Abstract

We report our findings on laser-diode end-pumped Yb:YAG slab output characteristics when using a compact positive confocal unstable–stable hybrid resonator at room temperature. Preliminary experimental results show that for an absorbed pump power of 680 W, a maximum output power of 156 W was produced at 1030 nm with a stability of 0.9%. An optical-to-optical efficiency of 22.9% and slope efficiency of 37.1% were obtained, and the beam quality M 2 factors in the unstable and stable direction were 1.04 and 1.01, respectively.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Yb:YAG is a laser crystal that has been proven capable of high power operation [1]. Owing to its simple electronic structure based on two relevant electronic manifolds, namely the 2F7/2 ground state and 2F5/2 excited state, Yb:YAG has advantageous spectroscopic properties uniquely favorable for diode-pumping schemes. Compared with the traditional material Nd:YAG, Yb:YAG has a lower thermal load, longer storage lifetime and broader absorption bands. The doping concentration of the crystal [2] can also be flexibly adjusted. However, the main disadvantage of Yb:YAG is its reabsorption loss due to the significant population rate in the lower laser level at room temperature. This leads to a number of deleterious effects, including increasing the laser threshold and reducing slope efficiency. Since Lacovara first reported performances on diode-pumped Yb:YAG laser [3] at room temperature in 1991, many excellent diode-pumping schemes have been launched and have obtained significant results. Examples include rod laser [4, 5], thin-disk laser [6] and slab laser [7, 8]. It should be noted that the partially end-pumped slab (Innoslab) laser invented by Du et al. [9] has proven to be extremely inspiring for researches on the Yb:YAG slab amplifier [10, 11]. It has also been successfully adapted to Nd:YAG [9], Tm:YLF [12], Nd:YVO4 [13] and Nd:GdVO4 [14] slab laser oscillators.

In this paper, we summarize our results on applying the advantages of Innoslab laser to Yb:YAG crystal at room temperature. With a suitable coupling system, the maximum output power of 156 W was obtained for absorbing 680 W pump power and an average stability of 0.9% was fitted. The optical-to-optical efficiency and slope efficiency achieved were 22.9 and 37.1%, respectively, while the beam quality M 2 factors in the unstable direction and stable direction were 1.04 and 1.01.

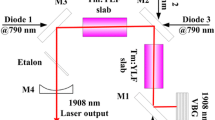

2 Experimental setup and simulation

Figure 1 shows the experimental setup for both the horizontal and vertical directions. The laser-diode stack consists of 3 × 4 bars with a central pump wavelength of 940 nm. Light emitted from each of these diodes is collimated by micro lens and coupled into a coupling system. The coupling system includes two cylindrical lenses M1 and M2. With a focus length of f1 = 90 mm, M1 focuses the pump light in the horizontal direction. In the vertical direction, the pump light is focused by M2 with a focal length of f2 = 80 mm. We simulated the pump density distribution on the input cross section of the crystal using Zemax. Results are illustrated in Fig. 2. The dimensional parameters of the Yb:YAG slab are 14 mm × 10 mm × 1 mm, and the doping level is limited to 2 at.%. A homogenous pump line of approximately 14 mm × 0.3 mm was coupled into the Yb:YAG crystal. Both ends (14 mm × 1 mm) were polished and coated with an antireflection coating for 940 and 1030 nm. The Yb:YAG crystal was mounted and bonded to a water-cooled copper heat sink with the large face (14 mm × 10 mm) down. An indium foil was used to improve thermal contact between the Yb:YAG crystal and the copper heat sink. By setting the temperature of the circulating water to 23 °C, the LD and laser crystal were adequately cooled. The hybrid resonator consists of a concave spherical input mirror (M3) with a 220 mm radius of curvature and a cylindrical output mirror (M4) with a −150 mm radius of curvature. Both the mirrors were coated for high reflection at 1030 nm and high transmission at 940 nm. M4 was cut and polished at one edge where the laser beam coupled out. In the vertical direction, the two mirrors form a stable resonator, whereas in the horizontal direction, it resembles an off-axis positive-branch confocal unstable resonator. The theoretical length of the resonator is L = (R3 + R4)/2 = 35 mm. However, when we take into consideration the refractive index of crystal, the actual geometry length of the resonator is adjusted to approximately 40 mm. The equivalent transmission of the resonator is T = 1 − |R4/R3| = 31.8%.

3 Results and discussion

The conversion of absorbed pump power into laser output power is shown in Fig. 3. A maximum output power of 156 W was obtained for an absorbed pump power of 680 W. The optical-to-optical efficiency and slop efficiency were 22.9 and 37.1%, respectively.

To measure the beam quality of the output laser, we used a spherical mirror with a focal length of 350 mm and a CCD camera. The M 2 factor is defined by [15]

where d 0 is the diameter of the beam waist, z is the distance to the beam waist, d (z) is the beam diameter at a distance z from the beam waist, and λ is the wavelength of the output laser. At an output power of 156 W, the beam diameters in both directions were measured with the CCD and are fitted as shown in Fig. 4. The beam quality M 2 factors in the unstable and stable direction are 1.04 and 1.01, respectively. In Fig. 5, we show the far-field distribution of the laser beam.

The beam qualities in the two directions are near diffraction limited. In the horizontal direction, due to the confocal unstable resonator itself, it can suppress the high-order mode and get collimated parallel light output [15]. That is why the beam quality is good in the unstable direction. In the vertical direction, Fig. 6a demonstrates the cross-sectional view of the crystal and Fig. 6b illustrates how the size of the TEM00 laser mode in the crystal changes with the amount of absorbed pump power. When the absorbed pump power reaches 680 W, the size of the TEM00 mode in the crystal matches the width of the pump line focused on the crystal, therefore h L ≈ h P ≈ 0.3 mm (shown in Figs. 2, 6b). This suggests that only the TEM00 mode can lase in the vertical direction [16]. That is why the beam quality is also good in the stable direction.

We measured the stability of the LD end-pumped slab laser at an output power of 156 W for 15 min. Results are shown in Fig. 7. The stability was approximately 0.9% with no obvious fluctuations observed.

4 Conclusion

In this paper we have reported that for an absorbed pump power of 680 W, a cw mode laser output of 156 W was generated at room temperature with a stability of 0.9%. The optical-to-optical efficiency and slope efficiency achieved were 22.9 and 37.1%, respectively. Beam quality M 2 factors of 1.04 and 1.01 were detected in the unstable direction and the stable direction. Further plans to enhance the performance of the system shall be carried out in the following ways. Firstly, the coupling system will be altered at the aim of reducing the width of the pump line to enhance the pump density in the crystal. Secondly, the doping level of Yb:YAG will be adjusted to improve the absorption efficiency. Thirdly, to control the crystal temperature more effectively and precisely, a microchannel cooler will be put to use. Last but not least, a double-end-pumped system will be used to improve the output power.

References

T.S. Rutherford, W.M. Tulloch, S. Sinha, R.L. Byer, Opt. Lett. 26, 1672 (2001)

K. Contag, M. Karszewski, C. Stewen, A. Giesen, H. Hugel, IEEE J. Quantum Electron. 29, 697 (1999)

P. Lacovara, H.K. Choi, C.A. Wang, R.L. Aggarwal, T.Y. Fan, Opt. Lett. 16, 1089 (1991)

E.C. Honea, R.J. Beach, S.C. Mitchell, J.A. Skidmore, M.A. Emanuel, S.B. Sutton, S.A. Payne, P.V. Avizonis, R.S. Monroe, D.G. Harris, Opt. Lett. 25, 805 (2000)

B.B. Hans, S.S. David, IEEE J. Sel. Top. Quantum Electron. 11, 600 (2005)

C. Stewen, K. Contag, M. Larionov, A. Giesen, H. Hugel, IEEE J. Sel. Top. Quantum Electron. 6, 650 (2000)

M. Ganija, D. Ottaway, P. Veitch, J. Munch, Opt. Express 21, 6973 (2013)

Q. Liu, M.L. Gong, F.Y. Lu, W.P. Gong, C. Li, D.D. Ma, Appl. Phys. Lett. 88, 101113 (2006)

K.M. Du, N.L. Wu, J.D. Xu, J. Giesekus, P. Loosen, R. Poprawe, Opt. Lett. 23, 370 (1998)

P. Russbueldt, T. Mans, G. Rotarius, J. Weitenberg, H.D. Hoffmann, R. Poprawe, Opt. Express 17, 12230 (2009)

P. Russbueldt, T. Mans, J. Weitenberg, H.D. Hoffmann, R. Poprawe, Opt. Lett. 35, 4169 (2010)

J. Li, S.H. Yang, A. Meissner, M. Hofer, D. Hoffmann, Laser Phys. Lett. 10, 055002 (2013)

P. Zhu, D.J. Li, P.X. Hu, A. Schell, P. Shi, C.R. Haas, N.L. Wu, K.M. Du, Opt. Lett. 33, 1930 (2008)

B. Deng, H.L. Zhang, L. Xu, Y.F. Mao, J.L. He, J.G. Xin, Chin. Phys. Lett. 31, 114201 (2014)

A.E. Siegman, Lasers (University Science Books, California, 1986)

G. Shayeganrad, Opt. Laser Technol. 44, 987 (2012)

Acknowledgements

This work is sported by Chinese 863 Project (2015AA043504) and Chinese Natural Scientific Foundation (61575021).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Mao, Y., Hao, X., Yuan, J. et al. Near-diffraction-limited 156 W laser-diode end-pumped Yb:YAG Innoslab laser operated at room temperature. Appl. Phys. B 122, 279 (2016). https://doi.org/10.1007/s00340-016-6552-3

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00340-016-6552-3