Abstract

We designed and fabricated the transmission quarter-wave plate phase retarder at 1064 nm using optical nanometric thin films of silicon oxide and titanium oxide. Final design consists of 32 layers. Transmissions of polarizations are equal and ≥99 % and their phase difference is 90°. System consists of two 16 layers systems that coated with the same condition on BK7 glass substrates then attached together with optical glue. Electron beam evaporation method was used for depositing materials. Photo spectrometer was used for measuring transmission spectrum of system. Transmission of polarizations was ≥95 % and equal. A polarimeter was used for testing systems. Polarization of beam was circular.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Quarter-wave and half-wave retarders (QWR and HWR) are widely used for the control and analysis of polarized light with numerous applications. The desired differential phase shift between two orthogonal linear polarizations is commonly obtained when light is transmitted through a natural crystalline or form birefringent plate or by total internal reflection in thin films. Transparent multilayer thin films deposited on a transparent substrate can provide QWR in transmission at oblique incidence in air [1]. Thin-film phase retarders are fabricated by using two materials with high and low refraction indices. In this research, we designed and fabricated a transmittance quarter-wave phase retarder at 1064 nm with optical nanometric thin films of SiO2 as low refraction index material and TiO2 as high refraction index material. The aim of this design is to get a circular polarized transmitted light. So the transmittance of s and p polarizations should be equal and their phase difference should be 90° [2].

2 Design principles

Suppose that the medium of incidence beam is named medium 0 and the medium of refraction is named medium 1. At the boundary of these two homogeneous thin films, we have Snell law [3]:

where n 0 and n 1 are refraction indices of two media (n 0 > n 1), θ is the angle of incident beam and φ is angle of refraction beam. The transmittance Fresnel coefficients for p and s polarizations assume their simplest forms [4]:

Coherent multiple beam interference in a tilted dielectric thin films introduces a differential phase shift between the p and s polarizations in transmission. If δ p and δ s are, respectively, p and s phases,

where N is n 0 /n 1 > 1.

A completely polarized beam was defined by two orthogonal components of electric field that exhibit complete coherence. Then, the ellipsometric parameters ψ and Δ (psi and Delta) are defined as [3]:

It has an upper bound in the limit of grazing incidence in transmission [4]:

Equation (9) indicates \(\Delta_{\hbox{max} } < 90^\circ\), so that quarter-wave retarder (QWR or 90° differential phase shift between the p and s components) is not feasible under conditions of partial transmittance at the two interfaces and needs more than two layers.

At oblique incidence, ψ and Δ are initially defined with respect to the plane of incidence. Provided the plane of incidence for any subsequent transmission does not change, then combining the effect of multiple surfaces straightforward. For the case of multilayer system, the relations should be repeated for each boundary. Since the p-direction and s-direction are completely independent, then, ignoring the phase shift between elements, we can write in the series of coated surfaces [3]:

In QWR, the total phase difference for s and p polarizations must be Δ = 90° and τ p and τ s must be equal to have circular polarization. It means tan ψ = 1.

3 Materials selection

The first step in designing this kind of system is materials selection. Thickness of each layer and the incident angle should be changed as degrees of freedom to get the desired transmittance coefficients and phase difference. This is done with a lot of complicated computations. Usually, these systems consist of only two materials with high and low refractive indices. Selected materials should have high transmittance and low absorption at the desired wavelength (in this case 1064 nm), also if this retarder is to be used in high power systems then the selected materials should have high laser damage threshold at 1064 nm for Nd:YAG laser. Another point is that the refractive indices difference should be high enough to get smaller number of layers. Other points include cost, roughness, ability of deposition, etc. [5].

In high power lasers, dielectric thin films coating is favorable, because these materials have low absorption and high stability. In the most of medical and scientific instruments, high power lasers are used. Oxide materials have good stability and transparency between dielectric materials. We selected silicon oxide with refraction index of 1.42 at 1064 nm for low refraction index material. If this material is coated under normal physical situations using electron beam evaporation at normal substance temperature, it has low absorption [6–8]. Laser damage threshold of a quarter-wave layer of silicon oxide at 1064 nm is about 20–28 J cm−2. This material has good thermal stability and is being used in high power lasers [5, 9]. For high refractive index, we selected titanium oxide with refraction index of 2.18 since its chemical stability is good [10]. It has 9.79 J cm−2 laser damage threshold at 1064 nm. The laser damage threshold parameters of the two samples were measured in the “1-on-1” regime according to ISO standard 11254-1, using Q-switch pulsed laser operating at 1064 nm with a pulse length of 12 ns [11].

4 Design procedure

After selecting suitable materials, the design procedure is started by calculating transmittance coefficients and phase difference of s and p polarizations for a double layer of SiO2 and TiO2 on BK7 glass substrate. Then, layer thicknesses, angle of incidence and the number of layers are used as degrees of freedom to be changed to get the desired values of s and p polarization transmittances \(T_{\text{p}} , T_{\text{s}}\) and phase difference ∆. A 15 layer system with acceptable performance is achieved by using thin film software which is presented in Table 1.

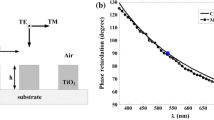

After several attempts, we noticed that it is not possible to get both transmittance and phase difference criteria at the same time with this type of systems. So we decided to split the design procedure and design a system for transmittance for s and p polarization and phase difference of 45°. Then put this system on both sides of the substrate to reach to 90° phase difference. Transmittance and phase difference curves for this 30 layers system are presented in Figs. 1 and 2. As it can be seen, the transmittance for both s and p polarizations is about 98 %, and the phase difference is about 90°.

5 Refining electric field distribution in system

Multilayer optical coatings are being used for various high power laser applications. The study of electric field distribution has assumed greater significance in the context of damage to optical coatings by intense pulsed laser radiation. While designing multiplayer phase retarders for high power lasers, it is generally ensured that the peak electric field amplitude for polarized radiation is kept minimal. In order to avoid damage to the phase retarders, the peak field amplitude inside the multilayers should also be low for polarized radiation [12]. Distribution of electric field at 1064 nm and in the fixed angle 45° in boundary and layers is an important element that must be considered in thin film designs. Maximum of electric field should not be in boundary and high refraction index layers because laser damage threshold will be reduced. So we must refine electric field distribution. Distribution of electric field for fifteen layers system is shown in Fig. 3 from air (medium 0) to the substrate (medium 16). Vertical lines indicated layers boundaries.

Silicon oxide has approximately three times higher laser damage threshold than titanium oxide as it represented in Sect. 3. We know half-wave layers have no effect on transmittance and phase difference spectrums and they are named absent layers in thin film technology.

The characteristic matrix of a dielectric thin film takes on a very simple form if the optical thickness is an integral number of quarter- or half-waves. That is, if

For even m, cos δ = ± 1 and sin δ = 0, so that the layer is an integral number of half wavelengths thick, and the optical matrix becomes

This is the unity matrix and can have no effect on the reflectance or transmittance of an assembly. It is as if the layer was completely absent [3]. So we added a half-wave layer of silicon oxide to final design on air boundary and refined design again to reach good result with thin film software. Peak of electric field shifted to this layer that has higher laser damage threshold and was reduced for p polarization. Final design has 32 layers and each side has 16 layers. This design is shown in Table 2.

Total thickness of this system is 2347.89 nm. Distribution of electric field after adding half-wave layer of silicon oxide is shown in Fig. 4.

It can be seen in Fig. 4 that electric field distribution is reduced in titanium oxide layers especially for p polarization. Transmittance for s and p polarizations for 32 layers system is up to 99 % and phase difference is 90° which are presented in Figs. 5 and 6.

6 System fabrication

Materials were deposited by using the electron beam evaporation (EBE) technique with Balzers BAK 760 coating machine. Substrate temperature was 250 °C, and chamber pressure was kept at 1.1 × 10−4 mbar. Titanium oxide layers were made at deposition rate of 0.3 nm/s. Silicon oxide was made at coating rate of 0.5 nm/s and the vacuum pressure of 1.5 × 10−4 mbar.

Optimum deposition conditions for TiO2 and SiO2 are summarized in Table 3.

7 Results and discussion

Transmittance spectrum of the 32 layers system was measured using a double-beam photo spectrometer, Shimadzu 3100 UV–Vis–NIR spectrophotometer. The incident beam on the system was kept at 45°. The result of the measurement is shown in Fig. 7. As it can be seen, transmittance at 1064 nm is more than 95 % for bout s and p polarizations which are in agreement with our calculations in design step.

The setup to measure the polarization of the output beam is shown in Fig. 8. We used a diode laser with low power (A few tenths of milliwatts) at wavelength 1064 nm. The beam after polarizer is a linear polarized light that is shown in Fig. 9.

The polarization of output beam is measured by polarimeter. Polarization of the output beam after the phase retarder is shown in Fig. 10 which shows a −88° phase difference between s and p polarizations.

8 Summary

Interesting features of the transmission of polarized light by interfaces and thin films are reviewed with emphasis on their application in the design of phase retarders.

In summary, we have designed a 32 layers transmittance quarter phase retarder by using two kinds of dielectric materials SiO2 and TiO2 at 1064 nm for oblique incidence and obtained circular polarization at 45° with computer coating design program and fabricated it.

Finally, it will be interesting to search for other optical materials that would be used for other spectral ranges.

References

S.R. Perla, R.M.A. Azzam, Embedded centrosymmetric multilayer stacks as complete-transmission quarter-wave and half-wave retarders under conditions of frustrated total internal reflection. J. Opt. Soc. Am. A 24(10), 3255–3260 (2007)

R.M. Azzam, F.A. Mahmoud, Tilted bilayer membranes as simple transmission quarter-wave retardation plates. J. Opt. Soc. Am. A Opt Image Sci Vis 18(2), 421–425 (2001)

A. Macleod, Thin- Film Optical Filters (Institute of Physics Publishing, Philadelphia, 2010)

R.M.A. Azzam, Polarization optics of interfaces and thin films. Phys. Status Solidi A 205(4), 709–714 (2008)

R. Wood, Laser-Induced Damage of Optical Materials (Institute of Physics Publishing, Philadelphia, 2003)

J.Y. Robic et al., Residual stress in silicon dioxide thin films produced by ion-assisted deposition. Thin Solid Films 290, 34–39 (1996)

H. Leplan et al., Residual stresses in evaporated silicon dioxide thin films: correlation with deposition parameters and aging behavior. J. Appl. Phys. 78(2), 962–968 (1995)

P. Gu, J. Tang, Damage threshold of (ZrO2/Y2O3)/SiO2 reflectors used for XeCl laser. Appl. Opt. 32(9), 1528–1530 (1993)

M. Alvisi et al., Deposition of SiO2 films with high laser damage thresholds by ion-assisted electron-beam evaporation. Appl. Opt. 38(7), 1237–1243 (1999)

H. Selhofer, E. Ritter, R. Linsbod, Properties of titanium dioxide films prepared by reactive electron-beam evaporation from various starting materials. Appl. Opt. 41(4), 756–762 (2002)

A. Benanej, The effect of porosity on the laser induced damage threshold of TiO2 and ZrO2 Single layer films. Opt. Laser Technol. 42, 1187–1192 (2010)

J.C. Monga, Multilayer thin film polarizers with reduced electric field intensity. J. Mod. Opt. 36, 769–784 (1989)

Acknowledgments

The authors wish to thank Graduate Office of the University of Isfahan for their supports.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Moradi, Z., Jahanshah, F., Fallah, H.R. et al. Design and fabrication of transmission quarter phase retarder at wavelength 1064 nm, using optical nanometric thin films. Appl. Phys. B 122, 216 (2016). https://doi.org/10.1007/s00340-016-6495-8

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00340-016-6495-8