Abstract

Ion implantation is one of the most competitive methods for the fabrication of optical waveguide structures in optoelectronic materials. Tb3+-doped aluminum borosilicate glass has been demonstrated to be a type of magneto-optical glass with high Verdet constant. In this work, the proton implantation technique with energies of (500 + 550) keV and fluences of (1.0 + 2.0) × 1016 ions/cm2 is performed to form planar waveguides in the Tb3+-doped aluminum borosilicate glass. The guiding modes of the fabricated waveguide were measured by the prism-coupling method at wavelengths of 632.8 and 1539 nm. The near-field light intensity distribution was measured by the end-face coupling method at the wavelength of 632.8 nm and calculated by the finite-difference beam propagation method at both 632.8 and 1539 nm. The optical properties of the double-energy proton-implanted magneto-optical glass waveguides show promise for use as multi-functional integrated optical devices in the visible and near-infrared bands.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Magneto-optical waveguides, as the basic elements of nonreciprocal devices for optical communication, have been extensively investigated in the last decades [1–7]. They can guide, modulate, isolate and circulate optical signal in advanced fiber communication systems [8]. The choice of appropriate host material with Faraday rotating effect and the technique of a waveguide fabrication are two key considerations in the design and realization of magneto-optical waveguide structures with excellent performances.

The magneto-optical or Faraday rotation glass is a kind of transparent material with high optical quality and has attracted more and more attention [9, 10]. Owing to outstanding magneto-optical performances, simple preparation and high resistance to laser damage, it has potential and important applications in the field of functional devices, such as magneto-optical isolators, solid-state lasers, magneto-optical modulators and magneto-optical switches [11]. The Faraday rotation glass used in this work is aluminum borosilicate magneto-optical glass doped with terbium (Tb3+) ions. Its Verdet constant is −0.33 min/Oe·cm at a wavelength of 632.8 nm, the laser threshold reaches 10 J/cm (1ω, 3 ns), the transparent rate T% (uncoated) is close to 82.0% from 500 to 1500 nm, and the surface homogeneity is up to ±1.0 × 10−6. Therefore, Tb3+-doped aluminum borosilicate glasses are excellent candidates for the fabrication of magneto-optical waveguides according to the optical advantages.

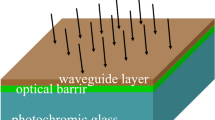

Ion implantation is considered as a versatile, controllable and reproducible technique useful for the realization of high-quality waveguides. A positive or negative change in refractive index could be formed after the ion implantation in the near-surface region, depending on the interaction of the implanted ions and the target material. At the end of the ion trajectory, often most irradiation damage occurs in terms of atomic displacements, accumulation of Frenkel defects and accumulation of implanted ions as interstitials in the substrate. It leads to a volume expansion with a consequent decrease of the physical density and a reduction of the refractive index [12–14]. In this manner, an optical waveguide is formed between air on the surface of the implanted sample and this low refractive index layer (called optical barrier) at the end of ion track [15]. Most of the previous Faraday rotating waveguides depend on the deposition of a magneto-optical film onto a suitable substrate material [5]. In contrast, the combination of ion implantation and magneto-optical glasses is a simple and direct way to fabricate magneto-optical waveguides, because the bulk material is Faraday rotation glass and no deposition or growth is necessary. Optical planar waveguides in Tb3+-doped aluminum borosilicate glasses via irradiation with 550-keV protons have been reported recently by our group [16]. However, the waveguide cannot confine the light with a wavelength of 1539 nm that is in the telecommunication window. As well known, 1.5-µm magneto-optical devices are indispensable in functional optical-communication networks. To overcome the problem, double irradiation at two energies of the protons has been designed and realized. The broadened optical barrier induced by the double-energy ion implantation can reduce light leakage, especially for the light with longer wavelength. In this work, (500 + 550) keV proton implantation with fluences of (1.0 + 2.0) × 1016 ions/cm2 is applied to fabricate waveguides in Tb3+-doped aluminum borosilicate glasses. We realize waveguide operation in the 1539-nm telecommunication band. The visible and near-infrared optical properties of the waveguide are investigated in detail.

2 Experiments

The Tb3+-doped aluminum borosilicate glass in the system of Tb2O3–SiO2–Al2O3–B2O3 was prepared by using the traditional melt-quenching method in the Xi′an Institute of Optics and Precision Mechanics of CAS by our research team. A 700 g mixture of high-purity raw materials was melted in a platinum crucible at a temperature of 1300 °C for 2 h. Then the melt was poured onto a preheated brass mold and annealed in a muffle furnace. A plate with dimensions of 15.0 mm × 3.0 mm × 2.0 mm was cut from the prepared glass and its surfaces were precisely polished for optical quality. Then, the density was measured by Archimedes method with distilled water as liquid medium. The refractive indices of the polished plate were recorded by a Model 2010 Prism Coupler at wavelengths of both 632.8 and 1539 nm.

One of the biggest facets of the polished plate (15.0 mm × 3.0 mm) was implanted with protons at the Institute of Semiconductors of CAS using an ion implanter at room temperature. Because multi-energy ion irradiation is an effective technique to broaden the “‘optical barrier” and hence reduce light leakage from the waveguide region, 500-keV protons with a fluence of 1.0 × 1016 ions/cm2 and 550-keV protons at a dose of 2.0 × 1016 ions/cm2 were successively used to irradiate the same Tb3+-doped aluminum borosilicate glass plate. The condition of the double-energy proton implantation was denoted as (500 + 550) keV and (1 + 2) × 1016 ions/cm2 in the whole text.

After the ion implantation, the effective refractive index of the proton-implanted magneto-optical glass waveguide in the visible (632.8 nm) and near-infrared (1539 nm) optical regions were obtained by the prism-coupling technique. The near-field modal profiles of the waveguide modes were measured through the end-face coupling method at a wavelength of 632.8 nm. During the near-field pattern measurement, a beam of light from a He–Ne laser was coupled to the front face of the waveguide (3.0 mm × 2.0 mm) through a 25× microscope objective. A camera was employed to observe the transmitted mode from the end face of the waveguide (3.0 mm × 2.0 mm) through another 25× microscope objective.

3 Results and discussion

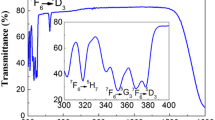

The bulk refractive index of the non-irradiated magneto-optical glass was measured by the m-line technique with a Model 2010 Prism Coupler with an accuracy of 0.0002. Figure 1a, b shows the substrate refractive index of the Tb3+-doped aluminum borosilicate glass at 632.8 and 1539 nm, respectively. The refractive index on the abscissa that corresponds to the critical knee of the curve is the substrate refractive index. Therefore, the substrate refractive index of the magneto-optical glass is 1.7384 at a wavelength of 632.8 nm (\(n_{sub}^{632.8}\)) and 1.7172 at a wavelength of 1539 nm (\(n_{sub}^{1539}\)).

The stopping and range of ions in matter code (SRIM 2010) [17] was utilized to simulate the nuclear energy loss distribution of (500 + 550) keV protons in the Tb3+-doped aluminum borosilicate glass. Figure 2 shows the nuclear energy deposition as a function of the irradiation depth. The nuclear energy loss distributions of double-energy protons were calculated as simple algebraic sums of the corresponding pairs of single-energy proton distributions [18]. For the first 2.5 µm near the magneto-optical glass surface, the nuclear energy loss is fairly constant in Fig. 2. However, it increases sharply at the end of the implanted proton track. A maximum deposition with a double-peak is obtained near the end of range, owing to the double-energy irradiation. As shown in Fig. 2, the double-energy proton implantation in this work forms a wider barrier layer than the single-energy irradiation in the previous report [16]. In detail, the energy combination of 500 and 550 keV results in a barrier width of 0.70 µm in the magneto-optical glass.

The optical microscope in transmission mode was employed to detect the microscopy photograph of the cross section for the proton-implanted Tb3+-doped aluminum borosilicate glass, as shown in Fig. 3. The cross-sectional shape of the planar waveguide is a strip through the microscopy photograph. The thickness of the modified layer (waveguide core region) is approximately equal to 3.6 µm, which is in accordance with the project range of the implanted protons in the Tb3+-doped aluminum borosilicate glass calculated by using SRIM 2010 in Fig. 2.

Figure 4a, b shows the dark-mode spectra (relative intensity of light versus effective refractive index) at wavelengths of 632.8 and 1539 nm (transverse electric polarization, TE) for the proton-implanted magneto-optical glass waveguide through the m-line method, respectively. According to the theory of the prism-coupled measurement, a narrow dip in the m-line curve would indicate a propagation mode and a broad dip would imply a radiation mode for optical waveguides. As one can see, three sharp dips and one broad dip are observed in Fig. 4a and one sharp dip and one broad dip are presented in Fig. 4b. It means that the proton-implanted magneto-optical glass waveguide can support three propagation modes for the 632.8-nm wavelength and one propagation mode for the 1539-nm wavelength. As reported in the previous work, a thin barrier layer leads to relatively strong light leakage into the substrate owing to optical tunneling effects [19]. For the same barrier, the longer the wavelength of light is, the more obvious the tunneling effect becomes. Therefore, more leakage of light with 1539-nm wavelength into the bulk occurred and no guided mode was observed at 1539 nm in the single-energy proton irradiated magneto-optical glass waveguide [16]. In contrast, the double-energy irradiated waveguide can confine the light at both 632.8 and 1539 nm well, because that the barrier is wide enough. In addition, Table 1 lists the effective refractive indices obtained from the dark-mode spectrum measurements performed at 632.8 and 1539 nm. As one can see, in Table 1 the refractive indices of the magneto-optical glass substrate (\(n_{sub}^{632.8}\) = 1.7384 and \(n_{sub}^{1539}\) = 1.7172) are higher than the effective refractive indices of all the modes for both the 632.8 and the 1539 nm wavelengths.

The refractive index modifications induced by irradiation damages to target materials during the ion beam implantation process can be simulated by the reflectivity calculation method (RCM) [20]. Figure 5a, b shows the refractive index profiles reconstructed by using RCM for the proton-implanted magneto-optical glass waveguide at wavelengths of 632.8 and 1539 nm, according to the experimentally obtained dark-mode spectroscopy in Fig. 4. It should be noted that the refractive index profiles at 632.8 and 1539 nm are both well-known barrier-confined distributions. As reported in the most light-ion implanted waveguides, the refractive index in the region between the optical barrier layer and the magneto-optical glass surface only slightly deceases after the proton implantation (Δn w = −0.00020 for 632.8 nm and Δn w = −0.00018 for 1539 nm), while a large reduction of refractive index is observed in the optical barrier region (Δn b = −0.0075 for 632.8 nm and Δn b = −0.0070 for 1539 nm). The mechanism for the negative refractive index change may be a structural damage and a volume expansion (swelling) during the proton irradiation trajectory. In addition, the optical barrier in Fig. 4 is broadened to 0.65 µm by the double-energy proton implantation. The tunneling effect can be considerably reduced by the broadened barrier, especially for the 1539-nm wavelength case. Table 1 lists the comparison between the experimentally measured effective refractive indices and the calculated mode indices. One difference between calculated mode and measured one is lower than 2.0 × 10−4.

Figure 6a shows the measured near-field light intensity profile at a wavelength of 632.8 nm in the proton-implanted magneto-optical glass waveguide. It was recorded by the end-face coupling method. The strip and homogeneous pattern infers good confinement of the light with 632.8-nm wavelength in both the dimension perpendicular to the biggest surface of the Tb3+-doped aluminum borosilicate glass and the propagation of the fundamental mode. However, the mode profile is not presented in a satisfactory manner, because the camera is saturated to some. The propagation loss of the magneto-optical glass waveguide is about 1.56 dB/cm at a wavelength of 632.8 nm, which is measured by the back-reflection method [21]. The finite-difference beam propagation method (FD-BPM) is one of the most commonly used numerical techniques to calculate and analyze guided-wave propagation in optical waveguide structures [22, 23]. It was applied to calculate the propagation properties of light at 632.8 and 1539 nm in the proton-implanted magneto-optical glass waveguide, based on the refractive index profiles reconstructed by RCM in Fig. 5a, b. Fig. 6b, c is the calculated propagation mode of the waveguide by FD-BPM for the light with 632.8 and 1539 nm, respectively. The simulated near-field mode profile is in accordance with the measured one at a wavelength of 632.8 nm, by comparing Fig. 6a, b. It indicates that the reconstructed refractive index profile at 632.8 nm seems to be adequately precise for the proton-implanted magneto-optical glass waveguide. Because the same methods (such as the prism-coupling method, RCM and FD-BPM) were used in the case of 1539 nm wavelength, the reconstructed refractive index profile at 1539 nm is a reasonable distribution and can be used to investigate the near-infrared properties of the waveguide. Therefore, the proton-implanted waveguide can confine the light with a wavelength of 1539 nm, according to the Fig. 6c.

4 Conclusion

This work reports on the fabrication and characterization of the Tb3+-doped aluminum borosilicate glass planar waveguide using the double-energy proton implantation method. The prism-coupling measurements of the ion beam irradiated waveguides revealed that double-energy proton irradiation in Tb3+-doped aluminum borosilicate glasses can result in visible and near-infrared waveguides operated at 632.8 and 1539 nm. The refractive index profile of the planar waveguide is an “optical barrier” confined type, which was reconstructed by the RCM. The maximum refractive index decreases of 0.002 and 0.0018 are obtained for 632.8 and 1539 nm wavelengths, respectively. The near-field distribution of the propagation modes has good optical confinement properties in the planar waveguide structure. The propagation loss was estimated to be 1.56 dB/cm at the wavelength of 632.8 nm. The realization of waveguides on the magneto-optical glass is an important step in the fabrication of a waveguide isolator.

References

L.D. Tzuang, K.J. Fang, P. Nussenzveig, S.H. Fan, M. Lipson, “Non-reciprocal phase shift induced by an effective magnetic flux for light”. Nat. Photon 8, 701–705 (2014)

W.V. Parys, B. Moeyersoon, D.V. Thourhout, R. Baets, M. Vanwolleghem, B. Dagens, J. Decobert, O.L. Gouezigou, D. Make, R. Vanheertum, L. Lagae, “Transverse magnetic mode nonreciprocal propagation in an amplifying AlGaInAs/ InP optical waveguide isolator”. Appl. Phys. Lett. 88, 071115 (2006)

S. Ghosh, S. Keyvavinia, W. Van Roy, T. Mizumoto, G. Roelkens, R. Baets, “Ce:YIG/Silicon-on-Insulator waveguide optical isolator realized by adhesive bonding”. Opt. Express 20, 1839–1848 (2012)

T. Mizumoto, Y. Shoji, R. Takei, “Direct wafer bonding and its application to waveguide optical isolators”. Mater. 5, 985–1004 (2012)

H. DÖtsch, N. Bahlmann, O. Zhuromskyy, M. Hammer, L. Wilkens, R. Gerhardt, P. Hertel, A.F. Popkov, “Applications of magneto-optical waveguides in integrated optics: review”. J. Opt. Soc. Am. B 22, 240–253 (2005)

T. Shih, R.R. Gattass, C.R. Mendonca, E. Mazur, “Faraday rotation in femtosecond laser micromachined waveguides”. Opt. Express 15, 5809–5814 (2007)

E. Pross, H. Dammann, W. Tolksdorf, “Light guidance and mode conversion in magneto optic buried channel waveguides”. J. Appl. Phys. 68, 3849–3855 (1990)

A. Hocini, M. Bouras, H. Amata, “Theoretical investigations on optical properties of magneto-optical thin film on ion-exchanged glass waveguide”. Opt. Mater 35, 1669–1674 (2013)

H. Akamatsu, K. Fujita, Y. Nakatsuka, S. Murai, K. Tanaka, “Magneto-optical properties of Eu2+-containing aluminoborosilicate glasses with ferromagnetic interactions. Opt. Mater 35, 1997–2000 (2013)

C.B. Pedroso, E. Munin, A. Balbin Villaverde, N. Aranha, V.C. Solano Reynoso, L.C. Barbosa, “Magneto-optical rotation of heavy-metal oxide glasses”. J. of Non-Cryst. Solids 231, 134–142 (1998)

W.N. Li, K.S. Zou, M. Lu, B. Peng, W. Zhao, “Faraday glasses with a large size and high performance”. Int. J. Appl. Ceram. Technol 7, 369–374 (2010)

G. V. Vázquez, R. Valiente, S. Gómez-Salces, E. Flores-Romero, J. Rickards, R. Trejo-Luna, “Carbon implanted waveguides in soda lime glass doped with Yb3+ and Er3+ for visible light emission”. Opt. Laser Technol. 79, 132 (2016)

P.J. Burnett, T.F. Page, “An investigation of ion implantation-induced near-surface stresses and their effects in sapphire and glass”. J. Mater. Sci 20, 4624–4646 (1985)

P.D. Townsend, P.J. Chandler, L. Zhang, Optical Effects of Ion Implantation. (Cambridge University Press, Cambridge, 1994)

F. Chen, “Micro- and submicrometric waveguiding structures in optical crystals produced by ion beams for photonic applications”. Laser Photon. Rev. 6(5), 622–640 (2012)

C.X. Liu, Y.W. Li, R.L. Zheng, L.L. Fu, L.L. Zhang, H.T. Guo, Z.G. Zhou, W.N. Li, S.B. Lin, W. Wei, “Optical waveguides in magneto-optical glasses fabricated by proton implantation”. Opt. Laser Technol. 85, 55–59 (2016)

J.F. Ziegler, “SRIM-The stopping and range of ions in matter”, http://www.srim.org

I. Bányász, Z. Zolnai, M. Fried, S. Berneschi, S. Pelli, G. Nunzi-Conti, “Leaky mode suppression in planar optical waveguides written in Er:TeO2-WO3 glass and CaF2 crystal via double energy implantation with MeV N+ ions”. Nucl. Instrum. Methods Phys. Res. B 326, 81–85 (2014)

F. Chen, “Photonic guiding structures in lithium niobate crystals produced by energetic ion beams”. J. Appl. Phys. 106(8), 081101 (2009)

P.J. Chandler, F.L. Lama, “A new approach to the determination of planar waveguide profiles by means of a nonstationary mode index calculation”. Opt. Acta 33, 127–143 (1986)

R. Ramponi, R. Osellame, M. Marangoni, “Two straightforward methods for the measurement of optical losses in planar waveguides”. Rev. Sci. Instrum. 73, 1117–1121 (2002)

Y. Tan, J. R. Vázquez de Aldana, F. Chen, “Femtosecond laser written lithium niobate waveguide laser operating at 1085 nm”. Opt. Eng. 53, 107109 (2014)

Rsoft Design Group, Computer software BeamPROP version 8.0, http://www.rsoftdesign.com

Acknowledgements

This work was financially supported by the National Natural Science Foundation of China (Grant Nos. 11405041 and 61177084), and NUPTSF (Grant No. NY214159), and Research Center of Optical Communications Engineering & Technology, Jiangsu Province (Grant No. ZSF0401).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Chun-Xiao Liu and Xiao-Liang Shen these authors contributed equally to this work.

Rights and permissions

About this article

Cite this article

Liu, CX., Shen, XL., Zheng, RL. et al. Visible and near-infrared waveguides formed by double-energy proton implantation in magneto-optical glasses. Appl. Phys. B 123, 56 (2017). https://doi.org/10.1007/s00340-017-6644-8

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00340-017-6644-8