Abstract

Due to the absence of the detrimental three-photon absorption, LiTaO3 is a promising crystal for terahertz generation when pumping with an 800-nm pump wavelength. The nonlinear optical, photorefractive and dielectric (except the bandwidth) properties at the optical and the terahertz wavelength are very similar to those of LiNbO3. The absorption coefficient and refractive index spectra of 1 mol% Mg-doped stoichiometric LiTaO3 measured by terahertz time domain spectroscopy are presented. Optimization calculations have been performed, and results for a hybrid-type high-energy terahertz source using LiTaO3 are presented. About 90 % diffraction efficiency is predicted with a practically feasible contact grating.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Optical rectification of ultrashort laser pulses is an effective method of generating high-energy THz pulses. The tilted pulse-front technique was created to achieve velocity-matched optical rectification within THz generation materials that have larger refractive index in the THz range than in the optical range [1]. This powerful generation method enabled the generation of extremely high THz pulse energies (up to 430 µJ) with 0.67 mol% Mg-doped stoichiometric LiNbO3 (LN) [2]. In conventional tilted pulse-front pump schemes, the pulse-front tilt is introduced by diffraction on an optical grating. The pumping spot on the diffraction grating is imaged into the LN crystal enabling the tilt angle to be tuned. Unfortunately, imaging errors are caused by the optical element (usually lens or telescope) resulting in a temporal broadening of the pump pulse. This is especially pronounced and manifests as a significant reduction of the THz conversion efficiency in the case of high pump energies, when wide pump beams are used [3]. To avoid this unwanted effect, a so-called contact-grating (CG) THz source was proposed [4].

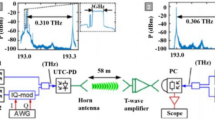

The groove density required for a LiNbO3 (LN) CG is extremely large, causing problems in the manufacturing process and reducing the diffraction efficiency. To overcome this weakness, a hybrid tilted pulse-front (HTPF) setup (Fig. 1) was proposed [5], which combines both a conventional grating and a technically feasible contact grating into a single scheme. This means that the pulse-front tilt is realized in two steps. This enables the concept to obtain near equal values for the tangent of the pulse-front tilt angle change in both steps. The reduction of imaging errors and the achievement of high diffraction efficiency at the CG can, therefore, be simultaneously reached by this setup.

The scheme of the HTPF THz source. The notations and symbols used in the paper are collected in Table 1

The idea of the HTPF source, together with the description of the optimization procedure for a setup containing LN as a nonlinear optical material was given in Ref. [5]. The two-step pulse-front-tilt property of the HTPF is especially advantageous for LiTaO3 (LT), since the required tilt angle is larger than for LN. Furthermore, the larger band gap of LT allows pumping at the easily available 800-nm wavelength without the appearance of three-photon absorption. In the present work, the optimization method of the HTPF [5] is adopted for the case of LT.

2 LiTaO3 as a potential THz generator crystal

Due to its remarkable d 33 second-order nonlinear optical tensor element [6–8], LT is a promising material for nonlinear frequency conversion. The application of Mg dopant and using stoichiometric crystal instead of congruent one are proven solutions for the reduction of the coercive field in LN. Similar behavior was found in the case of LT [9, 10]. Adaptation of these solutions for periodically poled LT opened the way for large-scale nonlinear applications based on quasi-phase-matched devices [9, 11]. LT has an extremely large nonlinear optical coefficient (161 pm/V which is nearly equal to that of LN); therefore, LT is a potential candidate for THz generation [12]. Narrow-band THz generation by optical rectification [13, 14] and by difference frequency generation process [15] in domain-inverted LT structure has also been demonstrated.

Nonlinear optical applications such as THz generation with the optical rectification of near infrared ultrashort pulses require the absence of photorefractive damage. Undoped stoichiometric LT (SLT) shows a significantly higher photorefractive damage threshold than that of undoped stoichiometric LN (SLN) [17]. Reducing the TaLi antisite defects by Mg doping and/or bringing the Li content closer to the stoichiometric composition, the photorefractive sensitivity can be further reduced [16]. SLT with Mg concentration between 0 and 2 mol% shows the same damage threshold as the 0.67 mol% doped SLN [17] often used as nonlinear frequency converter and THz generator material.

In nonlinear materials, beside the absorption originating from the usual complex dielectric function (due to phonon polariton resonances in case of LN and LT), multiphoton absorption at the pump wavelength might occur, resulting in free carriers leading to induced THz absorption [3]. The significance of this effect increases with the pump intensity and can lead to the saturation of the THz conversion efficiency. The order of the occurrence of multiphoton absorption is determined by the bandgap. In LN, at the 800-nm pump wavelength, which is typically used due to the widespread use of the Ti:Sapphire laser, the three-photon absorption is present due to the position of the UV absorption edge which is between 300 and 325 nm [18, 19]. At high pump energies, its detrimental influence on the THz efficiency was experimentally demonstrated [20] and theoretically confirmed with a three-dimensional model [21]. For near-stoichiometric LT, the UV absorption edge value is shorter (264 [22, 23], 260 nm [24]) which allows pumping at the easily available 800-nm wavelength without the appearance of three-photon absorption. Therefore, at this wavelength, the LT-based HTPF source is more promising than the LN-based one.

When designing a THz source, the THz absorption of the material has key importance due to its influence on the conversion efficiency. Information regarding the THz refractive index is also useful because of velocity matching. In the case of LN, the effect of absorption originating from the complex dielectric function can be significantly reduced by using Mg-doped stoichiometric composition instead of the congruent one and by using cryogenic temperatures [25, 26]. The study of the dielectric properties of congruent LT in the THz range was the subject of several works [26–30]. In the 0.1–2 THz frequency range, congruent LT has higher absorption coefficient values than LN for the extraordinary polarization, which has relevance in case of THz generation [30]. As far as we know, THz absorption of undoped and Mg-doped SLT (Mg:SLT) has not been reported so far, for the important extraordinary polarization.

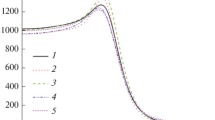

Index of refraction and absorption coefficient belonging to the THz range was determined for 1 mol% Mg:SLT with a Tera K8 time-domain THz spectrometer (Menlo System). For the precise polarization set of the THz beam, a wire grid polarizer was used. The measurements took place at 300 K, and the terahertz setup was blown with nitrogen gas to avoid the effects of water absorption. The material parameters for extraordinary polarization were calculated in the acceptable frequency range 0.25–2.5 THz taking into account the dynamic range of the spectrometer.

The absorption coefficient spectrum is shown in Fig. 2 by solid curve. The dashed curve belongs to undoped congruent LT [30]. As seen, the absorption of the 1 mol% Mg:SLT is reduced when compared to the congruent composition. It is well known from the previous THz-TDS investigations performed on SLN, that the optimal Mg concentration to have minimal THz absorption is 0.67 mol%. For comparison, Fig. 2 also shows the absorption spectrum for 0.67 mol% SLN. As seen, at low THz frequencies, the absorption coefficient values of Mg:SLT and Mg:SLN are similar. The index of refraction spectra of 1 mol% Mg:SLT is shown in the inset. The refractive index values are typically 30 % larger than those of LN. The index of refraction and absorption coefficient data belonging to 0.5 and 1 THz are given in Table 2.

The notations and acronyms used in the paper are collected in Table 1. The relationship between the pulse-front tilt angle (γ) and the angular dispersion inside the medium is [33]:

According to Ref. [34] and using Eq. (1), one can obtain:

The L d is the characteristic distance in which the initially transform-limited pulse with pulse length of τ 0 will be broadened to \(\sqrt 2 \tau_{0}\). According to Ref. [34], it is:

Using Eqs. (2) and (3), one obtains:

We note that in this brief deduction, the effect of material dispersion, and pulse distortions were neglected; only angular dispersion was taken into consideration. The effective interaction length, where the intensive THz generation is expected, can be identified with the L d characteristic distance given in (4). This implies that L d is inversely proportional to the pump wavelength; therefore, pumping with a shorter wavelength is more advantageous. This gives 800-nm pump wavelengths an advantage over longer ones (e.g., 1030 or 1064 nm).

The material parameters of 0.67 mol% Mg:SLN and 1.0 mol% Mg:SLT are given in Table 2. The data correspond to room temperature. The viewpoint of the comparison is based on the applicability for THz generation. The supposed pump wavelength was 800 nm, the phase matching THz frequency was assumed to be 0.5 and 1 THz. The refractive index and absorption coefficient values of LT for the THz range are results of present investigation (the details are given above). LT and LN have very similar properties in respect of photorefraction, second-order nonlinearity and THz absorption. Because of the larger n THz value in case of LT, a larger γ (~70°, see Table 2) is needed. This means two-factor reduction in L d for LT compared to LN (Eq. (4)]. Nevertheless, the absence of three-photon absorption more than compensates for this weakness.

3 Optimization of the LiTaO3-based HTPF THz source

The concept of the HTPF source, together with the description of the optimization procedure for a setup containing LN as a nonlinear optical material is given in Ref. [5]. In the present work, this optimization method is adopted for the case of LT. Giving the most relevant formulae, the details of the procedure including the mathematical deductions are not repeated here.

When designing the LT-based HTPF setup, the optimization of the diffraction efficiency at the contact-grating (η CG) is a cardinal point.

In course of the optimization, the pulse-front tilt values (directly before entering into the CG) were set to be γ 0 = 71°, 73° and 75°. In these cases, the tan(γ 0,conv.)/tan(γ 0) ratio falls between ~2 and ~1.5, where γ 0,conv. is the pulse-front tilt angle just in front of the crystal in a conventional setup. A similar ratio was supposed in the case of the source based on LN [5]. For each of the three cases, the angle of incidence on the CG (θ i2) was considered to be an independent variable, which determines the grating constant of the CG (p 2) through the velocity-matching condition expressed by Eq. (3) of Ref. [5]. The necessary groove density as a function of θ i2 is plotted for γ 0 = 75° in Fig. 3. The groove density increases with θ i2 from ~1500 to ~3500 1/mm. Technically, the groove density should be as low as possible. Advantageously, the δ wedge angle plotted in the graph is significantly lower than it would be in the conventional setup (δ = γ ≈ 70°). Its importance is clearly perceptible in the case of wide beams, because the significant path length difference due to the beam edges may lead to distorted THz beam profiles. When choosing the optimal geometry, these types of characteristics (Fig. 3) have to be taken into consideration together with efficiency results shown below.

At a given angle of incidence (and hence, fixed p 2), the highest η CG was located by systematic variation of the filling factor (F) and the groove depth (h) of the rectangular profile of the CG in wide parameter range [5]. The numerical calculations were performed by the GSolver software (Grating Solver Development Company).

In Fig. 4, the highest η CG values belonging to optimal F and h are shown versus the incident angle (θ i2) for each γ 0. As it is seen, efficiency increases with γ 0. The fluctuation in the curves is the manifestation of the same effect observed as a bifurcation in Fig. 4a and as an abrupt jump in Fig. 4b of Ref. [5]. High, ~90 % peak diffraction efficiency is predicted for pulse-front tilt of γ 0 = 75°. The marked values belong to local maxima where the grating period is relatively low, and the F and h parameters are also advantageous from the aspect of production technologies.

The geometrical parameters given in Table 3 belong to the high-efficiency points marked in Fig. 4.

Based on the results shown in Table 3, we can conclude that the most promising arrangement occurs with γ 0 = 75°. Besides the high, 90.9 % value of diffraction efficiency, the 1991 1/mm groove density, the filling factor of 0.4 and the groove depth of 0.35 µm are also very advantageous.

The contour plot shown in Fig. 5 depicts the diffraction efficiency versus h and F. The size of the darker area around the maximum (>85 %) points to the tolerance of the groove depth and the filling factor; they are about 0.07 μm and 0.02, respectively.

To minimize imaging errors, the distances between the setup elements and the angle of incidence on the first grating, namely the geometry, have to be constructed according to the recipe given by Eqs. (4–8) of Ref. [5].

The angle of incidence on G1 (Fig. 1) is given by [5]:

where

and

The symbols used in Eqs. (5–7) are identified in Table 1 and Fig. 1.

High diffraction efficiency on G1 is also a requirement. The diffraction efficiency of a transmission grating is usually maximum for the Littrow configuration having an incident angle of

Therefore, to maximize the efficiency, the incidence angle has to be as close as possible to θ Littrow. In Fig. 6, the required θ i incident angles based on Eqs. (5–7) and the Littrow angle [Eq. (8)] are plotted versus the groove density by dashed and solid lines, respectively. At the intersection of the two curves, the groove density is 2115 1/mm and the diffraction efficiency is 93.8 %. Although gratings with this special groove density are unusual, its custom-order is possible. A ± 10° deviation from the Littrow angle means acceptably high diffraction efficiency; therefore, the curves belonging to the 10° vicinity of the Littrow-configuration are also added to the graph by dotted lines. Within this region, the closest groove density which can be found in catalogs is 1850 1/mm (LightSmyth High Efficiency Pulse Compression Transmission Grating T-1850-800s Series).

With such grating under the incident conditions shown in the graph 77.3 % diffraction efficiency can be reached.

To reach high diffraction efficiency with the CG, the use of refractive index matching fluid is often needed. Advantageously, the proposed HTPF setup does not require this, making possible cryogenic cooling for absorption reduction.

4 Conclusions

It was pointed out that at the 800-nm pump wavelength, the hybrid-type LiTaO3 is a concurrent of the LiNbO3-based high-energy THz sources. The main advantage of the LiTaO3-based method is the possibility of efficient THz generation at 800-nm pump wavelength due to the absence of three-photon absorption at this wavelength. Absorption coefficient and refractive index spectra of LiTaO3 measured by terahertz time-domain spectroscopy are also given. At low THz frequencies, the absorption coefficient values of the 1 mol% Mg-doped stoichiometric LiTaO3 and the 0.67 mol% doped stoichiometric LiNbO3 are similar. Results from the optimization show that taking into account the losses at the first optical grating and at the contact grating, the pump beam can be coupled into the THz generator LiTaO3 crystal with about 80 % resultant efficiency. The setup can be realized with a practically feasible contact grating having groove density of about 2000/mm.

References

J. Hebling, G. Almási, I.Z. Kozma, J. Kuhl, Opt. Express 10(21), 1161–1166 (2002)

J.A. Fülöp, Z. Ollmann, C. Lombosi, C. Skrobol, S. Klingebiel, L. Pálfalvi, F. Krausz, S. Karsch, J. Hebling, Opt. Express 22(17), 20155–20163 (2014)

J.A. Fülöp, L. Pálfalvi, G. Almási, J. Hebling, Opt. Express 18(12), 12311–12327 (2010)

L. Pálfalvi, J.A. Fülöp, G. Almási, J. Hebling, Appl. Phys. Lett. 92(17), 171107 (2008)

L. Pálfalvi, Z. Ollmann, L. Tokodi, J. Hebling, Opt. Express 24(8), 8156–8169 (2016)

I. Dolev, A. Ganany-Padowicz, O. Gayer, A. Arie, J. Mangin, G. Gadret, Appl. Phys. B 96(2), 423–432 (2009)

W. Martienssen, H. Warlimont, Springer Handbook of Condensed Matter and Materials Data (Springer, Berlin Heidelberg, 2005)

T. Suhara, M. Fujimura, Waveguide Nonlinear-Optic Devices (Springer, Berlin Heidelberg, 2013)

H. Ishizuki, T. Taira, Opt. Express 16(21), 16963–16970 (2008)

K. Kitamura, Y. Furukawa, K. Niwa, V. Gopalan, T.E. Mitchell, Appl. Phys. Lett. 73(21), 3073–3075 (1998)

S. Kumaragurubaran, S. Takekawa, M. Nakamura, K. Kitamura, J. Cryst. Growth 292(2), 332–336 (2006)

J. Hebling, A.G. Stepanov, G. Almási, B. Bartal, J. Kuhl, Appl. Phys. B 78(5), 593–599 (2004)

Y.-S. Lee, T. Meade, V. Perlin, H. Winful, T. Norris, A. Galvanauskas, Appl. Phys. Lett. 76(18), 2505–2507 (2000)

Y.-S. Lee, T. Meade, M. DeCamp, T. Norris, A. Galvanauskas, Appl. Phys. Lett. 77(9), 1244–1246 (2000)

N.E. Yu, C. Kang, H.K. Yoo, C. Jung, Y.L. Lee, C.-S. Kee, D.-K. Ko, J. Lee, K. Kitamura, S. Takekawa, Appl. Phys. Lett. 93(4), 041104 (2008)

F. Holtmann, J. Imbrock, C. Baumer, H. Hesse, E. Kratzig, D. Kip, J. Appl. Phys. 96(12), 7455–7459 (2004)

K. Kitamura, Y. Furukawa, S. Takekawa, T. Hatanaka, H. Ito, V. Gopalan, Ferroelectrics 257(1), 235–243 (2001)

K. Polgár, L. Kovács, I. Földvári, I. Cravero, Solid State Commun. 59(6), 375–379 (1986)

L. Kovács, G. Ruschhaupt, K. Polgár, G. Corradi, M. Wöhlecke, Appl. Phys. Lett. 70(21), 2801–2803 (1997)

X. Wu, S. Carbajo, K. Ravi, F. Ahr, G. Cirmi, Y. Zhou, O.D. Mücke, F.X. Kärtner, Opt. Lett. 39(18), 5403–5406 (2014)

S.-C. Zhong, Z.-H. Zhai, J. Li, L.-G. Zhu, J. Li, K. Meng, Q. Liu, L.-H. Du, J.-H. Zhao, Z.-R. Li, Opt. Express 23(24), 31313–31323 (2015)

C. Bäumer, C. David, A. Tunyagi, K. Betzler, H. Hesse, E. Krätzig, M. Wöhlecke, J. Appl. Phys. 93(5), 3102–3104 (2003)

W.T. Hsu, Z.B. Chen, C.C. Wu, R.K. Choubey, C.W. Lan, Materials 5(2), 227 (2012)

A.L. Alexandrovski, G. Foulon, L.E. Myers, R.K. Route, M.M. Fejer, UV and Visible Absorption in LiTaO3. In Proceedings of the SPIE 3610, Laser Material Crystal Growth and Nonlinear Materials and Devices, vol 44 (1999)

L. Pálfalvi, J. Hebling, G. Almási, Á. Péter, K. Polgár, K. Lengyel, R. Szipöcs, J. Appl. Phys. 95(3), 902–908 (2004)

M. Unferdorben, Z. Szaller, I. Hajdara, J. Hebling, L. Pálfalvi, J. Infrared Millim. Terahertz Waves 36(12), 1203–1209 (2015)

K. Seiji, K. Hideaki, N. Seizi, T. MitsuoWada, Jpn. J. Appl. Phys. 42(9B), 6238 (2003)

S. Kojima, T. Mori, AIP Conf. Proc. 1627(1), 52–57 (2014)

L. Wu, L. Jiang, C. Ding, Q. Sheng, X. Ding, J. Yao, J. Infrared Millim. Terahertz Waves 36(1), 1–6 (2015)

M. Schall, H. Helm, S.R. Keiding, Int. J. Infrared Millim. Waves 20(4), 595–604 (1999)

O. Gayer, Z. Sacks, E. Galun, A. Arie, Appl. Phys. B 91(2), 343–348 (2008)

W.-L. Weng, Y.-W. Liu, X.-Q. Zhang, Chin. Phys. Lett. 25(12), 4303 (2008)

J. Hebling, Opt. Quantum Electron. 28(12), 1759–1763 (1996)

J.C. Diels, W. Rudolph, P.F. Liao, P. Kelley, Ultrashort Laser Pulse Phenomena (Elsevier, Amsterdam, 2006)

Acknowledgments

Financial support from Hungarian Scientific Research Fund (OTKA) grant number 113083 is acknowledged. The present scientific contribution is dedicated to the 650th anniversary of the foundation of the University of Pécs, Hungary. The authors thank Matthew Cliffe for his help in improving the presentation of the manuscript.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Tokodi, L., Buzády, A., Hebling, J. et al. Possibility of high-energy THz generation in LiTaO3 . Appl. Phys. B 122, 235 (2016). https://doi.org/10.1007/s00340-016-6513-x

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00340-016-6513-x