S. Herman, A.M. Rubenchik, B.W. Shore, M.D. Perry, J. Opt. Soc. Am. B 13, 459 (1996). https://doi.org/10.1364/JOSAB.13.000459

E.G. Gamaly, N.R. Madsen, M. Duering, A.V. Rode, V.Z. Kolev, B. Luther-Davies, Phys. Rev. B 71, 174405 (2005)

B.C. Stuart, M.D. Feit, S. Herman, A.M. Rubenchik, B.W. Shore, M.D. Perry, Phys. Rev. B 53, 1749 (1996)

M. Lenzner, Int. J. Mod. Phys. B 13, 1559 (1999)

A.-C. Tien, S. Backus, H. Kapteyn, M. Murnane, G. Mourou, Phys. Rev. Lett. 82, 3883 (1999)

A. Kaiser, B. Rethfeld, M. Vicanek, G. Simon, Phys. Rev. B 61, 11 437 (2000)

J. Bonse, S. Baudach, J. Krüger, W. Kautek, M. Lenzner, Appl. Phys. A 74, 19–25 (2002). https://doi.org/10.1007/s003390100893

S. Küper, M. Stuke, Appl. Phys. B 44, 199–204 (1987)

J. Bonse, H. Sturm, D. Schmidt, W. Kautek, Appl. Phys. A 71, 883–884 (2000)

N. Ichimura, H. Kondo, Y. Harada, S. Hashimoto, J. Lumin. 87–89, 586–588 (2000)

G. Raciukaitis, M. Brikas, P. Gecys, M. Gedvilas. in High-power laser ablation VII, ed. by C. R. Phipps, Proc. of SPIE Vol. 7005, 70052L, (2008), pp. 0277–786. https://doi.org/10.1117/12.782937

S. Martin, A. Hertwig, M. Lenzner, J. Kruger, W. Kautek, Appl. Phys. A 77, 657–665 (2003)

Y. Jee, M.F. Becker, R.M. Walser, J. Opt. Soc. Am. B 5, 648–659 (1988)

D. Bauerle. Laser processing and chemistry, 4th Edition, (Springer, Switzerland AG, 2001)

J. Krüger, W. Kautek, Ultrashort pulse laser interaction with dielectrics and polymers. Adv. Polym. Sci. 168, 247–289 (2004)

Y. Jee, M.F. Becker, R.M. WalserLaser-induced damage on single-crystal metal surfaces. J. Opt. Soc. Am. B 5, 648–659 (1988)

A. Fatemi, L. Yang. Cumulative fatigue damage and life prediction theories: a survey of the state of the art for homogeneous materials. Int. J. Fatigue 20, 9–34 (1998)

K.S. Song, R.T. Williams, Self-trapped excitons (Springer, Berlin, 1993)

R.F. Haglund, N. Itoh, in Laser ablation. principles and applications, ed. by J.C. Miller (Springer, Berlin, 1994)

N. Lasemi, U. Pacher, C. Rentenberger, O. Bomatí-Miguel, W. Kautek, Laser-assisted synthesis of colloidal Ni/Niox core/shell nanoparticles in water and alcoholic solvents. ChemPhysChem 18, 1118–1124 (2017)

C. Wu, M.S. Christensen, J.-M. Savolainen, P. Balling, L.V. Zhigilei, Generation of subsurface voids and a nanocrystalline surface layer in femtosecond laser irradiation of a single-crystal Ag target. Phys. Rev. B 91, 035413 (2015)

E.T. Karim, M.V. Shugaev, C. Wu, Z. Lin, H. Matsumoto, M. Conneran, J. Kleinert, R.F. Hainsey, L.V. Zhigilei, Experimental characterization and atomistic modeling of interfacial void formation and detachment in short pulse laser processing of metal surfaces covered by solid transparent overlayers. Appl. Phys. A 122, 407 (2016)

N. Lasemi, U. Pacher, L.V. Zhigilei, O. Bomatí-Miguel, R. Lahoz, W. Kautek, Pulsed laser ablation and incubation of nickel, iron and tungsten in liquids and air. Appl. Surf. Sci. 433, 772–779 (2018)

A.M. Howatson, P.G. Lund, J.D. Todd, Properties of matter, engineering tables and data, 41 (Springer, Dordrecht, 1972)

T. Häfner, J. Heberle, M. Dobler, M. Schmidt, Influences on incubation in ps laser micromachining of steel alloys. J. Laser Appl. 28, 022605 (2016)

Y. Ren, J.K. Chen, Y. Zhang, J. Appl. Phys. 110, 113102 (2011)

J. Byskov-Nielsen, J. Matti Savolainen, M. Snogdahl Christensen, P. Balling, Appl Phys A 101, 97–101 (2010). https://doi.org/10.1007/s00339-010-5766-1

S. Küper, M. Stuke, Appl. Phys. Lett. 54, 4 (1989). https://doi.org/10.1063/1.100831

S. Baudach, J. Bonse, J. Krüger, W. Kautek. Appl. Surf. Sci. 154–155, 555–560 (2000)

J. Bonse, J.M. Wrobel, J. Kruger, W. Kautek. Appl. Phys. A 72, 89–94 (2001)

Z. Sun, M. Lenzner, W. Rudolph, Generic incubation law for laser damage and ablation thresholds. J. Appl. Phys. 117, 073102 (2015). https://doi.org/10.1063/1.491328

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Benocci, R., Batani, D. & Roman, H.E. Incubation models for under-threshold laser ablation with thermal dissipation. Appl. Phys. B 125, 22 (2019). https://doi.org/10.1007/s00340-019-7132-0

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00340-019-7132-0