Abstract

In this study, we present the development and characterization of Cu plasma X-ray source driven by 20 W average power high repetition rate femtosecond laser in ambient atmosphere environment. The peak Cu-Kα photon flux of 2.3 × 109 photons/s into full solid angle is demonstrated (with a process conversion efficiency of ~ 10−7), using pulses with peak intensity of 4.65 × 1014 W/cm2. Such Cu-Kα flux is significantly larger than others found in comparable experiments, performed in air environment. The effects of resonance plasma absorption process, when optimized, are shown to increase measured flux by the factor of 2–3. The relationship between X-ray photon flux and plasma-driving pulse repetition rate is quasi-linear, suggesting that fluxes could further be increased to 1010 photons/s using even higher average powers of driving radiation. These results suggest that to fully utilize the potential of high repetition rate laser sources, novel target material delivery systems (for example, jet-based ones) are required. On the other hand, this study demonstrates that high energy lasers currently used for plasma X-ray sources can be conveniently and efficiently replaced by high average power and repetition rate laser radiation, as a way to increase the brightness of the generated X-rays.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Recent years saw an ever growing interest in research of both high-harmonic, and pulsed hard X-ray generation via femtosecond laser pulses. Short X-ray pulses can be used in a wide range of areas starting from astrophysics [1] or medicine [2], and ending by various structural analysis methods, most promising being X-ray spectroscopy and diffraction measurements [3,4,5]. Such techniques are characterized by femtosecond temporal and angstrom spatial resolutions [6], allowing direct observation of atom-level structural changes in different samples. Femtosecond X-ray pulses used for such purposes can have durations as low as ~ 100 fs; they are traditionally generated at large-scale infrastructures such as synchrotrons and free-electron lasers [7, 8]. However, the pulse energies of modern lasers are continuously growing, whereas pulse durations can be significantly shorter than 100 fs. At the same time, the repetition rates of laser pulses are rising, and the overall increase of both average and peak power of radiation makes laser driven plasma X-ray sources a viable alternative. Such sources are capable of producing Kα X-ray photon (typically 5–15 keV) fluxes up to and above 1010 photons/s [9].

Depending on determined target size of the flux, the intensity of driving laser pulses can exceed 1021 W/cm2 [10]. Generation of such pulses with extremely high peak powers is a problem that scales badly: as soon as the components of laser system start to operate close to their damage threshold, the only way to increase the number of photons per pulse is increasing the size of the laser components, which poses considerable cooling-related problems and increases the dollar-per-photon price of the laser, because of the difficulty of producing large-area optical components of sufficient quality. It is also worth noting, that while a Kα photon (in the vicinity of ~ 10 keV) flux of ~ 1010 photons per second may not require such excessive pulse intensity values (~ 1018 W/cm2 is more typical [9]), effects of such pulse peak power on X-ray generation efficiency might not be fully utilized if X-ray source is created in an ambient air environment.

As an alternative, X-ray photon flux can be increased using lasers featuring moderate pulse energies (and in turn beam intensity values), but operating at higher pulse repetition rates. In other words, as long as the average power of the laser is more or less constant, and the pulse energy is sufficient for X-ray generation, the way to obtain more photons can be the increase of the repetition rate, while keeping the peak intensity of the pulse more or less constant. In such cases, however, effective target renewal becomes a considerable problem. The more traditional “tape” delivery systems that are typically used with solid targets are characterized by their limited renewal capabilities, i.e. target linear velocities rarely exceed several tens of centimeters per second [9, 11, 12], which in turn requires increased peak power of separate pulses to maintain relatively large Kα photon fluxes (~ 1010 photons/s or more). On the other hand, while jet-based delivery systems do not suffer from such impediments, depending on target material they require either rather complex working conditions [13], or are limited by the resulting flux (~ 106 photons/s in full spectrum) if more easily handled materials, such as water, are used [14, 15].

The purpose of this paper is to show that a copper plasma X-ray source driven by high average power femtosecond laser pulses in ambient air environment, together with a “spinning disk” target translation system, can produce photon fluxes comparable to those found in other X-ray radiation generating systems [9, 16, 17], which make use of laser pulse intensities up to 100 times larger than the ones applied in this work. In accordance with this goal, an experimental setup utilizing a femtosecond laser with 20 W average power is presented, along with key characteristics (photon flux dependence on laser pulse energy and repetition rate) of produced plasma X-ray source.

2 Materials and methods

2.1 Target delivery

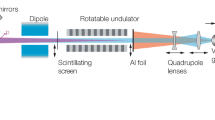

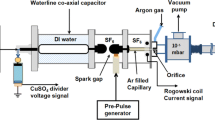

The layout of the setup for X-ray generation using a copper target is presented in Fig. 1. Pharos PH1-20 (Light Conversion Ltd., central wavelength λ ≈ 1026 nm, pulse energy E p = 50–400 μJ, pulse duration τ p ≈ 270 fs, average output power 20W) laser acted as a femtosecond pulse source for plasma driving. Prepulse contrast to main pulse was lower than 10−3, with a time interval of ~ 40 ns between them—in turn, effects of generated pre-plasma were considered to be negligible [18]. The laser beam was focused using singlet lenses with focal lengths of f = 75 mm and f = 100 mm. Pulses of linear polarization were used, corresponding to p polarization when the angle of radiation incidence θ was greater than zero. Polarization direction itself was controlled via a low-order λ/2 wave plate, placed before the focusing lens (see Fig. 1). Two target refreshment techniques were used to deliver fresh spot of the target (Cu foil) to the beam focus. The first method, referred to as ‘Lissajous scheme’ was implemented using an XYZ Aerotech positioning system (Aerotech ABL1500 and ABL1500WB stages, controlled via Aerotech A3200 controller). The Cu foil was moved transversely to the beam in xy plane by oscillating both axes at different frequencies and producing a Lissajous trajectory. In this case, a 100 mm lens was used to focus the laser beam onto 200 μm thick Cu foil. The maximum speed of target translation, limited by the translation stages was 0.06 m/s. When the angle θ between the plane of the target and the plane perpendicular to the laser beam was not equal to zero, the change in the focal position resulting from target translation was compensated by the Z stage shifting the focusing lens.

The radiation collection scheme, identical for both target delivery systems (a), and the ST target renewal setup (b), used for the generation of hard X-rays via femtosecond laser pulse driven plasma source. The Lissajous target delivery system replaces the rotational stage seen in (a) and (b) with an XY Aerotech positioning system

The second target refreshment scheme, referred to as ‘Spinning-Translation (ST)’ scheme allowed faster target delivery. The 30 μm thick Cu foil targets were fitted on a mechanical rotation stage rotating at up to 4700 RPM, corresponding to the linear velocity of 20 m/s at the edges of the holder (values up to 5 m/s were calculated to be necessary in order to completely separate target areas exposed to a single driving pulse). To fit pulse-affected areas as compactly as possible without letting them overlap, the exact spinning RPM values v rot were varied in accordance with applied repetition rates of laser pulses. At the same time, the rotation stage was translated in the focal plane of the lens using the mentioned Aerotech positioning system. The driving laser light was focused using a 75 mm lens to a focal spot of approximately 30 μm in diameter. For each laser pulse, a target area of about 60 μm × 60 μm (out of ~ 27 cm2 total) was dedicated without overlap, as verified by the brightfield image obtained with Olympus BX51 microscope (see Fig. 2b). The Cu target had to be replaced after filling its entire area with laser shots (corresponding to the time of approximately 13 s at the highest repetition rates). The angle θ between the target plane and the beam incidence was compensated using the Z stage of the Aerotech positioning system as before.

Typical spectrum of an X-ray radiation plasma source, obtained via Amptek X-123 spectrometer, with laser pulses of 30 kHz repetition rate and 400 μJ energy fired upon Cu target. Black circle marks the location of second order pile-up artifacts (a). Micrograph of a section of Cu target filled up with damaged areas produced by single femtosecond pulses of 50 kHz repetition rate and 400 μJ pulse energy (b)

2.2 Detection of X-rays and data preprocessing

The generated X-rays were detected by Amptek X-123 spectrometer which uses a thermoelectrically cooled Si-PIN junction detector (area—25 mm2, thickness—0.5 mm), that transmits signals via pre-amplifier to digital pulse processor DP5, consisting of shaping—amplifier and a multichannel analyzer. Before entering detector, the incident photons pass a protective 25 μm Be foil and a collimator. The measurements were performed in ambient air environment, with no additional gas jets (such as helium) delivered to the target. The distance d between the detector and the target was set to 250 mm, and the collection angle ϕ was 15° with respect to the plane xy of the optical table (see Fig. 1). In most cases, the measured X-ray flux needed to be further attenuated by several additional 95 μm thick Al foils acting as absorbers for photons with energies under ~ 6 keV (see Fig. 2a). These were used to diminish the bremsstrahlung contribution and pre-select the characteristic spectral lines; minimizing the counting rate of the spectrometer was also important to avoid possible detector saturation and photon pile-up phenomena—in turn, spectrometer total input counting rate was always limited to a value equal to 20–30% of applied laser pulse repetition rate. The angular distribution of X-rays from laser driven plasma sources has been modeled [19, 20], and measured to be almost isotropic in the entire solid angle (deviations are within 10%): this allowed to calculate total flux by detecting only a fraction of emitted radiation entering the detector. The presented fluxes were recalculated for the entire solid angle, and corrected for the absorption in air (and also in Be and Al layers, when necessary), using NIST-provided mass absorption coefficient values [21].

The X-ray photon flux was estimated by counting the photons matching Kα wavelengths of the target material. This is a common method of X-ray plasma source characterization [9, 22, 23]. Such choice was also influenced by the fact that the used spectrometer exhibits high detection efficiency (> 90%) only in the range of 2–13 keV, while the generated bremsstrahlung radiation covers a much larger spectral interval. Cu targets proved to be the most suitable material for plasma generation—its Kα 1 , Kα 2 and Kβ lines correspond to near 100% detection efficiency of spectrometer. It is, however, important to note that the instruments like X-123 are usually used to investigate phenomena no shorter than ~ 1 μs. Since this was not the case (we used a high repetition rate femtosecond laser as a driving source), the measured spectra were distorted by pulse pile-up artifacts, which had to be corrected.

An example of measured spectra is shown in Fig. 2a, where the measurements were performed with additional absorbing Al foils placed between the spectrometer and Cu target. The Kα signal is diminished, but clearly observable, making data processing tasks easier. On the right side of the line spectrum, an instance of small pile-up artifacts is present. Coincident photons are counted as one, resulting in measured energies two times higher than those of characteristic Cu lines. Such artifacts become more apparent at higher laser pulse energies. To correct for these artifacts, we used the method described in other studies, where similar detection devices were utilized [24]. The data are recalculated by integrating an area of ~ 550 eV centered on the characteristic line peak of ~ 8.04 keV (with similar integration processes applied to harmonic artifacts). Subtraction of bremsstrahlung part of the integral results in Cu-Kα lines of about 250–300 eV FWHM width. Each harmonic is scaled by a factor accounting for the order of coincidence (1), although in case of this work, only small traces of second order pile-up artifacts were witnessed (with no third order lines in sight, see Fig. 2a, as a result, artifact counts consisted of no more than 5–10% of original first order detections. It is worth noting, that such photon counting method gives similar results to one, which applies Poisson statistics for spectral artifact correction [16, 25]. In short, Kα fluxes were evaluated using Eq. (1):

where N i —number of counts corresponding to ith order of detection coincidences, d—distance between spectrometer and Cu target, T Air, T Al, T Be—values of air, Al and Be layers’ transmission spectra at Kα line peak energy (in case of Cu ~ 8.04 keV), S det—area of Si-PIN detector, t—measurement time. The latter depends strongly on pulse repetition rate values: as the repetition rate increases, the target material is used up more quickly, and the time spent on a single measurement is reduced.

It must be noted that the absence of bremsstrahlung radiation makes the process of artifact correction much easier and quicker. The amount of artifacts in obtained spectra can be reduced by introducing additional photon flux absorbents with the penalty of increasing integration time of detected signal. Comparative measurements showed, however, that flux data retrieved by simply filtering out a part of bremsstrahlung input and using Eq. (1) are identical within the experimental error to the results obtained at lower counting rates.

3 Results and discussion

The dependencies of X-ray flux on the laser repetition rate f rep and pulse energy E p, (measured using Lissajous target translation scheme) are shown in Fig. 3. The fluxes were calculated using Eq. (1), with laser pulse angle of incidence θ kept at zero. The results shown in Fig. 3a were obtained at the maximum velocity of target translation stages—0.06 m/s. Such velocity allows exciting fresh target spots at f rep between 2.5 and 10 kHz: at lower repetition frequencies, pulse-affected target areas become fully separated at speeds of ~ 0.02 m/s; at higher repetition rates the shot-to-shot refreshment of the target becomes impossible with the linear stages. Presumably, the insufficient target refreshment results in the decrease of X-ray flux at higher laser repetition rates, observed in Fig. 3a. When the target is moved at the constant maximum speed of 0.06 m/s, Kα photon flux reaches a peak at f rep value of 5 kHz, and then declines, when repetition rate is increased further. The sharp decrease of generated photons at higher frequencies can be explained by the fact that the increase in the average driving power can no longer compensate the ineffective delivery of fresh target material.

The dependence of Cu- Kα photon flux ϕ Kα on the pulse repetition rate at different pulse energies, at the maximum linear motion velocity (0.06 m/s) of Cu target, with Lissajous translation scheme in use (a). The same dependence, at the constant translation intervals of the target between the pulses ~ 6 μm (b)

When the distance between the damaged target areas is kept constant at a value of 6 μm (see Fig. 3b), the measured fluxes exhibit monotonous (near-linear) increase with respect to the average power of applied laser pulses. This suggests that the brightness of generated X-rays can be increased further, if the target renewal issue is solved.

To address the fresh target delivery problem at higher laser repetition rates, further experiments were performed using ST delivery scheme. The X-ray flux varied no more than 10% when the deviation of the target plane from the focus was within ~ 400 μm. This corresponds well with findings in other studies performed using different laser pulse parameters and experimental conditions [18, 26]. The dependence of X-ray flux on the laser repetition rate at different pulse energies is presented in Fig. 4a. It can be seen, that with ST target delivery scheme, the detected fluxes exhibit a quasi-linear dependence on f rep all the way up to the values of ~ 50 kHz, which in case of 400 μJ pulse energy correspond to the entire 20 W average power available from Pharos PH1-20 laser.

Generated Cu-Kα photon flux ϕ Kα as a function of laser pulse repetition rate at different energies, using ST target delivery system with target linear velocity reaching values of 5 m/s (a). The dependence of Cu-Kα photon flux ϕ Kα on laser pulse polarization direction, at the incidence angle between the target plane and the normal to the beam propagation direction θ = 30° (b), obtained using the ST scheme. The polarization direction Δβ is measured from p polarization

Kα photon flux dependence on laser pulse intensity approximation ϕ Kα ~ I a for each repetition rate was also evaluated, with coefficients a being estimated to be about 1.3–1.6. Such result is consistent with the previous studies done at similar experimental conditions; for example, with driving pulse intensity values approaching 1014–15 W/cm2, the exponent a was estimated to be near 2 [27] (in case of larger intensities, a > 2 [28]). The calculated values of Cu-Kα photon generation efficiency approached ~ 2 × 10− 7, while the highest detected Cu-Kα photon flux was ~ 2.3 × 109 photons per second (into the 4π solid angle)—such value is significantly larger than the ones found in previous works performed in ambient air environment, using Cu targets and comparable pulse intensities [29]. This is largely a result of the atypically high average power (~ 20 W) of the applied plasma-driving pulses. Even more so, while such flux does not reach the size of ~ 1011 Cu-Kα photons/s, which is rarely exceeded by table-top X-ray sources [11], it is evident that effective target material renewal at high pulse repetition rates (along with sharper beam focusing) allows generated Cu-Kα photon flux to pass the threshold of ~ 109 photons/s and, if average power of driving pulses was greater (considering the witnessed quasi-linear photon flux and pulse repetition rate relationship), even approach the vicinity of ~ 1010 photons/s, usually obtained with pulse energies and intensity values exceeding those used here by several orders of magnitude [9, 16,17,18]. In these cases, however, Kα photon conversion efficiency can reach 10−6–10−5, instead of the ~ 10−7 presented earlier in this work. Such difference can be explained by two experimental conditions, both of which can be responsible of reduction of conversion efficiency by several orders of magnitude: first, relatively low values of pulse intensity applied in this work [18], and second, the presence of air environment and the effects of air plasma—similar conversion efficiency and measured Cu-Kα fluxes were reported when pulses of ~ 1016 W/cm2 intensity were focused onto Cu targets, under typical atmospheric conditions [30].

It is worth mentioning that along with ST scheme, thinner Cu targets were applied (30 μm thick instead of 200 μm). In general, thinner foils have been shown to produce greater amounts of Kα photons (under conditions comparable to those used in our experiments), when hot-electron stopping range within the target and mean free path of Kα photons are roughly equal [31]. However, the differences between Cu-Kα fluxes obtained using both Lissajous translation and ST schemes are too great to be explained solely by such phenomenon [31]. Additional factors influencing the measured X-ray flux could be the focal length of the focusing lens (100 mm in Lissajous vs 75 mm in ST scheme) and the surface microstructure of the two copper foils (visually, the reflection from thinner film was more specular, whereas that from 200 µm film was more diffuse).

To check whether the resonance absorption of laser radiation in the target plasma played a role in the generation of observed X-rays (which may become important at the encountered peak intensities of ~ 4.65 × 1014 W/cm2 [32]), the flux dependence on laser pulse polarization direction and angle of incidence θ was investigated (see Fig. 1b: rotation from s to p polarization (via λ/2 wave plate) is marked by solid and dashed lines). The results are plotted in Fig. 4b. To reduce the effects of spectral artifacts in the spectrometer and at the same time maintain sufficiently high average pulse power and intensity, the target was fired upon with pulses of a decreased 10 kHz repetition rate and 300 μJ energy.

It is evident that Cu-Kα photon flux ϕ Kα , at the angle of laser beam incidence of θ = 30°, has a clear maximum at p pulse polarization, where the number of generated photons doubles (see Fig. 4b: here Δβ is the polarization direction; Δβ = 0° corresponds to p polarization, Δβ = 90°—to s polarization). It can be concluded, that resonance absorption does play a part in X-ray photon generation process during the performed tests. Increase of Kα flux due to this effect is not especially large, most probably due to the fact that the pulse intensity values are at the lower limit of resonance absorption, and the inverse-bremsstrahlung absorption is still the dominating process of X-ray photon generation. One can also observe, that when necessary conditions for plasma resonance absorption are optimized, the previously mentioned Cu-Kα flux of ~ 2.3 × 109 photons/s can be potentially increased even further to 4.5–5 × 109 photons/s and arrive even closer to the 1010 photons/s milestone found in other works.

The presented data clearly demonstrate that when target material renewal is ensured (provided by the ST system utilized in this work), the increase in the repetition rate of the driving laser results in an almost linear growth of the generated X-ray photon flux. This implies that in the quest for brighter tabletop X-ray sources, high average power femtosecond lasers may form a viable alternative to more traditional high pulse energy lasers. It was also shown, that upon optimization of parameters of experimental setup (i.e. effective target renewal, beam focusing etc.), even in ambient air environment the generated Cu-Kα photon flux, at plasma-driving pulse intensity of 4.65 × 1014 W/cm2, can get as high as 2.3 × 109 photons/s (with a conversion efficiency of ~ 10−7). If conditions for resonance absorption of laser radiation (traces of which were distinctly noticeable) were to be optimized, Cu-Kα photon flux could potentially approach ~ 5 × 109 photons/s and come even closer to the vicinity of ~ 1010 photons/s. These values are not only significantly larger than the ones found in similar works where comparable experimental conditions were applied [29], but they also approach fluxes typically obtained when plasma-driving pulses of intensity of several orders of magnitude higher than the one presented in this work are used [9, 16,17,18], especially when presence of air plasma and its effects on conversion efficiency are taken into account [30]. Such result is a consequence of larger (up to 10 times [18]) average power values of plasma-driving pulses compensating lower pulse intensities. It is worth mentioning, that Ti:Sapphire systems are a common choice for plasma-driving [9, 16,17,18]: it is reasonable to expect that a pulse wavelength of 800 nm (in comparison to ~ 1026 nm provided by Pharos PH1-20) results in a slight reduction of conversion efficiency.

It is also important to note, that analogous table-top plasma X-ray sources, due to difficulties arising with target material renewal and system stability, are relying on driving laser pulses of repetition rates of ~ 1 kHz or lower [9, 16, 29], with most attention given to pulse intensity. This approach, however, also limits the repetition rate of X-ray pulses themselves, as opposed to the one discussed in this work, where ultra-short X-ray pulses are fired at rates of tens of kHz without relying on cathodes and high-voltage sources or complex laser systems [33, 34], thus broadening the range of applicability of the X-ray source in XAS of similar fields.

Naturally, the primary drawback of the X-ray photon source presented in this work is the fast consumption of the target material: for example, at 50 kHz repetition rate, the target requires replacement in about 13 s. To make the system practical, two solutions may be pursued. One would entail increasing the available target area (i.e. radius of the spinning disk), and devising a fast target replacement system. If the single-run time of 1 min could be achieved, and the copper foil could be (automatically) replaced in 5–10 s, the overall available measuring time may become acceptable. Alternatively, more advanced and novel target delivery systems with higher throughput could be employed, e.g. jet-based ones [14, 15]. High average power lasers are generally easier to scale up than high pulse energy lasers. If target delivery issues are overcome, such high repetition rate laser sources could not only be effectively used as a substitute for the ones providing laser pulses of high energy, which is not always easily achievable, but could also relatively easily increase the repetition rates of X-ray pulses themselves.

4 Conclusions

We have demonstrated and characterized a laser-driven plasma source for X-ray generation based on high repetition rate and high average power femtosecond solid-state laser system, used in ambient air environment. The obtained brightness of the X-rays and conversion efficiency are comparable to those achieved using multi-millijoule pulsed laser sources. This suggests that high repetition rate, high average power solid state laser systems are attractive alternatives in the quest for the brighter tabletop femtosecond X-ray sources, if efficient target renewal systems are devised.

References

P. Beiersdorfer, Annu. Rev. Astron. Astrophys. 41, 343–390 (2003)

A. Momose, T. Takeda, Y. Itai, K. Hirano, Nat. Med. 2, 473–475 (1996)

R. Neutze, R. Wouts, D. van der Spoel, E. Weckert, J. Hajdu, Nature 406, 752–757 (2000)

A.H. Chin, R.W. Schoenlein, T.E. Glover, P. Balling, W.P. Leemans, C.V. Shank, Phys. Rev. Lett. 83, 336 (1999)

M. Chergui, A.H. Zewail, Chem. Phys. Chem. 10, 28–43 (2009)

M. Kozina, T. Hu, J.S. Wittenberg, E. Szilagyi, M. Trigo, T.A. Miller, C. Uher, A. Damodaran, L. Martin, A. Mehta, J. Corbett, J. Safranek, D.A. Reis, A.M. Lindenberg, Struct. Dyn. 1, 034301 (2014)

A.M. March, A. Stickrath, G. Doumy, E.P. Kanter, B. Krässig, S.H. Southworth, K. Attenkofer, C.A. Kurtz, L.X. Chen, L. Young, Rev. Sci. Instrum. 82, 073110 (2011)

T. Pfeifer, C. Spielmann, G. Gerber, Rep. Prog. Phys 69, 443–505 (2006)

F. Zamponi, Z. Ansari, C.V. Korff Schmising, P. Rothhardt, N. Zhavoronkov, M. Woerner, T. Elsaesser, M. Bargheer, T. Trobitzsch-Ryll, M. Haschke, Appl. Phys. A 96, 51–58 (2009)

A.Y. Faenov, J. Colgan, S.B. Hansen, A. Zhidkov, T.A. Pikuz, M. Nishiuchi, S.A. Pikuz, I.Y. Skobelev, J. Abdallah, H. Sakaki, A. Sagisaka, A.S. Pirozhkov, K. Ogura, Y. Fukuda, M. Kanasaki, N. Hasegawa, M. Nishikino, M. Kando, Y. Watanabe, T. Kawachi, S. Masuda, T. Hosokai, R. Kodama, K. Kondo, Sci. Rep. 5, 13436 (2015)

S. Lee, I.W. Choi, I. Sohn, K. Lee, G.I. Shim, Y.U. Jeong, B.H. Han, W.J. Ryu, H. Kim, H. Cha, J. Korean Phys. Soc. 67, 800–806 (2015)

Y. Jiang, T. Lee, W. Li, G. Ketwaroo, C.G. Rose-Petruck, Opt. Lett 27, 963–965 (2002)

C. Reich, C.M. Laperle, X. Li, B. Ahr, F. Benesch, C.G. Rose-Petruck, Opt. Lett. 32, 427–429 (2007)

W. Fullagar, M. Harbst, S. Canton, J. Uhlig, M. Walczak, C.-G. Wahlström, V. Sundström, Rev. Sci. Instrum. 78, 115105 (2007)

L. Miaja-Avila, G.C. O’Neil, J. Uhlig, C.L. Cromer, M.L. Dowell, R. Jimenez, A.S. Hoover, K.L. Silverman, J.N. Ullom, Struct. Dyn. 2, 024301 (2015)

M. Iqbal, Z. Urrehman, H. Im, J.G. Son, O. Seo, H. Stiel, P.V. Nickles, D.Y. Noh, K.A. Janulewicz, Appl. Phys. B 116, 305311 (2014)

B. Hou, J. Easter, A. Mordovanakis, K. Krushelnick, J.A. Nees, Opt. Express 16, 17695–17705 (2008)

C.L. Rettig, W.M. Roquemore, J.R. Gord, Appl. Phys. B 93, 365–372 (2008)

Y. Hironaka, K.G. Nakamura, K. Kondo, Appl. Phys. Lett. 77, 4110 (2000)

B. Hou, A. Mordovanakis, J. Easter, K. Krushelnick, J.A. Nees, Appl. Phys. Lett. 93, 201503 (2008)

J.H. Hubbell, S.M. Seltzer, Tables of X-ray mass attenuation coefficients and mass energy-absorption coefficients (National Institute of Standards and Technology, 1996)

P.M. Nilson, J.R. Davies, W. Theobald, P.A. Jaanimagi, C. Mileham, R.K. Jungquist, C. Stoeckl, I.A. Begishev, A.A. Solodov, J.F. Myatt, J.D. Zuegel, T.C. Sangster, R. Betti, D.D. Meyerhofer, Phys. Rev. Lett. 108, 085002 (2012)

J. Weisshaupt, V. Juve, M. Holtz, S.A. Ku, M. Woerner, T. Elsaesser, S. Alisauskas, A. Pugzlys, A. Baltuska, Nat. Photon 8, 927–930 (2014)

M. Hagedorn, J. Kutzner, G. Tsilimis, H. Zacharias, Appl. Phys. B 77, 49–57 (2003)

Y. Danon, B. Sones, R. Block, Nucl. Instr. Methods Phys. Res. A 524, 287–294 (2004)

W. Lu, M. Nicoul, U. Shymanovich, A. Tarasevitch, P. Zhou, K. Sokolowski-Tinten, D. von der Linde, Phys. Rev. E 80, 026404 (2009)

J. Badziak, J. Makowski, P. Parys, L. Ryc, J. Wolowski, E. Woryna, A.B. Vankov, J. Phys. D Appl. Phys. 34, 1885–1891 (2001)

M. Schnürer, M.P. Kalashnikov, P.V. Nickles, Th Schlegel, W. Sandner, N. Demchenko, R. Nolte, P. Ambrosi, Phys. Plasmas 2, 3106 (1995)

S.A. Pikuz, O.V. Chefonov, S.V. Gasilov, P.S. Komarov, A.V. Ovchinnikov, I.Yu.. Skobelev, S. Yu., M.V. Ashitkov, A. Agranat, Zigler, A.Y. Faenov, Laser part. Beams 28, 393–397 (2010)

M. Hada, J. Matsuo, Appl. Phys. B 99, 173–179 (2010)

D. Salzmann, C. Reich, I. Uschmann, E. Förster, Phys. Rev. E 65, 036402 (2002)

W.L. Kruer, The physics of laser plasma interactions. (Westview Press, Boulder Co, 2003)

A. Egbert, B.N. Chichkov, Proc. SPIE 4978, 92 (2003)

D. Papp, R. Polanek, Z. Lecz, L. Volpe, A.P. Conde, A.A. Andreev, IEEE Trans. Plasma Sci. 44, 2382–2392 (2016)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Baguckis, A., Plukis, A., Reklaitis, J. et al. Generation of plasma X-ray sources via high repetition rate femtosecond laser pulses. Appl. Phys. B 123, 290 (2017). https://doi.org/10.1007/s00340-017-6868-7

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00340-017-6868-7