Abstract

To know the line edge inspection in any pattern device, super-resolution optical microscope is efficient and necessary due to diffraction limit. As a step toward these issues, we are reporting the polarization parametric indirect microscopic imaging for patterned device line edge inspection. Sub-nanometer resolution imaging techniques such as atomic force microscope (AFM) and scanning electron microscope (SEM) can cause injurious damage to the sample, and it is more costly, time-taking imaging system. The optical microscopy has better imaging effectiveness, low cost, easy assemble. However, the optical microscopes still have to overcome a critical limit in optical resolution caused by the diffraction of visible light. Three different samples with different thickness have been studied. In this new attempt, we examined whether the etched part is fully etched without SiNx, (SiNx SiO2 + Au) in sample 1, 2 and without photoresist in sample 3, respectively. The maximum line edge resolution of PIMI image is better than resolution of the conventional microscope. All the measurements have been done by parametric indirect microscopic imaging (PIMI) system. PIMI images of third pattern device have been compared with the SEM images.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

For advanced lithography metrology, Scatterometry Critical Dimension (SCD) is a common metrology technique applied to control processes. SCD has the capability to report accurate data information such as photoresist Side Wall Angle (SWA) and photoresist height. However, it is a model-based technological method. Photolithography has played an important role in the modern semiconductor industry as device requirements with shrink pitch and compact dimension. To produce the best line resolution, scanners require tight control of focus and exposure. Recently, the inspection of the edge line in photoresist layers has been a serious issue and it requires a super-resolution optical microscope. In atomic force microscope, one of the major downsides is the single scan image size, which is the order of 150 × 150 µm, compared with millimeters for a scanning electron microscope. It has relatively slow scan time, which can lead to thermal float on the sample. In 1930s, microscopes using electrons such as the scanning electron microscope (SEM) [1] and transmission electron microscope (TEM) [2] were invented. Those two microscopes have much higher resolutions of tens of nanometers, compared with the typical optical microscope due to the shorter De Broglie wavelength of electrons. The disadvantage of a Scanning Electron Microscope starts with the size and cost. SEMs are expensive, large and must be housed in an area free of any possible electric, magnetic or vibration interference. In addition, SEMs are limited to solid, inorganic samples small enough to put inside the vacuum chamber that can be handled with reasonable vacuum pressure. So it is an important issue to achieve the best resolution through an optical microscope.

The optical microscope is very easy to handle and cheaper as compared to SEM, AFM and TEM. In 1870s, Abbe discovered that when an object is observed by optical devices such as microscopes or telescopes, the features smaller than half of the wavelength of light are not resolvable because of diffraction phenomena [3]. Due to the diffraction limit, resolution achievable using a conventional optical microscope is intrinsically limited to approximately two hundred nanometers in visible light. Realizing microscopes with higher resolution have been an active research area. We have already reported the PIMI techniques in the sense of super-resolution imaging using different nanoparticles and some researchers have been reported the super-resolution imaging based on superlens [4,5,6,7,8], further many researchers have been reported based on metamaterial hyperlens for super-resolution image [9,10,11,12,13,14,15,16,17]. Hyperlenses overcome the diffraction limit by transforming evanescent waves, responsible for imaging sub-wavelength features of an object, into propagating waves. In this sense, we have already reported the application of (PIMI) system under the sample of graphene layers [18].

It is well known that the resolution and evaluation of the image quality technique are important for imaging system assessment such as radar [19]. However, there is no method for applying the resolution assessment of the super-resolution PIMI system. In 1980s, the spatial resolution of the order of few nanometers was realized by atomic force microscopy (AFM) [20, 21]. The biggest limitation of NSOM and AFM is that both do topography imaging, which examines only the surface in the near-field. To overcome such limitations, far-field microscopy with super-resolution and bio-compatibility has been successfully developed and widely used. We have reviewed our study in image resolution with different methods [22,23,24,25,26]. Recently we have reported the light scattering by sub-wavelength Cu2O particle [27], and application of PIMI method of sensing the scattering signals from a sub-micrometer particle [28]. In our present work, we have discussed and reported the patterned integrate semiconductor device line edge analysis of super-resolution parametric indirect microscopic imaging (PIMI).The detail discussion is given in the following sections.

2 Theory

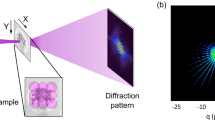

The details theory of PIMI system have already been reported in [18]. In dark-field PIMI, the angled illumination with different linear polarizations excites different anisotropic characteristics in the Sample under Measurement (SUM). These anisotropic features originate in the SUM due to the atomic or the molecular directionality which causes the refractive index variation with the direction of vibration of light [27]. For every polarization illumination, the shape of the far-field point spread function (PSF) is changed due to the near-to-far-field coupling produced as a result of the optical anisotropy. As we modulated the linear polarization for a complete cycle, this modulation of linear polarization makes us enable to sinusoidally formulate the far-field changes at each pixel in the imaging plane. By fitting and filtration at each pixel, the width of the PSF is narrowed down which enable to differentiate between two close-ranged points. In other words, we can image beyond the diffraction limit.

Using the Jones model [29,30,31,32], the pixel intensity Ii over a particular range of polarization angle α is given as [18].

where

I dp is the average intensities over all polarization status transmitted through or reflected from each field points of the SUM, so its value is least affected by scatterings near-field change of polarization status, and sin δ is the sine of phase difference between two orthogonal polarization states, ϕ is the polarization angle of the slow axis. The field intensities at individual pixel of the CCD matrix were recorded while extensive the polarization which is achieved by turning a linear polarization disc in a control component. The intensity variation with parameters, such as the polarization phase and angles, was fit to Eq. (1). From the derived equation, the values of the parameters such as Idp, sin δ and ϕ can be extracted. From the above polarization parameters, using the relationship between Jones’s and Mueller’s model, the Stokes parameters, S0, S1, S2 and S3 can be further calculated with Eq. (3).

where Ex and Ey are the x and y optical field components, \(i=\sqrt { - 1}\), * represent the complex conjugate, S0, S1, S2, S3 are Stokes parameters along with the depolarization intensity, Idp, phase difference, sin δ, and polarization angle, ϕ can be retained to each pixel coordinates in the sensor space to form individual parameter maps, or indirect images as we call them, with the contrasts not built by the optical intensity but the spatial polarization parameters related to near-field characteristics. We put the grating structure [18] with different polarizations at each pixel and fit the far-field changes using Eq. (1) by employing fitting criteria [18].

2.1 Sample description

The top-view geometry of all sample patterns is shown in Fig. 1. In the first sample, 30 nm SiNx is coated on GaN and etched with finger-type patterns. In the second sample, 0.1 μmSiNx + 0.4 μm SiO2 is coated on Au and etched with finger-type patterns similarly, the third sample photoresist on GaN is developed with finger-type patterns. The parameter and thickness of all metals are shown in Fig. 1.

3 Experimental set-up

PIMI is shown in Fig. 2. In this PIMI setup, the light ray is incorporating the conventional optical microscopy, incident light from the source with the module’s rotation polarizer control, analyzer of polarization composed of a quarter and a polarizer, optical image field detection matrix (CCD). The imaging system consists of a white light source illuminating the sample through an objective and CCD camera. In the actual experiment, PIMI system illustrated in Fig. 2 was built using an Olympus reflection microscope system BX51M as the basic optical microscopic path, and inserted into it with polarization-modulation mechanics with the angle precision of 0.05 degrees. The optical intensity data collection monochrome CCD in the system was manufactured by Basler (piA2400-17gm) with the pixel resolution of 3.45 micron and output dynamic range of 12 bits. Furthermore, the PIMI has the sub-100 nm resolution, which is capable of wide view-field and far-field measurement compared with the SEM.

4 Approximate resolution from PIMI image through the edge method

The (Point Spread Function) PSF as a symmetric function of the PIMI, which has already mentioned [33], can be described by a one-dimensional Gaussian function. Therefore, the function of PSF as shown in Eq. (4):

where a1, a2 were determined by the selection of coordinate and resolution, respectively.

The ideal (Edge Spread Function) ESF can be described by Eq. (2):

where \(\phi\) is integration of the standard normal distribution.

The ESF can be extracted from the real image from PIMI [24].The parameter for the description of the resolution is the Full-Width-Half-Maximum (FWHM) of PSF as shown in Eq. (6):

And the resolution from geometrical optics is:

where \(M\) is the magnification.

5 Results and discussion

As explained in the previous section, PIMI obtains optical images indirectly by analyzing optical intensity dependence on polarization parameters, and then extracts sample’s edge structural or compositional information. For the information of edges in the pattern device, we have done the measurements by the PIMI system. As we know that PIMI enables one to obtain optical images with much higher resolution than that obtained by conventional optical microscopes. From Figs. (3, 4, 5), the variation of image intensity with each pixel between the direct image I00 and Stokes parameter, indirect image ϕ for both samples have been compared. In whole manuscript, we have selected only dark-field images for the analysis of edge information, because of the more efficient sensing power and optical anisotropy when compared to the bright-field images. In optical microscopy, dark field describes an illumination technique used to enhance the contrast in unstained samples. It works by illuminating the sample with light that will not be collected by the objective lens and thus will not form part of the image. This produces the classic appearance of a dark, almost black, background with bright objects on it. The sensitivity of ϕ is higher than the other Stokes parameter; therefore, we have used only ϕ PIMI images. For the investigation of edges in pattern devices, photoresist layer needs to be super-resolution microscopy. Therefore, we have tried to solve this issue using the finger-type patterned integrated semiconductor device line edge analysis by developed microscopy (PIMI). With polarization PIMI, we can extract sub-wavelength features in the far-field region which is lacked by the conventional microscopy. In a conventional optical microscope, its resolution is ultimately limited by the diffraction of the beam. PIMI, however, adopts modulated scanning on one or more polarization parameter, such as the angle of polarization perpendicular to the optical axis, while continuously measuring the optical field strength variation at all image points represented by pixel in the CCD matrix. There are some other general issues about the GaN sample, which have been tackled by our PIMI technique. First, one may see the pattern with five fingers shown in (Fig. 1, top view) and one should scan the area between fingers to see whether there is SiNx left or not? Further we have to check whether SiNx is on the fingers or in between the fingers. We also need to know, without photoresist area in the third sample. Based on the line edge resolution and other general issues of GaN sample, we have done the measurements of three different samples by the PIMI techniques. We have also compared the image intensity variation between the direct image (I00) and Stokes parameter, indirect image (ϕ) we have selected only dark images for the analysis of line edge resolution for all the samples, because it’s sensing is more efficient compared to the bright images. In all the PIMI parameter, the sensitivity of (ϕ) is higher than the other parameter, therefore, we have used only (ϕ) PIMI image during the line edge analysis. The details discussion for each sample is given in the following Figs. (3, 4, 5) and contrast calculation in Tables (1, 2, 3).

In reference of line edge resolution on photoresist layer, it is very important to know about image contrast. To make the image quality, this method applies an orientation certainty level (OCL), mean square error (MSE) calculation [34, 35] to the I00 and ϕ images. Figure 3 shows the variation of intensity curve between indirect and direct image (ϕ), (I00) for the sample 1. Further, for the inspection of edge, we simply draw a line in both ϕ and I00 images at the same position, which can see in Fig. 3a, b. We have calculated the contrast, OCL and MSE with the help of PIMI data as shown in Table 1. The contrast of ϕ image is four times better than I00 image. Similarly, for sample 2. The details are shown in Fig. 4, and calculated values of contrast in Table 2.

In the same way, we draw a line in the ϕ and I00 images of the sample 2 at the same position and plotted an intensity curve between them, shown in Fig. 4. From the results, the contrast of ϕ image is nine times better than I00 image and the contrast table seen in Table 2. Furthermore, we have done a similar calculation and drew the curve for sample-3, which has been compared with the SEM image.

The SEM images are not possible for another two samples, due to the sample issue. The section (a, b) in Fig. 5, are the images of indirect (ϕ) and direct (I00) of the PIMI system. At the same way, again we draw a line at the same position in ϕ and I00 images. The contrast has been calculated with help of PIMI data and compared with the SEM image. One can easily differentiate between SEM images and our developed PIMI images. We can compare the direct and indirect PIMI images, which are shown in section (a, b) in Fig. 5. In our PIMI parameter (ϕ), the edge and spots can be seen clear as compared to conventional image (I00) and justified by SEM image shown in Fig. 5. From the results, it is revealed that the contrast of the ϕ image is two times better than I00 image as shown in Table 3. With all results, it is revealed that the low-noise PIMI data also help to achieve the above-mentioned higher edge resolution. The high sensitivity and resolution in PIMI also increase the easiness of imaging. In comparison between all sample’s OCL and contrast table, we found that the image contrast of ϕ is about four times more than direct image. From comparative exhibition as above, polarization PIMI shows the line edge resolution much better than that of conventional microscopy. Among the PIMI parameter ϕ has a wider range of sensing the signals. We found that the resolution of PIMI image is more accurate near about 70 nm. Also, we achieved the resolution of the conventional microscopy as 350.6 nm for the sample whose ideal resolution is about 300 nm using the same objective parameter. Similarly, we have calculated the edge resolution with the help of above-mentioned methods for sample 1, sample 2 and sample 3, which are found to be around 70 nm. In this way, we can also calculate the resolution of any of the sample images using the edge method through the PIMI system. With the help of the results, one can easily find the edge in any patterned integrated semiconductor device line of any sample and also survey the side wall in the photoresist.

6 Conclusion

Polarization PIMI allows line edge scattering photon status information being selectively collected and spatially resolved into super-resolution parametric images and etched GaN-based finger and the developed photoresists. The resolutions of the PIMI images have been calculated by above-mentioned method, which is better than conventional images, around 70 nm. The new optical system, indirect microscopy is very useful to make GaN-based best electronic devices which can be used in the CorEnergy industrial company.

References

M.V. Ardenne, UK Patent 511204-A, 1938

R. Reinhold, DE Patent 906737, 1931

E. Abbe, Beiträge zur Theorie des Mikroskops and der mikroskopischenWahrnehmung. Arch. Mikroskop. Anat. 9(1), 413–418 (1873)

X. Zhang, Z. Liu, Superlenses to overcome the diffraction limit. Nat. Mater. 7(6), 435–441 (2008)

B. Kaleem Ullah, M. Garcia-Camara, M. Habib, N. P. Yadav, X. Liu, An indirect method of imaging the stokes-parameter of a submicron particle with sub-diffraction scattering. J. Quant. Spectrosc. Radiat. Transf. 213, 35–40 (2018)

K. Ullah, B. Garcia-Camara, M. Habib, X. Liu, A. Krasnok, S. Lepeshov, J. Hao, J. Liu, N.P. Yadav, Chiral all-dielectric trimer nanoantenna. J. Quant. Spectrosc. Radiat. Transf. 208, 71–77 (2018)

X. Kaleem Ullah, M. Liu, Habib, Z. Shen, Subwavelength far field imaging of nanoparticles with parametric indirect microscopic imaging, ACS Photonics 5, 1388–1397 (2018)

N. Fang, H. Lee, C. Sun, X. Zhang, Sub-diffraction-limited optical imaging with a silver superlens. Science 308(5721), 534–537 (2005)

H. Dong, J. Wang, K.H. Fung, T. Cui, Super-resolution image transfer by a vortex-like metamaterial. Opt. Express 21, 9407–9413 (2013)

Z. Jacob, L.V. Alekseyev, E. Narimanov, Optical hyperlens: far-field imaging beyond the diffraction limit. Opt. Express 14, 8247–8256 (2006)

A. Fang, K. Thomas, M. Soukoulis Costas, Optical anisotropic metamaterials: negative refraction and focusing. Phys. Rev. B 79, 245127–245133 (2009)

Z. Liu, H. Lee, Y. Xiong, C. Sun, X. Zhang, Far-field optical hyperlens magnifying sub-diffraction-limited objects. Science 315, 1686 (2007)

Q. Meng, X. Zhang, L. Cheng, P. Cao, Y. Li, H. Zhang, G. Wang, Deep sub wavelength focusing of light by a trumpet hyperlens. J. Opt. 13, 075102–075105 (2011)

M. Iwanaga, Hyperlens-array-implemented optical microscopy. Appl. Phys. Lett. 105, 053112 (2014)

A. Salandrino, N. Engheta, Far-field sub diffraction optical microscopy using metamaterial crystals: theory and simulations. Phys. Rev. B 74, 075103 (2006)

J. Rho, Z. Ye, Y. Xiong, X. Yin, Z. Liu, H. Choi, G. Bartal, X. Zhang, Spherical hyperlens for two-dimensional sub-diffraction imaging at visible frequencies. Nat. Common. 1, 143 (2010)

B. Wood, J.B. Pendry, D.P. Tsai, Directed sub wavelength imaging using a layered metal-dielectric system. Phys. Rev. B 74, 115116 (2006)

X. Liu, B. Qiu, Q. Chen, Z. Ni, Y. Jiang, M. Long, L. Gui, Characterization of graphene layers using super resolution polarization parameter indirect microscopic imaging. Opt. Express. 22, 20446–20456 (2014)

Y. Zhou, C. Li, L. Tang, C. Gao, L. Ren, L. Ma, Permanent target for synthetic aperture radar image resolution assessment, In 2015 IEEE International Geoscience and Remote Sensing Symposium (IGARSS)(IEEE2015), pp. 4284–4287

G.K. Bennig, US Patent 4724318 A, 1988

G. Binnig, C.F. Quate, C. Gerber, Atomic force microscope. Phys. Rev. Lett. 56, 930–933 (1986)

Y. Takahashi, T. Akashi, T. Shimakura, T. Tanigaki, T. Kawasaki, H. Shinada, N. Osakabe, Resolution assessment of an aberration corrected 1.2-MV field emission transmission electron microscope. Microsc. Microanal. 21, 1865–1866 (2015)

J. Montoya, A. Ferrero, L. Yu, S. Leng, C. McCollough, WE-FG-207B-09: experimental assessment of noise and spatial resolution in virtual non-contrast dual-energy CT images across multiple patient sizes and CT systems. Med. Phys. 43, 3836–3836 (2016)

G. Brown, I. Daniels, C. Richardson, P. Revell, D. Peppercorn, M. Bourne, Techniques and trouble-shooting in high spatial resolution thin slice MRI for rectal cancer. Br. J. Radiol. 78, 927 (2005)

F. Huth, A. Govyadinov, S. Amarie, W. Nuansing, F. Keilmann, R. Hillenbrand, Nano-FTIR absorption spectroscopy of molecular fingerprints at 20 nm spatial resolution. Nano Lett. 12, 3973–3978 (2012)

Y. A.Arbabi, M. Horie, Bagheri, A. Faraon, Dielectric meta-surfaces for complete control of phase and polarization with subwavelength spatial resolution and high transmission. Nat. Nanotechnol. 10, 937–943 (2015)

K. Ullah, X. Liu, N. Yadav, M. Habib, L. Song, B. Garcia-Camara, Light scattering by subwavelength Cu2O particle. Nanotechnology 28, 134002 (2017)

K. Ullah, X. Liu, X. Jichuan, J. Hao, B. Xu, Z. Jun, W. Liu, A polarization parametric method of sensing the scattering signals from a submicrometer particle. IEEE Photonics Technol. Lett. 29(1), 19–22 (2017)

Q. Zhan, J.R. Leger, High-resolution imaging ellipsometer. Appl. Opt. 41(22), 4443–4450 (2002)

T.G. Browna, M.A. Alonso, A. Vella, Focused beam scatterometry for deep sub wavelength metrology. Proc. SPIE 8949, 89490Y1, (2014)

A. Echalier, R.L. Glazer, V. Fülöp, M.A. Geday, Assessing crystallization droplets using birefringence. Acta Crystallogr. D Biol. Crystallogr. 60(4), 696–702 (2004)

C. Ye, S. Liu, X. Teng, Q. Fang, G. Li, Morphological and optical characteristics of nanocrystalline TiO2 thin films by quantitative optical anisotropy and imaging techniques. Meas. Sci. Technol. 17(2), 436–440 (2006)

Z.-L. Zhu, F.-G. Liu, X.-Y. Tao, An improved slanted-edge method to obtain edge spread function. Nanchang DaxueXuebao-GongkeBan. (J. Nanchang Univ. Eng. Technol. Edn.) 35, 78–82 (2013)

Q. Zhao, F. Liu, L. Zhang, D. Zhang, A comparative study on quality assessment of high resolution fingerprint images, In Proceeding of 17th IEEE International Conference on Image Processing (IEEE, 2010), pp. 3089–3092

P.K. Pandey, Y. Singh, S. Tripathi, Image processing using principle component analysis. Int. J. Comput. Appl. 15, 37 (2011)

Acknowledgements

The authors wish to acknowledge the financial support by the NSFC Grant (No. 61275163), Research Fund for International Young Scientists NSFC Grant (No. 61750110520), Jiangsu Postdoc Research Fund Grant (1601001B) and National Key Research and Development Program of China (2017YFF0107100).

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Yadav, N., Wang, W., Ullah, K. et al. Polarization parametric indirect microscopic imaging for patterned device line edge inspection. Appl. Phys. B 124, 167 (2018). https://doi.org/10.1007/s00340-018-7037-3

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00340-018-7037-3