Abstract

We present a potential tool to monitor growth of a crack in a glass plate using interferometry, where fringes characteristic of optical dislocations can be seen. It is experimentally observed that interference fringes can be used to visualize the stress field that is activated near the tip of a crack. In an interferometric setup, an optical wave-front is transmitted through the crack site of glass plate which results in a local phase jump in the test beam. This phase jump reveals itself in the fringe pattern in the form of fork fringes, where branching of fringes is seen at the crack tip and along the crack line. Using the Fourier transform fringe analysis method and phase-unwrapping method, we optically track the crack tip. The positions of fork fringes provide the location and trajectory of crack tip.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

The generation of crack and its propagation is a subject of considerable interest in the field of glass fracture [1,2,3]. In general, many factors are responsible for the initiation of cracks in materials, such as granular defects in the form of voids and inclusion, manufacturing process induced and by design, atomic scale lattice defects, and unavoidable local stress concentration due to external pressure [3]. Furthermore, the crack that is generated suddenly may grow to cross a critical length and in turn results in equipment and personnel damage. Therefore, this area has received much attention over the last four decades in the modeling of different schemes to track the crack generation and its growth in materials [4,5,6,7,8,9]. A number of models have been formulated to measure the stress, which is responsible for inducing the cracks such as linear elastic fracture mechanics (LEFM). LEFM is derived from the Westergaard [10] solution and has been studied in detail by Dugdale and Ruiz [11] and by Gdoutos [1]. The Dugdale model [12] was the first to develop a crack model incorporating plasticity and has an advantage that it provides a simple closed-form result for the plastic zone size in plane stress. However, it is applicable only for the static crack and is unable to predict the crack closure. Furthermore, Bilby, Cottrell, and Swinden introduced BCS model [13] based on the dislocation theory to model the crack problems. To track the crack growth in plane strain, Atkinson [14] formulated another model based on the dislocation theory. Furthermore, this model was developed by Kanninen et al. [15] to study fatigue crack growth in materials.

Earlier, crystal dislocations were used as a tool to model stress field distribution in materials [13,14,15]. However, glass is amorphous and will not have dislocation structures in it. Interference fringes formed under monochromatic laser light illumination from a glass subjected to stress and can be interpreted in terms of wave-front dislocations. Here, we use the concept of the wave-front dislocations in optical fields as a tool to visualize crack growth in glass plate. The activated dislocations in optical fields may be either pure screw dislocations or pure edge dislocations or mixed screw-edge dislocations [16]. These optical dislocations result from local phase jump at crack sites and may be of the order of \(\psi \left( {r,\phi } \right)\sim 2\pi m\), where m is the integer topological charge and \(\psi \left( {r,\phi } \right)\) is the phase distribution of the optical field. This gives birth to an optical vortex, which is a wave-front point defect. It can be detected by forming fork fringes in interferometers [17, 18]. Using the Fourier transform fringe analysis method and phase-unwrapping method, we track the optical dislocations generated near the crack tip in glass plate with the help of fork fringes. Furthermore, we observe that as the crack propagates in the glass plate, an array of optical dislocations is activated in the test wave-front along the path of the crack and hence these dislocations help us to track the crack growth. This method is hence a potential tool and offers an insight into crack growth mechanism in glass plate.

Phase singularity in wave physics was reported first time in a seminal paper by Nye and Berry [19] in 1974, in terms of wave-front dislocations. By taking the analogy from crystal dislocations, mainly three types of wave-front dislocations are defined in the optical field—screw dislocation, edge dislocation, and mixed screw-edge dislocations [16]. Optical vortex is defined as a phase singular point, where field amplitude vanishes and local phase \(\psi \left( {r,\phi } \right)\) around this point varies linearly from 0 to 2π. Mathematically, it can be given by the exponential phase function \(\exp \left( {im\phi } \right)\), where \(\phi\) is the azimuthal angle and m is the topological charge which determines the helicity and phase variation of the helical phase ramp around the phase singular point. Mathematically, it is expressed by the relation \(m=\left( {{1 \mathord{\left/ {\vphantom {1 {2\pi }}} \right. \kern-0pt} {2\pi }}} \right)\oint {\nabla \psi \cdot {\text{d}}l}\). There are many methods [20] for the generation of the optical vortex beam using computer-generated holograms (CGHs), spiral phase plate (SPP) [21], adaptive helical mirror [22], wedge plates [23], wave-front local tilts [24, 25], and so on.

In this paper, we describe an experimental method to detect cracks in glass plates by forming interference fringes. An optical wave-front when transmitted through the crack site of glass plate results in a local phase jump in the test beam. In an interferometric setup, this phase jump reveals itself in the fringe pattern in the form of fork fringes, where branching of fringes is seen at the crack tip and along the crack line.

2 Theory

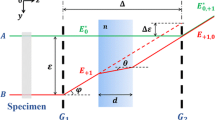

Stress is responsible for crack generation in glass plate, which is proportional to the applied external force. A force can be applied to a glass plate in different ways that might enable the generation of crack. Here, we loaded the glass plate in the tearing mode [26], where shear forces are parallel to the crack front. The crack surfaces slide over each other in the z direction by a tilt angle \(\alpha\), as illustrated in Fig. 1a. In this mode, the crack growth may only take place along the x direction.

The induction of optical vortices or phase singularities in the probing optical wave-front is due to crack generation in the glass plate. This can be understood mathematically by finding the optical path difference between the two interfering beams—one passing through the crack site and the other forming the reference beam. Due to the application of stress, the glass plate bends with variable local tilt \(\alpha\) in the transverse direction, which introduces extra optical path. This is depicted with the help of Fig. 1b. Consider a glass plate of thickness t having two parallel sides and the rays that would have gone through it at normal incidence, now after the formation of the crack travel longer path inside the glass due to the variable tilt introduced in the glass around the crack tip. Therefore, the total change in the optical path length through the glass plate \(\Delta l\) is found from the difference between the optical path lengths before and after the introduction of tilt at a local point. Using the Snell’s law this is given by [27]:

where \({n_1}<{n_2}\). The indices of refraction of two different media are \({n_1}\) (air) and \({n_2}\) (glass). \(\alpha\) is tilt angle and \(\beta\) is the angle of refraction as shown in Fig. 1b. s is the length of the light path in the tilted glass plate and l is the distance over which optical path length \(\Delta l\) is measured. The value of local phase variation is \(2m\pi\) when the optical path length \(\Delta l\) is equal to \(m\lambda\). Further, Rotschild et al. [27] and Singh et al. realized the generation of optical vortex with higher order topological charge using adjustable spiral phase plate and cracked glass plate [28].

3 Experiment, results, and discussion

A Mech–Zehnder interferometric setup as shown in Fig. 2 is used for the detection of crack and its growth in the glass plate. A spatially filtered and collimated He–Ne laser beam is used. In one arm of the interferometer, the specimen, piece of glass plate, is clamped and the other arm provides the plane reference beam. Initially, the beam is incident normally onto the glass plate. A screw is used to apply appropriate force for the distribution of stress fields to generate the crack. During the crack formation, the deformation that occurs in the glass is further imprinted into an input beam which passes through the defect site resulting in object beam, as shown in Fig. 3a. With the help of beam splitter BS2, the test beam and reference beam are brought together to form interference fringes. The crack detected by optical interferometer shows fork fringes at the output of the interferometer. It is worthwhile to differentiate the method of vortex generation given by Rotschild’s in Ref. [27] and our current work. He has used Sagnac interferometer, where the object and the reference waves are imaged on to a CCD, whereas here plane waves are used in a Mach–Zehnder configuration. While the aim of Rotschild et al., is to describe a method of vortex generation using crack, we use the formation of helical waves during the crack formation and growth as a failure-testing tool for glass plates. Creation of a single vortex of higher charge is demonstrated by Rotschild et al., whereas in our testing method, multiple vortices of single charge along the crack line are created.

Optical wave passing near the crack site experiences extra optical path, as the tilt around the crack tip continuously varies. Due to this, the wave-front acquires the shape of a helical ramp. Such optical wave-front is known as optical phase singularity or optical vortex. They can be detected by forming fork fringes, in which one interference fringe terminates right at the middle of the interferogram, while other fringes around it are intact. The presence of fork fringes in the interferograms as shown in Fig. 3b reveals that object beam has local phase variation of \(\psi \left( {r,\phi } \right)\sim 2\pi m\) that gives birth to an optical vortex in the object beam. This phenomenon shows that the stress pattern around the crack tip deforms the glass in such a way that it is transferred into the object beam in the form of local phase variation as the input beam passes through the crack sites in the glass plate. Furthermore, to find how much phase variation is introduced in the object beam during the crack generation, we computed the phase map of the recorded interferograms using the Fourier transform fringe analysis method [29, 30] and the results are shown in Fig. 3c, where phase varies on grayscale from 0 (black) to 2π (white). This result reveals the magnitude and sign of topological charge carried by the object beam and their exact locations in the glass plate. Interference fringes in Fig. 3b have only one fork and consequently in its phase map only one phase singular point appears around which phase varies once from 0 to 2π in the counterclockwise direction, i.e., \(m=+1\), as shown in Fig. 3c.

Next, we used this technique of monitoring the generation of optical vortices to track the crack growth in the glass plate as well. To perform the real time investigation of crack growth, we used the same methodology and the experimental setup as we used earlier for the generation of crack. Crack in the glass plate is induced in such a manner that it starts from one end and terminates close to the center of the plates. To visualize the crack growth, we continuously recorded the interferograms of object beam with reference plane beam using a CCD camera, as the crack is generated and propagated in glass plate. We took a number of snap shots of these interferograms from the recorded video (see movie), shown in first row of Figs. 4 and 5. The approximate thickness and refractive index of glass plate are 4 mm and 1.51, respectively.

Visualization of crack growth in glass plate. First, second, and third rows show recorded interferograms, wrapped phase maps, and crack growth, respectively, for three different positions of crack tip (see movie). Grayscale color bar in third row is in radian and valid for each unwrapped phase maps (g–i) and scale bar in g is valid for all the images of Fig. 4. Wrapped phase map d–f varies on grayscale from 0 (black) to 2π (white)

Visualization of crack growth in glass plate. First, second, and third rows show recorded interferograms, wrapped phase maps, and crack growth, respectively, for three different positions of crack tip (see movie). Grayscale color bar in third row is in radian and valid for each unwrapped phase maps (g–i) and scale bar in g is valid for all the images of Fig. 5. Wrapped phase map d–f varies on grayscale from 0 (black) to 2π (white)

Initially, we observed the interferograms (see movie) with no deformation in the glass plate and fringes are shown in Fig. 4a. Fringes are continuous and parallel. As the deformation sets in, crack is generated and the straight line fringes are transformed to fork fringes, as shown in Fig. 4b. On either sides of the crack, the number of fringes is not same, and there is a new fringe starting from the middle of the interferogram, which is unusual. Normally, in interferometric non-destructive testing (NDT) methods, fringes usually start from (or end at) the boundary. Otherwise, they form closed loops enclosing at least an extrema inside. New fringes starting from the middle of the interferograms are characteristics of helical wave formation. These are phase singularities and in their immediate neighborhood all phase values are present. The fork or spiral fringes are examples of fringes formed due to the presence of phase singularities in the wave-fronts during interference. Since interference fringes are phase difference contours, and it is well known that closed contours enclose extremum, contours can touch each other at saddles and contours can terminate on vortices. That is why, a new fringe originates or terminates at the phase singular point. In our case, the opposite phase gradients on either side of the crack, leads to the phenomenon of vortex formation due to tilts in the wave-front that propagates through such structures. As the glass surfaces on either side of the crack line are tilted in the opposite direction by tilt angle \(\alpha\), the transmitted wave-front is also split in two wave-fronts on either side of crack line with opposite phase gradients. Crack creates regions of oppositely oriented tilts. Wave-front positions along the crack line are corresponded to the phase discontinuity line at which fringes get terminated or originated in the form of fork fringes. The computed phase maps of the recorded interferograms given in the first row of Fig. 4 are shown in the second row of Fig. 4, respectively. Interference fringes in Fig. 4b have only one fork and consequently in its phase map only one phase singular point appears around which phase varies once from 0 to 2π in the counterclockwise direction, i.e., \(m=+1\), as shown in Fig. 4e. In contrary, no phase singularity is observed in Fig. 4d, i.e., \(m=0\), as corresponding interference fringes in Fig. 4a have no fork. We used the two dimensional (2D) Goldstein branch cut phase unwrapping algorithm [31, 32] to find the object beams from the recorded interferograms. This provides the trajectory of the crack growth in the glass plate. The crack paths corresponding to the interferograms of Fig. 4a–c are depicted in the third row of Fig. 4g–i, respectively. Initially, no crack is seen in Fig. 4g, as this is confirmed from Fig. 4a, d. Furthermore, the generation of crack is observed in Fig. 4h and it can be seen from Fig. 4b, e. Next, we correlated the positions of phase singular point with the tip of the crack from Fig. 4e, h and observed that they occur near to the tip of crack. Furthermore, we track the growth of the generated crack in the glass plate, as given in Fig. 4i. During the crack growth, the deformation in glass is such that optical vortices are seen at two different places along the crack path. This can be seen from the position of fork fringes in the interferogram and corresponding phase singular points in its phase map shown in Fig. 4c, f, respectively. Grayscale color bar in third row of Fig. 4 is in radian and valid for each unwrapped phase maps Fig. 4g–i and scale bar in Fig. 4g is valid for all the images of Fig. 4.

Normally, interferograms in which fringe shifts across the phase step reveal thickness difference. However, here, we do not see fringe shifts in the two regions, but the birth of new fringes from the crack line. The charges of the optical vortices generated are also of same polarity. Such fringes can be seen in two wedge arrangements [24]. New fringes are created as the growing crack separates the two regions on either side of which the tilts are opposite [25]. Such a configuration can lead to vortex formation by pure wave-front tilts, a phenomenon different than the one in Ref. [27]. However, since the thickness of the glass plate on either side of the crack is same, the linear phase difference variation can be attributed to the varying tilt component of the two parts of the cracked glass plate. This varying tilt across the crack is the source for the development of stress and propagation of crack.

We further tracked the crack growth which moves towards the center of the glass plate and the corresponding results such as interferograms (see movie), wrapped phase maps, and corresponding trajectory of crack growth are depicted in first, second, and third rows of Fig. 5, respectively. Optical dislocations are activated at five, six, and seven different locations in the wave-front and are revealed in the form of fork fringes shown in interferograms, Fig. 5a–c, respectively. By correlating the wrapped phase maps and trajectory of crack growth of these interferograms, we note that as the crack propagates optical dislocations in the probing wave-front are activated at many places along the crack line. In this way, fork fringes locate the tip and propagation of the crack and provide an insight view of the crack growth in the glass plate. In the Fourier transform plane, the first and central orders are filtered out very carefully to get the smooth phase map, and it can be seen from the interferograms of Figs. 3, 4 and 5 that it carries sufficient carrier frequency that zero and first orders can be easily separated out to get the phase map. In our case, we used polished glass plate to avoid unwanted generation of singularities from the speckles. In addition, speckles fields carry the dipolar phase singularities, i.e., phase profile of complex speckle field consists of equal and opposite topological charges. From the interferograms and their wrapped phase maps of Figs. 3, 4 and 5, we can see that there are no fork fringes of equal and opposite topological charges that shows absence of speckle fields in the object beam. Moreover, a vortex has large spatial frequency bandwidth as the phase gradient in a vortex follows the relation \(\nabla \psi =\frac{m}{r}\hat {\phi }\) [33]. Hence, losing some frequency components does not harm the result. From Figs. 4 and 5, it is observed that crack is propagating nearly perpendicular to the straight line fringes and in results generation of an array of fork fringes are seen which are oriented along these straight line fringes in the interferograms. In other cases, when crack propagated parallel to the straight line fringes, the tip of the crack can be located by following the fork location, where fringe bifurcation would take place and the length of the fork fringes would change along the crack propagation. In addition, in this case, all the fork fringes would be appeared along the same fringe line. The presented method is capable to measure the crack growth in both the extreme cases.

4 Conclusion

In conclusion, we presented an experimental tool to track the crack growth in the glass plate using the concept of optical dislocations. Due to the generation of crack, the activated phase variation is imprinted into an optical wave front by transmitting it through the defect sites in the glass plate. This results a local phase jump of \(\psi \left( {r,\phi } \right)\sim 2\pi m\) in the optical wave-front that gives the birth of optical vortex which generate fork fringes after interference with plane waves. We analyzed the interferograms carrying the fork fringes using the Fourier transform fringe analysis method and phase-unwrapping method, to find the position of the dislocations and trajectory of crack tip. Hence, we optically track the optical dislocations generated near to the crack tip in the glass plate using the fork fringes which in turn provides the location of crack tip. In this process, an array of optical dislocations is activated along the path of the crack, as it propagates in the glass plate, and hence, by following the path of these optical dislocations, we experimentally tracked the crack growth. This method offers an insight of crack growth in the glass plate and can be applied in other transparent materials.

References

E.E. Gdoutos, Fracture Mechanics Criteria and Application (Kluwer Academic Publishers, Dordrecht, 1990)

R.G. Forman, V.E. Kearney, R. Engle, Numerical analysis of crack propagation in cyclic loaded structures. J. Basic Eng. 89, 459–464 (1967)

D.A. Hills, P.A. Kelly, D.N. Dai, A.M. Korsunsky, Solution of Crack Problems: The Distributed Dislocation Techniques (Kluwer Academic Publishers, Dordrecht, 1996)

G.I. Barenblatt, The mathematical theory of equilibrium cracks in brittle fracture. Adv. Appl. Mech. 7, 55–129 (1962)

H.L. Ewalds, R.J.H. Wanhill, Fracture Mechanics (Delftse Uitgevers Maatschappij, Delft, 1989)

G.P. Cherepanov, Mechanics of Brittle Fracture (MacGraw Hill, New York, 1979)

L.B. Freund, Dynamic Fracture Mechanics (Cambridge University Press, Cambridge, 1990)

S. Henaux, F. Creuzet, Crack tip morphology of slowly growing cracks in glass. J. Am. Ceram. Soc. 83, 415–417 (2000)

B. Freedman, G. Bartal, M. Segev, R. Lifshitz, D.N. Christodoulides, J.W. Fleischer, Wave and defect dynamics in nonlinear photonic Quasi crystals. Nature 440, 1166–1169 (2006)

H.M. Westergaard, Bearing pressure and cracks. J. Appl. Mech. 6, 49–53 (1939)

D.S. Dugdale, C. Ruiz, Elasticity for Engineers (McGraw-Hill, New York, 1971)

D.S. Dugdale, Yielding of steel sheets containing slits. J. Mech. Phys. Solids 8, 100–104 (1960)

B.A. Bilby, A.H. Cottrell, K.H. Swinden, The spread of plastic yield from a notch. Proc. R. Soc. Lond. A 272, 304–314 (1963)

C. Atkinson, M.F. Kanninen, A simple representation of crack tip plasticity: the inclined strip yield superdislocation model. Int. J. Fracture 13, 151–163 (1977)

M.F. Kanninen, C. Atkinson, C.E. Feddersen, A fatigue crack growth analysis method based on a simple representation of crack tip plasticity. Am. Soc. Test Mat. STP 637, 122–140 (1977)

I. Basistiy, M. Soskin, M. Vasnetsov, Optical wavefront dislocations and their properties. Opt. Commun. 119, 604–612 (1995)

A.G. White, C.P. Smith, N.R. Heckenberg, H. Rubinsztein-Dunlop, R. Mcduff, C.O. Weiss, C. Tamm, Interferometric measurements of phase singularities in the output of a visible laser. J. Mod. Opt. 38, 2531–2541 (1991)

D.P. Ghai, S. Vyas, P. Senthilkumaran, R.S. Sirohi, Detection of phase singularity using a lateral shear interferometer. Opt. Laser Eng. 46, 419–423 (2008)

J. Nye, M. Berry, Dislocations in wave trains. Proc. R. Soc. Lond. A Math Phys. Sci. 336, 165–190 (1974)

P. Senthilkumaran, Singularities in Physics and Engineering—Properties, Methods, and Applications (IOP Publishing, Bristol, 2018)

M. Beijersbergen, R. Coerwinkel, M. Kristensen, J. Woerdman, Helical wavefront laser beams produced with a spiral phase plate. Opt. Commun. 112, 321–327 (1994)

D.P. Ghai, P. Senthilkumaran, R. Sirohi, Adaptive helical mirror for generation of optical phase singularity. Appl. Opt. 47, 1378–1383 (2008)

Y. Izdebskaya, V. Shvedov, A. Volyar, Generation of higher order optical vortices by a dielectric wedge. Opt. Lett. 30, 2472–2474 (2005)

S. Vyas, P. Senthilkumaran, Vortices from wavefront tilts. Opt. Lasers Eng. 48, 834–840 (2010)

S. Vyas, P. Senthilkumaran, Two dimensional vortex lattices from pure wavefront tilts. Opt. Commun. 283, 2767–2771 (2010)

G.R. Irwin, in Fracture Encyclopedia of Physics, Handbuch der Physic, ed. by Vol V.I. Flugge (Springer Verlag, Berlin, 1958), pp. 551–590

C. Rotschild, S. Zommer, S. Moed, O. Hershcovitz, S.G. Lipson, Adjustable spiral phase plate. Appl. Opt. 43, 2397–2399 (2004)

B.K. Singh, D.S. Mehta, P. Senthilkumaran, Generation of vortices using cracked glass plate, in Proceedings of the International Conference on Fiber Optics and Photonics©OSA wp0.6, 2012

M. Takeda, H. Ina, S. Kobayashi, Fourier transform method of fringe-pattern analysis for computer-based topography and interferometry. JOSA 72, 156–160 (1982)

T. Ishida, K. Kakushima, T. Mizoguchi, H. Fujita, Role of dislocation movement in the electrical conductance of nanocontacts. Sci. Rep. 2, 1–5 (2012)

R.M. Goldstein, H.A. Zebken, C.L. Werner, Satellite radar interferometry: two-dimensional phase unwrapping. Radio Sci. 23, 713–720 (1988)

D.C. Ghiglia, M.D. Pritt, Two-Dimensional Phase Unwrapping: Theory, Algorithms and Software (Wiley Inter-science, New York, 1998)

B.K. Singh, M. Bahl, D.S. Mehta, P. Senthilkumaran, Study of internal energy flows in dipole vortex beams by knife edge test. Opt. Commun. 293, 15–21 (2013)

Acknowledgements

We thank the University Grant Commission (UGC) of India for the financial support [Grant No. F.30-356/2017 (BSR)].

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

Supplementary material 1 (MP4 5514 KB)

Rights and permissions

About this article

Cite this article

Singh, B.K., Mehta, D.S. & Senthilkumaran, P. Interferometric visualization of crack growth in glass plate. Appl. Phys. B 125, 21 (2019). https://doi.org/10.1007/s00340-019-7131-1

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00340-019-7131-1