Abstract

We report a diode-pumped Tm3+-doped double-clad all-fiber laser operating at 1940 nm with a master oscillator power amplifier configuration; 50 W of seed was generated in master oscillator with 144 W pump power, corresponding to a slope efficiency of 40.1 %. With 212 W pump power, the seed was amplified to 140.9 W in power amplifier, corresponding to a slope efficiency of 47.1 %. The peak wavelength was 1939.57 nm with a narrow spectral line-width of 0.09 nm. The beam quality factor of M 2 was 1.29. Neither amplified spontaneous emission nor parasitic lasing was observed during the amplification process. The output power was only limited by the pump power.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

The Tm3+-doped double-clad fiber lasers operating at 2-µm eye-safe region are attractive sources in many applications, including biotechnology, military and industry [1–3]. There exists rich absorption on CO2, H2O, N2O and NH3 in the waveband of 2 µm [4]. As the absorption of OH− at 1.9 μm falls in the region, the laser source would be very useful for atmospheric LIDAR sensing, bio-medicine and surgical applications [5–7]. In addition, laser at 3–5 or 8–10 µm can be generated with laser at 2 µm by nonlinear frequency down-conversion [8, 9]. Laser at 2 µm can be generated with laser at 1.9 µm by pumping Ho3+-doped crystal. Besides, the Tm3+-doped laser materials have two main advantages: a suitable pump source (commercially available high power laser diodes (LDs) around 800 nm [10]) and an efficiency-enhancing cross-relaxation process resulting in two ions in the upper laser level for one pump photon [11]. Wang et al. demonstrated an all-fiber laser with a master oscillator power amplifier (MOPA) configuration in 2015, and 310 W single frequency laser was obtained at 1971 nm by two-stage amplification. The line-width was estimated to be less than 3 MHz, and the slope efficiency was 56 % [12]. That’s the highest power with narrow spectral line-width in 2 μm waveband by all-fiber laser up to date. Thulium is a quasi three level system which suffers from strong reabsorption loss below 1.95 μm at room temperature [13], so it is difficult to generate high output power below 1.95 μm.

One of the main applications of the lasers operating at 1.94 μm is used to generate the laser at 2.05 and 2.10 µm by pumping Ho:YLF crystal [14, 15] and Ho:YAP crystal [16], respectively. The laser operating at 1.94 µm can be mainly generated by diode lasers, solid-state lasers and fiber lasers. Kelemen et al. presented an MBE grown (AlGaIn) (AsSb) quantum-well diode laser in 2010. The laser wavelength was from 1.8 to 2.3 µm. Up to 20 W of continue wave (CW) output power at 1940 nm was obtained by 3-bar module [17]. Tm:YAP and Tm:YLF crystals are the main media of solid-state lasers to generate the laser operating at 1940 nm. Up to 50 W of output power was obtained from a-cut composite Tm:YAP crystal in 2015 [18]. Tm:YLF crystal has a shorter thermal lens focal length (less than 100 mm) than that of Tm:YAP crystal. Ding et al. obtained 50.3 W of CW output power at 1940.2 nm with 156 W pump power by pumping Tm:YLF crystal in 2015. And the laser beam quality factor of M 2 was 2.4 at the highest output power [19]. As there exist many peaks of water absorption in 1940 nm waveband, it is necessary to adjust the solid-state laser wavelength carefully from damaging cavity lenses and crystals. As optical fiber is a completely closed waveguide, the influence of water absorption by free space is slight in all-fiber laser. For obtaining higher power, all-fiber laser might be the best choice to generate the laser around 1940 nm. Meleshkevich et al. in IPG Photonics Inc. obtained 415 W CW laser operating at 1940 nm in 2007. A number of eighteen CW Er-doped fiber lasers operating at 1567 nm were served as the pump sources. The cavity consisted of a pair of Fiber Bragg Gratings (FBGs) and an 8 m-long Tm-doped fiber with 20 µm core diameter. The output of the Tm-doped fiber laser was terminated by a single-mode fiber so as to obtain good beam quality, and the spectral line-width was about 1 nm [20]. For this configuration, the thermal management might be a trouble for the mode mismatching in the fusion between the multi-mode active fiber and the single-mode passive fiber. Meanwhile, the reflectivity of the output coupled FBG was around 21 %, which might lead to a high power density in laser cavity. In addition, the line-width of 1 nm was so wide for applications in some fields, such as LIDAR sensing. When the lasers are served as pumping sources, output power, spectral line-width and beam quality are the main parameters that should be considered.

In this letter, a maximum CW output power of 140.9 W Tm3+-doped all-fiber laser with a MOPA configuration was reported, corresponding to the optical efficiency of 39.6 %. The peak wavelength was 1939.57 nm with a spectral line-width of 0.09 nm. And the beam quality factor of M 2 was estimated to be 1.29 at the highest output power.

2 Experimental setup

The schematic of the laser system is shown in Fig. 1. Two fiber-coupled LDs (produced by nLIGHT, Inc.) in master oscillator (MO) stage can deliver 140 W of pump power, and the other two LDs in power amplifier (PA) stage can deliver 240 W of pump power. The temperature of the LDs was kept at 20 °C with a water cooler. The pump power was launched into the laser cavity via a 2 × 1 fiber combiner in MO stage. The all-fiber laser was pumped by a co-propagating scheme to protect the LDs. The LMA (large mode area) TDF (Tm3+-doped fiber) in both MO and PA stages were placed in the “U-shape” channel with 100-mm-diameter bronze plate for effective heat management and mode control. The bronze plate was kept at 15 °C with a water cooler. Poor splicing or angle bending would lead to an overburning at each splice between two kinds of fiber, so all of the splices were kept straightened and placed into the bronze heat sink for efficient thermal dissipation. The Cladding stripper was used to eliminate the light in inner cladding so as to obtain good beam quality factor of M 2. A collimating lens (T > 99.5 % @ 1.9–2.1 μm) was used to make the output laser from diverging to collimating. The focal length of the collimating lens was 10 mm. This makes it easy to collect and measure the laser. The dichroic mirror (T > 98 % @ 790 nm, R > 99.8 % @ 1.94 μm) was used to separate the laser and the pump.

2.1 Master oscillator

The MO stage was used to provide excellent seed to PA stage for power scaling. The two LDs at 790 nm could deliver 147 W pump power in total. The fiber pigtail of the LDs was single cladding fiber with 200/220 µm core/cladding diameter, and 0.22 NA (numerical aperture). Up to 144 W of pump power was launched into the laser cavity via a 2 × 1 fiber combiner (LIGHTCOMM Inc., China). The pump arm fiber of the combiner was single-clad passive fiber with 200 μm core diameter (0.22 NA), and 220 μm cladding diameter. The fiber was matched with the LD fiber. The signal arm fiber was double-clad passive fiber with 25 μm core diameter (0.09 NA) and 400 μm inner cladding diameter (0.46 NA). A pair of specially designed chirped FBGs was used to complete the laser cavity with LMA TDF. One of the FBG was served as input cavity mirror with a high reflectivity (HR, R > 99 %). The central wavelength was 1940.02 nm, and the spectral FWHM (full width at half maximum) was 2.00 nm. The other one was acted as an output cavity mirror with a partial reflectivity (PR, R = 10.1 %). The central wavelength was 1940.00 nm, and the spectral FWHM was 1.00 nm. The fiber of the FBG was the same with the double-clad passive fiber which was produced by Nufern Inc.. It had 25/400 μm core/inner cladding diameter and 0.09/0.46 NA. The LMA TDF (Fiberhome Co. Ltd., China) was designed for operation at shorter wavelengths. The core of TDF had 25 µm diameter and 0.09 NA. The inner cladding of TDF had 400 µm diameter and 0.46 NA with pure silica material. Large inner cladding area had ensured sufficient pump power in the laser cavity to generate high laser power. The absorption coefficient was 1.67 dB/m @ 790 nm. We have tried to use the TDF with high absorption coefficient of 9.5 dB/m @ 790 nm in the past experiment, but we could not obtain high laser output power for the heat accumulative. The TDF had burned out before the output power achieving 40 W. For solving the heat dissipation problem, low doping coefficient TDF was used in the experiment. The 5 m-long TDF was served as the gain medium, which was placed in the “U-shape” channel with 100-mm-diameter bronze plate for mode control and effective heat removal. For obtaining good seed in MO stage for power scaling, a cladding stripper was carefully designed at the terminal of the MO stage. A 1.4 m-long passive fiber had the same size and NA with the active fiber so as to match with the mode field. In the middle the fiber, 8 cm-long fiber was peeled off coating and steeped in KHF2 saturated solution for 40 min. Then, the part of the fiber was took out and cleaned by ultrasonic cleaner. When the light in inner cladding passed through the stripper, they would diffuse and spill from the rough surface. So the residual pump power and higher order modes passed through the inner cladding of MO stage can be eliminated by the cladding stripper. Taking into account the large amount of heat when it worked, the cladding stripper was packaged in a black aluminum box for moving conveniently and cooling efficiently.

2.2 Power amplifier

The PA stage was used to amplify the seed from the MO stage. 212 W of pump power was launched into the TDF via a (2 + 1) × 1 fiber combiner in total; 4.9 m-long TDF was served as gain medium to provide sufficient gain. The active fiber was placed into the “U-shape” channel with 100-mm-diameter bronze plate for mode control and effective heat removal as also. A cladding stripper was designed at the terminal of the PA stage to eliminate the laser and pump light in inner cladding for a good output beam quality. The output facet was cleaved at 8° to frustrate parasitic lasing.

3 Experimental results and discussion

In MO stage, 64.7 W of output power was produced with 144 W of pump power, corresponding to the slope efficiency of 50.8 %. It generated 50.9 W pure laser output power in MO stage by utilizing a dichroic mirror (R > 99.5 % @ 1.9 μm, 45°). The slope efficiency was 41.2 %, corresponding to the optical efficiency of 35.3 %, as shown in Fig. 2.

For eliminating the inner cladding laser and getting good beam quality, a cladding stripper was carefully designed in fiber terminal of the MO stage; 54.9 W of output power was obtained via the cladding stripper. Finally, 50 W of seed was obtained by utilizing the dichroic mirror and cladding stripper. The slope efficiency was 40.1 %, corresponding to the optical efficiency of 34.7 %, as shown in Fig. 3. In contrast to the experimental data, we know that 0.9 W of seed passed in the fiber inner cladding was eliminated by the cladding stripper. If the laser was not eliminated, it would affect the beam quality of power scaling. Meanwhile, 100-mm-diameter “U-shape” channel heat sink could also control the modes. The beam quality factor of M 2 was estimated of 1.26 in x-direction and 1.28 in y-direction according to 90/10 knife-edge method with a lens and a dichroic mirror at the laser output terminal in MO stage. As shown in Fig. 4.

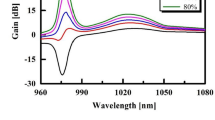

The laser spectrum was measured with a spectral analyzer (Bristol 721A) as shown in Fig. 5. The peak wavelength was 1939.54 nm at 50 W of seed. More than 19 dB optical signal-to-noise ratio (OSNR) was achieved in this work. The inset of Fig. 5 showed the spectral FWHM of 0.10 nm. The nonlinear optical effect was not observed. In PA stage, the different seeds of 5, 10.6, 19.6, 29.1, 19.4 and 50.0 W were launched into the PA stage separately for power scaling. The pure laser power of 85.3, 95, 106.8, 115.3, 127.4 and 140.9 W was obtained via the cladding stripper and dichroic mirror. The slope efficiency was increased from 41.4 to 47.1 % as shown in Fig. 6. The slope efficiency was increased with the seed. It indicated that the PA stage was consistently working in the amplifying region. The effect of the gain saturation was not observed.

Finally, it generated 140 W output power operating at the peak wavelength of 1939.57 nm in PA stage, and the OSNR was more than 16 dB, as shown in Fig. 7. The inset showed the waveform which was similar with that of the seed. The spectral FWHM was 0.09 nm at 140 W. The beam quality factor of M 2 was 1.29, as shown in Fig. 8. Based on the feature above, the spectral characteristics of the laser output were kept the same with the seed except for power promoting. No apparent indication of nonlinear effects was observed at the maximum output power. The all-fiber laser worked stably in continuous 8-h test with some drift over power level. In addition, the all-fiber laser had been applied to pump Ho:YLF laser, and got a satisfactory experiment result.

4 Conclusions

In this letter, we demonstrated a high power narrow spectral line-width all-fiber laser with a MOPA configuration. Up to 140.9 W of laser output power was obtained with 356 W of pump power, corresponding to the total optical efficiency of 39.6 %; 50 W of seed is generated in MO stage with the slope efficiency of 40.1 %, corresponding to the optical efficiency of 34.7 %. The maximum output power of 140.9 W was generated in PA stage with the slope efficiency of 47.1 %. Gain saturation was not observed in experiment. Under the maximum output power, the laser peak wavelength was 1939.57 nm with the spectral FWHM of 0.09 nm, and the beam quality factor of M 2 was 1.29. The seed was well amplified, and the spectral characteristics were not significantly changed. In addition, the laser output power was only limited by the pump power in PA stage in our experiment. In the future, it can generate higher output power by increasing the pump power in PA stage or utilizing N × 1 fiber combiner to deliver more pump light into TDF cavity, where N > 2.

References

T.Y. Dai, Y.L. Ju, B.Q. Yao, Y.J. Shen, W. Wang, Y.Z. Wang, Laser Phys. Lett. 9, 716 (2012)

T.Y. Dai, Y.L. Ju, X.M. Duan, W. Liu, B.Q. Yao, Y.Z. Wang, Appl. Phys. B 111, 89 (2013)

L. Han, B.Q. Yao, X.M. Duan, S. Li, T.Y. Dai, Y.L. Ju, Y.Z. Wang, Chin. Opt. Lett. 12, 081401 (2014)

R.M. Mihalcea, M.E. Webber, D.S. Baer, R.K. Hanson, G.S. Feller, W.B. Chapman, Appl. Phys. B 67, 283 (1998)

W. Shi, E.B. Petersen, N. Moor, A. Chavez-Pirson, N. Peyghambarian, in Conference on Nanophotonics and Macrophotonics for Space Environments V (NMSE), 81640 M (2011)

R.L. Blackmon, J.R. Case, P.B. Irby, S.R. Trammell, N.M. Fried, J. Biomed. Opt. 18, 028001 (2013)

S. Wenk, S. Furst, V. Danicke, D.T. Kunde, Adv. Med. Eng. 114, 447 (2007)

A. Dergachev, D. Armstrong, A. Smith, T. Drake, M. Dubois, Opt. Express 15, 14404 (2007)

E. Lippert, G. Rustad, G. Arisholm, K. Stenersen, Opt. Express 16, 13878 (2008)

P.A. Budni, L.A. Pomeranz, M.L. Lemons, C.A. Miller, J.R. Mosto, E.P. Chicklis, J. Opt. Soc. Am. B 17, 723 (2000)

S. So, J.I. Mackenzie, D.P. Shepherd, W.A. Clarkson, J.G. Betterton, E.K. Gorton, Appl. Phys. B 84, 389 (2006)

X. Wang, X.X. Jin, W.J. Wu, P. Zhou, X.L. Wang, H. Xiao, Z.J. Liu, IEEE Opt. Technol. Lett. 27, 677 (2015)

G. Frith, A. Carter, B. Samson, G. Town, Appl. Opt. 48, 5072 (2009)

C. Yang, Y.L. Ju, B.Q. Yao, T.Y. Dai, X.M. Duan, J. Li, Y. Ding, W. Liu, Y.B. Pan, C.Y. Li, Opt. Laser Technol. 77, 55 (2016)

J. Kwiatkowski, J.K. Jabczynski, W. Zendzian, Opt. Laser Technol. 67, 93 (2015)

R.L. Zhou, Y.L. Ju, W. Wang, G.L. Zhu, Y.Z. Wang, Chin. Phys. Lett. 28, 074210 (2011)

M.T. Kelemen, J. Gilly, R. Moritz, J. Schleife, M. Fatscher, M. Kaufmann, S. Ahlert, J. Biesenbach, in Conference on Laser Technology for Defense and Security VI, 76860 N (2010)

S.S. Cai, D.Z. Yang, P.H. Wu, C.Z. Hu, P.P. Jiang, Laser Phys. Lett. 12, 075001 (2015)

Y. Ding, D.X. Zhang, W. Wang, B.Q. Yao, X.M. Duan, Y.L. Ju, Y.Z. Wang, Optik 126, 855 (2015)

M. Meleshkevich, N. Platonov, D. Gapontsev, A. Drozhzhin, V. Sergeev, V. Gapontsev, CLEO Europe 2007, Technical Digest, CP2-3-THU (2007)

Acknowledgments

This work was partly supported by National Natural Science Foundation of China (Nos. 61308009, 61405047), China Postdoctoral Science Foundation funded project (Nos. 2013M540288, 2015M570290), Fundamental Research Funds for the Central Universities Grant (Nos. HIT.NSRIF.2014044, HIT. NSRIF.2015042) and Science Fund for Outstanding Youths of Heilongjiang Province (JQ201310), Heilongjiang Postdoctoral Science Foundation Funded Project (LBH-Z14085).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yang, C., Ju, Y.L., Yao, B.Q. et al. 140 W high power all-fiber laser at 1940 nm with narrow spectral line-width by MOPA configuration. Appl. Phys. B 122, 230 (2016). https://doi.org/10.1007/s00340-016-6504-y

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00340-016-6504-y