Abstract

By incorporating a CO2 laser centered at ~ 10.6 μm, a laser-triggered current gating of up to 50 mA was demonstrated in a two-terminal planar device based on a vanadium dioxide (VO2) thin film grown by a pulsed laser deposition method. The laser-triggered current on/off gating was realized by controlling the beam power of the CO2 laser to excite the VO2 device. The transient responses of the laser-triggered currents were investigated when periodical laser pulses from the CO2 laser stimulated the VO2 device at a variety of pulse widths and repetition rates. A switching contrast between off- and on-state currents was calculated as ~ 12,195, and average rising and falling times were measured as ~ 37 and ~ 23 ms, respectively.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Over the past several decades, power semiconductors have achieved remarkable progress in high-efficiency and high-frequency applications. Silicon-based power semiconductors have occupied the latter half of the twentieth century, and in recent years, enhanced power semiconductors based on compound semiconductors such as silicon carbide (SiC) and gallium nitride (GaN) were highlighted for the improvement of the device performance [1, 2]. Among them, a light-triggered thyristor, which is a power semiconductor capable of controlling electric current by light, has been made mainly of compound semiconductors. It has an advantage that its gate terminal is inherently isolated from power sources. Researches on these light-triggered thyristors have been carried out continuously in recent years [3, 4], and some of them have already been commercialized by several companies such as CREE and Siemens. In addition to these compound power semiconductors, oxide semiconductors are also actively studied as novel power semiconductors without PN junction structures. Unlike compound semiconductors, oxide semiconductors composed of a single material and a single layer enable fabrication of power semiconductors with a simpler structure. In addition, there has been an attempt to fabricate a power semiconductor capable of switching current using a vanadium dioxide (VO2) thin film that exhibits an electrical resistance switching of up to four orders of magnitude [5, 6]. VO2 thin films show a reversible phase transition (PT) between an insulating state and a metallic state, which can be triggered by temperature [7], pressure [8], light [9,10,11], and so on. Various electrical and optical devices such as electrical switches [5, 12,13,14,15,16] and oscillators [17, 18], resistance memory devices [19,20,21], microbolometers [11, 22], and actuators [23] have been suggested using a large change in electrical and optical properties associated with the PT. When a VO2 film is fabricated in the form of a two-terminal planar device, the PT can also be induced by applying an electric field between both electrodes of the device. When this field-induced PT is triggered in the VO2-based device, the current flowing through the device rapidly increases, which is caused by the negative differential resistance (NDR) of VO2 [24]. This VO2 device with a strongly nonlinear current–voltage (I–V) behavior can be beneficially applied to an electrical switching device. As an approach to the current switching through external stimulation, photo-assisted electrical gating was reported in a two-terminal planar VO2 device [25]. In a series of related studies since 2007, the threshold voltage, at which the field-induced PT was triggered, could be controlled by adjusting the output power of the infrared laser illuminating the VO2 device [25, 26]. In 2014, a laser-triggered current gating was achieved using a 1550 nm laser diode as an optical stimulus source [27]. This laser-triggered gating, also called bidirectional current switching, means that the forward or reverse field-induced PT of VO2 is triggered according to the switched state (on- or off-state) of an illumination laser. The maximum on-state current was 10 mA in this study, but the switching contrast between on- and off-state currents was as low as ~ 68.2 due to a high off-state current. In 2015, a photothermally induced current gating of up to 10 mA was realized in a two-terminal planar device based on a highly resistive VO2 thin film using a CO2 laser instead of a near infrared laser diode, and a switching contrast was attained to ~ 3333 [28]. As a follow-up study, a laser-triggered 20 mA gating was achieved in a similar VO2 device with a CO2 laser by optimizing an optical illumination setup and laser modulation parameters, resulting in a switching contrast of ~ 7067 [29]. In these previous studies, the CO2 laser used as the optical stimulus source acted like the gate terminal of a transistor or thyristor. The switching performance of a laser-triggered VO2 device such as a switching contrast has been continuously improved over ~ 100 times for years [27,28,29]. However, it is necessary to continuously enhance the switching contrast and maximum on-state current so as to reach the cost performance of commercial light-triggered thyristors.

Here, we report the first experimental demonstration of the laser-triggered current gating between 0 and 50 mA in a two-terminal planar device based on a VO2 thin film grown by pulsed laser deposition (PLD), which is implemented using a CO2 laser to photothermally excite the device. The fabricated planar device contains a highly resistive VO2 thin film between its two electrodes. The isolated VO2 film patch of the device measures 500 µm in both width and length. The output beam from the CO2 laser was focused onto the exposed VO2 patch surface with a beam focusing setup, so that it was directly launched into the film of the device. To determine a bias voltage range to enable laser-triggered gating operation, the I–V characteristics of the fabricated device were analyzed according to the switching state of the laser. Next, to obtain the modulation parameters of the laser that allow stable gating operation, we investigated the minimum energy per pulse (EPP) that could provoke a photothermally induced PT of the VO2 thin film under a selected DC bias voltage. With the VO2 device biased at a DC voltage chosen within the above bias voltage range and the laser power complying with the minimum EPP, a laser-triggered 50 mA gating could be realized at various pulse repetition rates. The switching contrast was evaluated as ~ 12,195 with a suppressed off-state current of ~ 4.1 μA. This switching contrast is improved by ~ 72.6% in comparison with the previous study [29], which results from the increase in the maximum on-state current and a low off-state current. Average rising and falling times were measured as ~ 37 and ~ 23 ms, respectively.

2 Experimental preparation

Figure 1 shows a schematic diagram of the experimental setup for laser-triggered current gating in a two-terminal planar VO2 device, implemented using a CO2 laser (Synrad FSVi30SAC) with a center wavelength of ~ 10.6 μm. The maximum output power of the CO2 laser was ~ 42.5 W, as measured by an optical power meter (Thorlabs PM100D and S314C). The output power of the CO2 laser was controlled by pulse width modulation (PWM) with a carrier frequency of 20 kHz. The actual output power is the inverted exponential decay function of the duty ratio of the carrier signal. The effective irradiation time can be controlled by a TTL signal of a function generator (Tektronix AFG3021C), which is fed into the laser controller via the external trigger port. The rising and falling times of the laser are ~ 29 and ~ 83 μs, respectively, when it operates at a repetition rate of 500 Hz and a duty ratio of 50%, resulting in a pulse width of 1 ms. The output beam of the laser is collimated by a built-in lens, and its 1/e2 beam diameter and full-angle beam divergence are ~ 2.35 mm and ~ 7.0 mRad, respectively. The collimated beam from the laser is steered by a gold-coated line mirror (Thorlabs NB1-L01) and is introduced into a plano-convex lens (Thorlabs LA7660-F) for beam focusing. The damage threshold and reflectivity of the gold-coated line mirror are 4000 W/mm and > 99% at 10.6 μm, respectively. The clear aperture and effective focal length of the plano-convex lens for beam focusing are ~ 20.32 and ~ 75.0 mm at a wavelength of 10.6 μm, respectively. The focused beam was launched into the exposed VO2 film at normal incidence. Its output power was measured as ~ 19.6 W when the PWM duty cycle was 50%. The position of the VO2 device was precisely adjusted using an xyz translation stage, so that the surface diameter of the beam spot became ~ 750 μm. The optical intensity at the VO2 film surface was calculated as ~ 3055.8 W/cm2 at an incident optical power of ~ 13.5 W. The optical fluence at a pulse width of 100 ms under the same laser and beam focusing condition is calculated to be ~ 305.58 J/cm2.

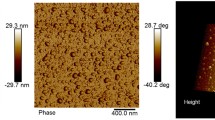

VO2 thin films were grown on 2-inch sapphire (Al2O3) substrates using a PLD method. The substrate temperature (650 °C) and the oxygen atmosphere (32 mTorr) were delicately adjusted to obtain highly resistive VO2 thin films for the purpose of attaining a low off-state device current. The average thickness of the grown films was measured as ~ 100 nm. For the fabrication of two-terminal planar VO2 devices, Au/Ti electrodes were deposited by photolithographic technique on the isolated VO2 films etched through ion-beam-assisted milling, as shown in Fig. 2. The inset at bottom right of Fig. 1 shows a plane-view optical microscope image of the fabricated device. The dimension of the fabricated device (L × W) was 500 × 500 μm2, where L and W were the electrode separation length and exposed film width, respectively. On behalf of a high break-over voltage and a large allowable on-state current, our VO2 devices were fabricated to have larger L and W than those used in our previous studies [28, 29], respectively. Figure 3 shows an X-ray diffraction (XRD) pattern of the VO2 thin film grown on the Al2O3 substrate. This pattern was analyzed before the grown film was processed into the form of a two-terminal device. Two peaks near 40° and 86° correspond to the (020) and (040) planes of the VO2 film, respectively, which confirms the existence of the monoclinic VO2 phase. The two strong peaks near 41° and 91° indicate the (0001) plane of the Al2O3 substrate. The inset of Fig. 3 shows the electrical resistance vs temperature (R–T) characteristics of the fabricated two-terminal VO2 device. Red squares and blue circles indicate heating and cooling curves, respectively. The upper limit of the gating performance such as the switching contrast can be inferred from the resistance variation of this R–T curve. The resistance of the device changes from ~ 1.38 MΩ at room temperature to ~ 71.3 Ω at 95 °C after the PT, and the resistance variation amounts to ~ 1.935 × 104. Hence, the maximum switching contrast attainable in our device is presumed to be no higher than ~ 1.935 × 104. To investigate the transient responses of laser-triggered currents of the device, a test electrical circuit composed of a sourcemeter (Keithley 2410), a VO2 device, and a standard resistor of resistance RE was constructed, as shown in Fig. 1. The sourcemeter was used as a voltage source for a DC bias VS, which was applied to the circuit in all the following measurements. The device current was observed by dividing the voltage across the resistor (RE), measured by a digital oscilloscope (Tektronix TDS2022C), by RE. When analyzing the I–V properties of the device, only the sourcemeter and the VO2 device were utilized instead of the oscilloscope and resistor.

3 Results and discussion

Figure 4a shows the I–V characteristics of the fabricated VO2 device. The I–V properties were measured in a voltage-controlled mode (V-mode) with the laser switched off and on, as indicated by blue circles and red squares, respectively. The compliance current was set at 50 mA to prevent excess current. The output power from the plano-convex lens was regulated to ~ 13.5 W by adjusting the PWM duty ratio as 31% to avoid damages to the device when the laser was switched on. This I–V curve measurement was carried out repeatedly to ensure the measurement stability of the electrical property of the device. The maximum standard errors for the device current were ~ 6.0 × 10−8 and ~ 2.3 × 10−4 A when the laser was switched off and on, respectively. When the device is excited by the focused laser beam, the temperature of the VO2 film immediately increases and soon exceeds its transition temperature (~ 68 °C). In addition, most of insulating VO2 grains change into metallic ones through photothermally induced PT, which is referred to as the forward PT. Therefore, under this laser excitation, the field-induced PT can easily be triggered even at low applied VS, accompanied by an abrupt jump of the device current due to a big drop in the device resistance. On the other hand, if the laser illumination is interrupted, the device temperature rapidly drops below the transition temperature, and VO2 grains return to the insulating state, which is referred to as the reverse PT. Owing to the upsurge in the film resistance, the current flowing through the device is also blocked. In other words, it is possible to trigger the forward or reverse PT by controlling the laser illumination power. To achieve a high switching contrast and stable gating operation, the device temperature should be maintained as low as the room temperature level when the laser is turned off. That is because the off-state current affecting the switching contrast significantly depends on the off-state device temperature. This off-state temperature is directly dependent on the average power of the laser, i.e., a product of its EPP and repetition rate. The EPP is calculated by multiplying the peak power and pulse width of the laser. Hence, these laser parameters such as the peak power, pulse width, and repetition rate should be appropriately balanced to achieve the stable gating operation and high switching contrast. The bias voltage and initial temperature of the device are additional factors affecting the gating operation. Joule heat induced by a high bias voltage causes the device to need more time to cool down to the off-state temperature after the end of laser illumination. Accordingly, the repetition rate of the laser should be decreased to ensure sufficient cooling time for the device. Next, the initial temperature of the device affects the overall switching performance. If the initial device temperature is much lower than room temperature, the repetition rate of the laser can be further elevated in comparison with the gating operation at room temperature, although a higher EPP (i.e., the product of the peak power and the pulse width) is required to turn on the device. This is because the device is cooled down faster during the illumination-free interval due to low ambient temperature. However, the initial temperature higher than room temperature will increase the off-state current, resulting in direct deterioration of the switching contrast. In particular, it needs more time for residual heat to sufficiently dissipate from the device during blocking of the laser, and thus, the repetition rate should be decreased for stable gating operation. Moreover, our VO2 devices used in the experiments are designed to have larger dimensions than previous studies [28, 29] for rapid heat dissipation to directly help the improvement of gating performances.

a I–V characteristics of the fabricated VO2 device, measured in V-mode with the CO2 laser switched off (blue circles) and on (red squares) and b laser-triggered reversible current gating according to the bias voltage with the CO2 laser repeatedly toggled on and off. The inset of a shows the I-mode I–V characteristics of the device, measured without laser excitation

The inset of Fig. 4a shows the I–V characteristic of the fabricated VO2 device, measured in current-controlled mode (I-mode) without laser excitation to investigate the break-over voltage of the device. As shown in this inset, there is no abrupt current rise or breakdown behavior at VS < 280 V without laser excitation, which implies that the break-over voltage is higher than 280 V. Prolonged increase of VS above the threshold voltage, or the break-over voltage, can cause the field-induced PT of the device even without laser illumination. However, when the PT is triggered by significantly high VS, the breakdown of the device is unavoidable, although the compliance current is set low. Figure 4b shows laser-triggered reversible current gating, which is measured at VS increasing from 0.5 to 10 V with the laser repeatedly toggled on or off for each state. This voltage sweep operation was carried out for ~ 29 s, and the temporal interval between laser-on states was less than 1 s. In the above bias range of VS (0.5–10 V), 27 reversible gating operations were obtained by periodically switching the CO2 laser on or off. As can be found from this gating result, a stable current gating of up to 50 mA occurs at VS > 3.8 V.

Figure 5a–d shows the transient responses of the laser-triggered device when the CO2 laser, whose illumination power from the plano-convex lens is ~ 13.5 W, is modulated at a fixed repetition rate of 1.0 Hz with on-state pulse widths of 50, 75, 100, and 150 ms, respectively. The transient responses of the current flowing through the VO2 device were measured in the test electrical circuit shown in Fig. 1 with VS = ~ 4.4 V and RE = 10 Ω, and the compliance current was set at 50 mA for all the measurements. The above bias voltage VS was determined by considering RE (10 Ω), the VS range (3.8–10 V) for stable gating operation, and the maximum on-state current (50 mA). As shown in Fig. 5a, b, the laser-triggered gating operation is unstable and intermittent, and the device current sometimes fails to reach 50 mA when the on-state pulse width is less than 100 ms. In contrast, the current gating operation becomes stable when the on-state pulse width exceeds 100 ms, as can be seen from Fig. 5c, d. From these results, the minimum EPP to trigger the photothermally induced PT was determined as ~ 764 mJ under this bias condition (VS = ~ 4.4 V) for the stable current gating of up to 50 mA. This minimum EPP was calculated by multiplying the optical fluence (~ 305.58 J/cm2) at the on-state pulse width of 100 ms and exposed film area of the device (2.5 × 10−3 cm2). The same minimum EPP was also obtained in single-pulse experiments. This minimum EPP is about 63 times higher than the previous study [29] using the same device structure and the CO2 laser. However, this minimum EPP can be regarded actually as not being so high in comparison with the previous minimum EPP if it is considered that the exposed film area of our VO2 device is 50 times larger than that of the previous device (L × W = 100 × 50 µm2) [29]. Some increase in the minimum EPP is attributed to the high resistivity of the fabricated VO2 film.

To examine the dependence of the laser-triggered gating on the repetition rate of the illumination laser, the current gating responses of the VO2 device were investigated for various repetition rates with the laser pulse satisfying the above minimum EPP. Figure 6a–f shows the transient responses of the laser-triggered device when the laser is modulated at six different repetition rates of 0.1, 0.5, 1.0, 2,0, 3.0, and 4.0 Hz, respectively. The illumination power from the plano-convex lens and the on-state pulse width were set as ~ 13.5 W and 100 ms to satisfy the minimum EPP, respectively. The same test circuit (VS = ~ 4.4 V and RE = 10 Ω) with the equal compliance current (50 mA) was employed again for the measurement. In this configuration, stable laser-triggered gating between 0 and 50 mA could be realized for the repetition rates of 0.1–4.0 Hz. The average off-state current was measured as ~ 4.1 μA, and the maximum switching contrast was evaluated as ~ 12,195. This switching contrast is higher by ~ 72.6% than that reported in the previous study [29]. This high switching contrast fundamentally comes from the increased maximum on-state current permitted to the device by the increased width (W) of its current channel and the suppressed off-state current that originates from the increased electrode separation (L) and the highly resistive VO2 thin film, whose resistivity amounts to ~ 0.107 Ω⋅m at room temperature. The resistivity of the VO2 film used in the previous study [29] was ~ 0.085 Ω⋅m at room temperature. Especially, average rising and falling times were measured as ~ 37 and ~ 23 ms, respectively. The increased on-state current and the expanded beam spot to cover the large device dimension are responsible for these response times slightly slower than the previous study [29]. The falling time relatively faster than the rising time mainly results from rapid heat dissipation due to the 2-inch Al2O3 substrate and Au/Ti electrodes larger than the VO2 film dimension. The falling time tends to increase slightly in accordance with the repetition rate, because the increased average power raises the off-state device temperature. This indicates that it takes more time for the device to be cooled down at higher repetition rates.

It is complicated to accurately calculate the temperature variation of the device due to laser heating. However, the energy balance of the device could be considered by restricting the discussion to the factors that have the greatest effect on the device temperature. In laser-triggered current gating in a VO2 device, one cycle of the gating can be decomposed into four stages: (1) at the onset of laser illumination, a VO2 device in the insulating state absorbs laser light, and the forward PT is triggered due to increased temperature; (2) a device current, which is greatly increased after the PT, causes Joule heat; (3) after the laser illumination ends, energy dissipation through the substrate and metal electrodes starts to overtake thermal energy being accumulated in the device; and (4) the device temperature falls below the transition temperature, and the device current is nearly blocked due to a great increase in the device resistance. At the first stage, the energy UON, which is effectively absorbed into the VO2 thin film and associated with the temperature change of the device, is given by UON = UEPP × α(T), where UEPP is the minimum EPP of the laser for triggering the PT, and α(T) is the temperature-dependent absorbance of VO2. Then, UON is calculated to be UEPP × α(T) = (~ 764 mJ) × (~ 0.8) = ~ 611 mJ, where UEPP is ~ 764 mJ determined from the experimental results shown in Fig. 5 and α(T) at room temperature is ~ 0.8 determined by considering the transmittance and reflectance of the VO2 film [30, 31]. At the second stage, the device is changed into the metallic state by laser heating. Then, Joule heat QC is generated by the device current. QC can be calculated by multiplying the on-state current, the voltage across the device, and the actual on-state duration, resulting in (50 mA) × [4.4 V − (10 Ω × 50 mA)] × (~ 86 ms) = ~ 16.8 mJ. Here, the actual on-state duration (~ 86 ms), which implies the temporal interval for which the on-state current flows, was determined by considering the average response time obtained from the transient responses of the device current with the on-state pulse width of the laser set at 100 ms. This Joule heat (QC) is ~ 36 times smaller than UON, so it is impossible to sustain the on-state current as well as turn on the device by only current-induced Joule heat without laser illumination.

At the third stage, after the laser illumination is blocked, heat energy that dissipates through the substrate and electrodes per unit time becomes larger than that generated in the device per unit time. The total thermal energy UT, which is generated by the laser and device current, is calculated to be UON + QC = ~ 627.8 mJ. Most of UT should be dissipated within one gating period (1 over repetition rate) for the reverse PT to be triggered, that is, for the device current to go down to the off-state current. In particular, complete dissipation of UT is needed within one gating period for stable gating operation over numbers of periods. It is difficult to accurately calculate dissipation power PD (i.e., dissipation energy per unit time) of our device, but a rough estimation on it is possible. In our experimental results, stable bidirectional gating operation could be achieved when the repetition rate of the laser was ≤ 4 Hz, as shown in Fig. 6. However, if the repetition rate exceeded 5 Hz, the off-state current continued to increase every gating cycle, and finally, the bidirectional gating operation could not be realized after tens of gating cycles. This indicates that for one gating period, thermal energy accumulated in the device is larger than dissipated energy at repetition rates more than 5 Hz. By considering UT and two gating periods at repetition rates of 4 and 5 Hz (i.e., 250 and 200 ms, respectively), PD is estimated to be in a range from 2.51 to 3.14 W. At the final stage, as the dissipated heat energy is greater than the generated one, the device temperature cannot be sustained above the transition temperature. Ultimately, the VO2 film in the device returns to the insulating state, and thus, the device current is blocked. This thermal energy balance described above supports the reversible current gating based on photothermal effect. For the reliability test of our laser-triggered gating, the current gating operation was carried out for 30 min using a repetition rate of 1 Hz and a pulse width of 100 ms, and no noticeable variation was observed in the measured responses.

4 Conclusion

In summary, a laser-triggered 50 mA gating was implemented in the fabricated two-terminal planar VO2 device using a CO2 laser with a center wavelength of ~ 10.6 μm. The bias voltage range for the stable current gating operation was determined by investigating the I–V characteristics of the fabricated device. The modulation parameters of the CO2 laser enabling the laser-triggered current gating were analyzed. The minimum EPP that could trigger the photothermally induced PT was determined as ~ 764 mJ by analyzing the transient responses of laser-triggered device currents. In the VO2 device biased at ~ 4.4 V, a current gating between 0 and 50 mA was realized for various repetition rates (0.1–4.0 Hz), where the peak power and pulse width of the laser were set as ~ 13.5 W and 100 ms to satisfy the minimum EPP, respectively. The switching contrast was evaluated as ~ 12,195 with a low off-state current of ~ 4.1 μA, and average rising and falling times were measured as ~ 37 and ~ 23 ms, respectively. The enhanced switching contrast and increased maximum on-state current with a cost-effective CO2 laser are expected to beneficially support the development of advanced oxide-based switching devices in future power electronics and electrical systems.

References

J. Rabkowski, D. Peftitsis, H.-P. Nee, Silicon carbide power transistors: a new era in power electronics is initiated. IEEE Ind. Electron. Mag. 6, 17–26 (2012)

B.J. Baliga, Gallium nitride devices for power electronic applications. Semicond. Sci. Technol. 28, 074011 (2013)

S.L. Rumyantsev, M.E. Levinshtein, M.S. Shur, L. Cheng, A.K. Agarwal, J.W. Palmour, Optical triggering of high-voltage (18 kV-class) 4H-SiC thyristors. Semicond. Sci. Technol. 28, 125017 (2013)

J. Hasegawa, L. Pace, L.V. Phung, M. Hatano, D. Planson, Simulation-based study about the lifetime and incident light properties dependence of the optically triggered 4H-SiC thyristors operation. IEEE Trans. Electron. Devices 64, 1203–1208 (2017)

Y. Zhou, X. Chen, C. Ko, Z. Yang, C. Mouli, S. Ramanathan, Voltage-triggered ultrafast phase transition in vanadium dioxide switches. IEEE Electron. Device Lett. 34, 220–222 (2013)

J. Kim, K. Park, B.-J. Kim, Y.W. Lee, Bidirectional current triggering in planar devices based on serially connected VO2 thin films using 965 nm laser diode. Opt. Express 24, 17720–17727 (2016)

F.J. Morin, Oxides which show a metal-to-insulator transition at the neel temperature. Phys. Rev. Lett. 3, 34–36 (1959)

E. Arcangeletti, L. Baldassarre, D. Di Castro, S. Lupi, L. Malavasi, C. Marini, A. Perucchi, P. Postorino, Evidence of a pressure-induced metallization process in monoclinic VO2. Phys. Rev. Lett. 98, 196406 (2007)

A. Cavalleri, C. Tóth, C.W. Siders, J.A. Squier, F. Ráksi, P. Forget, J.C. Kieffer, Femtosecond structural dynamics in VO2 during an ultrafast solid-solid phase transition. Phys. Rev. Lett. 87, 237401 (2001)

M. Rini, A. Cavalleri, R.W. Schoenlein, R. López, L.C. Feldman, R.F. Haglund Jr., L.A. Boatner, T.E. Haynes, Photoinduced phase transition in VO2 nanocrystals: ultrafast control of surface-plasmon resonance. Opt. Lett. 30, 558–560 (2005)

S. Han, C.H. Chun, C.S. Han, S.M. Park, Coupled physics analyses of VO x -based, three-level microbolometer. Electron. Mater. Lett. 5, 63–65 (2009)

G. Stefanovich, A. Pergament, D. Stefanovich, Electrical switching and Mott transition in VO2. J. Phys. Condens. Matter 12, 8837–8845 (2000)

H.-T. Kim, B.-G. Chae, D.-H. Youn, S.-L. Maeng, G. Kim, K.-Y. Kang, Y.-S. Lim, Mechanism and observation of Mott transition in VO2-based two- and three-terminal devices. New J. Phys. 6, 52 (2004)

A. Joushaghani, J. Jeong, S. Paradis, D. Alain, J.S. Aitchison, J.K.S. Poon, Voltage-controlled switching and thermal effects in VO2 nano-gap junctions. Appl. Phys. Lett. 104, 221904 (2014)

S. Zhang, M.A. Kats, Y. Cui, Y. Zhou, Y. Yao, S. Ramanathan, F. Capasso, Current-modulated optical properties of vanadium dioxide thin films in the phase transition region. Appl. Phys. Lett. 105, 211104 (2014)

P. Markov, R.E. Marvel, H.J. Conley, K.J. Miller, R.F. Haglund Jr., S.M. Weiss, Optically monitored electrical switching in VO2. ACS Photonics 2, 1175–1182 (2015)

H.-T. Kim, B.-J. Kim, S. Choi, B.-G. Chae, Y.W. Lee, T. Driscoll, M.M. Qazilbash, D.N. Basov, Electrical oscillations induced by the metal-insulator transition in VO2. J. Appl. Phys. 107, 023702 (2010)

G. Seo, B.-J. Kim, Y.W. Lee, S. Choi, J.-H. Shin, H.-T. Kim, Experimental investigation of dimension effect on electrical oscillation in planar device based on VO2 thin film. Thin Solid Films 519, 3383–3387 (2011)

H. Coy, R. Cabrera, N. Sepúlveda, F.E. Fernandez, Optoelectronic and all-optical multiple memory states in vanadium dioxide. J. Appl. Phys. 108, 113115 (2010)

R. Macaluso, M. Mosca, V. Costanza, A. D’Angelo, G. Lullo, F. Caruso, C. Calì, F. Di Franco, M. Santamaria, F. Di Quarto, Resistive switching behaviour in ZnO and VO2 memristors grown by pulsed laser deposition. Electron. Lett. 50, 262–263 (2014)

J. Kim, K. Park, S. Jo, B.-J. Kim, H.Y. Kang, S.Y. Nam, J. Oh, Y.W. Lee, Memristive states in vanadium-dioxide-based planar devices stimulated by 966 nm infrared laser pulses. Jpn. J. Appl. Phys. 54, 102601 (2015)

C. Chen, X. Yi, J. Zhang, B. Xiong, Micromachined uncooled IR bolometer linear array using VO2 thin films. Int. J. Infrared Millim. Waves 22, 53–58 (2001)

T. Wang, D. Torres, F.E. Fernández, A.J. Green, C. Wang, N. Sepúlveda, Increasing efficiency, speed, and responsivity of vanadium dioxide based photothermally driven actuators using single-wall carbon nanotube thin-films. ACS Nano 9, 4371–4378 (2015)

B.K. Ridley, T.B. Watkins, The possibility of negative resistance effects in semiconductors. Proc. Phys. Soc. Lond. 78, 293–304, (1961)

Y.W. Lee, B.-J. Kim, S. Choi, H.-T. Kim, G. Kim, Photo-assisted electrical gating in a two-terminal device based on vanadium dioxide thin film. Opt. Express 15, 12108–12113 (2007)

Y.W. Lee, B.-J. Kim, S. Choi, Y.W. Lee, H.-T. Kim, Enhanced photo-assisted electrical gating in vanadium dioxide based on saturation-induced gain modulation of erbium-doped fiber amplifier. Opt. Express 17, 19605–19610 (2009)

B.-J. Kim, G. Seo, Y.W. Lee, Bidirectional laser triggering of planar device based on vanadium dioxide thin film. Opt. Express 22, 9016–9023 (2014)

J. Kim, S. Jo, K. Park, B.-J. Kim, Y.W. Lee, Photo-thermally induced current switching in vanadium-dioxide-based devices using CO2 laser pumping. J. Nanosci. Nanotechnol. 15, 8484–8488 (2015)

J. Kim, S. Jo, K. Park, H.-J. Song, H.-T. Kim, B.-J. Kim, Y.W. Lee, 20 mA bidirectional laser triggering in planar devices based on vanadium dioxide thin films using CO2 laser. Opt. Express 23, 14234–14244 (2015)

H.S. Choi, J.S. Ahn, J.H. Jung, T.W. Noh, D.H. Kim, Mid-infrared properties of a VO2 film near the metal-insulator transition. Phys. Rev. B Condens. Matter 54, 4621–4628 (1996)

C. Chen, Z. Zhou, Optical phonons assisted infrared absorption in VO2 based bolometer. Appl. Phys. Lett. 91, 011107 (2007)

Acknowledgements

This research was supported by Basic Science Research Program through the National Research Foundation of Korea(NRF) funded by the Ministry of Education (2016R1D1A1B03933263).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kim, J., Jeong, S.J., Kim, BJ. et al. Laser-triggered current gating based on photothermal effect in VO2 thin-film device using CO2 laser. Appl. Phys. B 124, 67 (2018). https://doi.org/10.1007/s00340-018-6936-7

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00340-018-6936-7